Environment-friendly clean pulping process

A clean pulping and process technology, applied in the field of papermaking and pulping, can solve the problems of backward process, high production cost, large fuel consumption, etc., and achieve the effects of optimizing the pulping process, reducing equipment investment, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below in conjunction with specific embodiment, the present invention is further explained and illustrated, and "part" described in the embodiment all refers to "weight part":

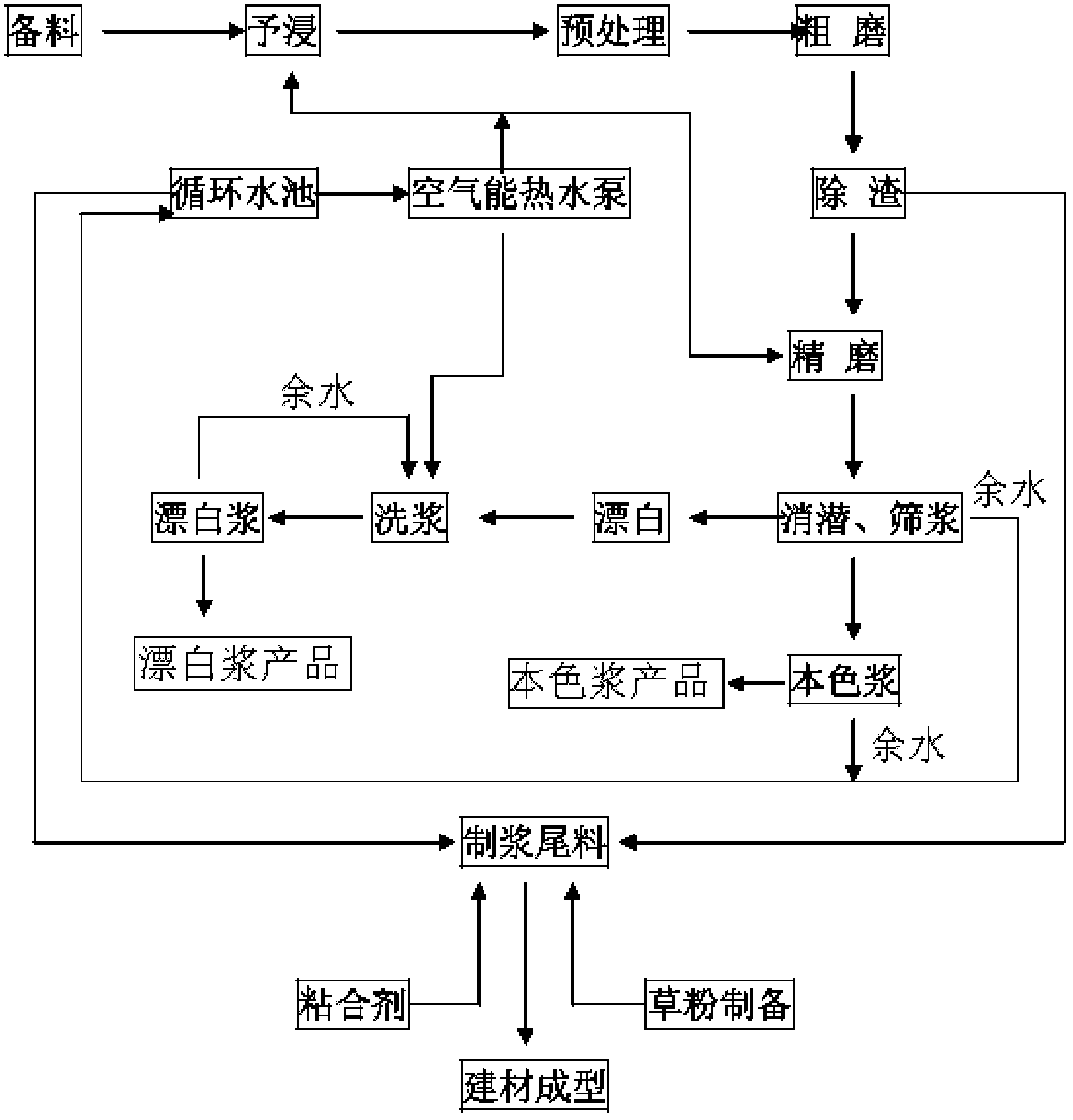

[0064] An environmentally friendly and clean pulping process, see pulping process figure 1 , using an air energy hot water pump to provide circulating water for pulping, and the temperature of the circulating water is 50°C;

[0065] (1) The pulping formula includes:

[0066] Pre-dipping agent: table salt, diisooctyl sulfosuccinate monosodium salt, ethanol with a volume concentration of 95%, calcium percarbonate (2CaCO 3 ·3H 2 o 2 )

[0067] Chelating Agents: Sodium Citrate, Opal.

[0068] Activator: tetraacetylethylenediamine, sodium nonanoyloxybenzenesulfonate, acetone (industrial grade).

[0069] Bleach: Peroxysulfuric acid (H 2 SO 5 ), potassium hydrogen peroxysulfate (KHSO 5 ).

[0070] Water treatment agent: polyaluminum chloride, acrylamide grafted starch, FeSO 4 .

[0071] Bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com