System for wet grinding kaolin paste

A kaolin and slurry technology, applied in the system field, can solve the problems of increased dispersant consumption, low production efficiency and high production cost, and achieve the effects of reduced quantity, high production efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

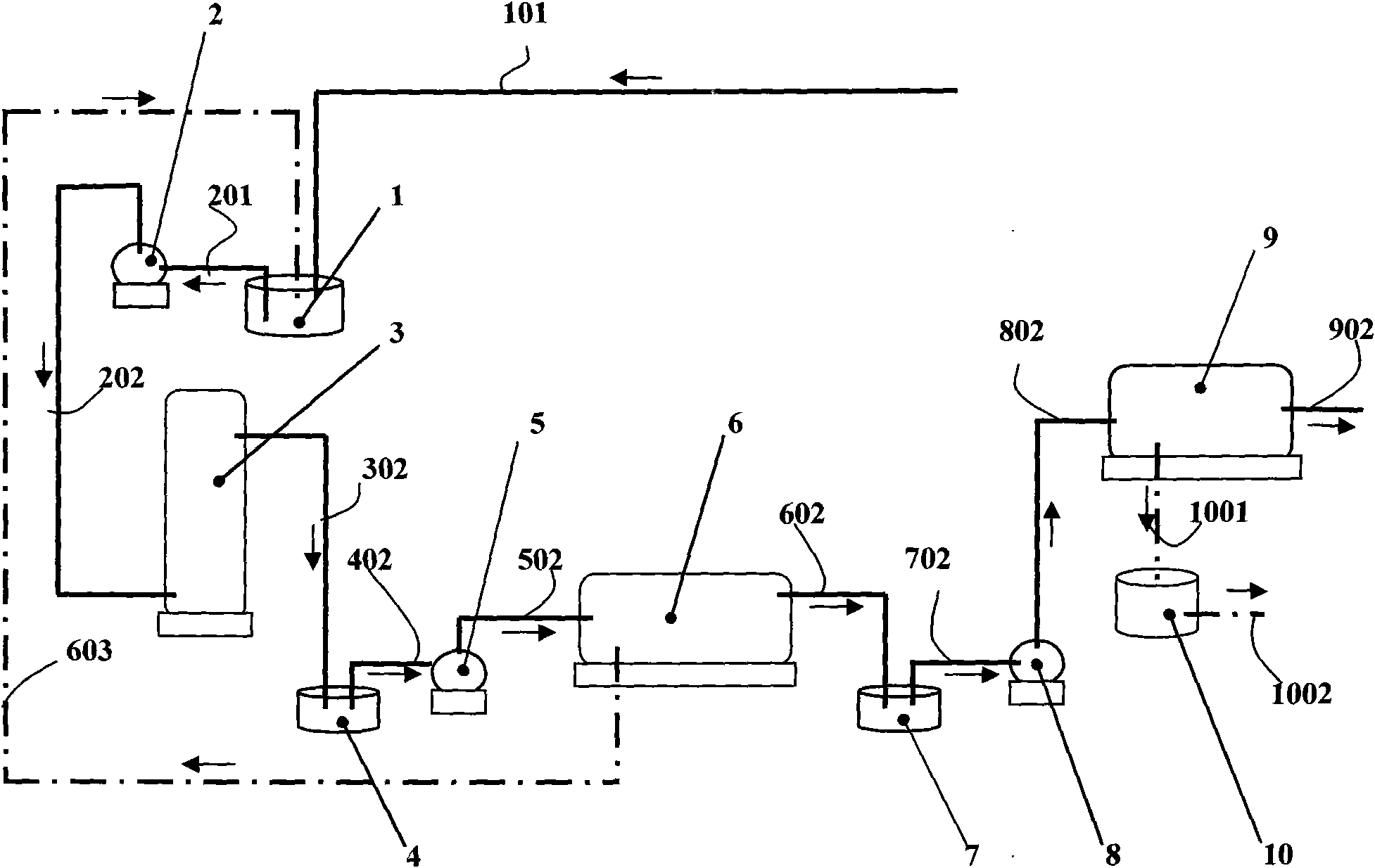

[0024] exist figure 1 Among them, a system for wet grinding kaolin slurry includes a slurry tank 1, a delivery pump 2, a flaker 3, a buffer tank 4, and a delivery pump 5; There is a suction pipe 201, and the suction port of the suction pipe 201 penetrates into the slurry liquid in the slurry tank 1 through the top of the slurry tank 1; at the same time, the discharge port of the delivery pump 2 and the feed port provided at the bottom of the peeler 3 A feeding pipeline 202 is arranged between them, and at the same time, a feeding pipeline 302 is arranged between the discharge port provided on the top of the peeling machine 3 and the buffer tank 4, and the discharge port of the feeding pipeline 302 enters the buffer tank through the top of the buffer tank 4 In the pond 4; Simultaneously; Suction pipe 402 is arranged between the buffer pond 4 and the suction port of delivery pump 5, and the suction port of its suction pipe 402 goes deep into the slurry liquid of buffer pond 4 th...

