Automated mask management system and method

A technology of automatic management and production management system, applied in the field of automatic management system of masks, can solve problems such as low yield rate, and achieve the effect of reducing error rate, facilitating data analysis, and reducing the scope of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

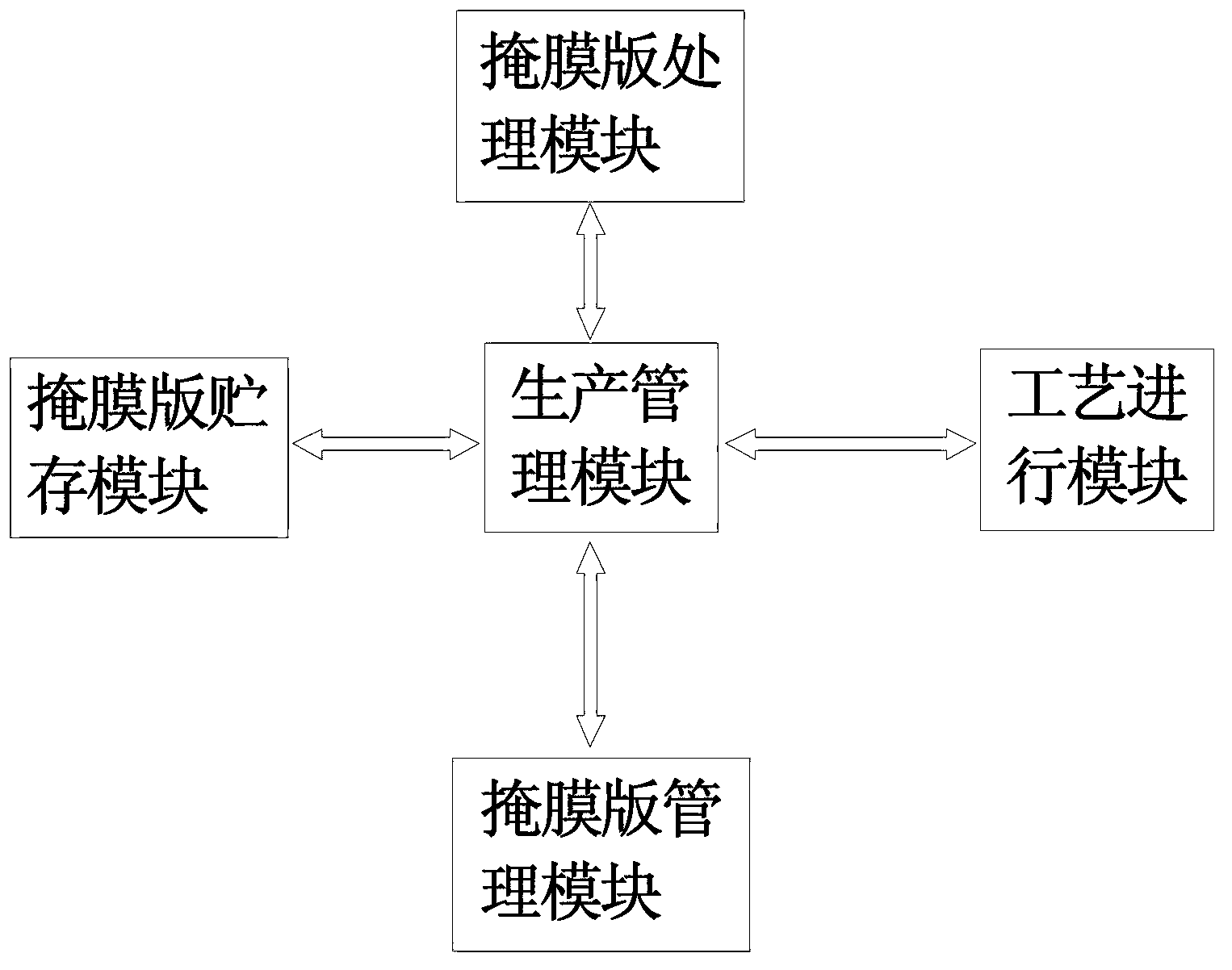

[0055] figure 1 It is a schematic structural diagram of the automatic management system of the mask according to Embodiment 1 of the present invention; as shown in the figure, the automatic management system of the mask includes a production management module, a mask management module, a process module, and a mask The processing module and the mask storage module, meanwhile, the production management module interacts with the mask management module, the process module, the mask processing module and the mask storage module through EAP and the server to interact with the data information of the mask .

[0056] Among them, the production management module is an automated production management system; the mask management module includes a data storage unit and a read / write unit, and the data storage unit stores the current data information of several masks; the process progress module includes a plurality of photolithography units and multiple detection units; the mask plate pro...

