Low-temperature evaporation, concentration and crystallization system and method using waste heat

A low-temperature evaporation, concentration and crystallization technology, used in chemical instruments and methods, energy and wastewater treatment, water/sewage treatment, etc. Achieve the effect of improving the reuse rate, treating a wide range of objects, and avoiding the risk of scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

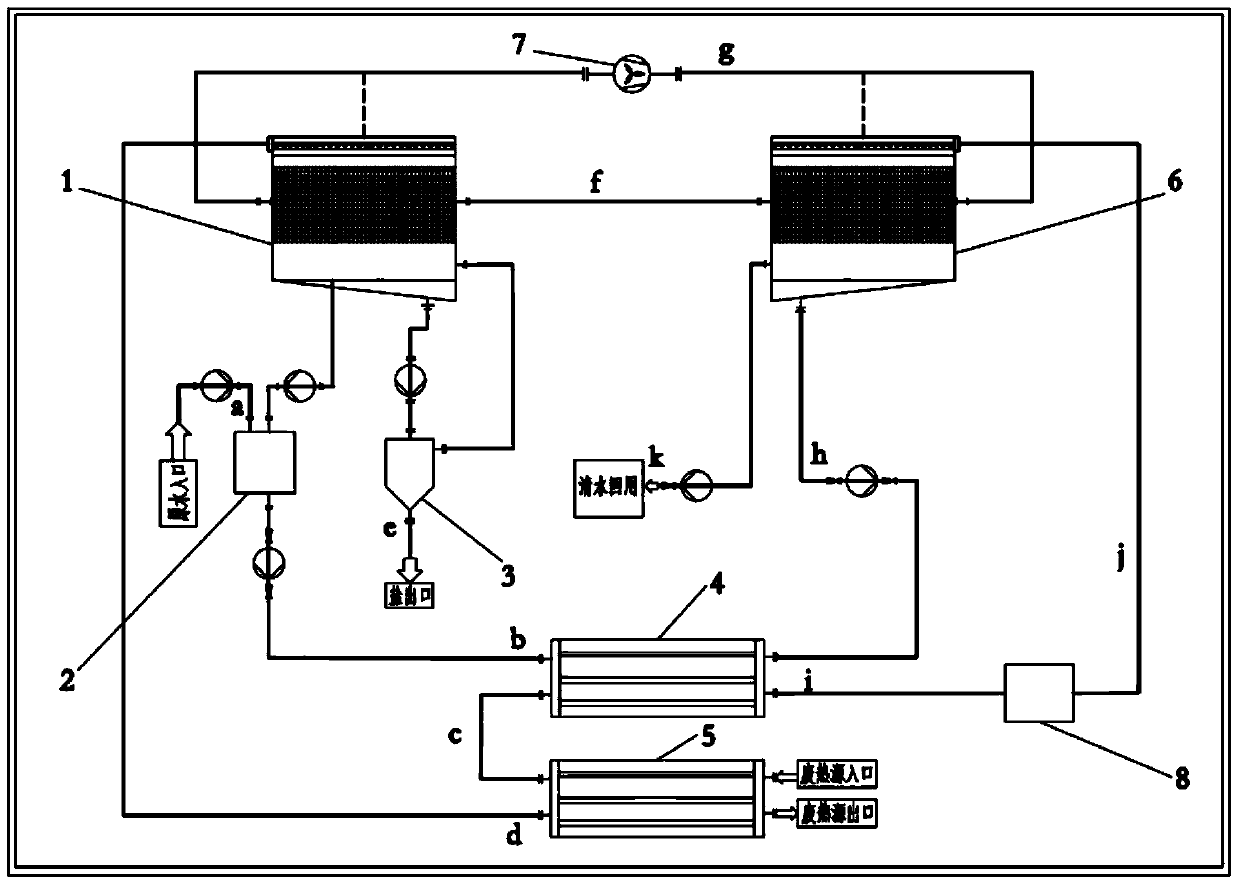

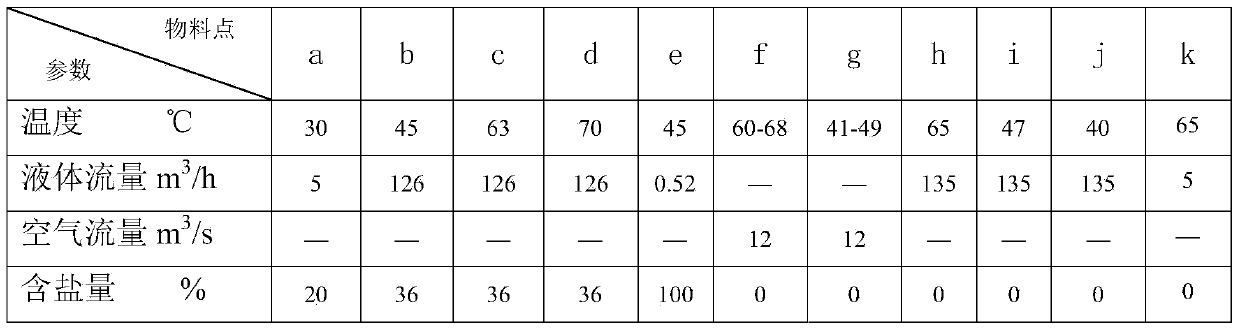

[0036] 20% sodium chloride in 5m 3 The flow rate of / h enters the concentrated evaporative crystallization system of the present invention for processing, and the processing results are as shown in Table 1: wherein, a, b to k in Table 1 correspond to figure 1 Sampling points a, b to k in .

[0037] Table 1 Sodium chloride concentrated brine evaporation concentration crystallization table

[0038]

[0039] After the concentrated brine is treated by the evaporative concentration and crystallization system and method of the present invention, the energy consumption required to obtain per cubic product water is less than 30KW·h.

Embodiment 2

[0041] 20% sodium sulfate concentrated brine with 5m 3 The flow rate of / h enters the concentrated evaporative crystallization system of the present invention for processing, and the processing results are as shown in Table 1: wherein, a, b to k in Table 1 correspond to figure 1 Sampling points a, b to k in .

[0042] Table 2 Sodium sulfate concentrated brine evaporation concentration crystallization table

[0043]

[0044] After the concentrated brine is treated by the evaporative concentration and crystallization system and method of the present invention, the energy consumption required to obtain per cubic product water is less than 30KW·h.

[0045] The evaporation concentration and crystallization system of the present invention is suitable for the treatment of high-concentration concentrated brine in various industries. Since the crystallization separation or concentration separation can be completed in an environment with a low temperature (30-80°C), the final produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com