Patents

Literature

61results about How to "Achieving low-carbon production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Orange peel dregs biologic fermentation method

InactiveCN103819239AImprove the ability to adapt to variable temperature fermentationImprove fermentation effectBio-organic fraction processingOrganic fertiliser preparationPotassiumOrganic compound

The invention discloses an orange peel dregs biologic fermentation method, and belongs to the technical field of orange peel dregs innocuous treatment. Orange peel dregs are used as a main raw material and added with a liquid micro organism bacterial agent, and is subjected to composting primary fermentation and composting fermentation, so as to prepare a fermentation product which is rich in organic substances and microelements such as boron, zinc and magnesium, and is proper in the proportions and contents of N, P and K. The content of the organic components of the fermentation product is not less than 45 percent, the pH value is within 6.5-8.5, the total content of N, P and K is not less than 6 percent, the moisture content is not greater than 30 percent, the fermentation product is rich in the microelements such as boron, zinc and magnesium, can be directly used as an organic fertilizer, meanwhile can be added with a microelement fertilizer or a chemical fertilizer to be compounded into an organic compound fertilizer, an organic-inorganic compound fertilizer and the like. The orange peel dregs biologic fermentation method is simple in process, low in cost and high in production efficiency, not only processes a large amount of orange peel dregs, but also prompts the treatment of other organic waste materials, so as to not only protect the environment, but also increase the economic benefits, achieve low-carbon production and explore a new method for the innoxious treatment of the orange peel dregs.

Owner:重庆圣沛农业科技有限公司

Organic compound fertilizer with citrus pomace and preparation method of organic compound fertilizer

InactiveCN103833467AImprove protectionPrevent calcificationBio-organic fraction processingOrganic fertiliser preparationWater contentChemistry

The invention discloses an organic compound fertilizer with citrus pomace and a preparation method of the organic compound fertilizer and belongs to the technical field of preparation of organic fertilizers. The preparation method comprises the following steps of reducing the acidity of the citrus pomace by adopting microbial fermentation for deacidification, decomposing nondegradable components such as pectin and cellulose in the citrus pomace by adopting a compound-enzyme preparation, carrying out composting fermentation by microbial liquid inoculant, finally adding batched materials such as urea, monoammonium phosphate and potassium sulfate, and carrying out insect killing, sterilization, granulation, drying, cooling, sieving, coating and packaging to prepare the organic compound fertilizer with rich organic matter and the contents of N, P and K meeting the need of the optimal proportion for growth of citrus. The organic compound fertilizer and the preparation method disclosed by the invention have the advantages that deacidifying yeast is adopted to reduce the acidity of the citrus pomace and replace the existing method for adding quick lime to carry out deacidification, calcification and alkalization of soil are effectively prevented, the content of the compound fertilizer is more than 55%, the pH value is 6.5-8.5, the total contents of N, P and K are more than or equal to 8%, the water content is less than or equal to 20%, the contents of trace elements such as B, Zn and Mg are rich, and the other quality indexes are superior to national standard of organic fertilizer respectively.

Owner:重庆圣沛农业科技有限公司

Preparation method for tea extract

The invention discloses a preparation method for a tea extract, belonging to the technical field of extraction of effective components of tea leaves. The preparation method comprises the following steps: firstly, carrying out low-temperature rapid freezing treatment on high-quality commercial tea leaves; then immediately crushing; then combining a high-voltage pulsed electric field (PEF for short) technology, an ultrasonic treatment technology and a low-temperature enzymolysis technology; and carrying out low-temperature extraction in a whole process. According to the preparation method for the tea extract, the loss of effective components, caused by high-temperature processing, is avoided, and the extraction rate of the effective components of the tea leaves is also improved. The process is simple and low in cost; the introduction amount of extraneous food additives, processing auxiliary agents and chemical substances is reduced; the natural nutritional ingredient and the flavor of the tea leaves are kept to the greatest extent, the low-carbon production is realized and the environment is protected.

Owner:LVJIN DEV FUJIAN

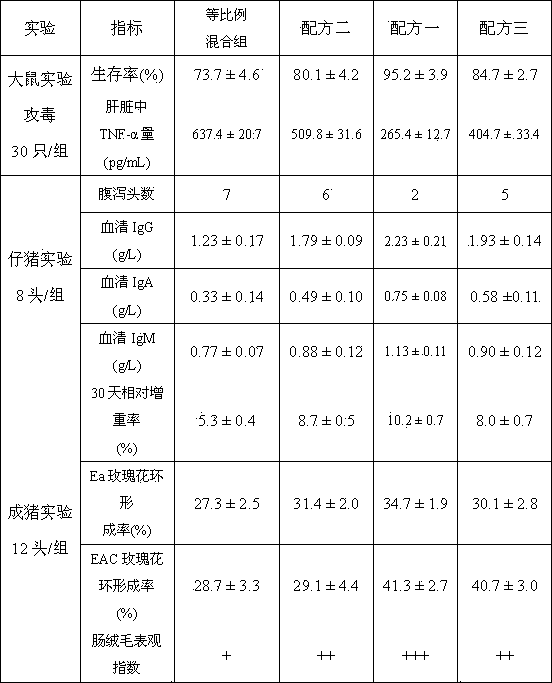

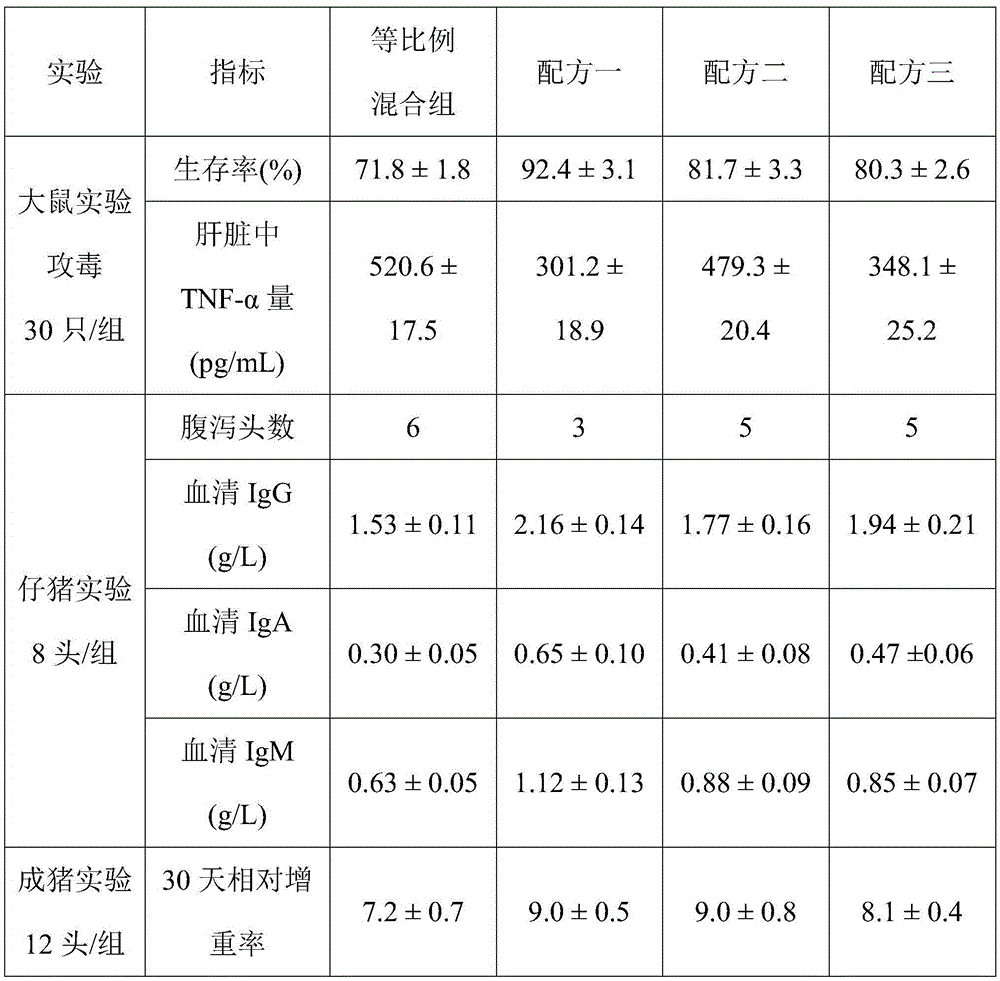

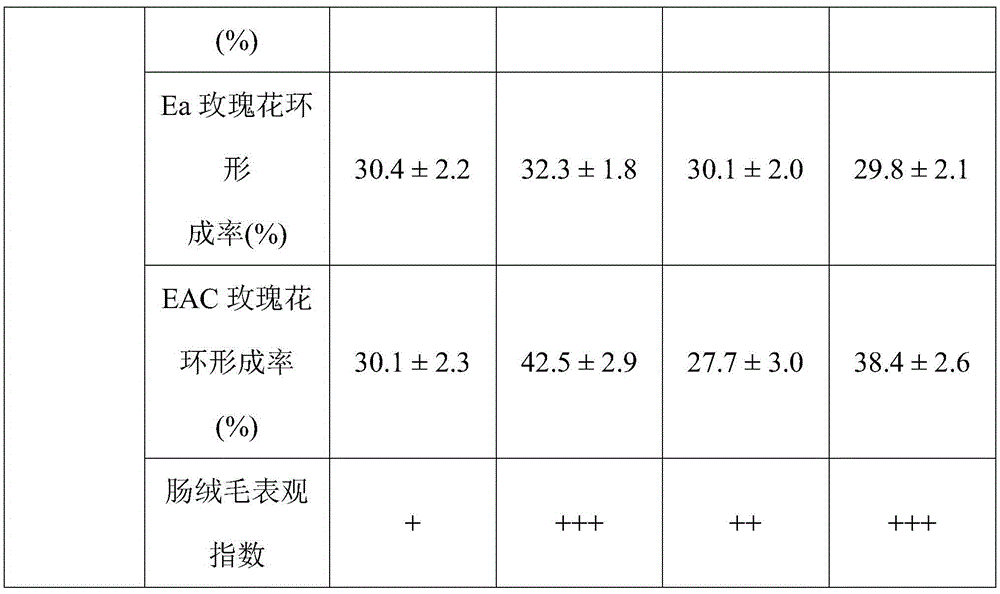

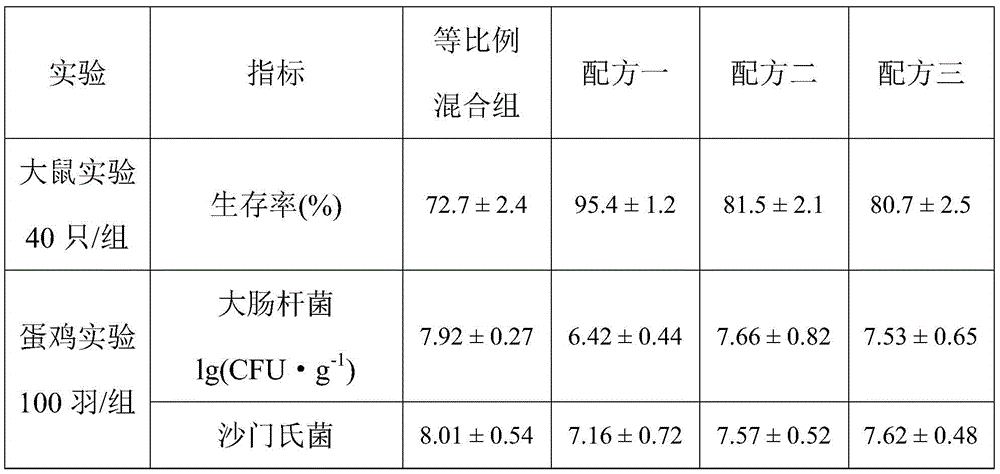

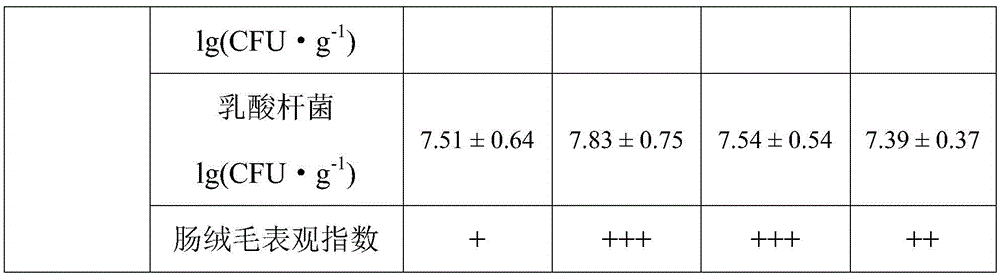

Method and product for producing forage immune enhancer by adopting soybean curb residue and orange peel

InactiveCN103734519AImprove securityAdd lessFood processingAnimal feeding stuffBiotechnologyAnimal science

The invention discloses a method for producing a forage immune enhancer by adopting a soybean curb residue and an orange peel. The method comprises the following steps: respectively crushing the soybean curb residue, dried pine needles, dry dunaliella cells and dry orange peel into coarse powder of 60-80 meshes; burdening the raw materials in parts by weight: 45-50 parts of soybean curb residue, 30-35 parts of dried pine needles, 2-5 parts of dry dunaliella cells, 15-18 parts of dry orange peel and 2.0-2.5 parts of an assistant, wherein the assistant is prepared from 49 parts of NaHCO3 and 1 part of MgSO4; the moisture content of the pine needles, the dunaliella cells and the orange peel is 3-5%, the moisture content of bean dregs is 18-20%; mixing the mixture of four coarse powder with the assistant according to the ratio, wherein the assistant accounts for 2.0-2.5% of dry weight of the total material; evenly mixing and then grinding for 30 minutes; filtering by a 400-mesh sieve; processing by using enzyme-aid micronization treatment, so as to obtain the forage immune enhancer product, wherein the treatment time is 15-30 minutes according to the quality and the humidity of the raw materials. By adopting the forage immune enhancer produced by the method disclosed by the invention, the production cost of the raw materials is significantly reduced, a lot of waste bean dregs produced in bean product production are recycled, low-carbon production is achieved, and the added value of products is increased.

