Production method of feed additive improving antibacterial ability of layers by making efficient use of tangerine peel and tangerine seed

A feed additive, orange peel technology, applied in animal feed, animal feed, application, etc., can solve the problems of rough product process, difficult to guarantee quality, single product formulation, etc., to improve intestinal health, improve production performance, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

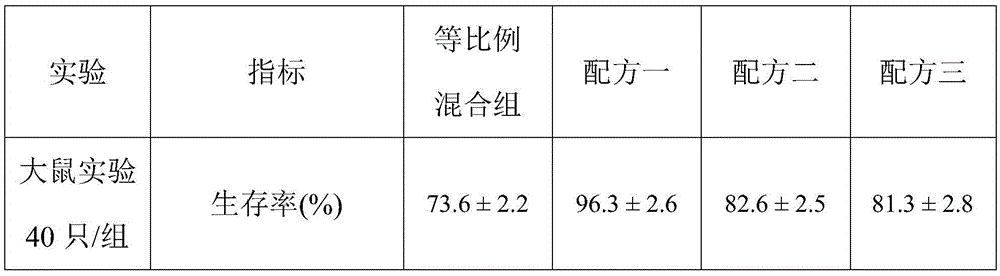

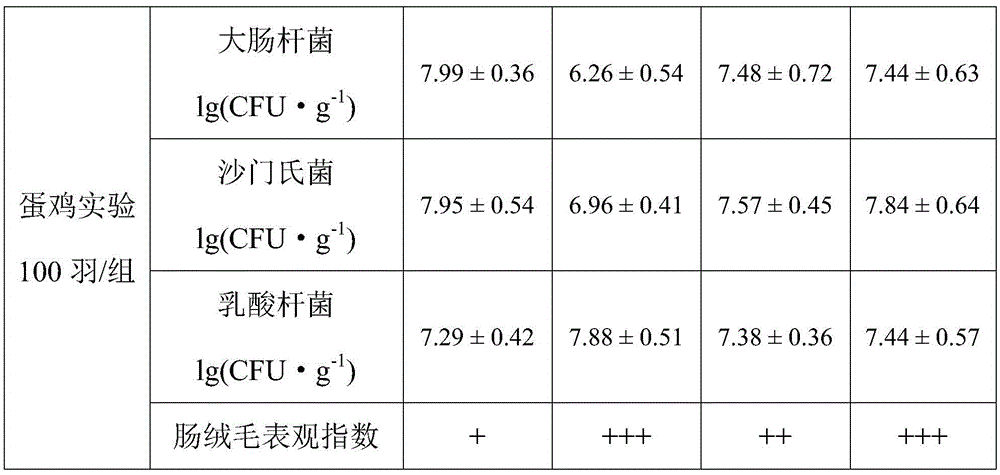

Examples

Embodiment 1

[0031] The raw material formula of the antibacterial additive for feeding is: 58 parts of orange peel, 24 parts of orange seeds, 27 parts of bean dregs, 4.3 parts of bamboo sheath leaves, 2.6 parts of brown dinoflagellates, and 5 parts of additives.

[0032] The production method is as follows: process the bean dregs with a small high-speed pulverizer to make the particle size reach 60 meshes, and obtain the bean dregs coarse powder; dry the orange seeds, deformed brown dinoflagellates, orange peels, and asparagus sheath leaves respectively to a water content of 3%. and other materials are processed separately with a small-scale high-speed pulverizer, so that the particle size reaches 60 meshes, and coarse powders of four kinds of materials are obtained; five kinds of coarse powders are mixed according to the formula ratio; sodium hydroxymethyl cellulose, 1.6 parts of sulfobutyl ether-β-cyclodextrin, and 1.7 parts of hydroxypropyl chitosan) were mixed evenly; after mixing, they...

Embodiment 2

[0035] The raw material formula of the antibacterial additive for feeding is: 57 parts of orange peel, 23 parts of orange seeds, 26 parts of bean dregs, 4.2 parts of bamboo sheath leaves, 2.5 parts of brown dinoflagellates, and 5 parts of additives.

[0036] The production method and product application method are the same as in Example 1.

Embodiment 3

[0038]The raw material formula of the antibacterial additive for feeding is: 59 parts of orange peel, 25 parts of orange seed, 28 parts of bean dregs, 4.4 parts of bamboo sheath leaves, 2.7 parts of brown dinoflagellates, and 5 parts of additives.

[0039] The production method and product application method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com