Potassium sulfate preparing process from sulfate-type salt lake bittern

A kind of salt lake brine and sulfate-type technology, which is applied in the direction of alkali metal sulfite/sulfite, bisulfite preparation, chemical instruments and methods, etc., can solve the problems of being in the test and not realizing industrialization, etc., and achieve cost Low, improve potassium recovery rate and grade, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

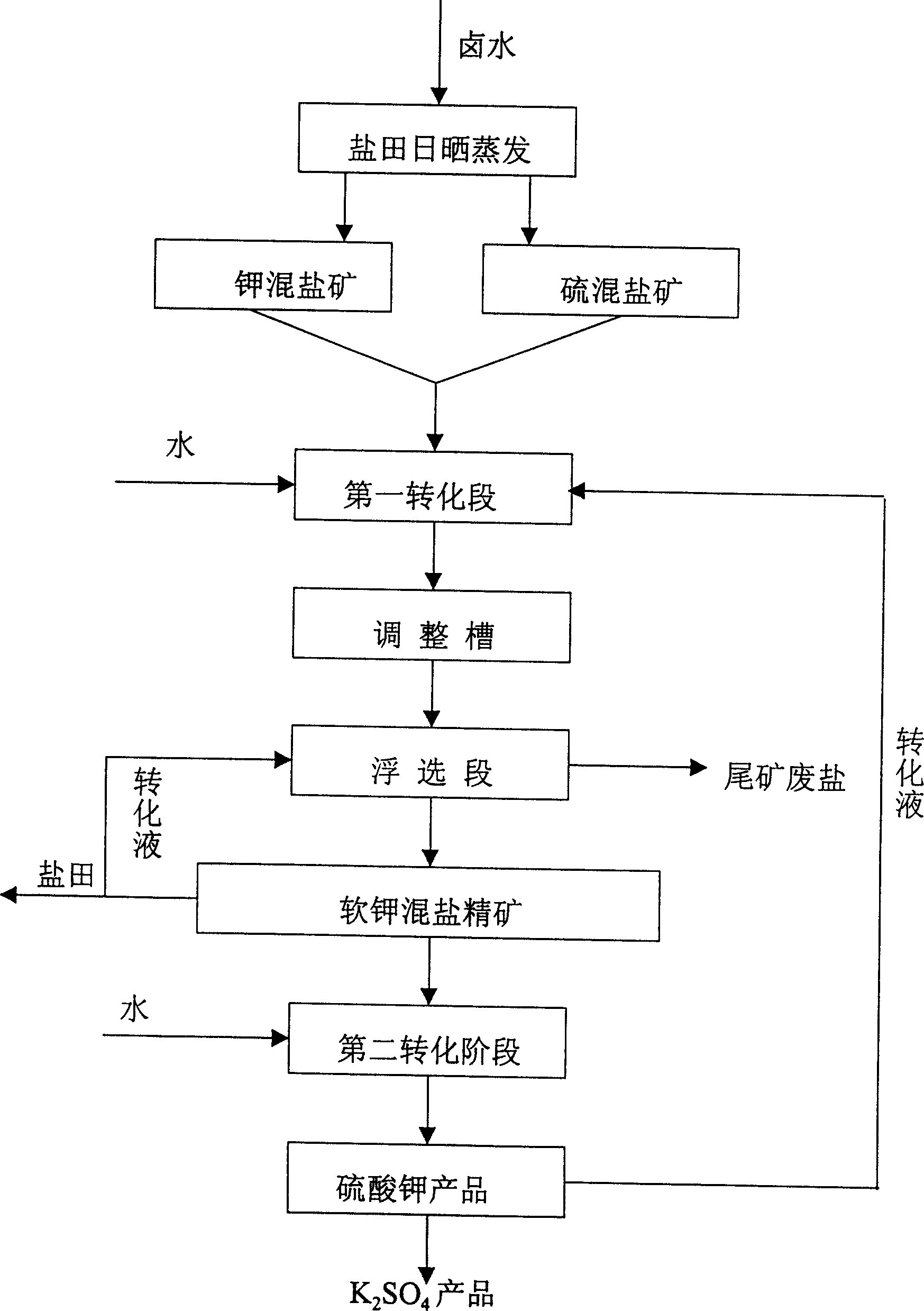

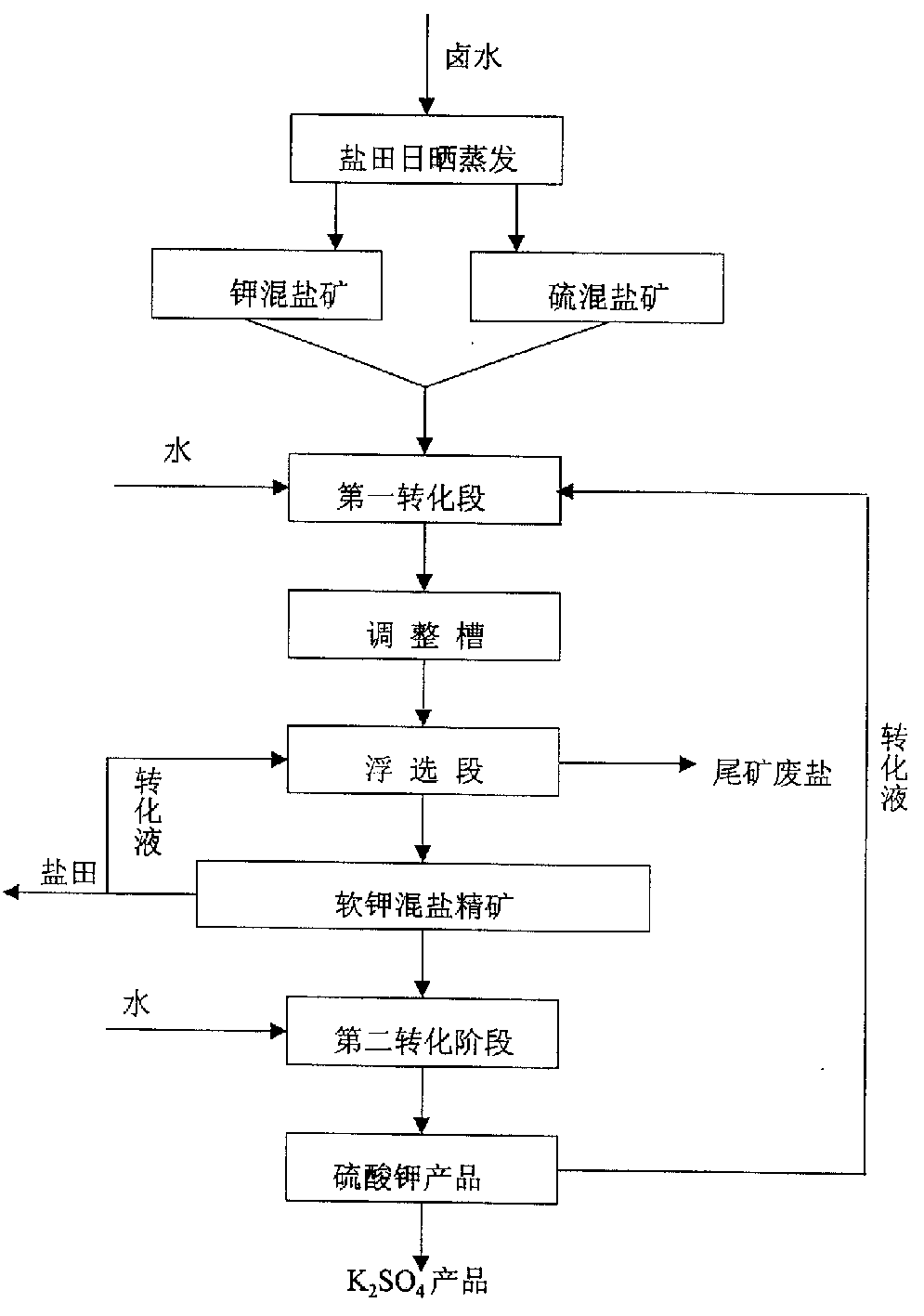

[0023] Below in conjunction with Fig. 1 and the example of a certain salt lake in Qinghai, the invention is further described in detail.

[0024] The brine of a salt lake in Qinghai (the brine components are: K0.7-1.3%, Mg0.9-2%, Cl12-18%, SO41.0-3.0%), in the salt field, the salt is concentrated and evaporated by the sun, and evaporated The process is carried out in stages in order to obtain salt mines with different compositions, and to separate the required sulfate ores and potassium mixed salt ores. According to the composition of these two ores, the ore blending is calculated. Take 300kg of potassium mixed salt ore, 500kg of sulfur mixed salt ore, and calculate the water volume of 300kg. After finishing, with the feeding speed of 6-12L / min (in terms of ore pulp), the slurry enters the 80L stirring tank, and then adds 250ml / T by C 4 -C 16 Fatty acid flotation agent and C 4 -C 16 The mixed flotation agents composed of polyol flotation aids are mixed evenly and enter the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com