Owner:SHAOYANG UNIV

Preparation technology of low-cost high-strength ceramic floor tile

InactiveCN103819176AAlleviating the crisis of scarcityReduce dependenceManufacturing technologyRed mud

The invention relates to a preparation technology of a low-cost high-strength ceramic floor tile, which comprises the following steps: 1)taking 30-40% of steel slag, 40-55% of bayer process red mud and 20-30% of talcum according to weight percentage for standby; 2)crudely crushing the steel slag into the particles with size below 10mm; 3)respectively performing ball milling on the steel slag particles and the bayer process red mud by a ball mill for 8 hours, and sieving through a sieve with 250 meshes; 4)placing the sieved raw material in a three-dimensional stereo feed mixer for mixing for 10 hours; and 5)adding water in a mixture, and preparing a green compact by an oil hydraulic press under 25MPa pressure, placing the dried green compact in a muffle furnace, and roasting to obtain the ceramic floor tile. The ceramic floor tile provided by the invention takes red mud and steel slag as main raw materials, and the red mud and steel slag substitute the rear kaolin with high cost and high quality, so that dependence of ceramic industry in our country to kaolin is reduced, and crisis of high-quality kaolin scarcity due to rapid development of industrial can be alleviated.

Owner:HENAN UNIV OF SCI & TECH

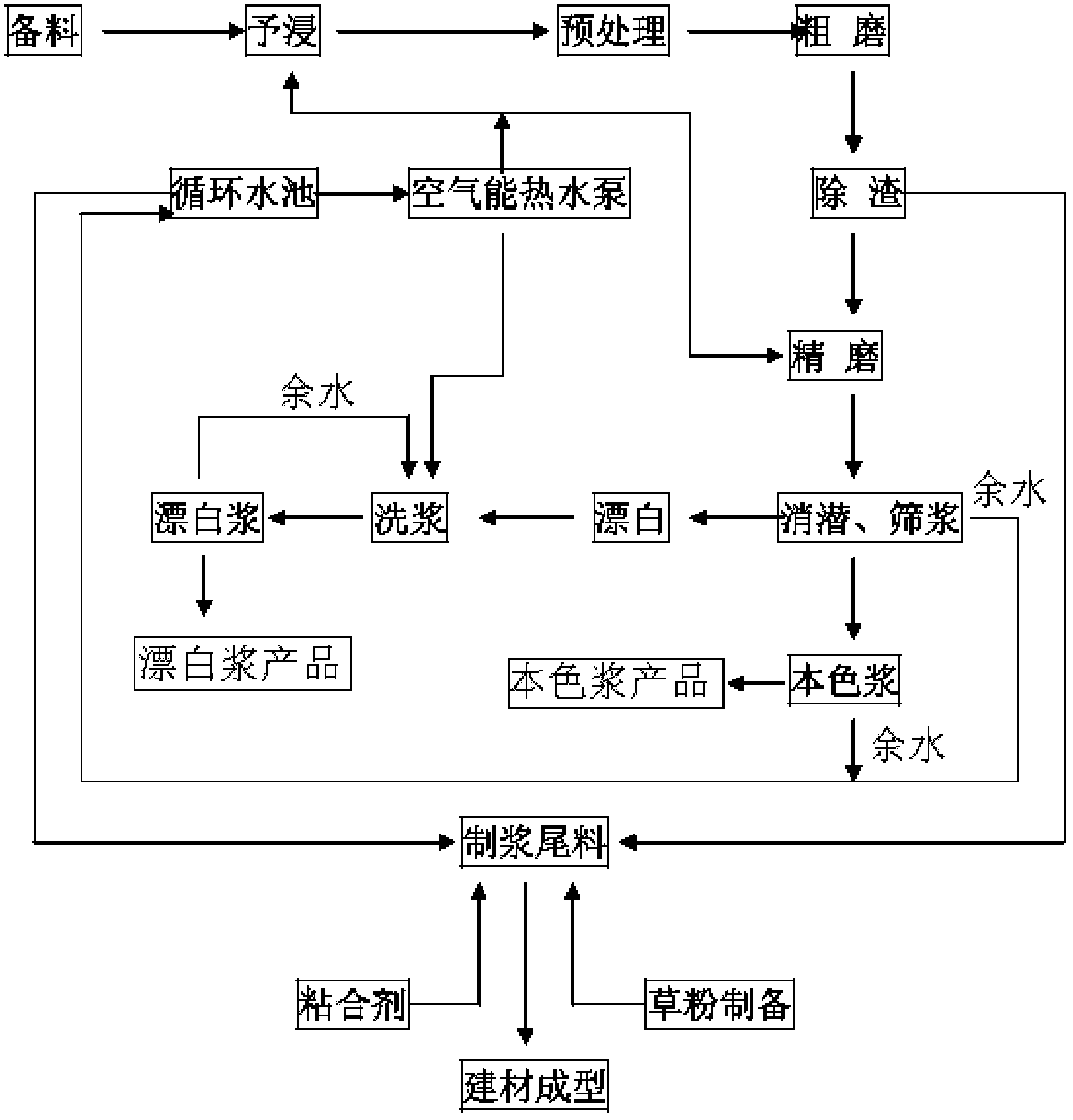

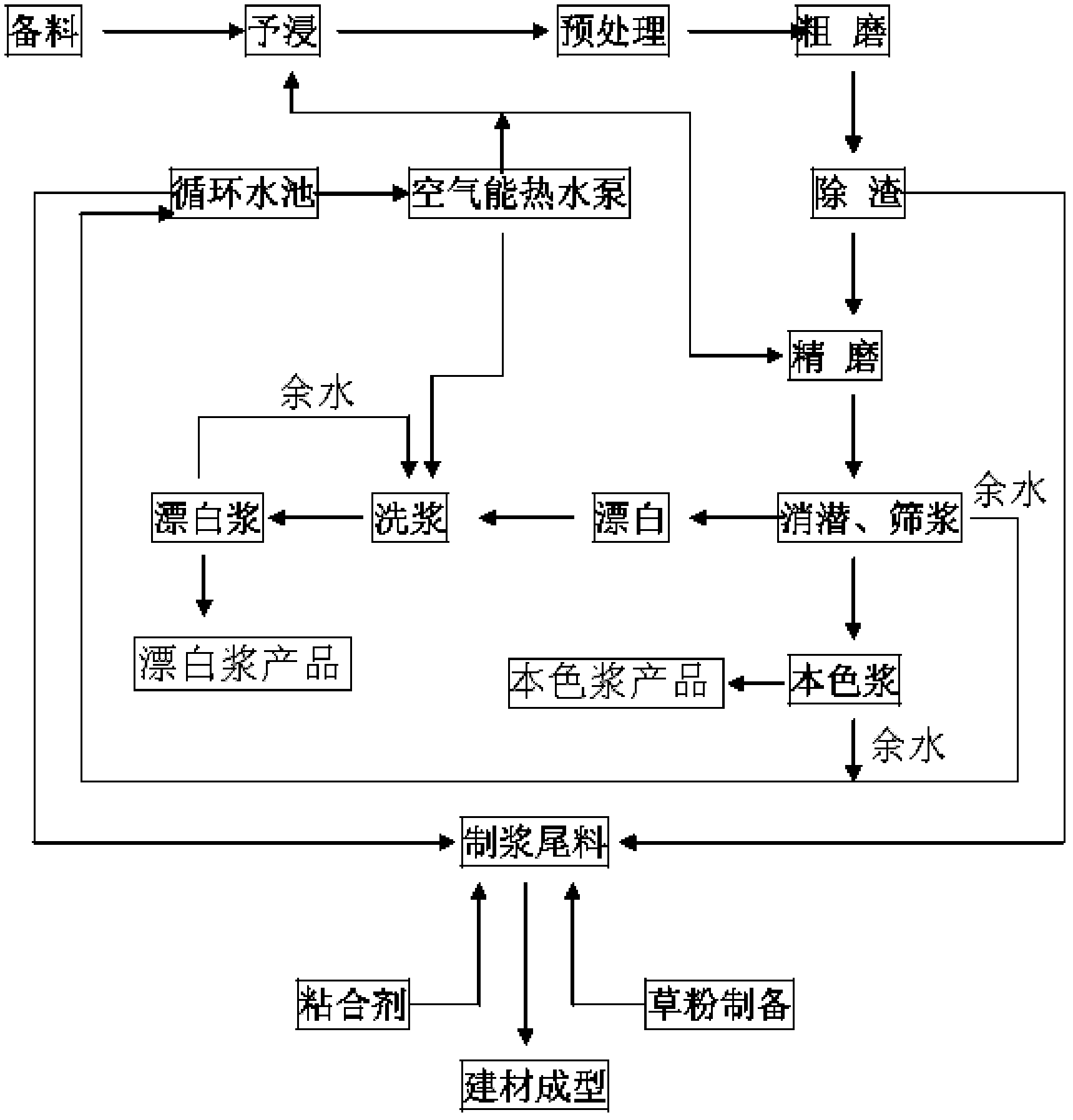

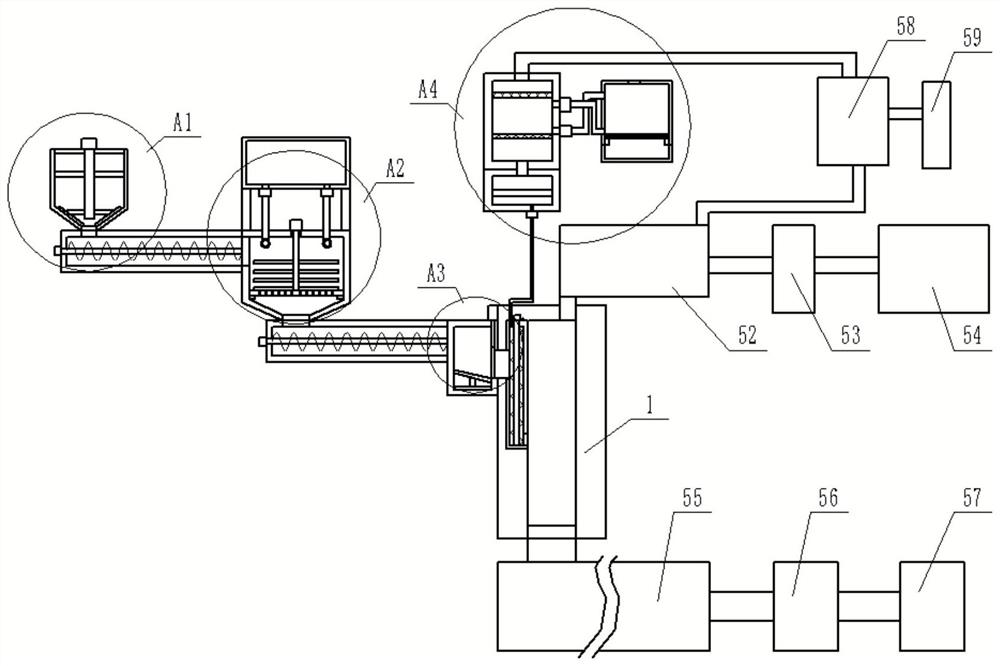

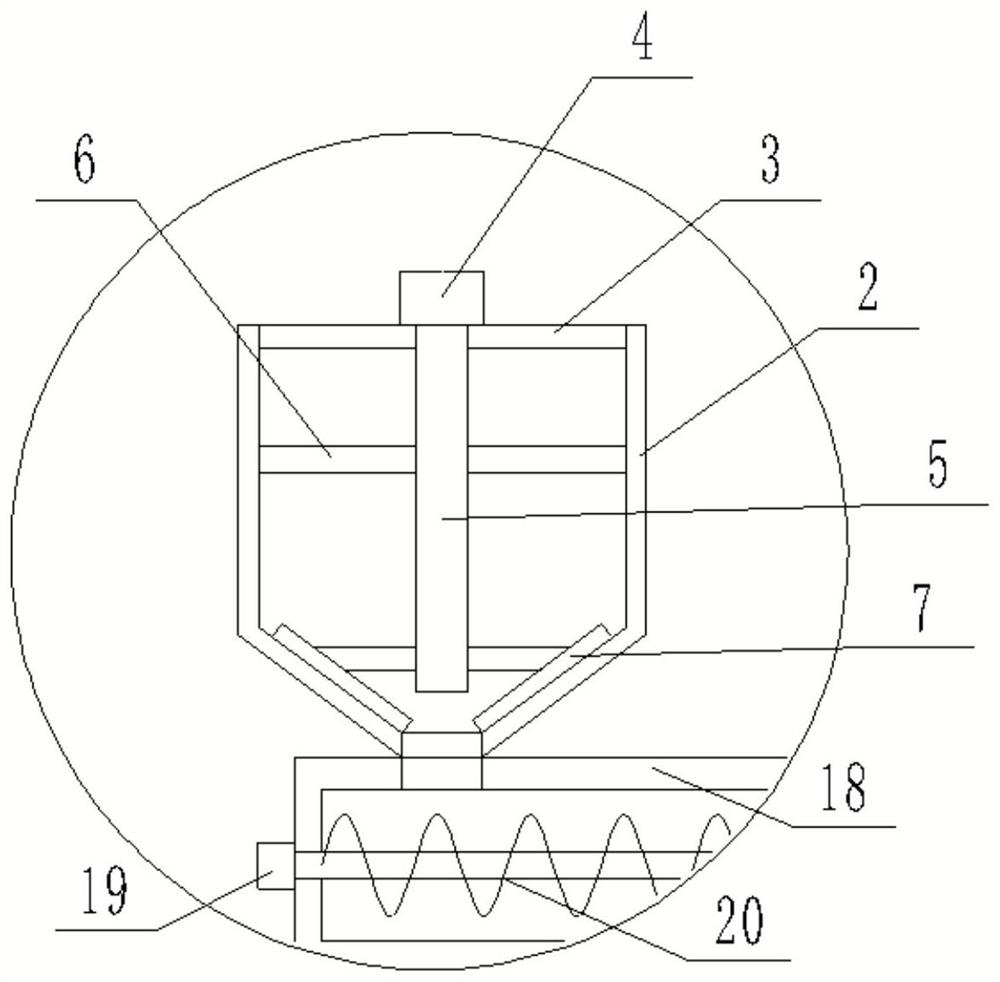

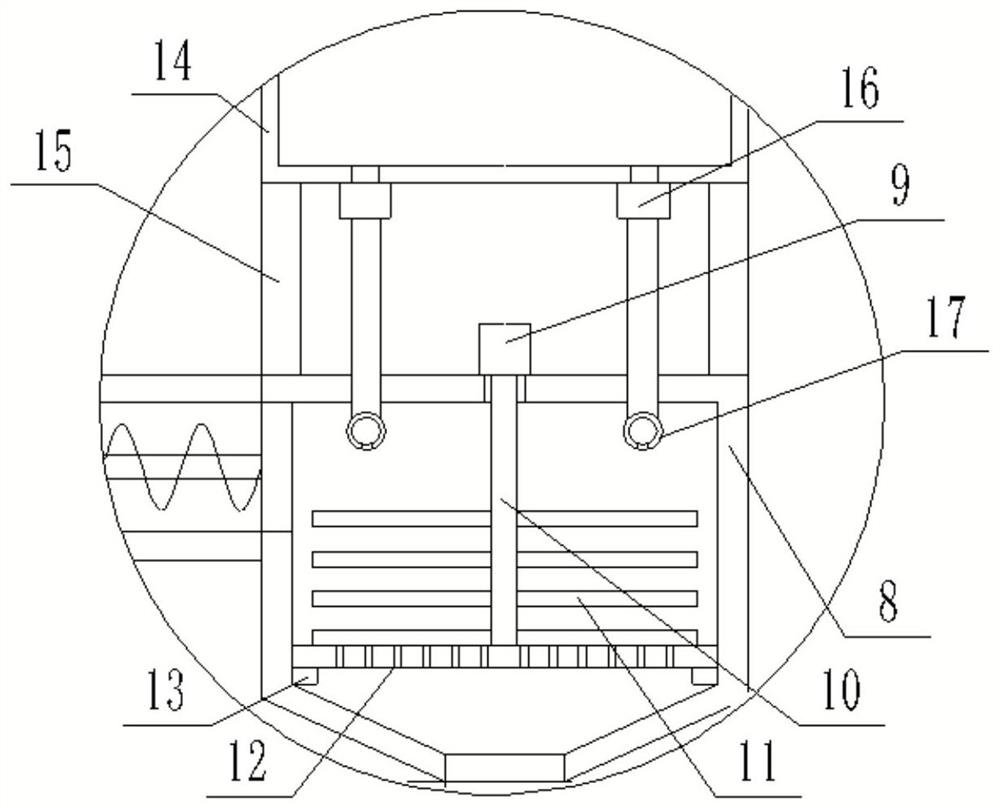

Environment-friendly clean pulping process

ActiveCN102587181AAchieving "Zero Emissions"Realize "Zero Emissions"Washing/displacing pulp-treating liquorsPulp bleachingWater circulationPulp and paper industry

The invention belongs to the field of paper-making pulping and particularly relates to an environment-friendly clean pulping process. The pulping process comprises four steps of: mechanical grinding, bleaching by using active hyperoxide, cyclic utilization of pulping residual water and comprehensive utilization of pulping tailing. According to the method, the mechanical grinding is used to replace chemical cooking for the pulping; environment-friendly chemicals are used for replacing conventional chemicals; the pulping process is changed; an air-source hot water pump is used to replace a boiler to provide hot-water circulation; and the purpose of environment-friendly clean pulping is achieved.

