Treatment method and system for reutilization and resource utilization of high-mineralization mine water

A technology with high salinity and treatment methods, applied in the field of water treatment, can solve problems affecting regional economic development, shortage of groundwater resources, and affecting industrial production, and achieve simple and easy process operation and maintenance, low energy consumption, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

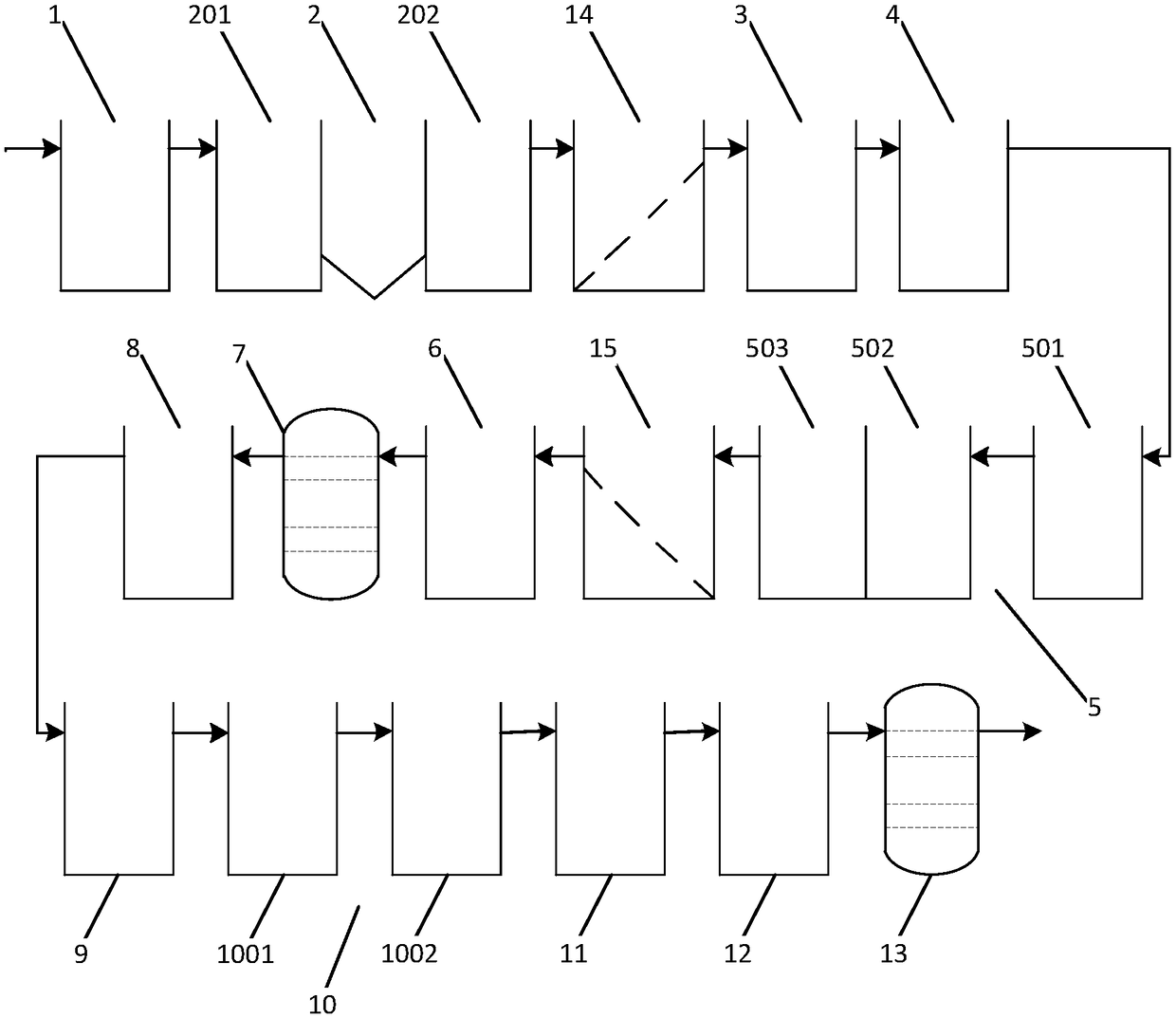

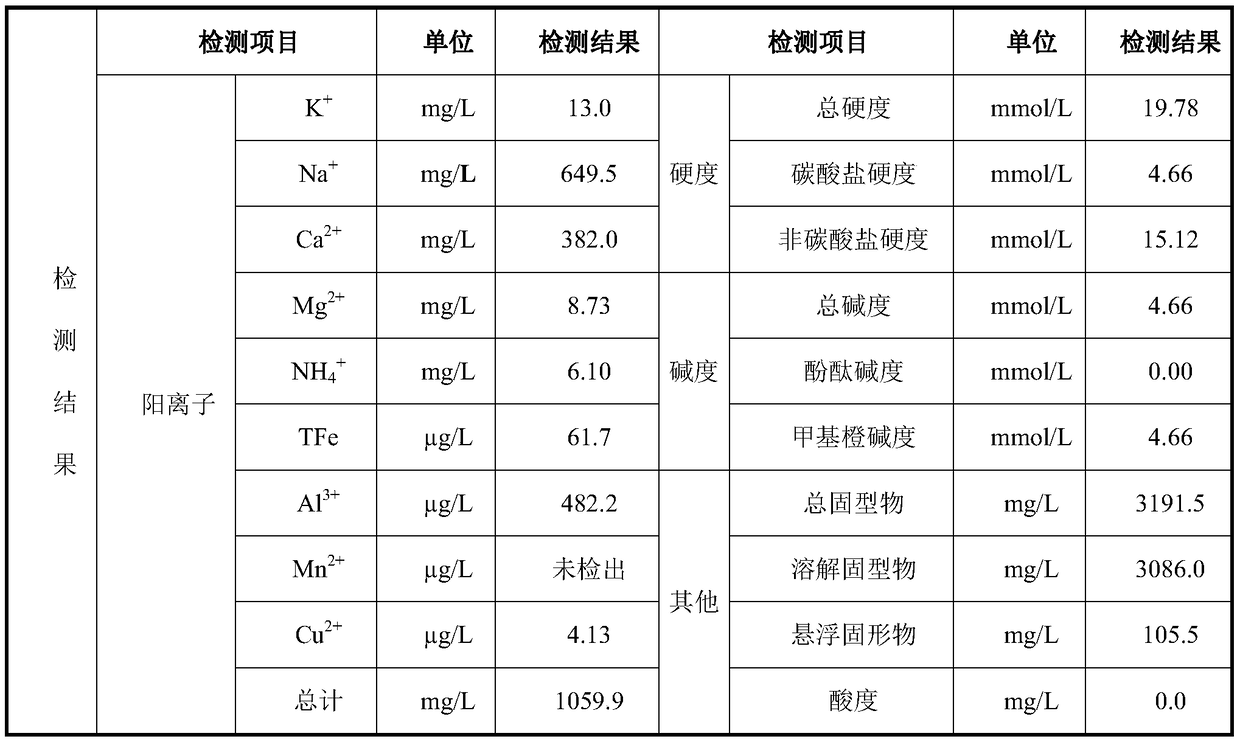

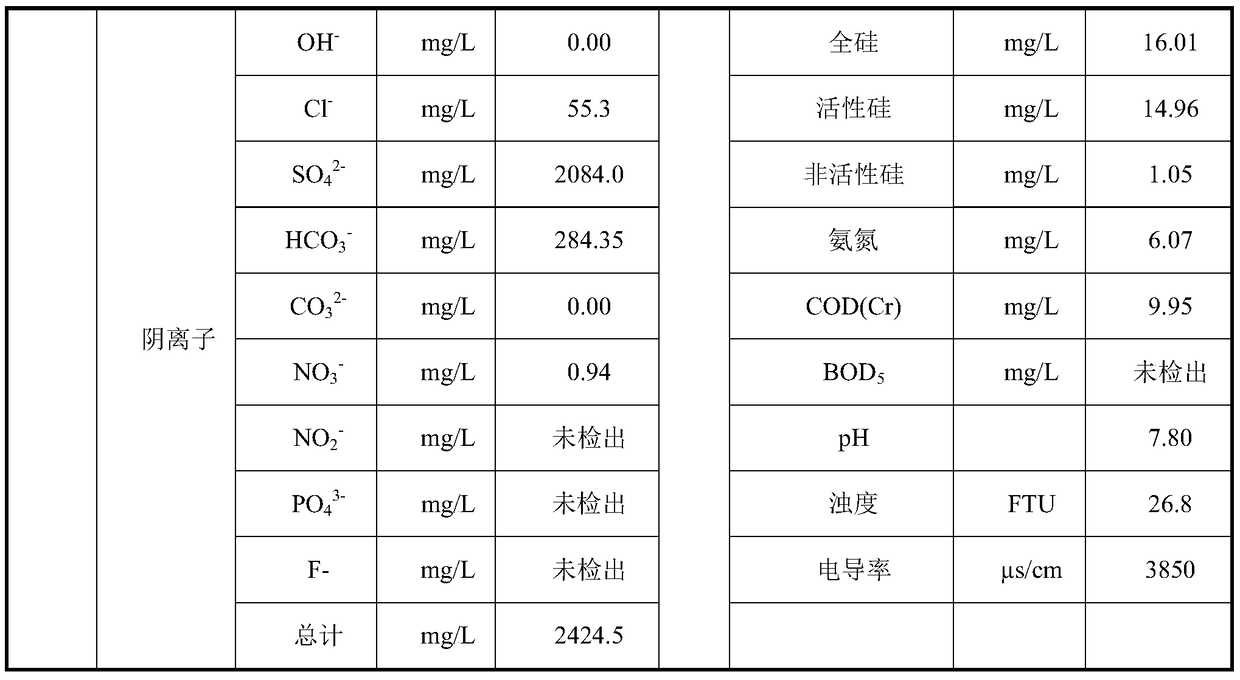

[0094] A treatment method for high salinity mine water reuse and resource utilization, comprising the following steps:

[0095] (1) Pretreatment and desalination section: the raw water first enters the high-efficiency clarification tank and is softened by adding chemicals, and then the effluent enters the ultrafiltration device to remove suspended solids, colloidal particles, bacteria, viruses, etc. and organic matter in the water, and then the effluent enters the first The reverse osmosis device performs desalination, the first reverse osmosis device discharges the water and reuses it, and the concentrated brine continues to be processed;

