High-silicon NaY molecular sieve as well as preparation method and application thereof

A molecular sieve, high-silicon technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., to achieve the effects of improving the silicon-aluminum ratio, reducing the difficulty of stirring, and reducing the synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

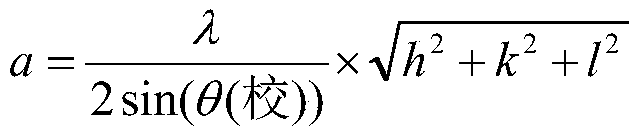

Method used

Image

Examples

Embodiment 1

[0031] The required silicon source and aluminum source in all embodiments and comparative examples in the present invention are laboratory self-made, and the following is the preparation method:

[0032] Get 250ml modulus and be the water glass of 3.26 (Shanghai Jiangqiao Welding Rod Auxiliary Material Factory Co., Ltd., SiO 2 Content is 30.54wt%) in a beaker, then add 74.44ml deionized water, stir for 1h, add 3.5g sodium fluorosilicate (99.0wt%, Sinopharm reagent, appropriate amount of ammonium sulfate, ammonium chloride or ethyl acetate Can play the same effect), stirred at room temperature for 4h, named as water glass S-1 (SiO 2Content is 25.19wt%), as a silicon source.

[0033] Get 250ml modulus and be the water glass of 3.26 (Shanghai Jiangqiao Welding Rod Auxiliary Material Factory Co., Ltd., SiO 2 content is 30.54wt%) is placed in the beaker, then add 250ml deionized water, stir for 1h, add 3.5g ammonium sulfate (99.0wt%, Sinopharm reagent), named as water glass S-2 (...

Embodiment 2

[0044] Take 7.11g NaOH, dissolve it in 9.14g deionized water, after the dissolution is complete, add 12.36g A-1 type sodium metaaluminate, then slowly add this mixed solution into 50.52g S-2 water glass solution, stir well , aged at room temperature for 24 hours to obtain a guide gel.

