Matrix type multi-channel input/output integrated control valve block

An integrated control valve, multiple input technology, applied in servo meter circuit, accumulator device, fluid pressure actuation device, etc., can solve the problem of impossible sharing of working cylinders, reduce the working speed of cylinders, increase production and operation costs, etc. problems, to achieve the effect of reducing project investment and production and operation costs, reducing energy consumption, and reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

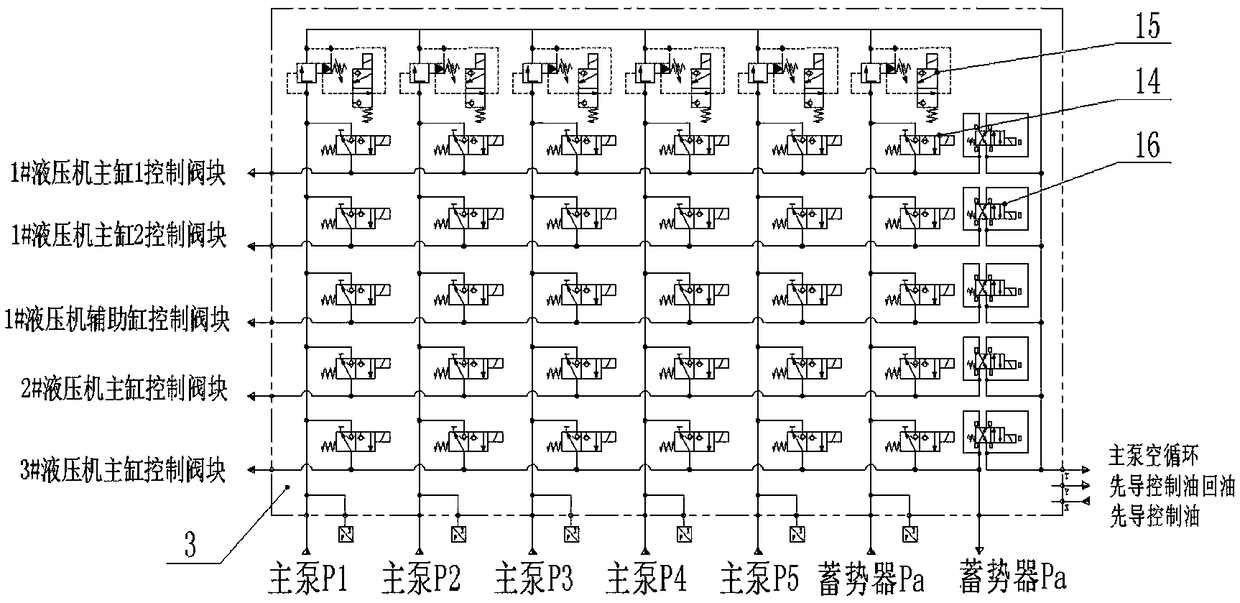

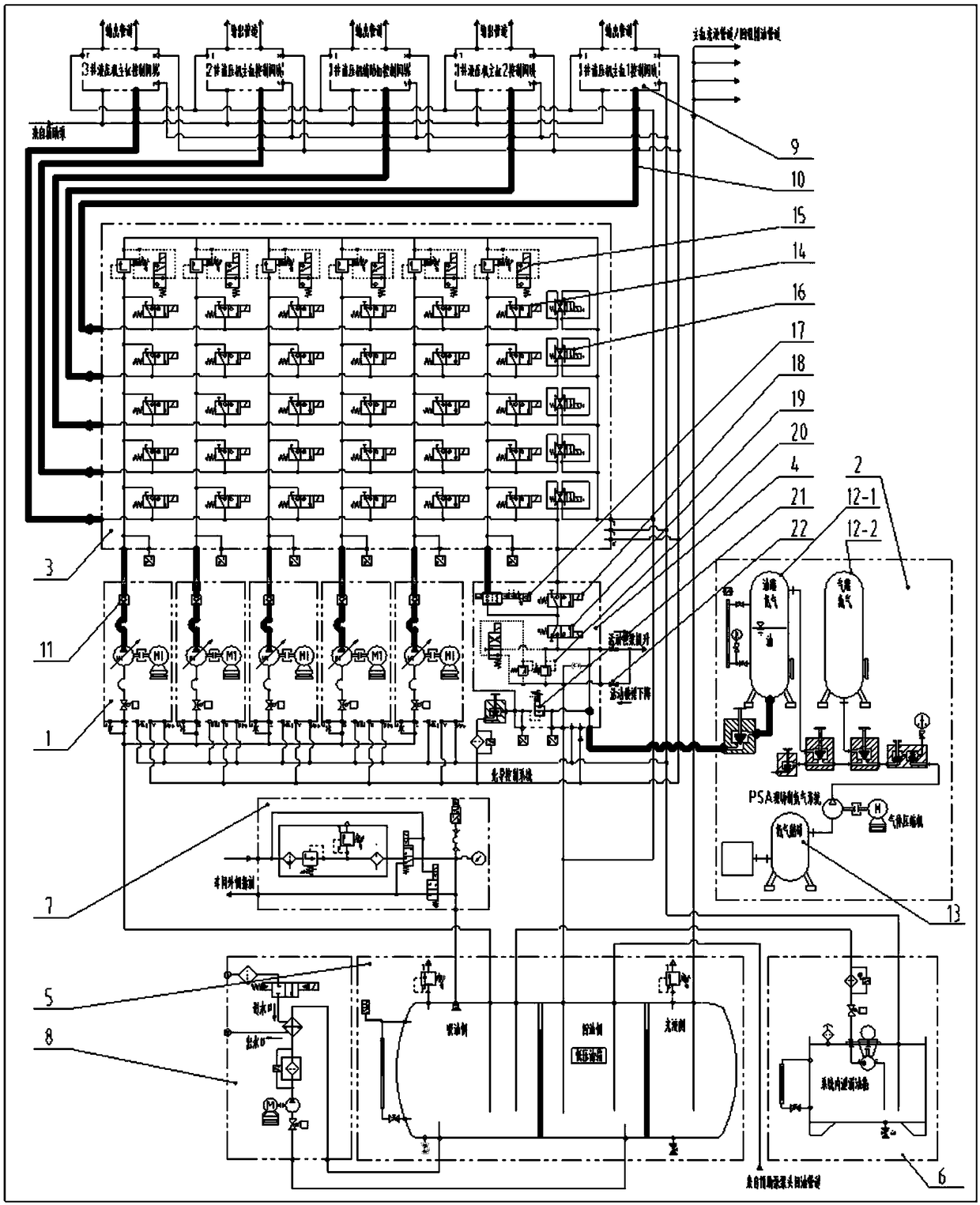

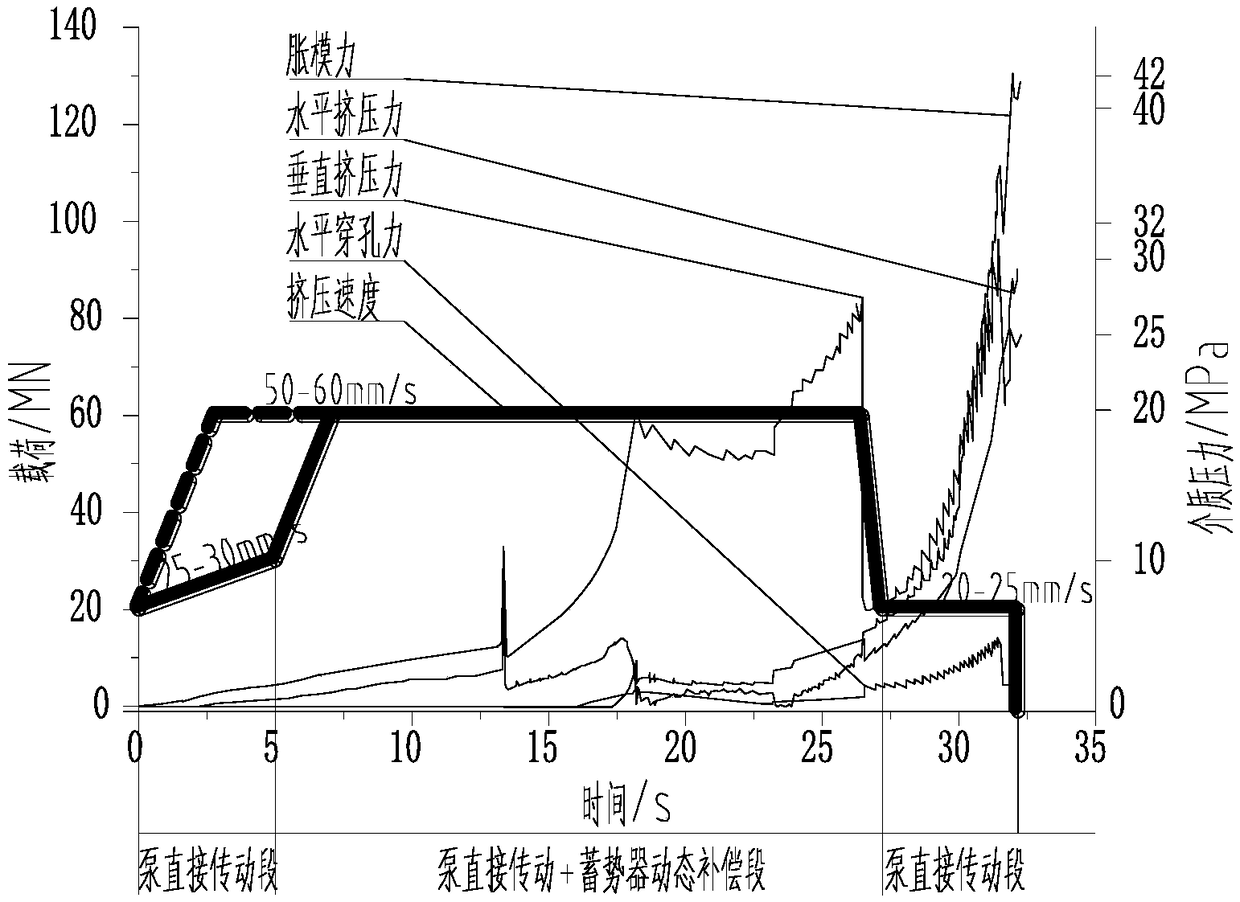

[0044] figure 1 It is a schematic diagram of the working principle of the present invention. It can be seen from the accompanying drawings that the matrix multi-channel input / output integrated control valve block includes several input flow channels and several output flow channels. The output flow channels are distributed in parallel in horizontal rows; the input flow channels and output flow channels are arranged in a matrix cross, each cross position of the input flow of each column and the output flow channel of each horizontal row is provided with an isolation valve, and the input flow of each column The flow channel and the corresponding horizontal output flow channel are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com