Reduction control device and method for N2O produced in denitrification dephosphorization process

A technology for denitrification and phosphorus removal and control device, which is applied in the direction of electrical program control, comprehensive factory control, and comprehensive factory control, and can solve problems such as the blank state of large-scale sewage treatment plants and the lack of research on sewage treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

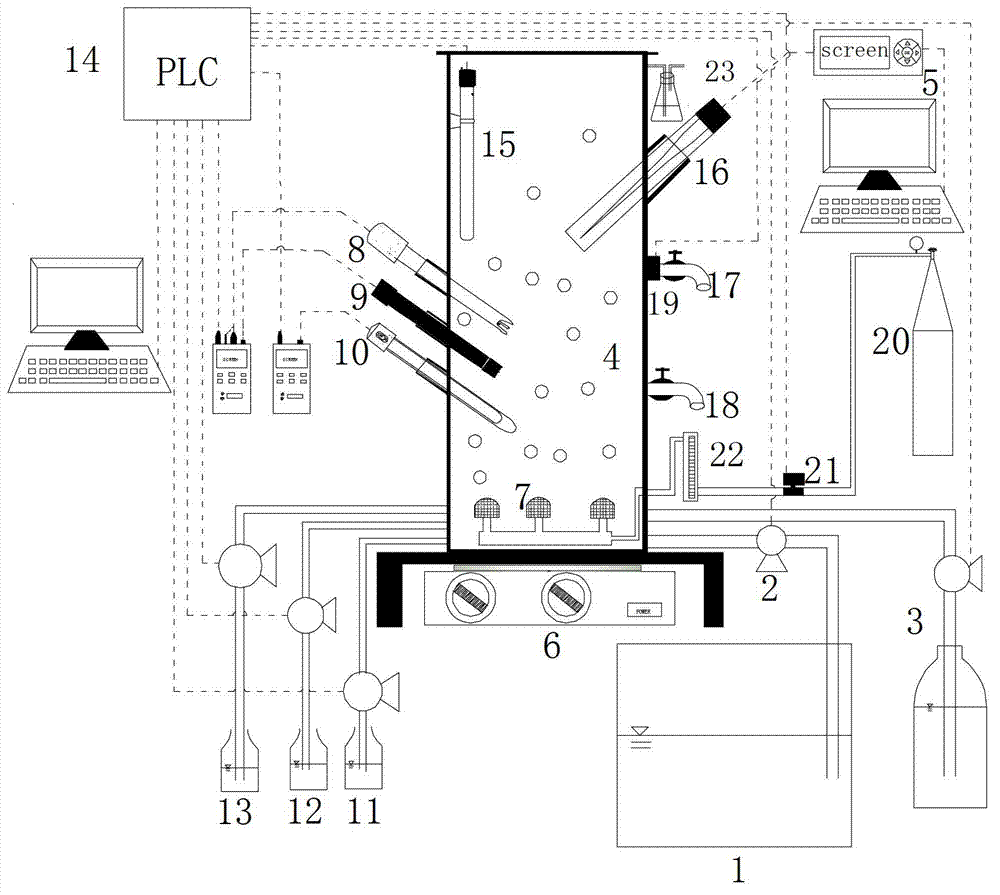

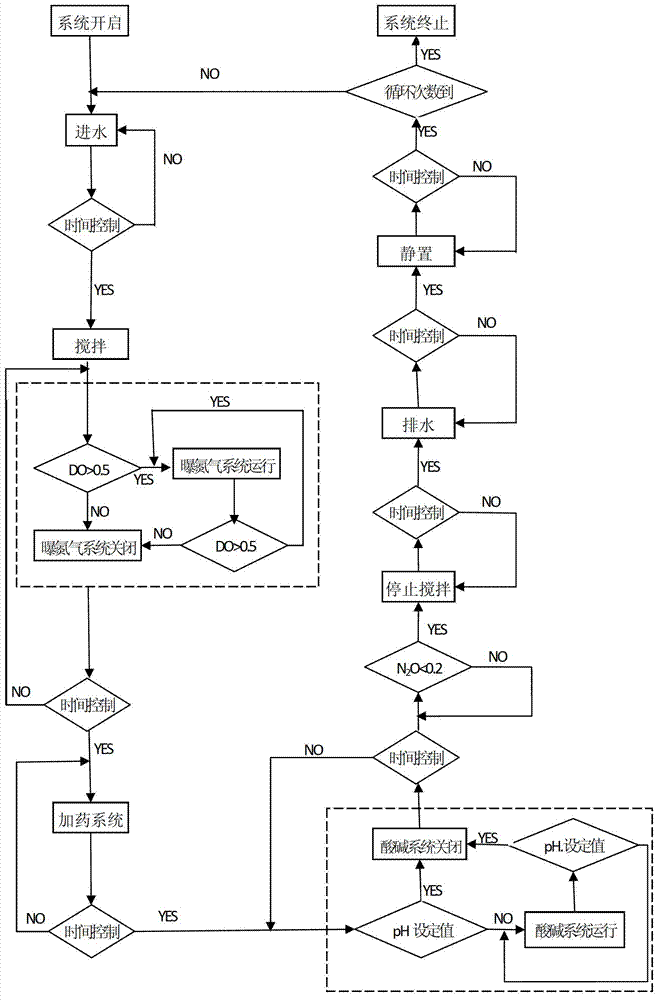

Method used

Image

Examples

Embodiment 1

[0030] 1. To investigate the effect of pH on N in the process of denitrification and phosphorus removal 2 Study on the Impact of O Generation Situations

[0031] Test method: Take the activated sludge rich in about 90% of phosphorus accumulating bacteria and add it to the SBR reactor. For phosphate water distribution, the magnetic stirrer starts to stir, the valve of the nitrogen tank is opened, the flow rate is controlled to be 0.1L / h, nitrogen is exposed for 15 minutes, and the anaerobic phosphorus release reaction is 2 hours. After the anaerobic phosphorus release reaction is completed, the sodium nitrite dosing system is opened. Sodium nitrite with a concentration of 2g / L is quantitatively fed into the SBR reactor with a peristaltic pump at a flow rate of 10ml / min within 2min, and the pH, temperature and dissolved oxygen in the system are detected in real time through the pH and temperature probes, and the dissolved oxygen probes are used online through the PLC. The contr...

Embodiment example 2

[0033] 2. To investigate the effect of temperature on N in the process of denitrification and phosphorus removal 2 Study on the Impact of O Generation Situations

[0034] Test method: Take the activated sludge rich in about 90% of phosphorus accumulating bacteria and add it to the SBR reactor. For phosphate water distribution, the magnetic stirrer starts to stir, and the valve of the nitrogen tank is opened, and the flow rate is controlled to be 0.1L / h and nitrogen is exposed for 15 minutes. The anaerobic phosphorus release reaction was performed for 2 hours. After the anaerobic phosphorus release reaction, the sodium nitrite dosing system was started, and the sodium nitrite with a mass concentration of 2g / L was quantitatively fed into the SBR reactor within 2 minutes at a flow rate of 10ml / min by a peristaltic pump. Real-time detection of pH, temperature and dissolved oxygen in the system through pH and temperature probes, dissolved oxygen probes, and PLC online control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com