Owner:谢明文

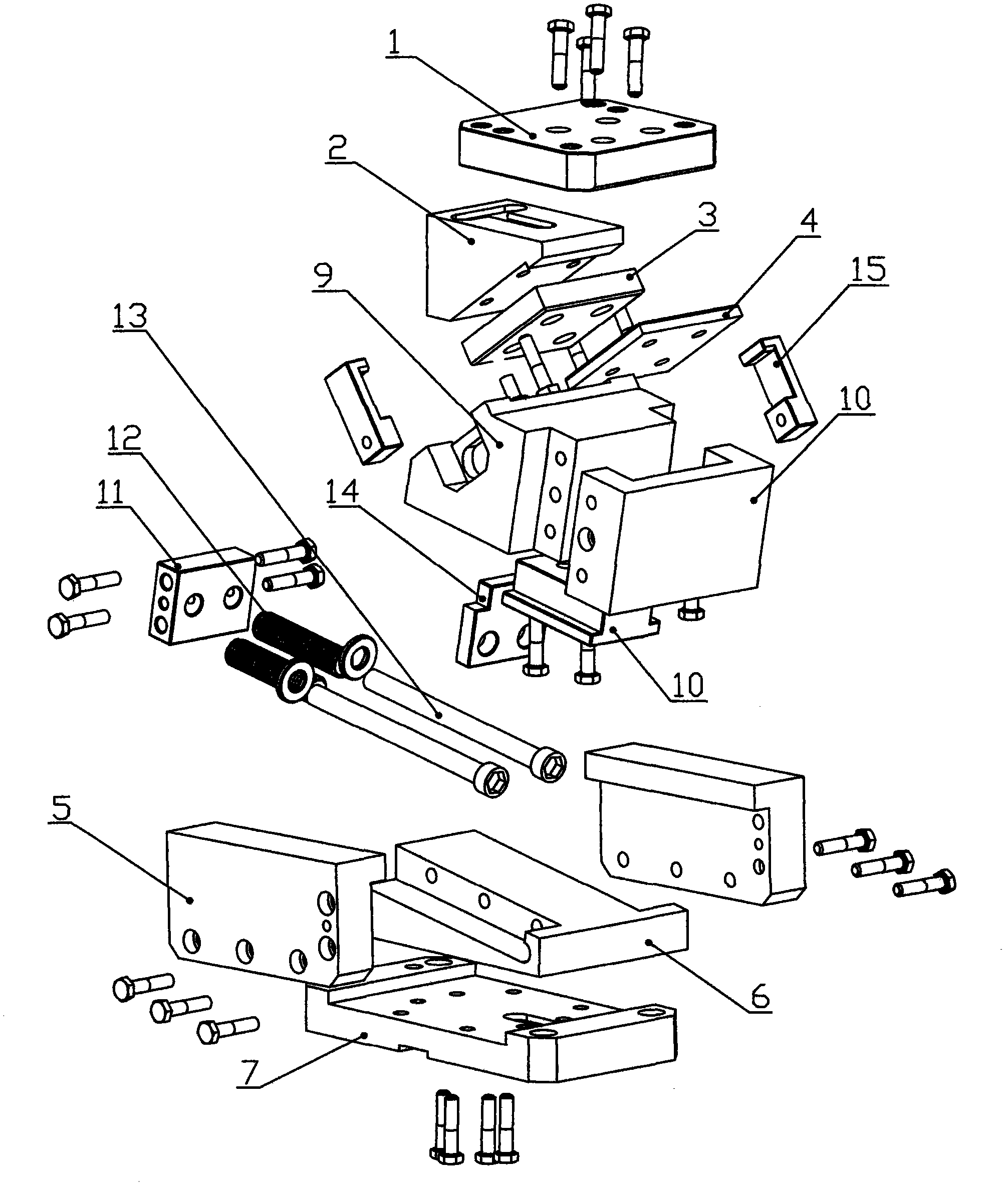

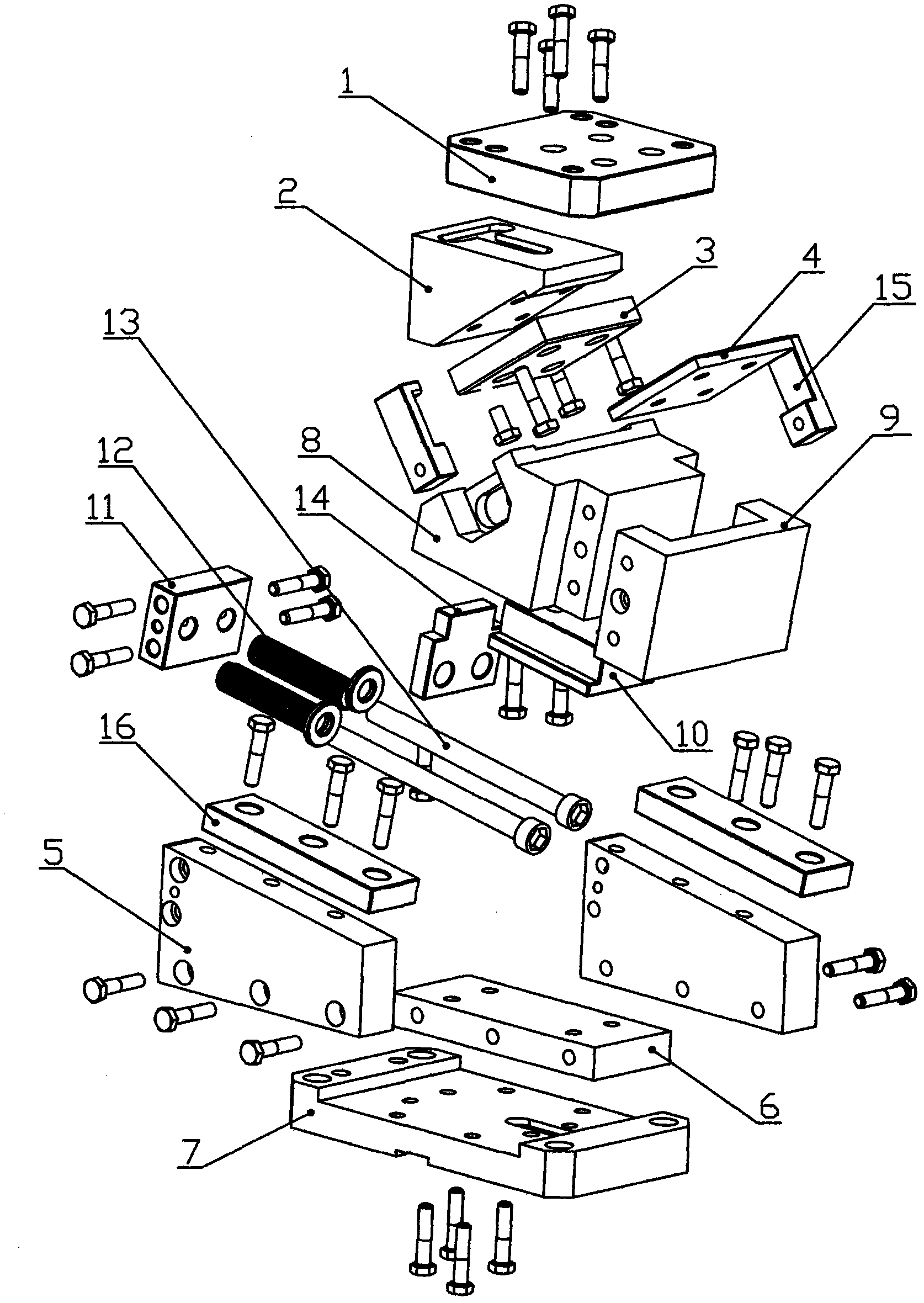

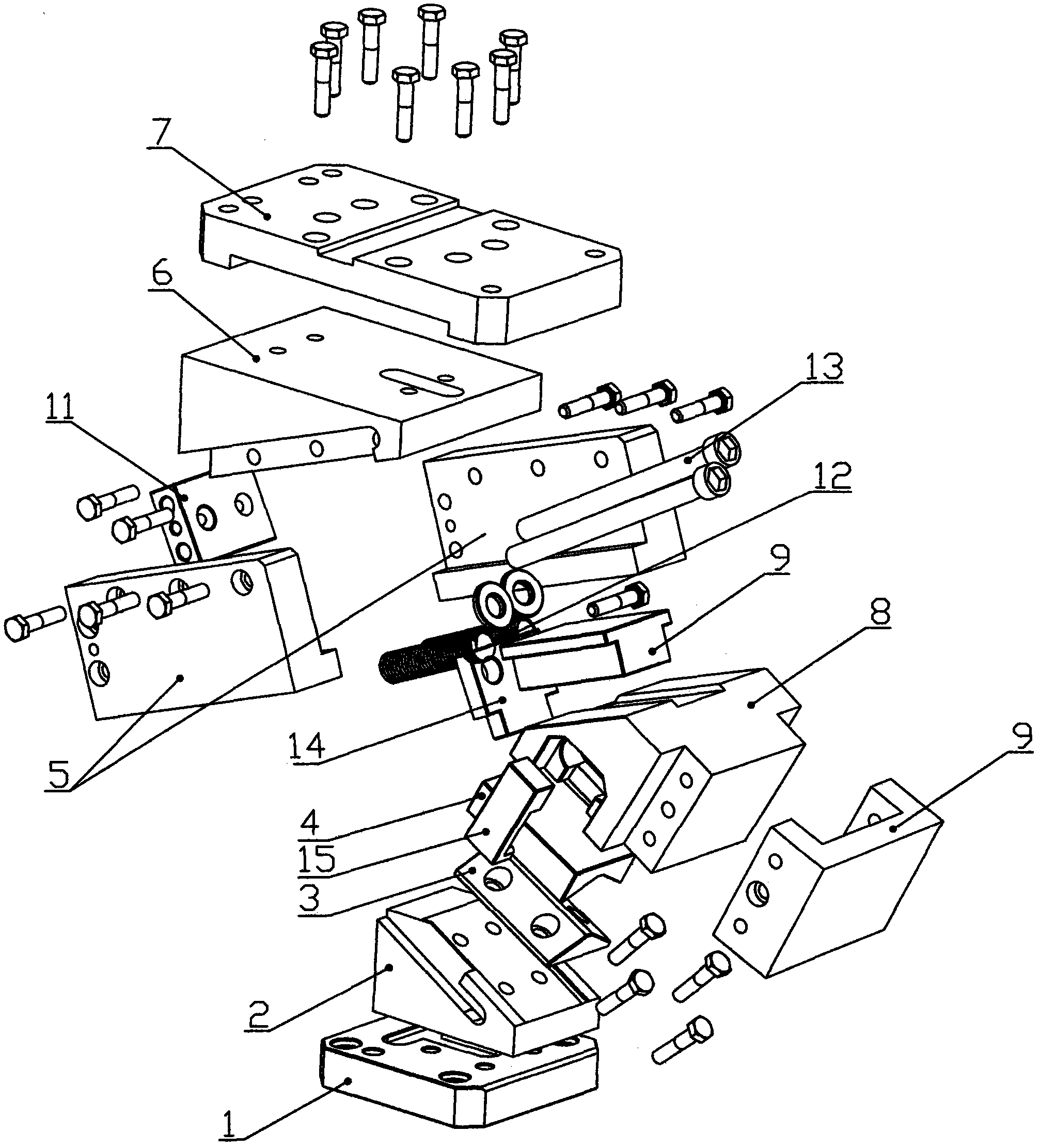

Multifunctional assembled inclined wedge

InactiveCN102000741AMeet the needs of alternate useAchieving low-carbon productionShaping toolsPress ramHigh volume manufacturingEngineering

The invention relates to a multifunctional assembled inclined wedge which comprises a driving block, a sliding block and a sliding block seat, wherein both the driving block and the sliding block seat are in a split structure; each of the driving block and the sliding block seat comprises a standard component and an adjusting component; the standard component is connected with a stamping mold; and the adjusting component is used for adjusting the working angle of the inclined wedge. In the invention, each component comprises the standard component and the adjusting component which can be detachably connected; a user only needs to replace the adjusting component for realizing any working angle according to the use requirement; in the use process, when one component is damaged, only the component needs to be replaced, and the use cost is saved; the angle of the adjusting component can be changed freely as required, thus meeting the requirement of users for alternately using different types of inclined wedge mechanisms; and simultaneously, in the production process of a manufacturer, because the standard components of different types of inclined wedge mechanisms are the same, the standard components of the different types of inclined wedge mechanisms can be produced in enormous quantities, while the adjusting components meeting the corresponding requirements can be respectively produced in bulk according to the requirements of the different types of inclined wedge mechanisms.

