Method for treating rare earth ammonium chloride wastewater

A treatment method and ammonium chloride technology, applied in rare earth metal compounds, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of low recycling rate of rare earth wastewater, achieve low production cost and improve recovery rate , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

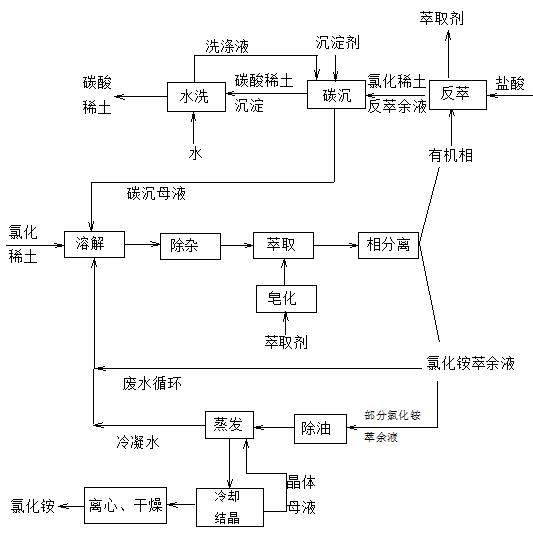

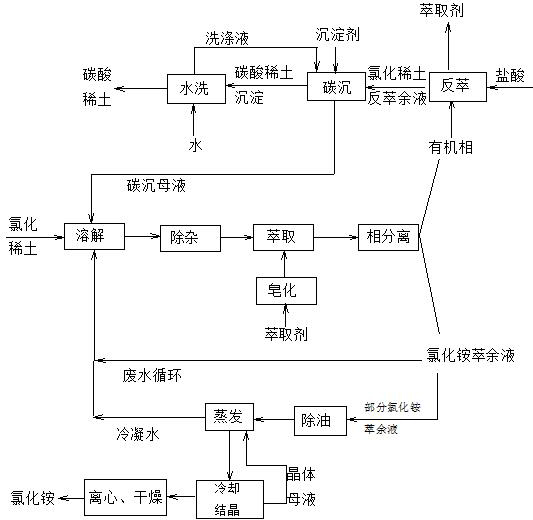

Image

Examples

Embodiment 1

[0033] Realize the treatment of rare earth ammonium chloride wastewater by the following steps, and its technology is.

[0034] (1) Dissolving the rare earth chloride, the mass fraction of the rare earth oxide in the solution is 250g / L, filtering and removing impurities to obtain the rare earth chloride feed liquid.

[0035] (2) Use kerosene to distill the extractant P 507 Dilute to 1.5mol / L, and then saponify with ammonia water (saponification degree is 35%) to obtain an organic phase.

[0036] (3) Mix the rare earth chloride feed liquid obtained in step (1) with the saponified organic phase in step (2) at a volume ratio of 2:1 in a mixing and clarifying extraction tank, so that the ammonium chloride raffinate and the rare earth-containing The organic phase of the elements is separated on standing.

[0037] (4) Return the ammonium chloride raffinate in step (3) to step (1), repeat steps (1) to (3), and circulate twice to increase the concentration of ammonium chloride in th...

Embodiment 2

[0045] Realize the treatment of rare earth ammonium chloride wastewater by the following steps, and its technology is.

[0046] (1) Dissolve the rare earth chloride, the mass fraction of the rare earth oxide in the solution is 150g / L, filter and remove impurities to obtain the rare earth chloride feed liquid.

[0047] (2) Use kerosene to extract the extractant P 204 Dilute to 1.5mol / L, and then saponify with ammonia water (saponification degree is 45%) to obtain an organic phase.

[0048] (3) Mix the rare earth chloride feed solution obtained in step (1) with the saponified organic phase in step (2) at a volume ratio of 1:1 in a mixing and clarifying extraction tank, so that the ammonium chloride raffinate and the rare earth-containing The organic phase of the elements is separated on standing.

[0049] (4) Return the ammonium chloride raffinate in step (3) to step (1), repeat steps (1) to (3), and circulate 4 times to increase the concentration of ammonium chloride in the a...

Embodiment 3

[0057] Realize the treatment of rare earth ammonium chloride wastewater by the following steps, and its technology is.

[0058] (1) Dissolve the rare earth chloride, the mass fraction of rare earth oxide in the solution is 300g / L, filter and remove impurities to obtain the rare earth chloride feed liquid.

[0059] (2) Use kerosene to distill the extractant P 507 Dilute to 1.5mol / L, then saponify with ammonia water (saponification degree is 40%) to get the organic phase.

[0060] (3) Mix the rare earth chloride feed liquid obtained in step (1) with the saponified organic phase in step (2) at a volume ratio of 2:1 in a mixing and clarifying extraction tank, so that the ammonium chloride raffinate and the rare earth-containing The organic phase of the elements is separated on standing.

[0061] (4) Return the ammonium chloride raffinate in step (3) to step (1), repeat steps (1) to (3), and cycle twice to increase the concentration of ammonium chloride in the ammonium chloride r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com