Method of removing small particulate matters in coal-fired flue gas by combining chemical agglomeration with acoustic agglomeration

A technology of chemical agglomeration and fine particles, applied in the field of coal-fired particle removal in thermal power plants, can solve the problems of high energy consumption and low removal efficiency of fine particles, and achieve the effect of promoting collision agglomeration, enhancing collision probability and speed, and improving agglomeration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

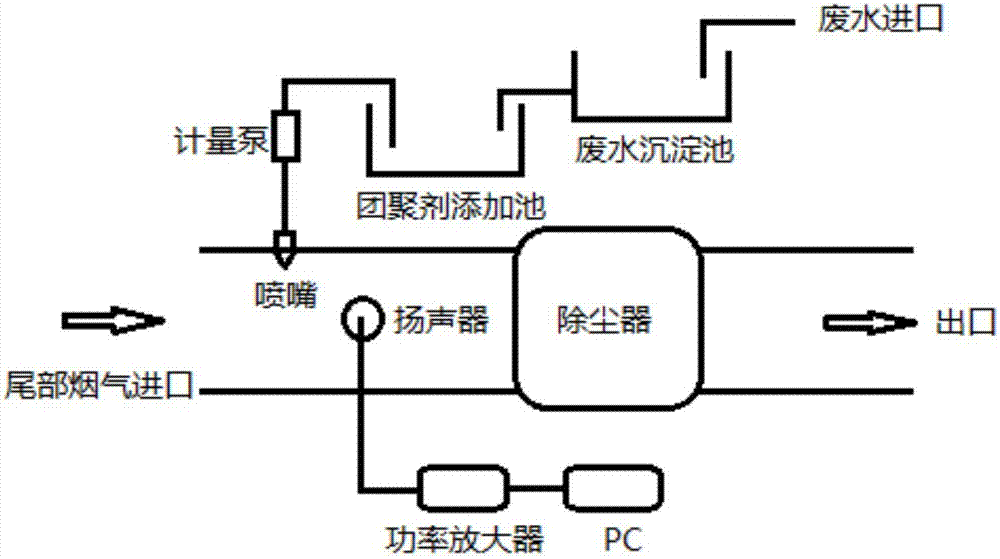

[0024] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] A method for chemical agglomeration combined with acoustic agglomeration to remove fine particles of coal-fired flue gas, comprising the following steps:

[0026] 1) Introduce the desulfurized and denitrified wastewater into the sedimentation tank, and after flocculation and precipitation, take the supernatant and introduce it into the agglomerating agent addition tank;

[0027] 2) In the agglomeration tank, add a surfactant and a high polymer coagulant, stir well, and use this as a chemical agglomeration agent;

[0028] 3) Under the action of the metering pump and air compressor, the chemical agglomerating agent is sprayed into the flue in front of the dust collector through the double-flow atomizing nozzle;

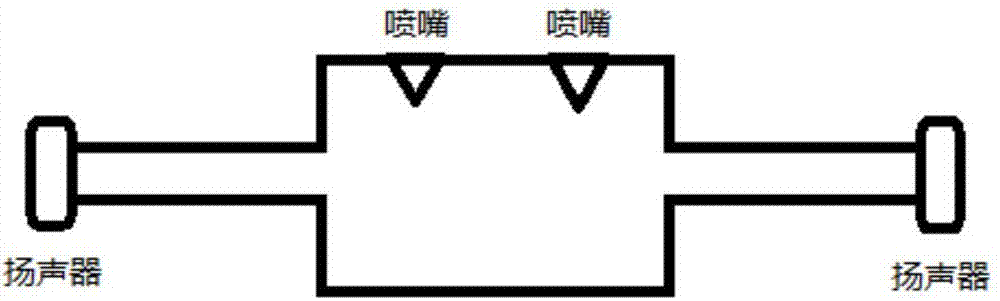

[0029] 4) Install speakers on both sides of the flue, and guide the sound field through the sound waveguide;

[0030] 5) The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com