Owner:QINGDAO NUOYIXIN MOLD PARTS

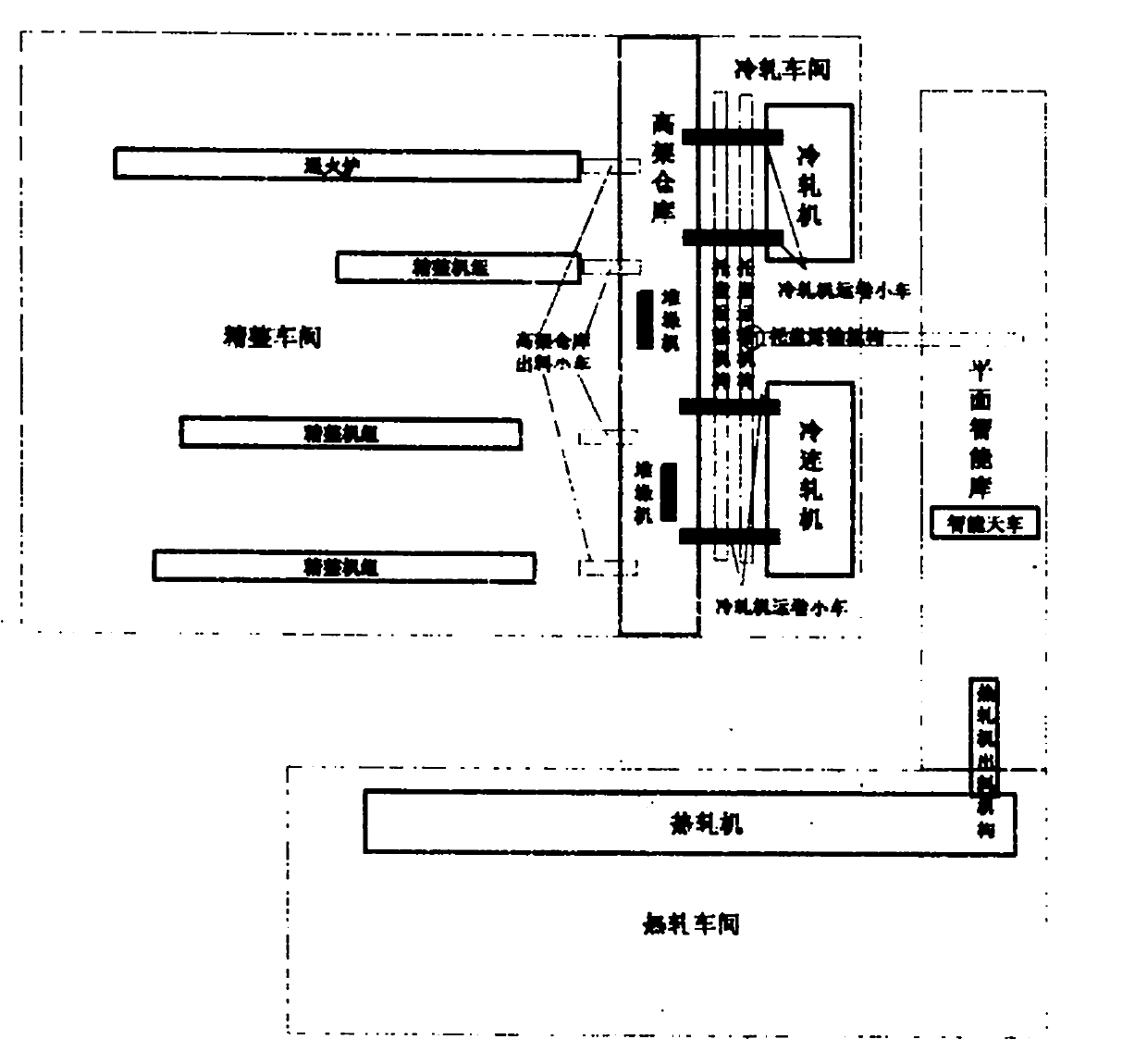

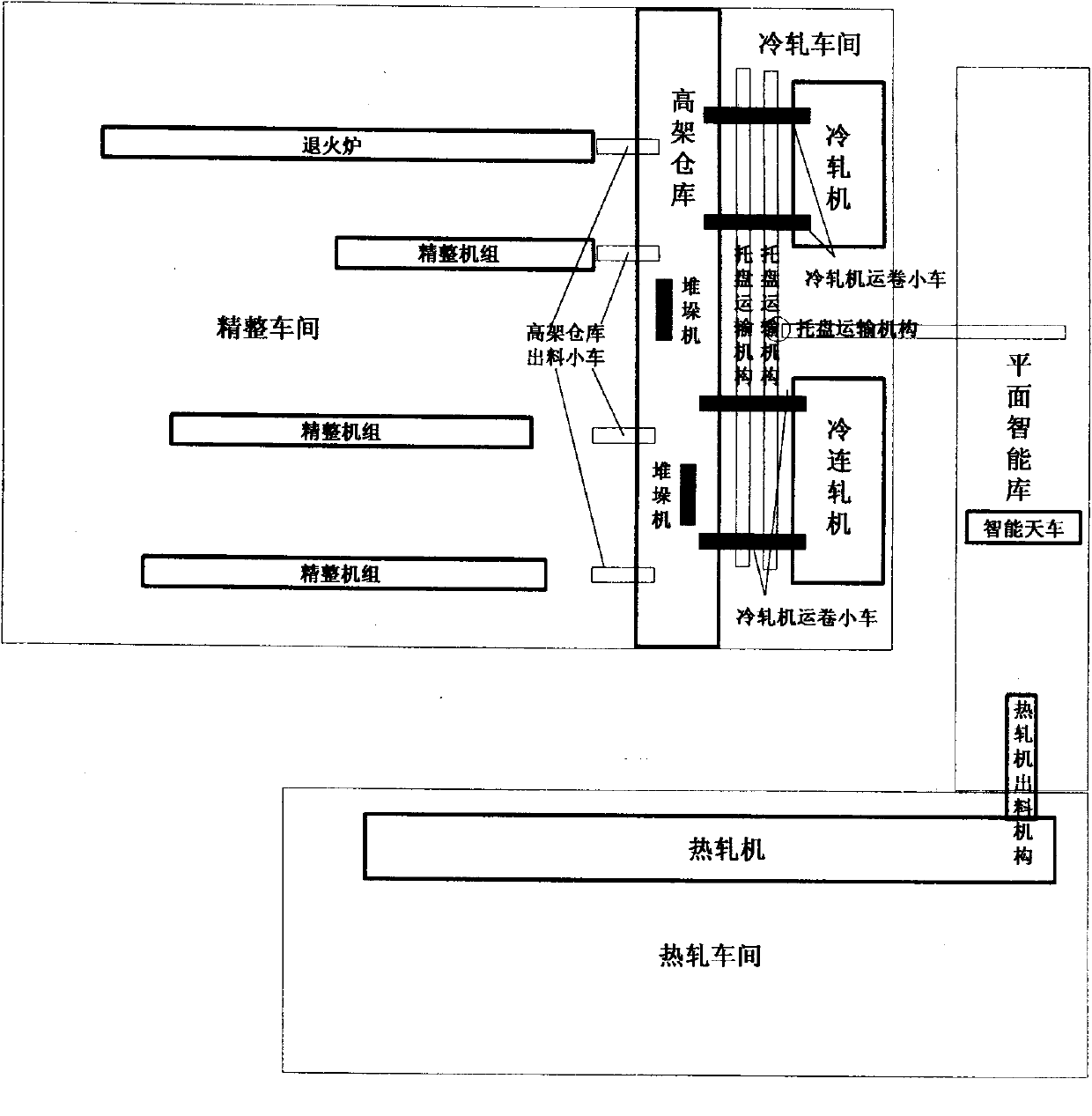

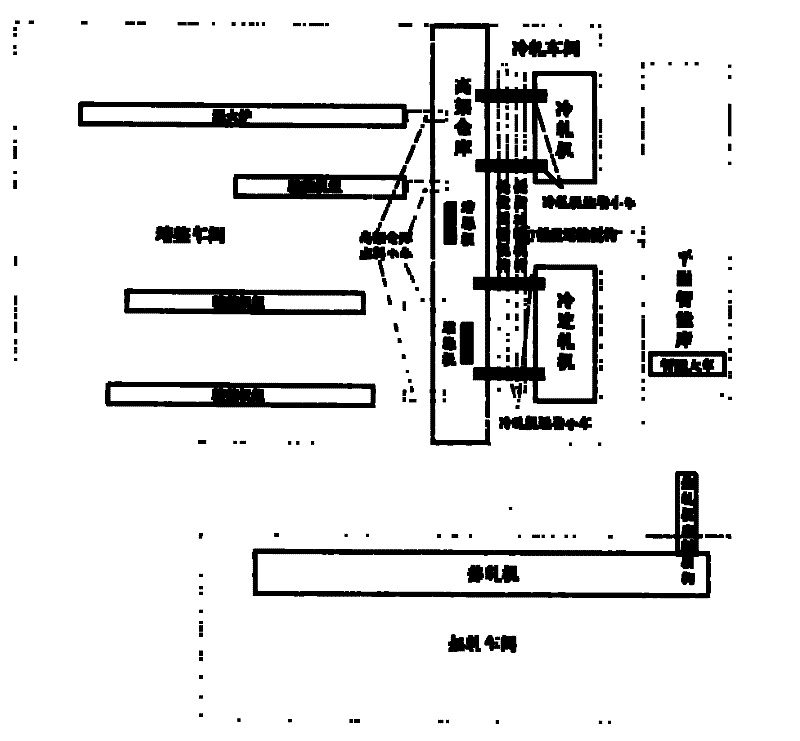

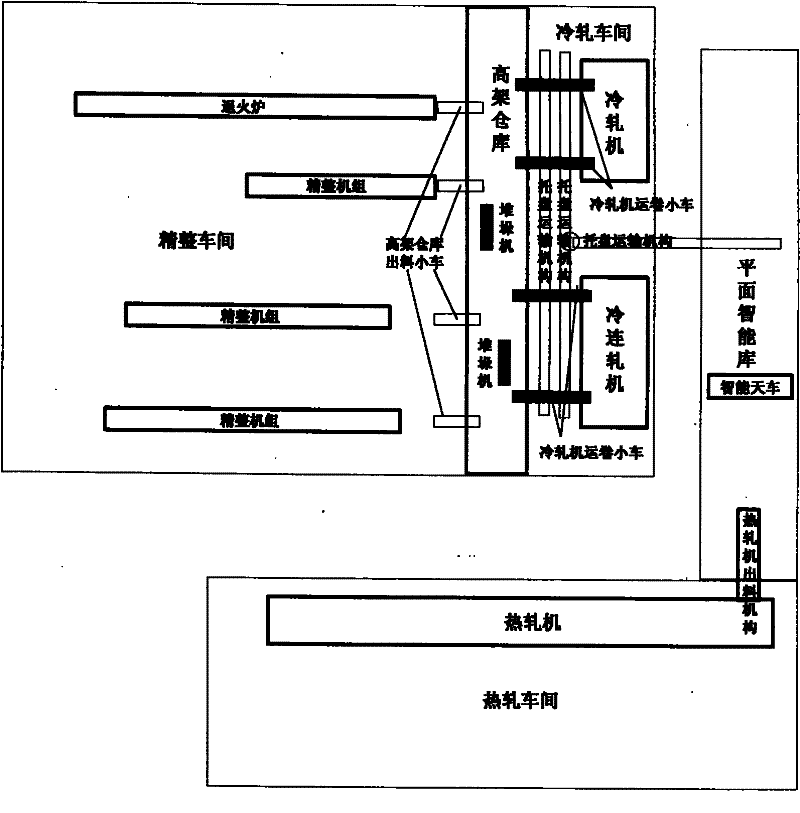

Collocation method for fusing intelligent plane warehouse and overhead warehouse in aluminum plate strip production equipment

ActiveCN101947547AScientific and orderly configurationReduce the use of areaMetal rolling arrangementsStackerManufacturing engineering

The invention discloses a collocation method for fusing an intelligent plane warehouse and an overhead warehouse in aluminum plate strip production equipment. The intelligent plane warehouse is arranged between a hot rolling workshop and a cold rolling workshop; the overhead warehouse is arranged among an annealing furnace, each finishing unit and a tray conveying mechanism; a track for running of a plurality of coil cars is mutually vertical to the tray conveying mechanism; and a track for a plurality of discharge cars in the overhead warehouse extends beside the annealing furnace or the each finishing unit. Hot-rolled coils on a hot mill discharge mechanism are hoisted to the corresponding positions for storage or cooling through an intelligent crane in the intelligent plane warehouse, and cold-rolled coils are stored at the corresponding positions through a stacker or cooled in the overhead warehouse. The aluminum plate strip production equipment collocated with the intelligent plane warehouse and the overhead warehouse is totally adjoined, needs no transport equipment such as the crane, a forklift or an automatic vehicle and the like, has the effect on shortest transport distance, realizes good circulation of low-carbon production of aluminum plate strips, and has the characteristics of lowest product storage quantity and shortest production period.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Bitter almond oil and extraction method thereof

The invention discloses bitter almond oil and an extraction method thereof. Bitter almonds are taken as raw materials, a low-temperature and biological processing technique is adopted in the whole process, loss of thermal-sensitive nutritional substances such as protein, higher fatty acid, vitamins and the like in the bitter almonds is effectively avoided, free oil, an emulsion, hydrolysate and almond dregs are obtained after microwave radiation sterilization, frozen-breaking, enzymolysis and vacuum centrifugation, free oil is obtained after the emulsion is subjected to biological demulsification and vacuum centrifugation, all the free oil is combined, and the bitter almond oil is obtained, wherein the bitter almond oil has a high oil extraction rate being 93%-97%, the content of nutritional and active substances is high, the food safety is high, the residual amount of cyanide is under 0.08 mg / kg, and the guarantee period of the bitter almond oil is long and can reach 5-6 years. With the adoption of the extraction method, the quality and the yield of products are improved, meanwhile, the variety, the yield and the additional value of byproducts obtained after the oil is extracted are increased, the extraction cost of the oil is further reduced, discharging of three wastes is avoided, environment protection is realized, and low-carbon production is truly realized.

Owner:河北龙王帽食品有限公司

Oxidization-resistant bitter almond oil and extraction method thereof

InactiveCN105368566AIncrease profitAvoid lostFatty substance preservation using additivesFatty-oils/fats productionHydrolysateNutrients substances

The invention discloses oxidization-resistant bitter almond oil and an extraction method thereof. Bitter almonds serve as a raw material, a low-temperature biological processing technology is adopted in the whole process, the loss of thermosensitive nutrient substances such as protein, higher fatty acid and vitamins in the bitter almonds is effectively avoided, free oil, emulsion, hydrolysate and almond residue are obtained through microwave irradiation enzyme deactivation, refrigeration crushing, enzymolysis and vacuum centrifugation, the emulsion undergoes biological demulsification and then undergoes vacuum centrifugation again to obtain free oil, and the free oil is merged to obtain the bitter almond oil which is high in grease extraction rate (93-97%), nutrition and active material content and food safety (the cyanide residue is 0.08 mg / kg or below) and long in guarantee period (5-6 years). According to the extraction method, the variety, yield and added value of by-products after grease extraction are increased while the product quality and yield are improved, the grease extraction cost is further reduced, the emission of three wastes is avoided, and the environment is protected.

