Dynamic compensation control system for flow and pressure of accumulators

A dynamic compensation and control system technology, applied to the driving device of forging presses, etc., can solve problems such as low start-up rate and operating efficiency, increased project investment, and increased production and operating costs, so as to reduce power consumption, purchase costs, The effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

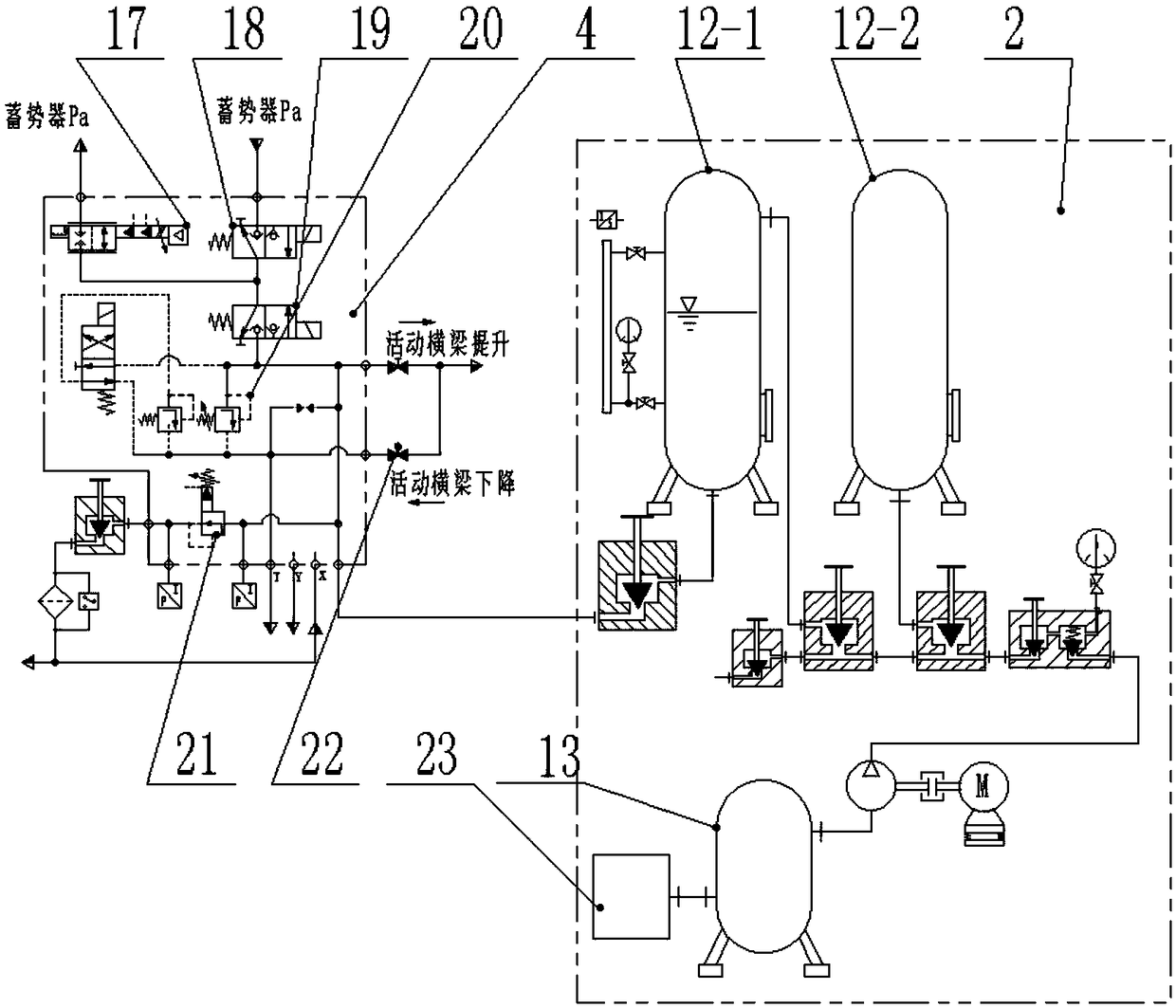

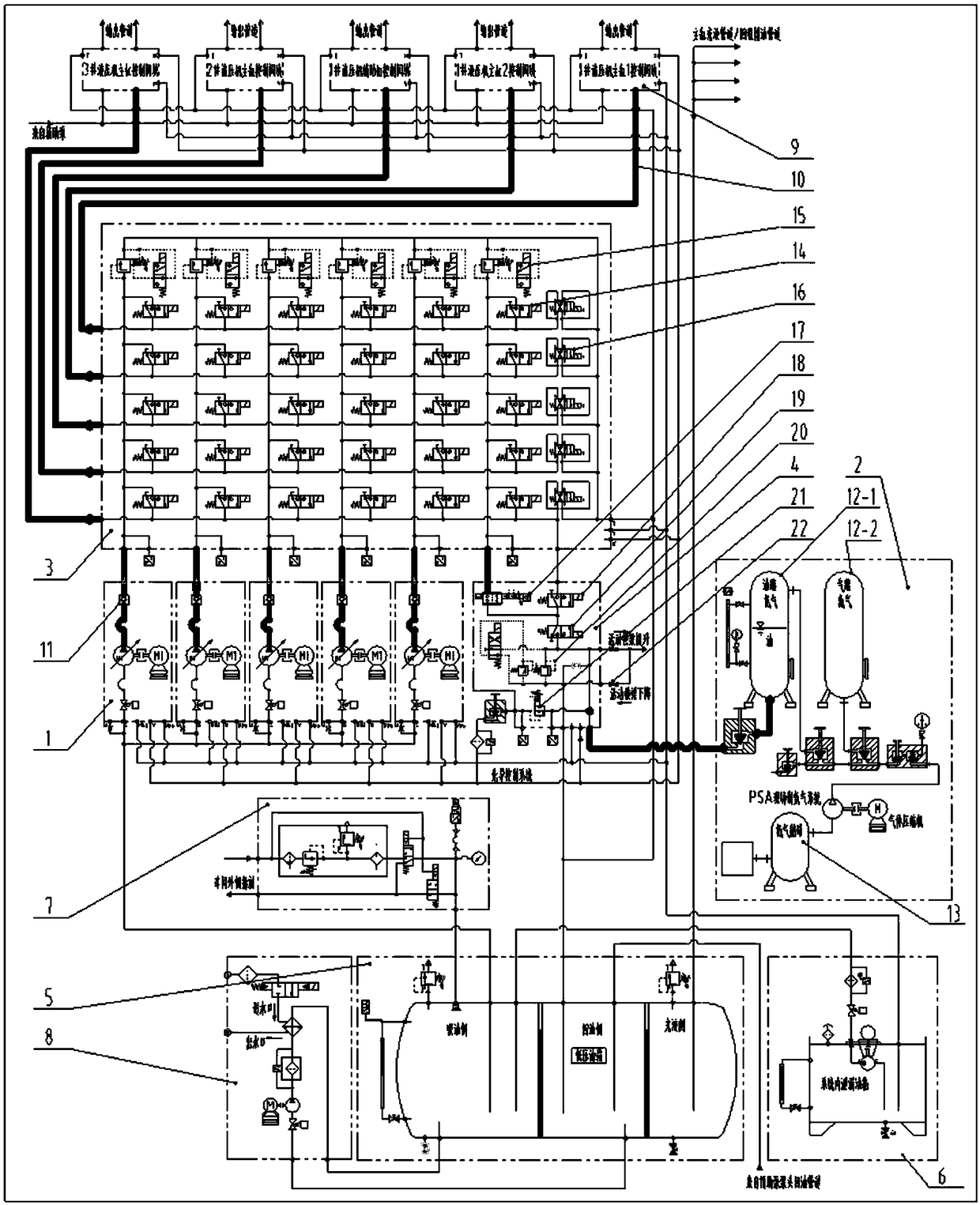

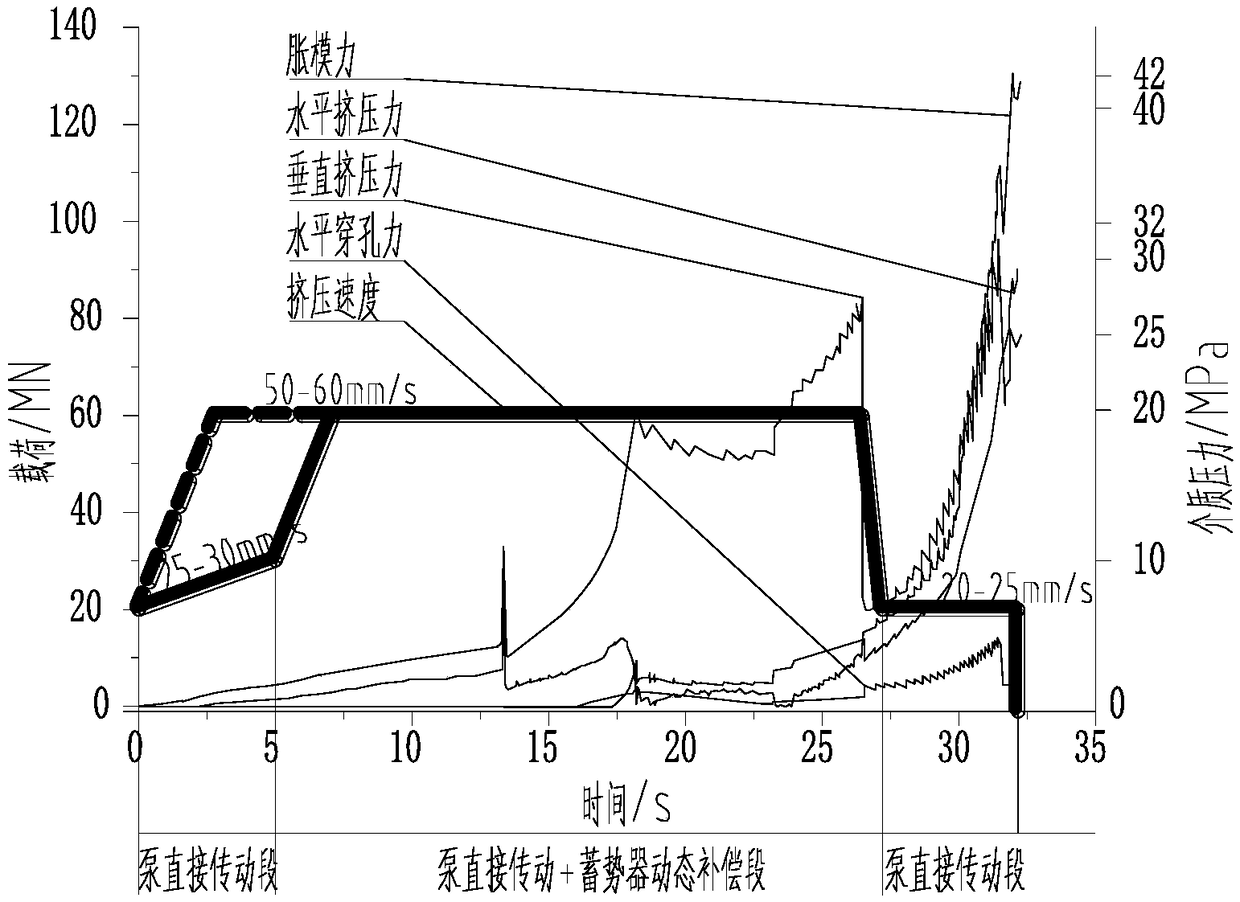

[0036] figure 1 It is a schematic diagram of the working principle of the present invention. It can be seen from the accompanying drawings that the accumulator flow and pressure dynamic compensation control system includes several high-pressure accumulators 2 and accumulator control valve blocks 4. The medium and high-pressure accumulators 2 include For several oil tanks 12-1 and gas tanks 12-2, the oil tank outlet pipes are directly connected to the accumulator control valve block 4, and the accumulator control valve block 4 controls the output compensation flow of the oil tank.

[0037] The accumulator control valve block 4 includes a high-frequency response proportional valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com