A kind of ibuprofen sodium salt refining device and process

A technology for sodium ibuprofen and a refining device is applied in the field of refining devices for sodium ibuprofen to achieve the effects of large production capacity, low gas flow rate, and easy manufacturing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

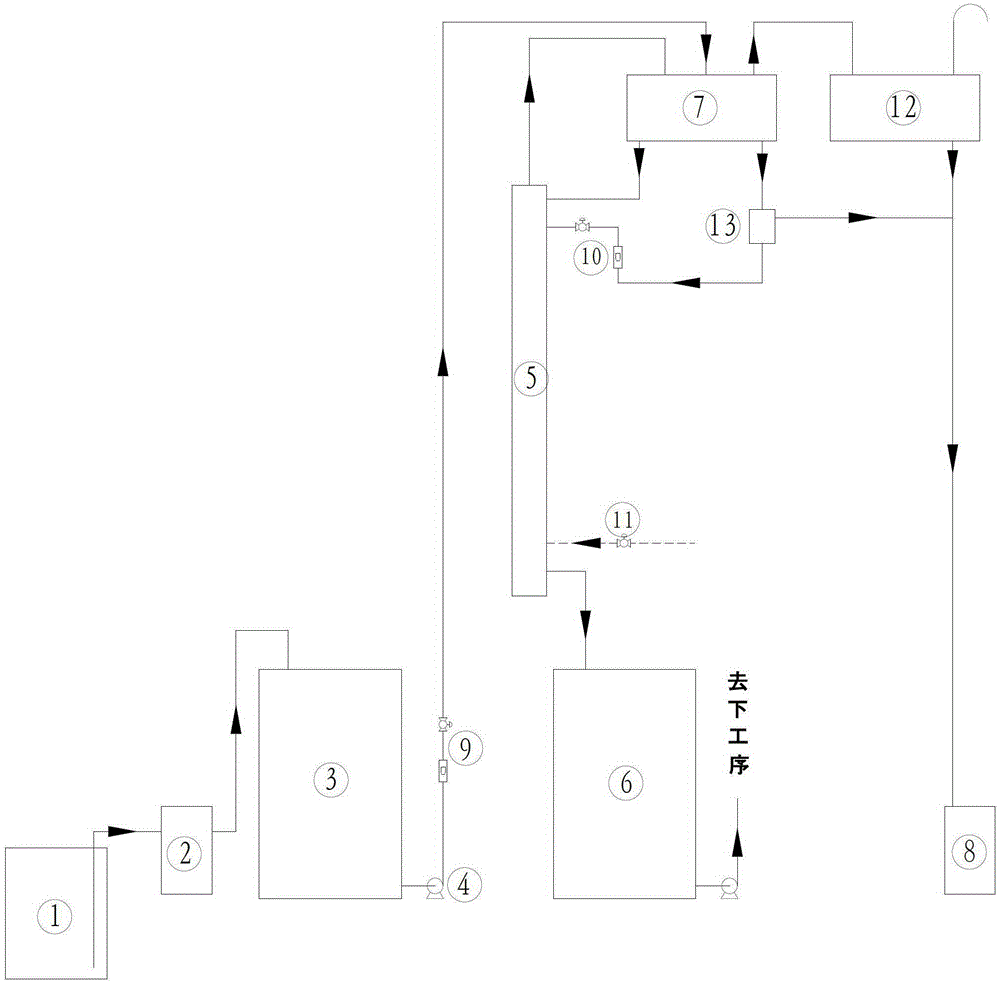

[0044] ⑴Add 5000L tap water to the sodium salt dissolving tank ①, raise the temperature to 65°C, add 2.8t ibuprofen sodium salt, and stir for 30 minutes.

[0045] ⑵Introduce the uniformly mixed ibuprofen sodium salt solution into the filter press ②, and filter through the filter screen, the insoluble matter is left on the filter screen of the filter press, and then discharged from the bottom; after the filtrate is absorbed by activated carbon, it enters the sodium salt solution Accept the tank ③ for temporary storage.

[0046] ⑶ The filtrate in the sodium salt solution receiving tank ③ is introduced into the primary condenser ⑦ through the feeding pump ④ and preheated to 85°C.

[0047] ⑷The preheated filtrate enters the stripping tower ⑤ from the top, the filtrate and steam exchange heat in the tower, the organic solvent is brought into the gas phase, and the filtrate from which organic matter is removed enters the stripping receiving tank ⑥ from the bottom of the stripping to...

Embodiment 2

[0051] ⑴ Add 5000L tap water to the sodium salt dissolution tank ①, raise the temperature to 68°C, add 2.9t ibuprofen sodium salt, and stir for 25 minutes.

[0052] ⑵Introduce the uniformly mixed ibuprofen sodium salt solution into the filter press ②, and filter through the filter screen, the insoluble matter is left on the filter screen of the filter press, and then discharged from the bottom; after the filtrate is absorbed by activated carbon, it enters the sodium salt solution Accept the tank ③ for temporary storage.

[0053] ⑶ The filtrate in the sodium salt solution receiving tank ③ is introduced into the primary condenser ⑦ through the feeding pump ④ and preheated to 88°C.

[0054] ⑷The preheated filtrate enters the stripping tower ⑤ from the top, the filtrate and steam exchange heat in the tower, the organic solvent is brought into the gas phase, and the filtrate from which organic matter is removed enters the stripping receiving tank ⑥ from the bottom of the stripping ...

Embodiment 3

[0058] ⑴ Add 5000L tap water to the sodium salt dissolving tank ①, raise the temperature to 70°C, add 3t of ibuprofen sodium salt, and stir for 40 minutes.

[0059] ⑵Introduce the uniformly mixed ibuprofen sodium salt solution into the filter press ②, and filter through the filter screen, the insoluble matter is left on the filter screen of the filter press, and then discharged from the bottom; after the filtrate is absorbed by activated carbon, it enters the sodium salt solution Accept the tank ③ for temporary storage.

[0060] ⑶ The filtrate in the sodium salt solution receiving tank ③ is introduced into the primary condenser ⑦ through the feeding pump ④ and preheated to 90°C.

[0061] ⑷The preheated filtrate enters the stripping tower ⑤ from the top, the filtrate and steam exchange heat in the tower, the organic solvent is brought into the gas phase, and the filtrate from which organic matter is removed enters the stripping receiving tank ⑥ from the bottom of the stripping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com