Owner:邵素英

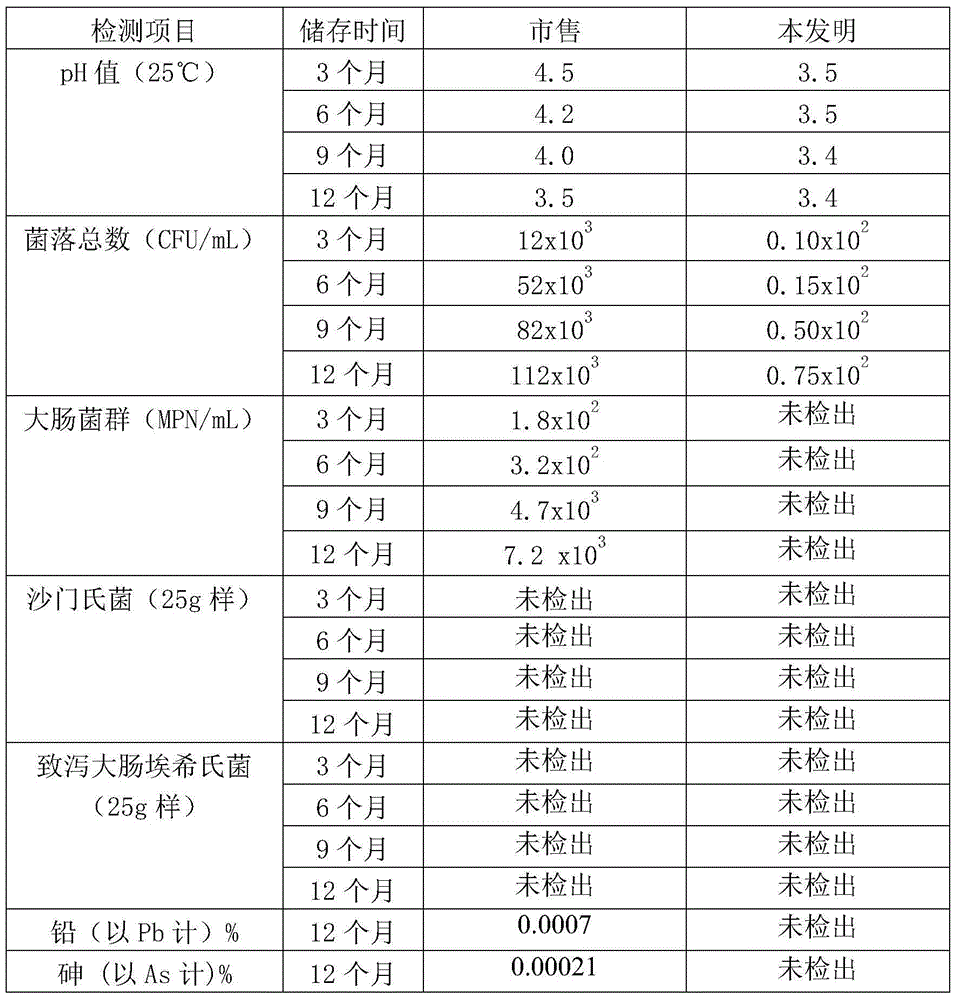

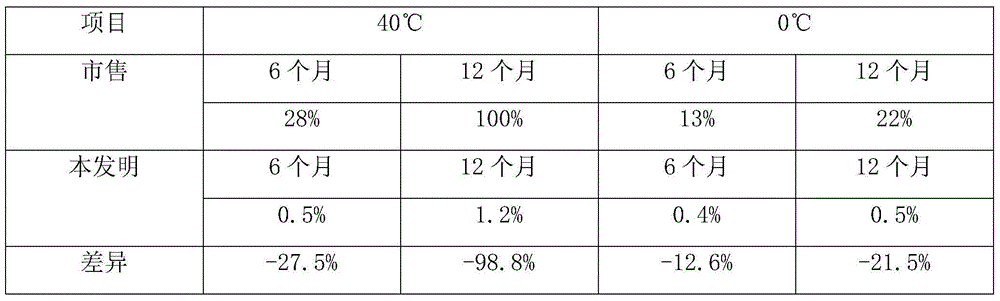

Preparation method of liquid acidic pectinase with strong stability

InactiveCN104450660AIncrease contentImprove adsorption capacityEnzyme stabilisationPectinaseFiltration

The invention discloses a preparation method of liquid acidic pectinase with strong stability, and belongs to the technical field of preparation of enzyme preparations. The preparation method of the liquid acidic pectinase with strong stability does not need addition of a chemical preservative and low-temperature treatment, and the liquid acidic pectinase with strong stability, which is stable and has a relatively long quality guarantee period, can be obtained by fermenting a crude enzyme solution and blending a concentrated solution by adopting a high-voltage pulse electric field at normal temperature, adding natural plant raw materials including a pectin decomposed product, a Chinese medicinal herb extract, modified dietary fibers and the like during blending, and then performing aseptic filtration and sterile filling. Experiments prove that the liquid acidic pectinase with strong stability, prepared by the method disclosed by the invention, has the total number of bacterial colonies of 75-110CFU / mL after being stored for 12 months at room temperature; and the enzyme activity loss rates of the liquid acidic pectinase which is stored for 12 months at 40 DEG C and 0 DEG C are 1.2-1.4% and 0.5-1.1% respectively.

Owner:邵素英

Low-cost high-strength porous sound absorption material and process for manufacturing same

The invention relates to a low-cost high-strength porous sound absorption material and a process for manufacturing the same. The low-cost high-strength porous sound absorption material comprises, by weight, 35-40% of steel slag, 25-30% of red mud, 15-20% of cement clinker, 3-5% of expansive agents, 3-5% of hydrogen peroxide which is a foaming agent, 1-3% of desulfurization gypsum, 2-4% of calciumcarbonate and 1-3% of glass fibers. The process includes (1), acquiring raw materials for standby application; (2), coarsely crushing the steel slag, the calcium carbonate and the desulfurization gypsum and carrying out wet grinding on the steel slag, the calcium carbonate and the desulfurization gypsum; (3), adding water into the steel slag, the calcium carbonate and the desulfurization gypsum, stirring the water, the steel slag, the calcium carbonate and the desulfurization gypsum, adding the foaming agent into the water, the steel slag, the calcium carbonate and the desulfurization gypsum to obtain first mixtures, injecting the first mixtures into cement molds and curing, drying and crushing the first mixtures; (4), adding water into the first mixtures, stirring the water and the mixtures to obtain slurry, injecting the slurry into molds, carrying out compression molding on the slurry, curing samples released from the molds in cement standard curing tanks under standard curing conditions and ultimately drying the samples to obtain the low-cost high-strength porous sound absorption material which is a finished product. The low-cost high-strength porous sound absorption material and the process have the advantages that the low-cost high-strength porous sound absorption material is mainly made of the red mud and the steel slag which are metallurgical industrial waste residues,the calcium carbonate and the gypsum are used as reinforcing agents, accordingly, the low-cost high-strength porous sound absorption material can be used as a sound absorption barrier for tunnels, subways and roads, and the problem of noise pollution of indoor places and the like can be solved.