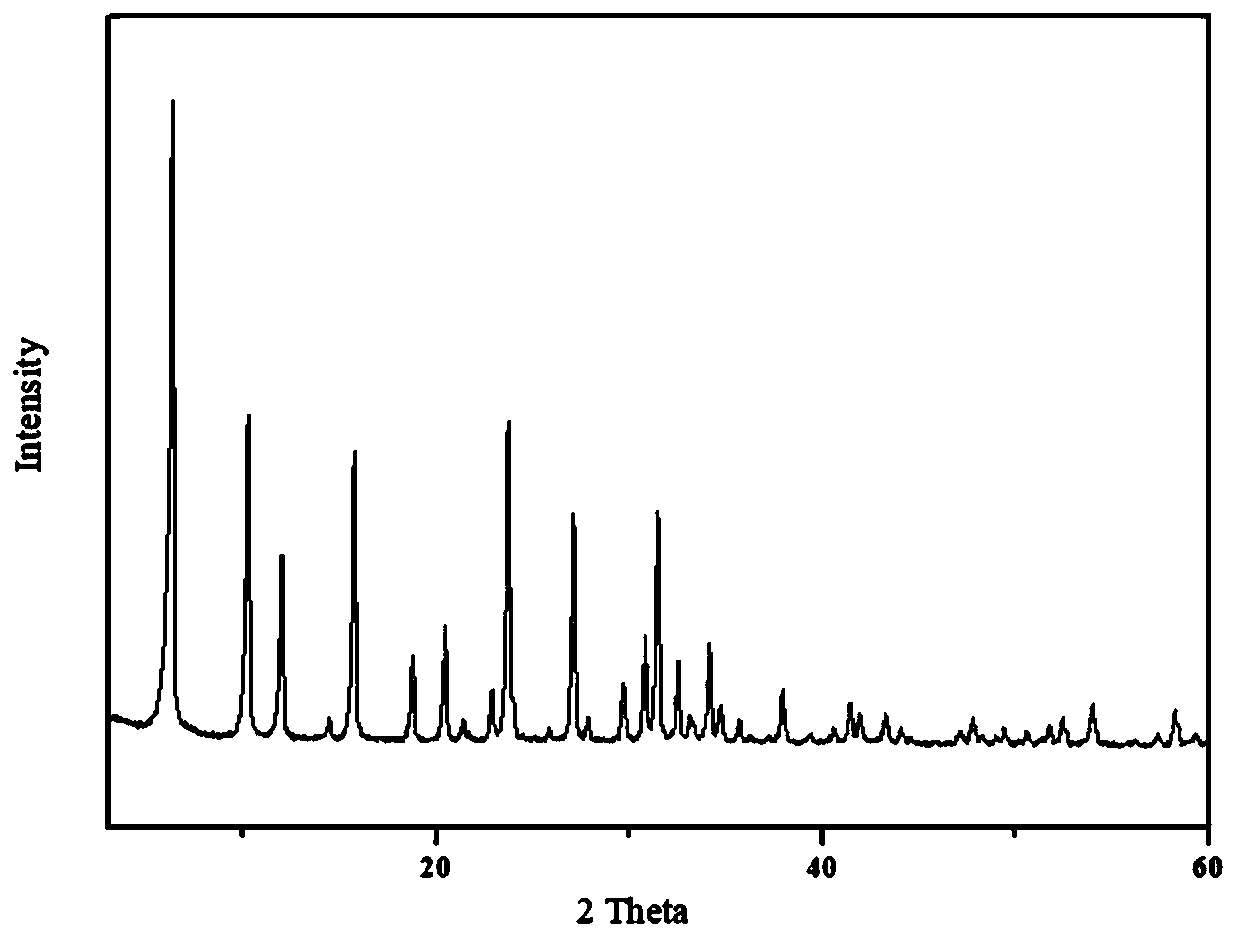

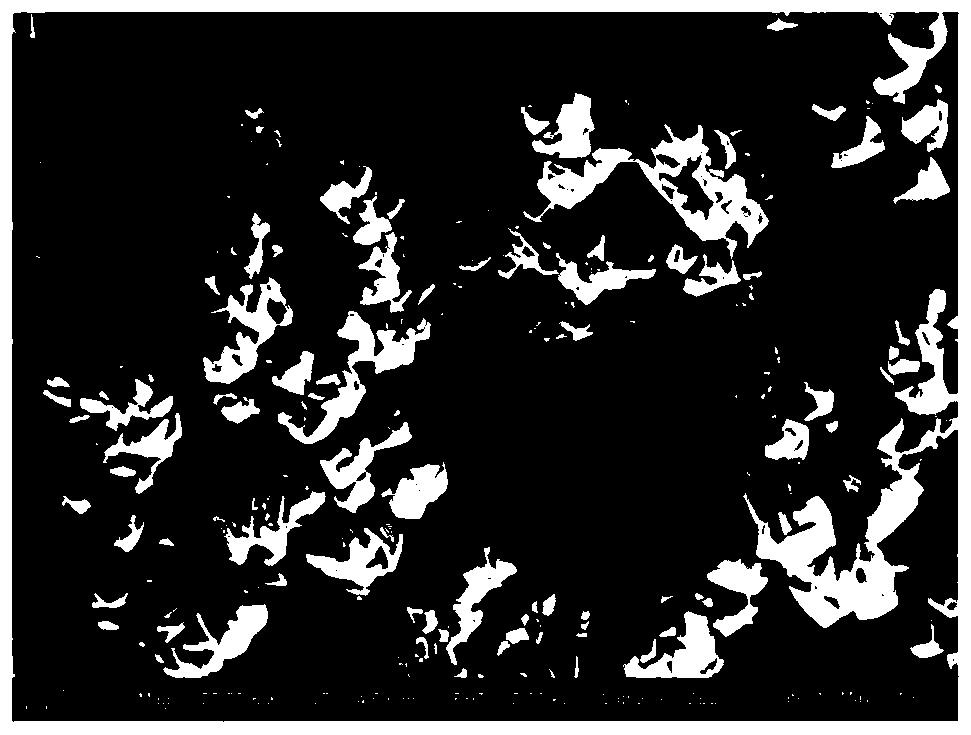

[0045] Take 84.20g of S-2 water glass and place it in a beaker, add 11.19g of guide gel, stir evenly, then add 7.78g of aluminum sulfate, 16.36g of A-1 type sodium metaaluminate and 3.59g of deionized water, and stir Evenly, put it into a polytetrafluoroethylene kettle, crystallize at 100°C for 24 hours, wash and dry after the reaction, and it is identified as NaY molecular sieve by XRD, SiO 2 / Al 2 o 3 =6.75, BET specific surface area is 664.68m 2 / g, the particle size is about 750nm.

Embodiment 3

[0047] Take 7.69g NaOH, dissolve it in 28.74g deionized water, after the dissolution is complete, add 7.69g A-2 type sodium metaaluminate, then slowly add this mixed solution into 35.73g S-1 water glass solution, stir well , aged at room temperature for 24 hours to obtain a guide gel.

[0048] Take 59.54g of S-1 water glass and place it in a beaker, add 11.11g of guide gel, stir evenly, then add 7.10g of aluminum sulfate, 10.84g of A-2 sodium metaaluminate and 33.61g of deionized water, and stir Evenly, put it into a polytetrafluoroethylene kettle, crystallize at 100°C for 24 hours, wash and dry after the reaction, and it is identified as NaY molecular sieve by XRD, SiO 2 / Al 2 o 3 =5.84, BET specific surface area is 672.78m 2 / g, the particle size is about 750nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com