Embodiment 2

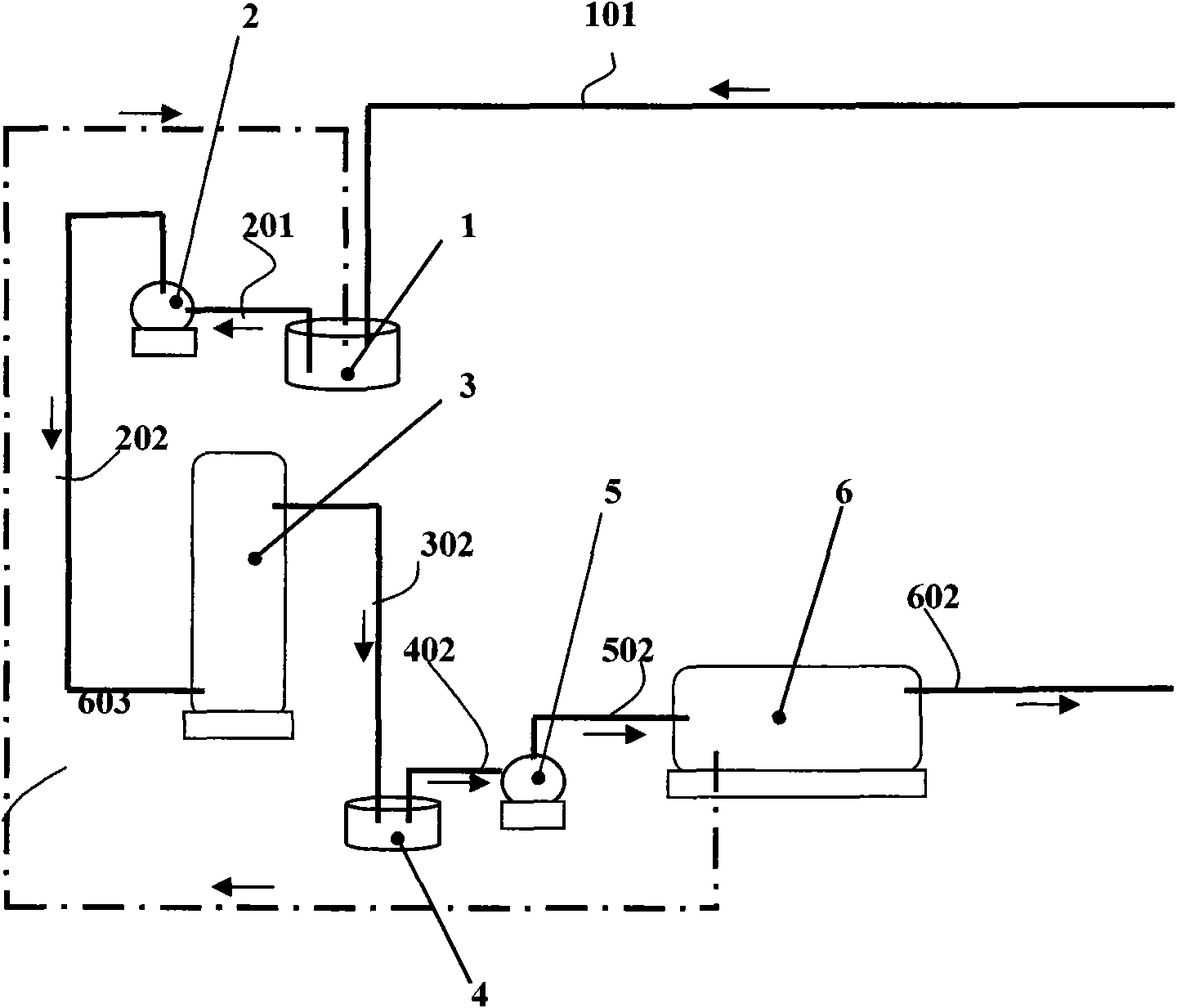

[0029] exist figure 2Among them, a system for wet grinding kaolin slurry includes a slurry tank 1, a delivery pump 2, a flaker 3, a buffer tank 4, and a delivery pump 5; There is a suction pipe 201, and the suction port of the suction pipe 201 penetrates into the slurry liquid in the slurry tank 1 through the top of the slurry tank 1; at the same time, the discharge port of the delivery pump 2 and the feed port provided at the bottom of the peeler 3 A feeding pipeline 202 is arranged between them, and at the same time, a feeding pipeline 302 is arranged between the discharge port provided on the top of the peeling machine 3 and the buffer tank 4, and the discharge port of the feeding pipeline 302 enters the buffer tank through the top of the buffer tank 4 In the pond 4; Simultaneously; Suction pipe 402 is arranged between the buffer pond 4 and the suction port of delivery pump 5, and the suction port of its suction pipe 402 goes deep into the slurry liquid of buffer pond 4 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com