[0096] (2) Concentrated brine concentration section: the concentrated brine obtained in step (1) is discharged into a high-density sedimentation tank and chemical agents are added to remove hardness and silicon, and then the effluent is softened again by ion exchange resin, and the effluent is decarbonized and then enters nanofiltration Th...

Embodiment 2

[0099] (1) Pretreatment and desalination section: the raw water first enters the high-efficiency clarification tank and is softened by adding sodium hydroxide and soda ash, and then the effluent enters the ultrafiltration device to remove suspended solids, colloidal particles, bacteria, viruses, etc. and organic matter in the water, and then effluent Enter the first reverse osmosis device for desalination, the first reverse osmosis device produces water and reuses after discharge, and the concentrated brine continues to be treated; the ultrafiltration device is a submerged ultrafiltration device, and the ultrafiltration membrane used is a pore size of 0.02 microns. Hollow fiber membrane;

[0100] (2) Concentrated brine concentration section: the concentrated brine obtained in step (1) is discharged into a high-density sedimentation tank and chemical agents are added to remove hardness and silicon, and then the effluent is softened again by ion exchange resin, and the effluent i...

Embodiment 3

[0103] A treatment method for high salinity mine water reuse and resource utilization, comprising the following steps:

[0104] (1) Pretreatment and desalination section: the raw water first enters the high-efficiency clarification tank and is softened by adding chemicals, and then the effluent enters the ultrafiltration device to remove suspended solids, colloidal particles, bacteria, viruses, etc. and organic matter in the water, and then the effluent enters the first The reverse osmosis device performs desalination, the first reverse osmosis device discharges the water and reuses it, and the concentrated brine continues to be processed;

[0105] (2) Concentrated brine concentration section: the concentrated brine obtained in step (1) is discharged into a high-density sedimentation tank and added with magnesium chloride, sodium hydroxide and soda ash to remove hardness and silicon, then the effluent is softened again by weak acid cation exchange resin, and the effluent is dew...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com