Owner:HENAN UNIV OF SCI & TECH

Ceramic sound absorbing material

InactiveCN108503328AAchieving low-carbon productionReduce the formation temperatureSound producing devicesCeramic materials productionRed mudCombined method

The invention discloses a ceramic sound absorbing material, which comprises: 20-28% of combined method red mud, 22-28% of steel slag, 13-18% of coal gangue, 8-12% of calcium carbide slag, 8-12% of boiler slag, 3-8% of quartz sand, and 8-15% of a 10% sodium hydroxide solution. According to the present invention, the steel slag, the coal gangue and the red mud are used as the main raw materials, wherein the coal gangue and the red mud are rich in Na2O and K2O, and can form low melting point eutectic mixtures and a large amount of glass phases with CaO, Al2O3 and SiO2 so as to be used as the fluxfor the sintering reaction, the steel slag contains a lot of simple oxides and complex oxides, the complex oxides in the steel slag absorb a large amount of latent heat during the being formed, and the latent heat is used during the firing of the ceramic sound absorbing material, such that the forming temperature of calcium aluminum melilite is lowered and is 50 DEG C lower than the firing temperature of the original sound absorbing material so as to achieve the low-carbon production of the porous ceramic sound absorbing material and save rge energy.

Owner:HAIMEN CITY RUITAI TEXTILE TECH CO LTD

A kind of citrus peel residue organic compound fertilizer and preparation method thereof

InactiveCN103833467BImprove protectionPrevent calcificationBio-organic fraction processingOrganic fertiliser preparationPhosphateCalcification

Owner:重庆圣沛农业科技有限公司

Method for producing feed additive from dregs of rhizoma polygonati odorati and rice husk

InactiveCN105981952AReduce manufacturing costAchieving low-carbon productionFood processingAnimal feeding stuffWater contentMeal powder

The invention discloses a method for producing feed immunopotentiator from dregs of rhizoma polygonati odorati and rice husk mainly. The feed immunopotentiator is prepared from raw materials: by weight, 70-72 parts of dried orange peel, 14-16 parts of dregs of rhizoma polygonati odorati, 25-27 parts of soybean dregs, 4.8-5.0 parts of rice husk, 5.7-5.9 parts of dinobryon, 1.3 parts of montmorillonite, 1.2 parts of L- arginine, and 2.5 parts of pegylation chitosan; wherein water content of the dried orange peel, dregs of rhizoma polygonati odorati, dinobryon and rice husk ranges from 3% to 5%, and water content of soybean dregs ranges from 18% to 20%. The five types of crude powder are mixed together according to the proportion and then are mixed with additives uniformly to form a mixture, the mixture is ground for 30 minutes and then screened by a sieve with 400 meshes, the ground mixture is further treated by chemical mechanical technology for 15-30 minutes according to mass and humidity of the raw materials, and thus the feed immunopotentiator is obtained. As the immunopotentiator is prepared from wastes such as fruit peels and vegetable dregs, production cost of raw materials in the prior art is reduced greatly; as a great amount of wastes in food production is recycled, low-carbon production is realized and product additional value is increased.

Owner:SHAOYANG UNIV

Flavored bitter almond oil and extraction method thereof

InactiveCN105368570AIncrease profitAvoid lostFatty substance preservation using additivesFatty-oils/fats refiningHydrolysateHeat sensitive

The invention discloses flavored bitter almond oil and an extraction method thereof. The flavoured bitter almond oil uses bitter almonds as raw materials, uses low temperature and biological processing filed, effectively prevents heat-sensitive nutrients in the bitter almonds such as proteins, higher aliphatic acids and vitamins and the like from losing, and prepares free oil, emulsions, hydrolysate and almond cakes after microwave irradiation enzyme, frozen-breaking, enzymatic hydrolysis and traditional vacuum, the emulsion is centrifuged in vacuum to obtain the free oil after being biologically broken, and the free oil is combined to prepare a bitter almond oil which is high in extraction yield of oil (93%-97%), high in nutrition and active material content, strong in food safety (cyanide residue is below 0.08mg / kg ) and long in shelf life (5-6 years). The method for extracting the flavored bitter almond oil improves quality and yield, improves kinds, yield and additional value of by-products after greases are extracted, further reduces extraction cost of greases, puts an end to emission of three wastes, and protects environment.

Owner:邵素英

Aqueous conductive agent used in alkaline manganese dioxide battery, and production method thereof

ActiveCN102306795AReduce the temperatureShort reaction timeCell electrodesNon-conductive material with dispersed conductive materialAntifoam agentElectrically conductive

The invention discloses an aqueous conductive agent used in an alkaline manganese dioxide battery, and a production method thereof. The invention belongs to the field of fine chemical materials. The conductive agent is characterized in that: the conductive agent is produced from an aqueous aid mixture, graphite conductive powder, and an aqueous resin base material; and the materials are mixed according to a weight ratio of 7:1:6. The aqueous aid mixture is prepared from mixed materials of an aqueous wetting agent, an aqueous rheological agent, an aqueous antifoaming agent, an aqueous bactericide and industrial purified water. The aqueous resin base material is prepared from mixed materials of hydroxyl-containing aqueous resin, an aqueous latent curing agent, an aqueous film forming auxiliary agent, an aqueous cooling catalyst and industrial purified water. The production method comprises steps that: the aqueous aid mixture is blended and mixed in a dispersion vessel; the graphite conductive powder is added into the dispersion vessel, and is wetted and dispersed; the aqueous resin base material is added, and the materials are mixed, such that the aqueous conductive agent is obtained. According to the invention, the conductivity, water resistance, adhesion, and battery-harming component contents of the product coating satisfy requirements of alkaline manganese dioxide battery manufacturers. Therefore, the product is suitable for industrialized productions.

Owner:福建省邵武市元涵石墨涂料厂

Collocation method for fusing intelligent plane warehouse and overhead warehouse in aluminum plate strip production equipment

ActiveCN101947547BScientific and orderly configurationReduce the use of areaMetal rolling arrangementsStorage garageHot rolled

The invention discloses a collocation method for fusing an intelligent plane warehouse and an overhead warehouse in aluminum plate strip production equipment. The intelligent plane warehouse is arranged between a hot rolling workshop and a cold rolling workshop; the overhead warehouse is arranged among an annealing furnace, each finishing unit and a tray conveying mechanism; a track for running of a plurality of coil cars is mutually vertical to the tray conveying mechanism; and a track for a plurality of discharge cars in the overhead warehouse extends beside the annealing furnace or the each finishing unit. Hot-rolled coils on a hot mill discharge mechanism are hoisted to the corresponding positions for storage or cooling through an intelligent crane in the intelligent plane warehouse, and cold-rolled coils are stored at the corresponding positions through a stacker or cooled in the overhead warehouse. The aluminum plate strip production equipment collocated with the intelligent plane warehouse and the overhead warehouse is totally adjoined, needs no transport equipment such as the crane, a forklift or an automatic vehicle and the like, has the effect on shortest transport distance, realizes good circulation of low-carbon production of aluminum plate strips, and has the characteristics of lowest product storage quantity and shortest production period.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Bitter apricot kernel oil with high extraction rate and extraction method thereof

InactiveCN105255582AIncrease profitAvoid lostFatty-oils/fats refiningFatty-oils/fats productionHydrolysateMicrowave irradiation

The invention discloses bitter apricot kernel oil with high extraction rate and an extraction method thereof. The bitter apricot kernel oil and the extraction method have the beneficial effects that bitter apricot kernels are taken as the raw materials, and the low temperature biological processing technology is adopted in the whole course, thus effectively avoiding losses of thermosensitive nutrients in the bitter apricot kernels, such as proteins, higher fatty acids and vitamins; free oil, emulsion, hydrolysate and apricot kernel residues are obtained after enzyme deactivation by microwave irradiation, freezing and breaking, enzymolysis and vacuum centrifuging; the emulsion undergoes vacuum centrifuging after undergoing biological demulsification to obtain free oil; the free oil is mixed to prepare the bitter apricot kernel oil with high oil extraction rate (93-97%), high nutrient and active substance content, strong food safety (the residual quantity of cyanides is below 0.08mg / kg) and long shelf life (5-6 years); the extraction method has the effects of increasing the variety, yield and added value of the byproducts after oil extraction while increasing the product quality and yield, further reducing the oil extraction cost, completely eradicating discharge of the three wastes and protecting the environment.

Owner:BEIJING KEHUITONG WISDOM SCI & TECH CO LTD

Low-cost Fe-Co alloy preparation method

The invention relates to a low-cost Fe-Co alloy preparation method and belongs to the technical field of soft magnetic materials. The low-cost Fe-Co alloy preparation method comprises the following steps of selecting high-cobalt slag, red mud and coke powder as raw materials; conducting coarse crushing on the high-cobalt slag; conducting ball milling on the high-cobalt slag subjected to coarse crushing, the red mud and the coke powder respectively and then conducting sieving; mixing the sieved raw materials in a blender mixer to obtain a mixture; adding a sodium carboxymethyl cellulose aqueoussolution to the mixture and then conducting pelletizing and drying; and conducting carbon thermal reduction smelting and conducting magnetic separation on an obtained reduction product to obtain an Fe-Co alloy. According to the low-cost Fe-Co alloy preparation method, the Bayer process red mud and the high-cobalt slag are used as the main raw materials, the soft magnetic alloy with the very highsaturated magnetic induction intensity is produced, is suitable for various types of complicated, miniature and multifunctional high-power soft magnetic devices and has the characteristics that the technological process is simple, and the cost is low.

