A kind of silver nano/copper foam material and its preparation method and application

A foamed copper and silver nanotechnology, applied in analytical materials, nanotechnology, nanotechnology and other directions, can solve problems such as the enhancement effect needs to be further improved, the number of hot spots is not good enough, the protection of nanostructures is not enough, and the preparation process is simple, fast and easy to master. , the effect of prolonging the storage time and improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation method of silver nano / copper foam material, comprising the following steps:

[0045] (1) Hydrochloric acid soaking of copper foam sheet: The cleaned and dried copper sheet with a specification of 0.5cm* 0.5cm * 0.5mm is immersed in a dilute hydrochloric acid solution with a mass fraction of 3.6% of 15mL, and soaked for 10min;

[0046] (2) The surface of the foam copper sheet is removed: the foam copper sheet after soaking in the step (1) of anhydrous ethanol and deionized water is used sequentially to remove the impurities on the surface of the foam copper sheet;

[0047](3) Preparation of the mixture: the silver nitrate solution with a concentration of 0.1 mol / L of 10mL and the 2mL 0.05g / mL PVP solution were fully mixed to obtain the mixture;

[0048] (4) Shaking reaction: The foam copper sheet after surface impurity removal in step (2) is immersed in the mixture obtained in step (3), and the shaking reaction is 30s;

[0049] (5) Post-reaction treatment: Rinse ...

Embodiment 2~5

[0051] In addition to the different concentrations of silver nitrate solution, the process conditions and preparation process of Examples 2 to 5 and Example 1 are the same. Wherein, the concentration of silver nitrate solution in Examples 2 to 5 is 0.2mol / L, 0.4mol / L, 0.8mol / L, 1.6mol / L, respectively.