Embodiment 2

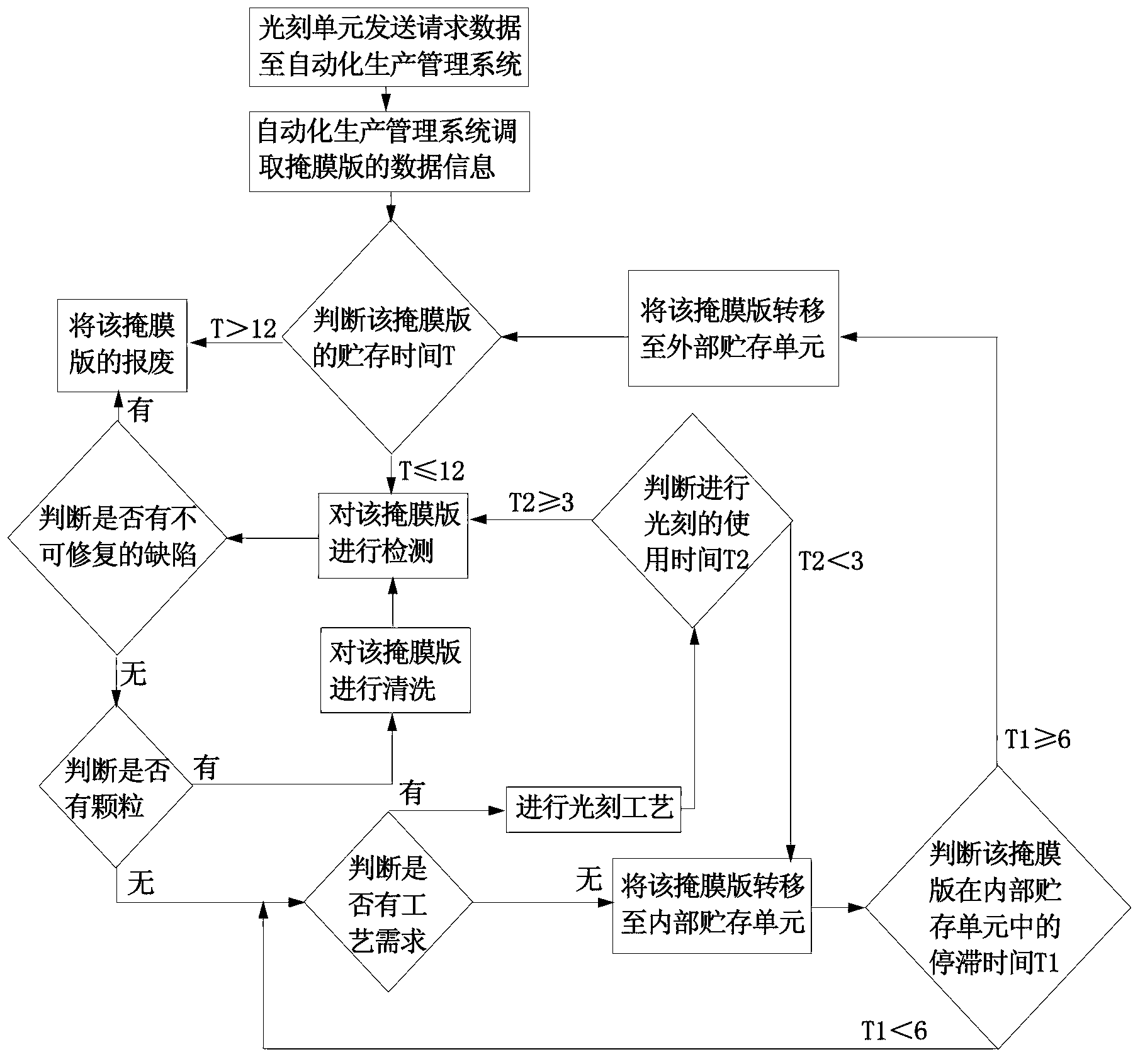

[0062] figure 2 It is a schematic diagram of the process structure of the mask in the automatic management system of the mask according to Embodiment 2 of the present invention; figure 2 As shown, when the photolithography unit needs the mask plate to carry out the photolithography process, the automatic production management system retrieves the data information of the mask plate from the data storage unit through the read / write unit according to the properties of the photolithography unit, and retrieves When the state of the data information of the mask plate is identified as the storage state, the storage time T under the storage state is judged. If the storage time T>12 months, such as the storage time is 13 months, 14 months, 15 months Months, etc., according to the judgment of the engineer, transfer the mask to the scrap unit for scrapping, and mark the current state of the mask as scrap; or continue to store the mask, and the current state of the mask is storage Stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com