Owner:HENAN UNIV OF SCI & TECH

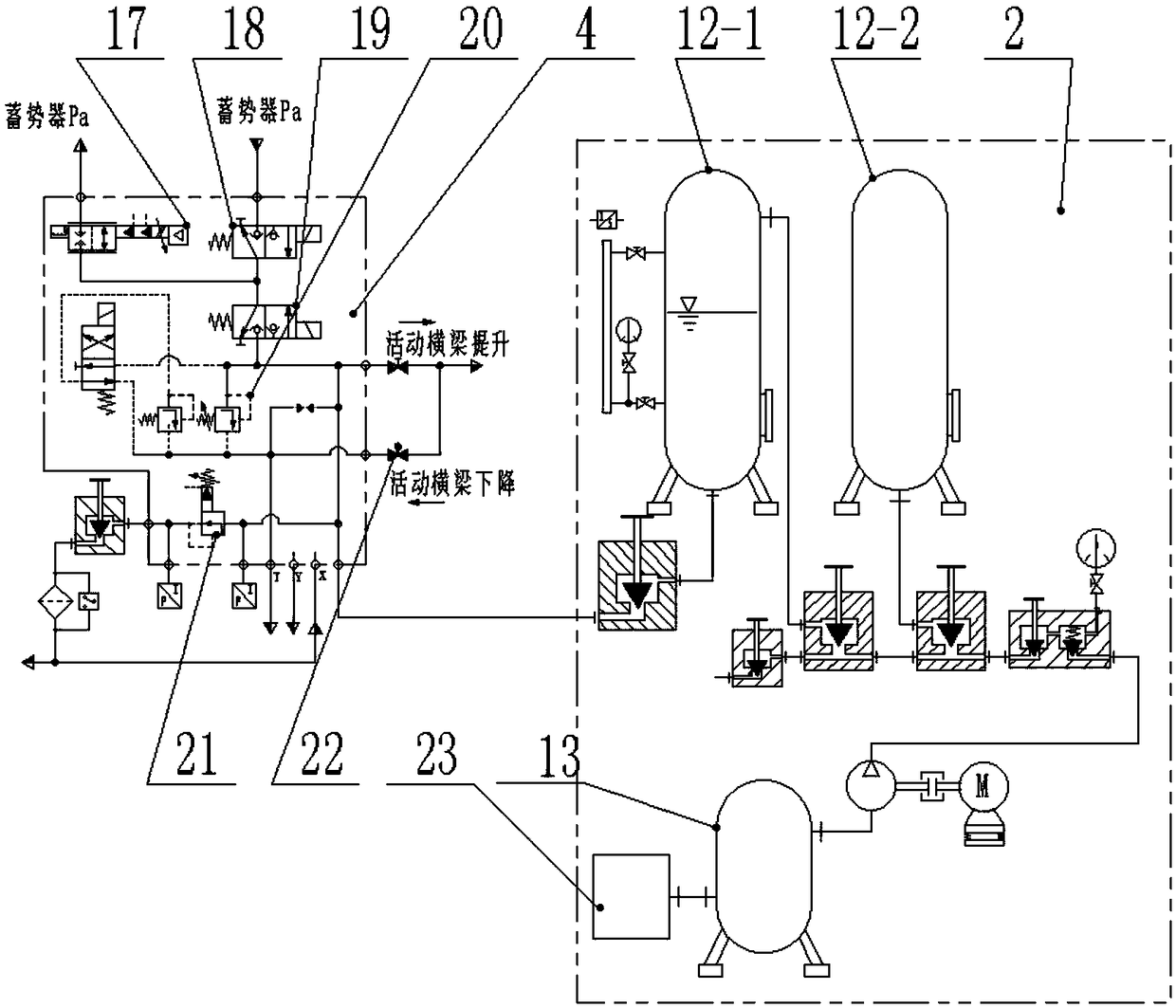

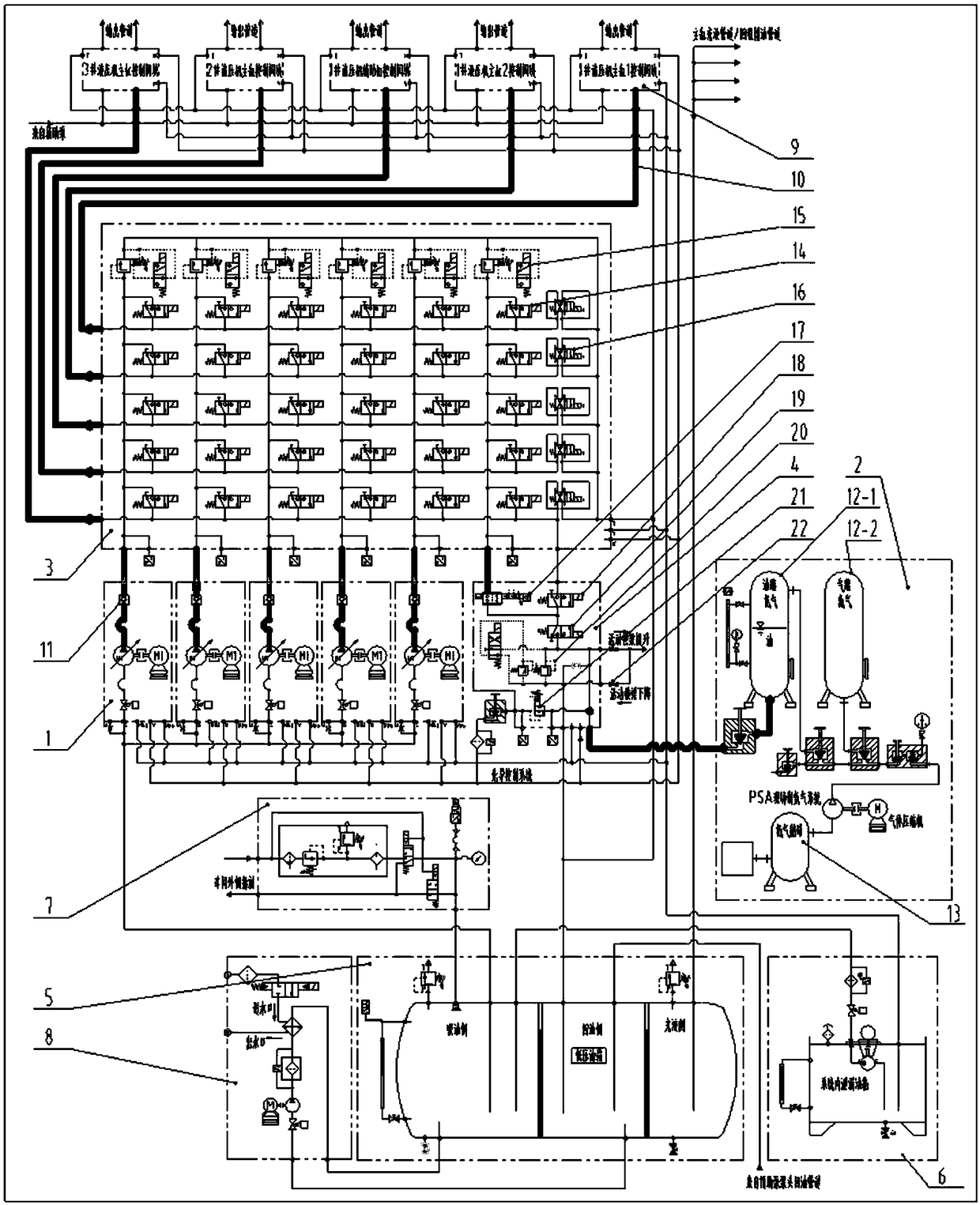

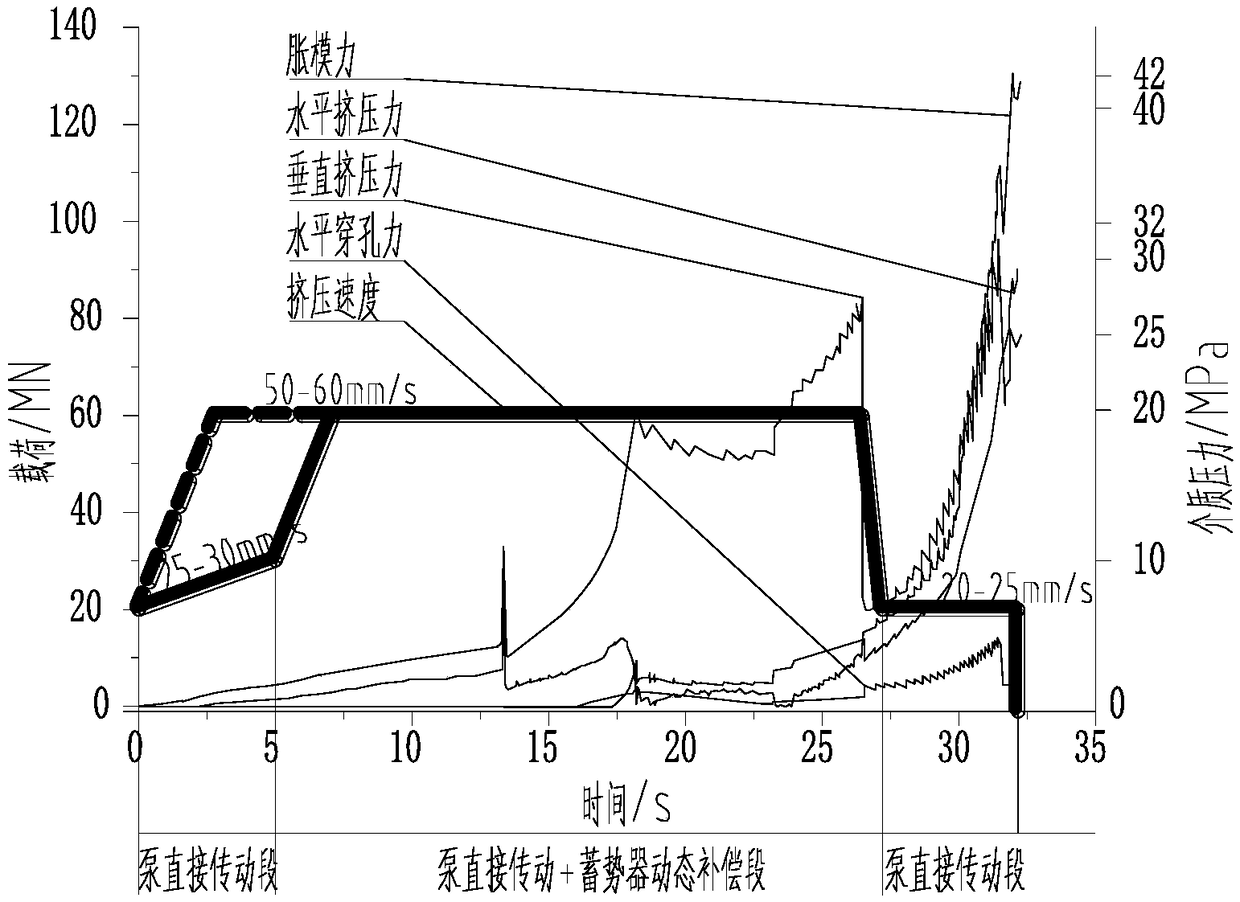

Dynamic compensation control system for flow and pressure of accumulators

PendingCN109248981AReduce the total installed powerReduce purchasing costsForging press drivesLow voltageHigh pressure

The invention discloses a dynamic compensation control system for flow and pressure of accumulators. The dynamic compensation control system for flow and pressure of the accumulator comprises a plurality of medium and high pressure accumulators and accumulator control valve blocks, each medium and high pressure accumulator comprises a plurality of oil tanks and gas tanks, a pipe of an outlet of each oil tank is connected with an accumulator control valve block, and the accumulator control valve blocks control compensation flow of output of the oil tanks. By the accumulators and the accumulatorcontrol valve blocks, output of maneuvering flow of the oil tanks can be controlled through a high frequency response proportional valve according to a process load curve of a hydraulic machine, in acycle period, power stored by the accumulators dynamically compensate flow required for a direct transmission system of an oil pump in a medium and low voltage load stage, thus, a main cylinder meetsthe requirement for specified working speed, and the main cylinder can serve as a pilot control oil source of a whole hydraulic system. By the dynamic compensation control system for flow and pressure of accumulators, installing total power required for establishment of an independent pump station of each hydraulic machine can be greatly reduced, idle or less power consumption of the accumulatorsis reduced effectively, the running efficiency is improved, the purchasing cost of the hydraulic system can be reduced remarkably, and project investment and production and running costs are reduced.

Owner:NANJING DEV ADVANCED MFG

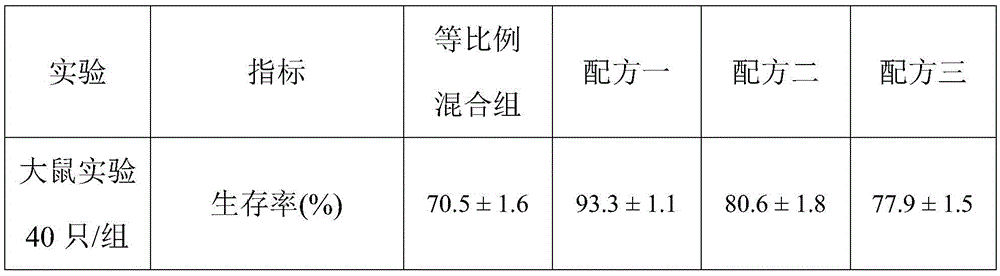

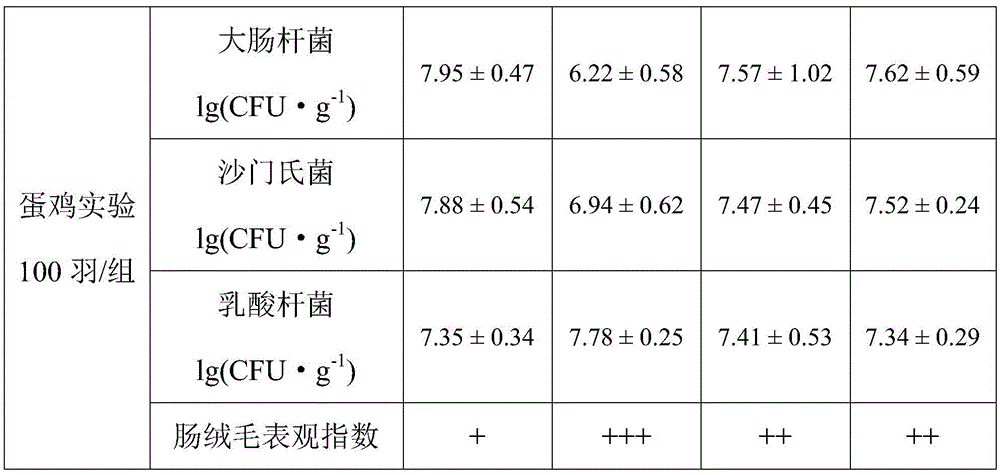

Production method of capsicum and honeysuckle containing feeding antimicrobial agent for laying hens

InactiveCN105995125AReduce manufacturing costAchieving low-carbon productionFood processingAnimal feeding stuffBiotechnologyMeal powder

The invention provides a production method of a capsicum and honeysuckle containing feeding antimicrobial agent for laying hens. The components include: orange peel, capsicum, bean dreg, honeysuckle leaf, Ochromonas ovalis Doflein, and an assistant. The water content of orange peel, capsicum, honeysuckle leaf and Ochromonas ovalis Doflein is 3-5%, and the water content of bean dreg is 18-20%. The production method consists of: mixing the five crude powder in proportion, then mixing the mixed powder with the assistant evenly; then treating the mixture by mechanochemical technique, using a high-energy vibration mill to conduct processing, under the conditions of a cooling circulating water temperature of 19-21DEG C, a frequency of 16Hz and a steel rod acceleration of 8-9g, conducting treatment for 17-18min, then stopping operation for 3.5min, and then conducting treating at a steel rod acceleration 6.7g for 12-13min, thus obtaining a feed additive finished product. The method provided by the invention employs fruit and vegetable peel pomace and other waste to produce the feeding antimicrobial agent, significantly reduces enteric pathogenic bacteria, also reduces the raw material production cost of the prior art, and recycles a lot of waste generated in food production, achieves low carbon production, and increases the added value of the product.