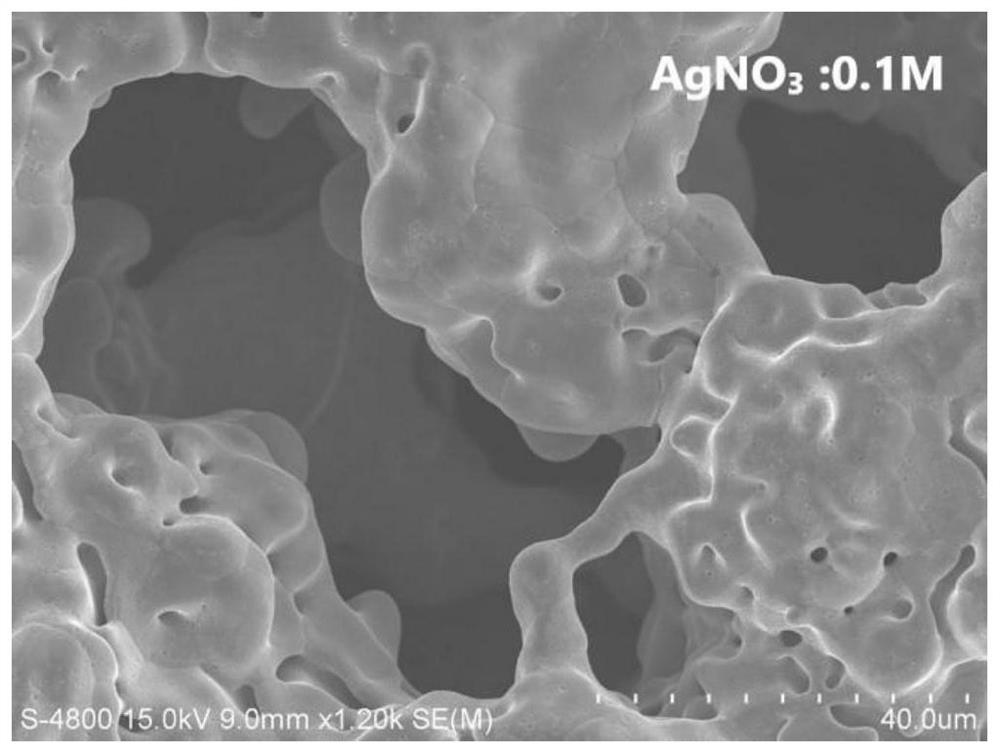

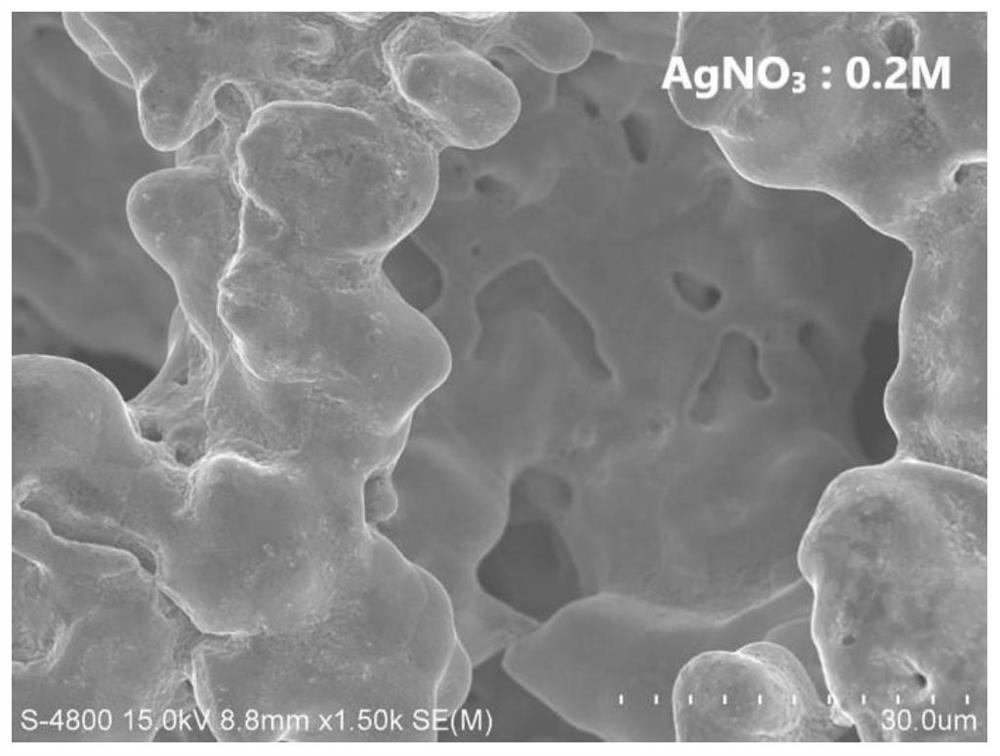

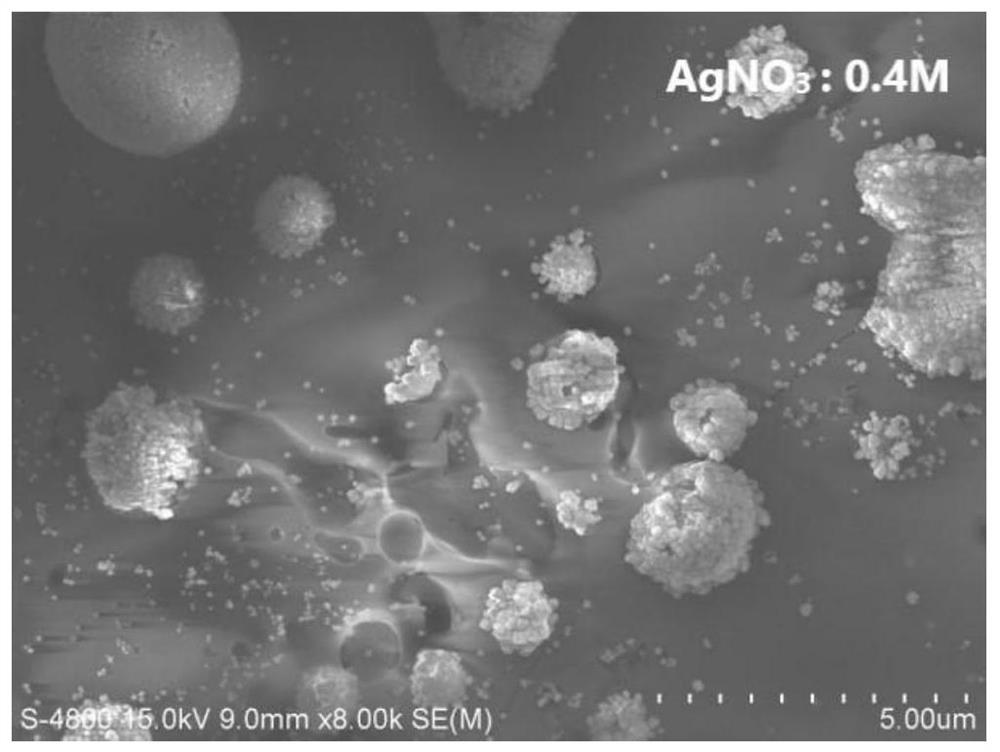

[0052] Figures 1 to 5 Respectively, examples 1 to 5 correspond to the preparation of silver nano / copper foam material SEM diagram, from Figures 1 to 5 As can be seen, along with AgNO 3 The higher the concentration, the deposition effect of silver nanoparticles on the surface of copper foam is first increased and then decreased.

[0053] At the same time, the present invention in 10- 4 mol / L 4-ATP as a probe molecule to obtain the silver nano / copper foam substrate SERS enhancement effect prepared from Example 1 to 5 is tested and analyzed, the test method is as follows:

[0054] (1) Cut the dry and clean silver nano / copper foam material into small pieces of suitable s...

Embodiment 6

[0060] Preparation method of silver nano / copper foam material, comprising the following steps:

[0061] (1) Hydrochloric acid soaking of copper foam sheet: The cleaned and dried copper sheet with a specification of 0.5cm* 0.5cm * 0.5mm is immersed in a dilute hydrochloric acid solution with a mass fraction of 3.6% of 15mL, and soaked for 10min;

[0062] (2) The surface of the foam copper sheet is removed: the foam copper sheet after soaking in the step (1) of anhydrous ethanol and deionized water is used sequentially to remove the impurities on the surface of the foam copper sheet;

[0063] (3) Preparation of the mixture: the silver nitrate solution with a concentration of 0.8 mol / L of 10mL and the PVP solution of 2mL of 0.05g / mL are fully mixed to obtain the mixture;

[0064] (4) Shaking reaction: The foam copper sheet after the surface of step (2) is submerged in the mixture obtained in step (3), and the shaking reaction is 10s;

[0065] (5) Post-reaction treatment: Rinse the ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com