Process for mineral processing of low-grade silicon calcium collophanite

A technology of siliceous calcium and colloidal phosphate rock, applied in flotation, solid separation and other directions, can solve the problems of affecting the flotation effect, no decarbonization link, difficult flotation, etc., to increase the decarbonization process and reduce production costs , Overcome the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

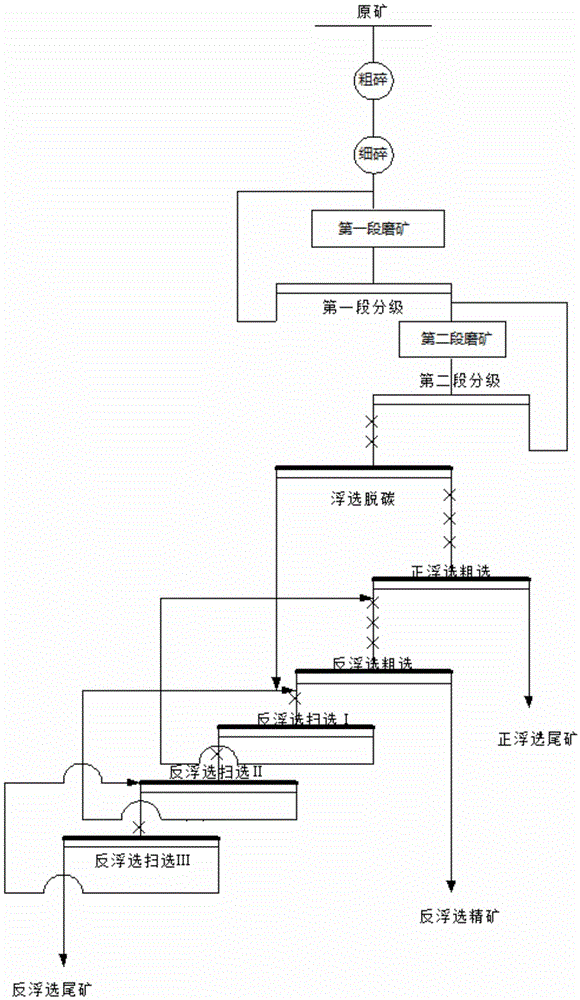

[0041] A low-grade silicon-calcium colloidal phosphate ore beneficiation process, the steps are as follows:

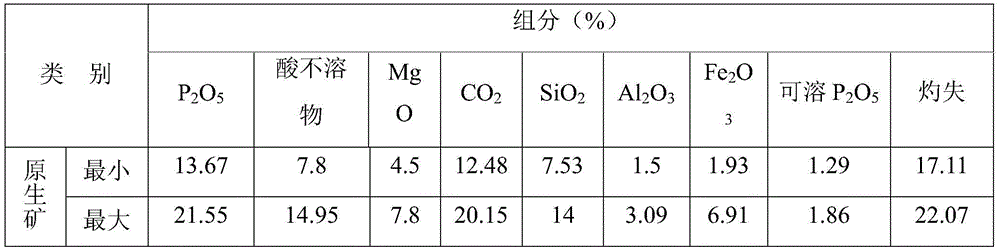

[0042] 1) Crushing section: the raw ore of siliceous calcareous collophosite contains P 2 o 5 19.48wt%, MgO3.18wt%, after sieving, those that meet the fineness requirements will directly enter the ball milling section. Those that do not meet the fineness requirements can enter the ball milling section after being coarsely crushed and finely crushed to the specified fineness requirements (below 15mm).

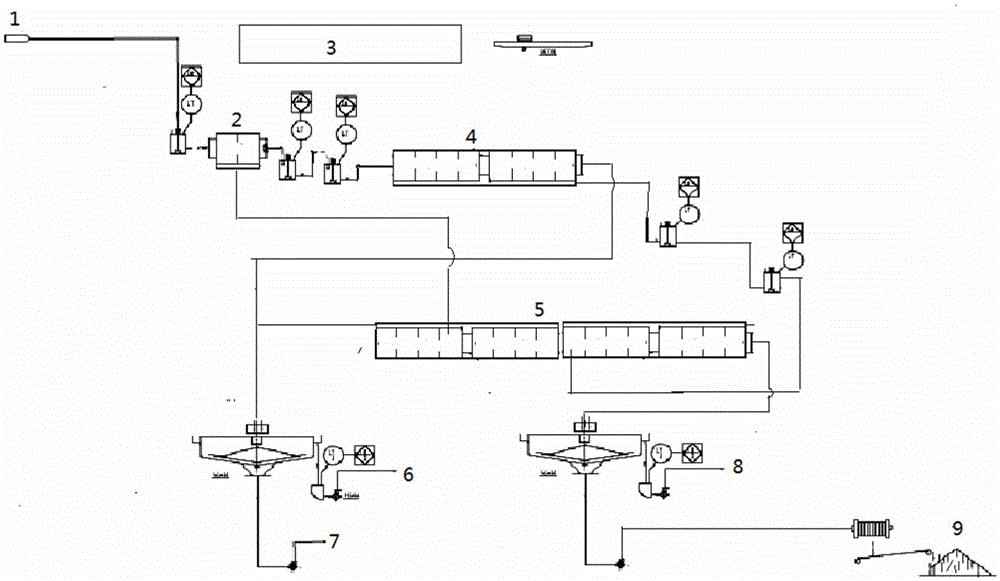

[0043] 2) Ball milling section: The crushed raw ore is sent to the silo by the belt conveyor, and fed to the first stage of the ball mill through the feeder. The raw ore after ball milling enters the classifier. After classification, the fineness requirement (less than 110 mesh) 95%) of the raw ore is returned to the ball mill for further grinding, and the raw ore that meets the fineness requirement (less than 110 mesh accounts for 95%) enters the second stage of grind...

Embodiment 2

[0067] A low-grade silicon-calcium colloidal phosphate ore beneficiation process, the steps are as follows:

[0068] 1) Crushing section: the raw ore of siliceous calcareous collophosite contains P 2 o 5 16.54wt%, MgO5.21wt%, SiO 2 11.78wt% is sieved, and those that meet the fineness requirement directly enter the ball milling section. Those that do not meet the fineness requirements can enter the ball milling section after being coarsely crushed and finely crushed to the specified fineness requirements (below 15mm).

[0069] 2) Ball mill section: The crushed raw ore is sent to the silo by the belt conveyor, and fed to the first section of the ball mill through the feeder, and the raw ore after ball milling enters the classifier. After classification, the fineness requirement (less than 110 mesh accounts for 95% ) is returned to the first stage of ball mill for further grinding, and the raw ore that meets the fineness requirement (less than 110 mesh accounts for 95%) enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com