Owner:SHAOYANG UNIV

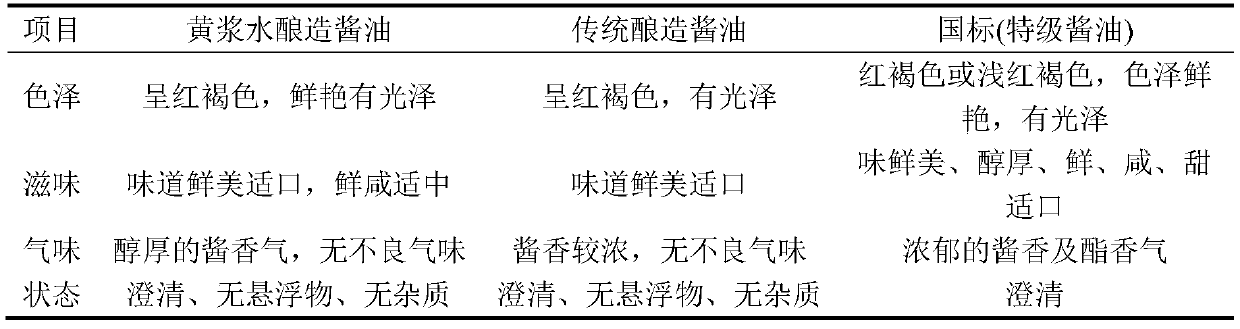

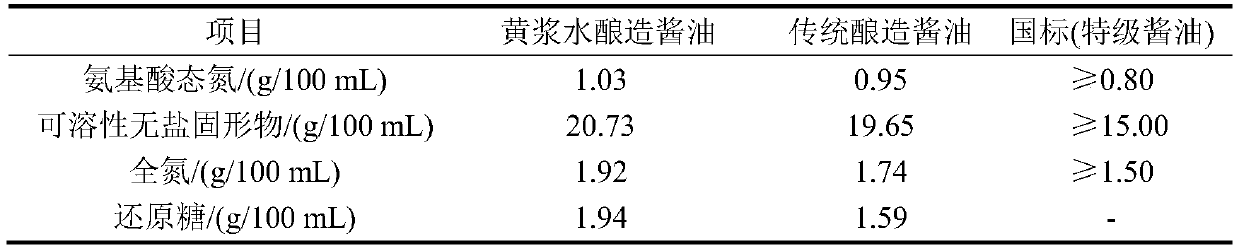

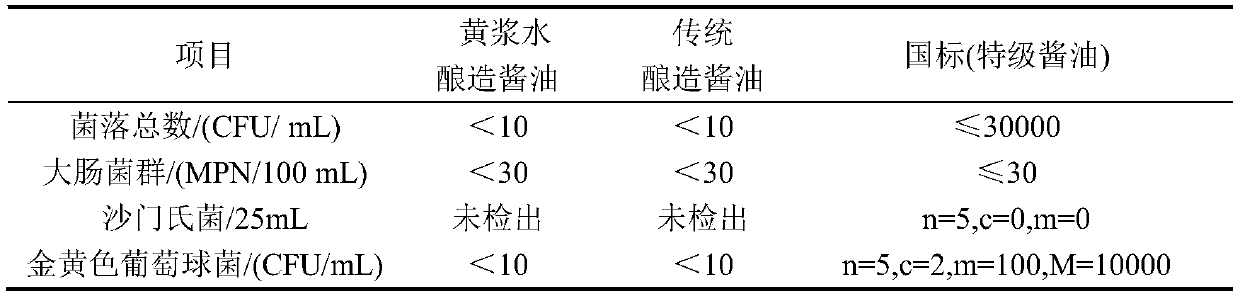

Preparation method for making soy sauce through yellow slurry

PendingCN109757703AReduce manufacturing costReduce processing costsFood scienceChemistrySewage treatment

The invention provides a preparation method for making soy sauce through yellow slurry. The preparation method comprises the following steps: 1) inoculating aspergillus oryzae in a mixture of soybeanand flour to prepare a yeast material; 2) adding the yellow slurry containing salt to the yeast material, mixing uniformly and then performing open-air fermentation for 25-35 days to obtain soy saucemash; 3) adding ester-producing yeast to the soy sauce mash, mixing uniformly and then conducting continuous open-air fermentation to obtain the soy sauce. According to the method, the yellow slurry is adopted to replace water in the process of producing the soy sauce in the high salt dilution process, the sewage treatment fee is saved, and the environment pollution is reduced. According to the method, the soy sauce yield can be improved, and the product quality can be improved.

Owner:FOODSTUFF INST BEIJING +1

A low-cost high-strength porous sound-absorbing material and its manufacturing process

The invention relates to a low-cost high-strength porous sound absorption material and a process for manufacturing the same. The low-cost high-strength porous sound absorption material comprises, by weight, 35-40% of steel slag, 25-30% of red mud, 15-20% of cement clinker, 3-5% of expansive agents, 3-5% of hydrogen peroxide which is a foaming agent, 1-3% of desulfurization gypsum, 2-4% of calciumcarbonate and 1-3% of glass fibers. The process includes (1), acquiring raw materials for standby application; (2), coarsely crushing the steel slag, the calcium carbonate and the desulfurization gypsum and carrying out wet grinding on the steel slag, the calcium carbonate and the desulfurization gypsum; (3), adding water into the steel slag, the calcium carbonate and the desulfurization gypsum, stirring the water, the steel slag, the calcium carbonate and the desulfurization gypsum, adding the foaming agent into the water, the steel slag, the calcium carbonate and the desulfurization gypsum to obtain first mixtures, injecting the first mixtures into cement molds and curing, drying and crushing the first mixtures; (4), adding water into the first mixtures, stirring the water and the mixtures to obtain slurry, injecting the slurry into molds, carrying out compression molding on the slurry, curing samples released from the molds in cement standard curing tanks under standard curing conditions and ultimately drying the samples to obtain the low-cost high-strength porous sound absorption material which is a finished product. The low-cost high-strength porous sound absorption material and the process have the advantages that the low-cost high-strength porous sound absorption material is mainly made of the red mud and the steel slag which are metallurgical industrial waste residues,the calcium carbonate and the gypsum are used as reinforcing agents, accordingly, the low-cost high-strength porous sound absorption material can be used as a sound absorption barrier for tunnels, subways and roads, and the problem of noise pollution of indoor places and the like can be solved.

Owner:HENAN UNIV OF SCI & TECH

Production method of bean dreg-containing feeding antibacterial agent

InactiveCN105995028AReduce manufacturing costAchieving low-carbon productionFood processingAnimal feeding stuffBiotechnologyArginine

The invention relates to a production method of a bean dreg-containing feeding antibacterial agent. The method consists of: crushing orange peel, ramie, bean dregs, populus euphratica leaf, and Pseudokephyrion into 60-80 mesh coarse powder respectively, burdening the raw materials by weight: 26-28 parts of orange peel, 15-17 parts of ramie, 34-36 parts of bean dregs, 4-4.2 parts of populus euphratica leaf, 3.5-3.7 parts of Pseudokephyrion, and 5 parts of an assistant, which is composed of 1.5 parts of magnesium aluminum silicate, 1.3 parts of L-arginine and 2.3 parts of polyethylene glycol chitosan, wherein the water content of the orange peel, ramie, Pseudokephyrion and populus euphratica leaf is 3-5%, and the water content of the bean dregs is 18-20%; and mixing the five coarse powder, then mixing the mixed powder with the assistant, and conducting mechanochemical treatment to obtain a finished product. Production of the feeding antibacterial additive from fruit and vegetable peel pomace can significantly reduce enteric pathogenic bacteria of laying hens, and also lowers the raw material production cost of the prior art. A lot of waste generated in food production is recycled, low carbon production can be achieved, and the added value of the product is increased.

Owner:SHAOYANG UNIV

Method for producing feed immuno-enhancer mainly from tangerine peel and taro peel residue

InactiveCN105981949AReduce manufacturing costAchieving low-carbon productionFood processingAnimal feeding stuffBiotechnologyPolyethylene glycol

A method for producing a feed immuno-enhancer mainly from tangerine peel and taro peel residue includes: crushing according to parts by weight, 24-26 parts of tangerine peel, 27-29 parts of taro peel residue, 14-16 parts of soybean residue and 5.4-5.6 parts of Ansheng Jinbeizao (sus.) respectively to coarse powders 60-80 mesh, with 1.9 parts of MgSO4, 2.6 parts of NaHSO3 and 2.7 parts of polyethylene glycol chitosan, wherein the water content of the tangerine peel, taro peel, Ansheng Jinbeizao (sus.) and Suaeda heteroptera seed is 3-5% and the water content of the soybean residue is 18-20%; mixing the five mixed solution according to the above-mentioned ratio and then with an aid; mixing well and grinding for 30 min, and screening with a 400-mesh screen; treating by chemo-mechanical techniques for 15-30 min according to the weight and humidity of materials to obtain the finished feed immuno-enhanced product. The production wastes such as fruit and vegetable peel residues are used to produce the feed immuno-enhancer, the material production cost of the prior art is significantly reduced, and the mass wastes produced in food product are recycled, enabling low-carbon production and increasing added value of products.

Production method of feed additive improving antibacterial ability of layers by making efficient use of tangerine peel and tangerine seed

InactiveCN105981976AReduce manufacturing costAchieving low-carbon productionFood processingAnimal feeding stuffBiotechnologyFood additive

A production method of a feed additive improving antibacterial ability of layers by making efficient use of tangerine peel and tangerine seed comprises: crushing according to parts by weight: 57-59 parts of tangerine peel, 23-25 parts of tangerine seed, 26-28 parts of tofu, 4.2-4.4 parts of sheathing leaf of Zizania lotifolia and 2.5-2.7 parts of Ochrominas mutabilis respectively to coarse powders 60-80 mesh, with 5 parts of an aid, wherein the aid is made from 1.1 parts of sodium carboxymethyl cellulose, 1.6 parts of sulfobutyl ether-Beta-cyclodextrin and 1.7 parts of hydroxypropyl chitosan; the tangerine peel, tangerine seed, Ochrominas mutabilis and sheathing leaf of Zizania lotifolia are 3-5% in water content, and soybean residue is 18-20% in water content; the five coarse powders are mixed according to the above-mentioned ratio and then mixed with the aid and chemo-mechanically treated to obtain a finished product. The feed antibacterial additive produced with wastes such as fruit and vegetable residue significantly decreases intestinal pathogenic bacteria in layers and also reduces the material production cost of the prior art, and mass wastes produced in food production are recycled, enabling low-carbon production and increasing added value of products.

Owner:SHAOYANG UNIV

Low-carbon carotenoid production method

InactiveCN105648020ARetention contentStable contentMicroorganism based processesFermentationFruit juiceRhodotorula

The invention discloses a low-carbon carotenoid production method. Trimmings of canned yellow peaches are taken as a main raw material and subjected to microwave color fixing, freezing, breaking and biological enzymolysis, juice with higher carotenoid content is obtained, a fermentation medium is obtained after component adjustment, Rhodotorula benthica with high carotenoid yield is inoculated to the fermentation medium for graded inoculation and temperature-shift fermentation, the Rhodotorula benthica is enabled to be proliferated to the greatest extent, fermentation broth is subjected to ultrahigh-pressure homogenization, vacuum centrifugation, demulsification and separation, an emulsion is obtained, and the finished product carotenoid is obtained after extraction, separation and purification of the emulsion, wherein the cell biomass of the fermentation broth is 38-52 g / L, and the yield of the carotenoid is 47-61 mg / L. The production method is simple, short in cycle, high in efficiency, energy-saving and environment-friendly, adopts low-temperature and bio-processing technologies in the whole process, reduces the production cost, eliminates hidden danger of environmental pollution, lays a firm foundation for sustainable development in the technical field of deep processing of the canned yellow peaches and has positive economic and social development significance.

Owner:邵素英

Environment-friendly clean pulping process

ActiveCN102587181BAchieving "Zero Emissions"Realize "Zero Emissions"Washing/displacing pulp-treating liquorsPulp bleachingWater circulationPulp and paper industry

Owner:谢明文

Low-carbon environment-friendly resource utilization process and system for high-mercury cyanogen-containing gold separation waste residues

ActiveCN114425555AAchieve recyclingHarmlessTransportation and packagingSolid waste disposalProcess engineeringEnvironmental engineering

The system comprises a rotary kiln and a treatment device communicated with the rotary kiln, the treatment device comprises a raw material storage mechanism, a crushing and screening mechanism and a metering mechanism, and a decomposing furnace of the rotary kiln is arranged on the side face of the metering mechanism; a mercury removal mechanism is embedded in one side of an inner cavity of the decomposing furnace, the side face of the mercury removal mechanism communicates with a metering mechanism, a detection mechanism is arranged on one side of the mercury removal mechanism, the top face of the mercury removal mechanism communicates with an adsorption mechanism, and the bottom of the decomposing furnace communicates with a cement preparation mechanism of a rotary kiln; and the top of the decomposing furnace is communicated with a raw material adding mechanism of the rotary kiln, so that harmless treatment and resource utilization of the hazardous wastes can be realized at the same time. The system can realize the following processes in sequence: high-mercury cyanogen-containing gold separation waste residue storage and crushing and screening pretreatment, mercury removal and mercury product recovery, and decyanation production of cement through collaborative treatment of the rotary kiln.

Owner:山西丽浦创新科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com