Method for drying-in-shade pelletizing by using converter waste gas

A technology for waste gas and converter, which is applied in the field of using converter waste gas to dry in the shade, can solve the problems of large loss of sensible heat and latent chemical heat of converter waste gas, high cost of pelletizing process, long pelletizing time, etc. The effect of high compressive strength and improved ball formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

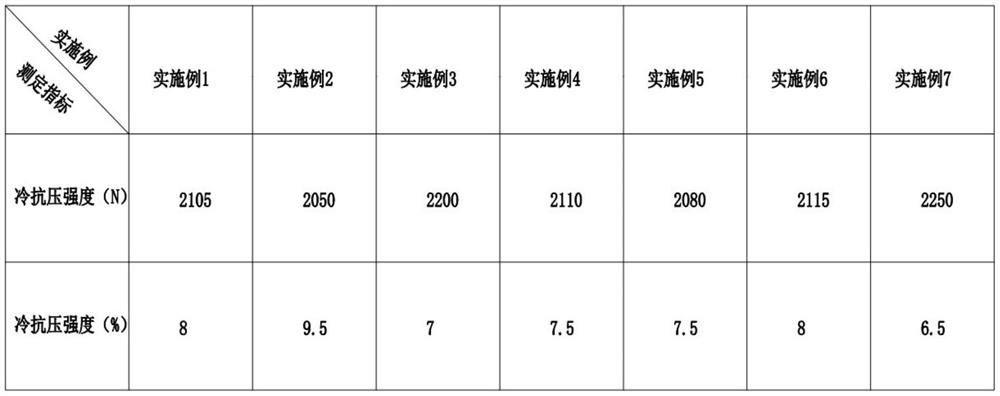

Embodiment 1

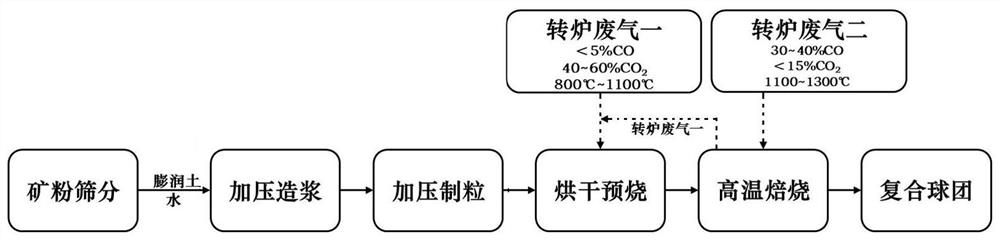

[0061] This embodiment provides a method for making pellets by using converter exhaust gas in the shade, including the following steps: S1. Preparation of raw materials: treating vanadium-titanium-magnetite powder to a particle size below 35 mesh.

[0062] S2. Pressurized pulping: After the vanadium-titanium magnetite powder, bentonite and water are fully mixed and stirred, a pressure of 5000N is used to pressurize and control the water to form a non-Newtonian fluid slurry.

[0063] S3. Pressurized granulation: the pulp is pressurized and extruded through a round-hole die to prepare green balls, and the obtained green balls have a diameter of 8mm.

[0064] S4. Drying and pre-burning: transport the green balls to the dryer, pass the first converter waste gas with a temperature of 1100°C into the dryer to dry the green balls, and use the oxidative atmosphere of the first converter waste gas to treat the raw The balls were micro-oxidized and calcined for 5 minutes to obtain pelle...

Embodiment 2

[0068] This embodiment provides a method for making pellets in the shade using converter waste gas, which includes the following steps:

[0069] S1. Preparation of raw materials: process the ore powder to a particle size below 35 mesh.

[0070] S2. Pressurized pulping: After the mineral powder, additives and water are fully mixed and stirred, a pressure of 10000N is used to pressurize and control the water to form a non-Newtonian fluid slurry.

[0071] S3. Pressurized granulation: the pulp is pressurized and extruded through a round-hole die to prepare green balls, and the obtained green balls have a diameter of 12 mm.

[0072] S4. Drying and pre-burning: transport the green balls to the dryer, pass the waste gas of the first converter at a temperature of 900°C into the dryer, and dry the green balls, and use the oxidative atmosphere of the first converter waste gas to treat the raw The balls were micro-oxidized and calcined for 10 minutes to obtain pellets.

[0073] S5. Hig...

Embodiment 3

[0076] This embodiment provides a method for making pellets in the shade using converter waste gas, which includes the following steps:

[0077] S1. Preparation of raw materials: process the ore powder to a particle size below 35 mesh.

[0078] S2. Pressurized pulping: After the mineral powder, additives and water are fully mixed and stirred, a pressure of 5000N is used to pressurize and control the water to form a non-Newtonian fluid slurry.

[0079] S3. Pressurized granulation: The pulp block is pressurized and extruded through a round-hole die to prepare green balls, and the obtained green balls have a diameter of 8.5 mm.

[0080] S4. Drying and pre-burning: transport the green balls to the dryer, pass the first converter waste gas with a temperature of 1100°C into the dryer to dry the green balls, and use the oxidative atmosphere of the first converter waste gas to treat the raw The balls were micro-oxidized and calcined for 10 minutes to obtain pellets.

[0081] S5. Hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com