Production method of bean dreg-containing feeding antibacterial agent

An antibacterial agent and bean dregs technology, which is applied in the production field of feed antibacterial agent, can solve the problems of single product formulation, difficult quality assurance, rough product process, etc., and achieves the goal of reducing production cost, improving production performance and improving intestinal health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

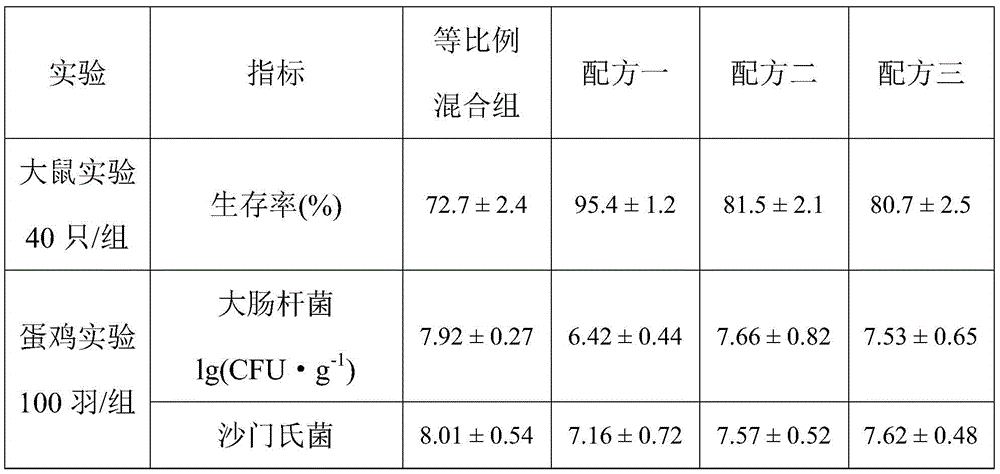

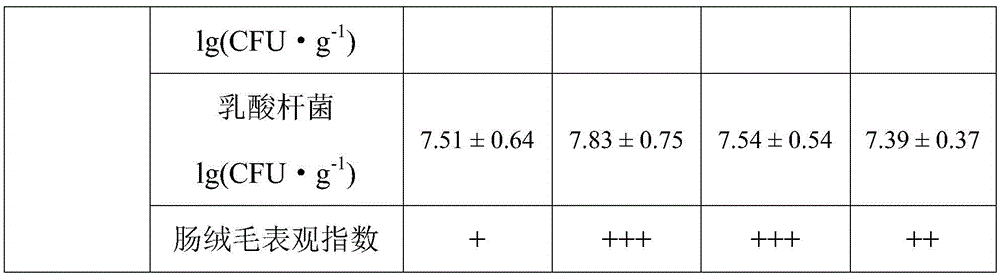

Examples

Embodiment 1

[0031] The raw material formula of the antibacterial additive for feeding is: 27 parts of orange peel, 16 parts of ramie, 35 parts of bean dregs, 4.1 parts of Populus euphratica leaves, 3.6 parts of Pseudomonas aureus, and 5 parts of additives.

[0032] The production method is that the bean dregs are processed with a small high-speed pulverizer to make the particle size reach 60 meshes, and the bean dregs coarse powder is obtained; the materials such as ramie, pseudochrysalis, orange peel and Populus euphratica leaves that are dried to a water content of 3% are Carry out separate processing with small-scale high-speed pulverizer respectively, make particle diameter reach 60 orders, make the coarse powder of four kinds of materials; Mix five kinds of coarse powders according to formula ratio; Aluminum, 1.3 parts of L-arginine, 2.3 parts of polyethylene glycol chitosan) mixed evenly; after mixing, it was treated by mechanochemical method and processed by high-energy vibrating mi...

Embodiment 2

[0035] The raw material formula of the antibacterial additive for feeding is: 26 parts of orange peel, 15 parts of ramie, 34 parts of bean dregs, 4.0 parts of Populus euphratica leaves, 3.5 parts of pseudochrysalis, and 5 parts of additives.

[0036] The production method and product application method are the same as in Example 1.

Embodiment 3

[0038] The raw material formula of the antibacterial additive for feeding is: 28 parts of orange peel, 17 parts of ramie, 36 parts of bean dregs, 4.2 parts of Populus euphratica leaves, 3.7 parts of pseudochrysalis, and 5 parts of additives.

[0039] The production method and product application method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com