Rapid harmless plant organic residue treatment and fertilizer utilization process and equipment thereof

A technology of harmless treatment and treatment equipment, which is applied in the preparation of organic fertilizers, the treatment of biological organic parts, organic fertilizers, etc., can solve the problems of no proportion, pollute the environment, and deal with difficulties, so as to increase the service life and improve the soil The environment and the effect of solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

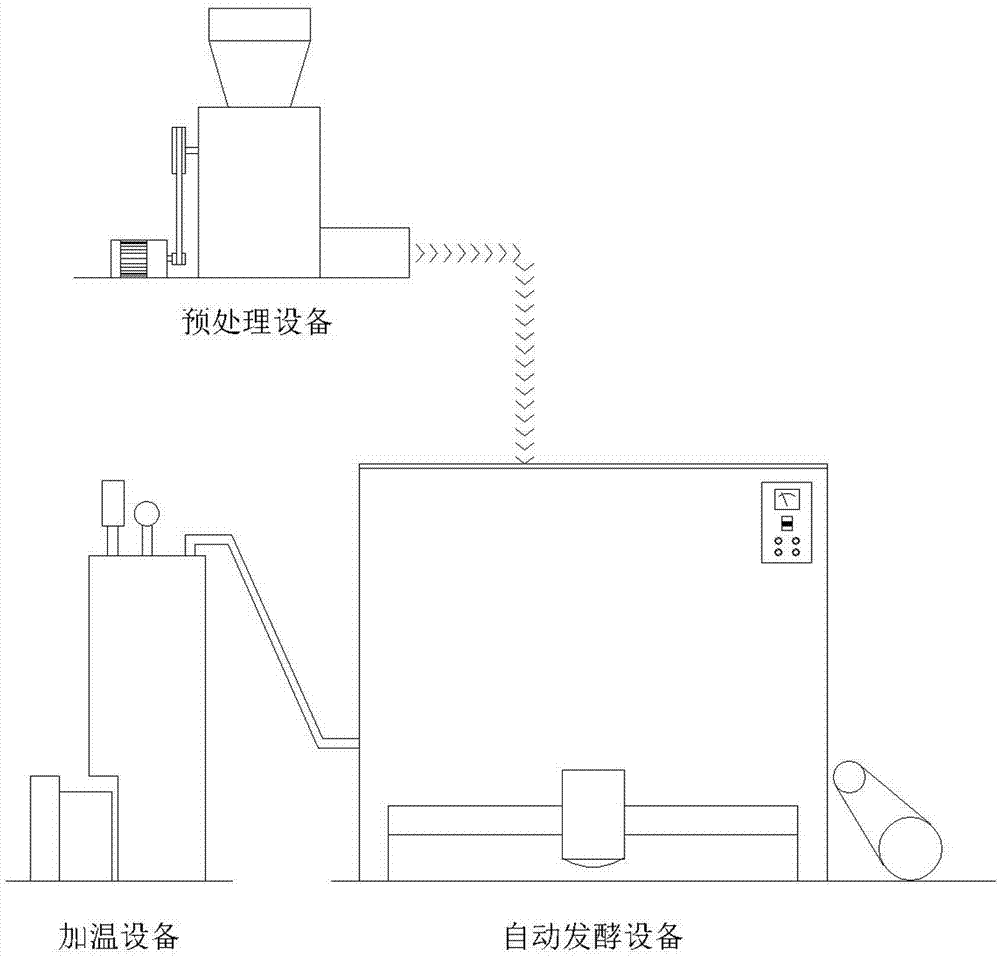

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0027] The rapid and harmless treatment and fertilizer utilization process of plant organic residues adopts the process of automatic mechanical treatment and rapid fermentation treatment to process vegetable residues. The specific process steps are as follows:

[0028] (1) Material pretreatment: Classify the collected vegetable residues into green leafy vegetable residues, solanaceous vegetable residues, melon and fruit vegetable residues, and tuber vegetable residues, and put them into crushing equipment for crushing;

[0029] (2) Proportion: mix the sorted vegetable residues with wood chips, chaff and oil meal respectively, adjust different proportions according to different classifications, mix evenly, and keep the moisture content of the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com