Multifunctional assembled inclined wedge

A multi-functional, wedge-wedge technology, used in punching machines, presses, metal processing equipment, etc., can solve the problems of waste of resources and small production volume, and achieve the effects of reducing logistics costs, simplifying production, and shortening delivery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

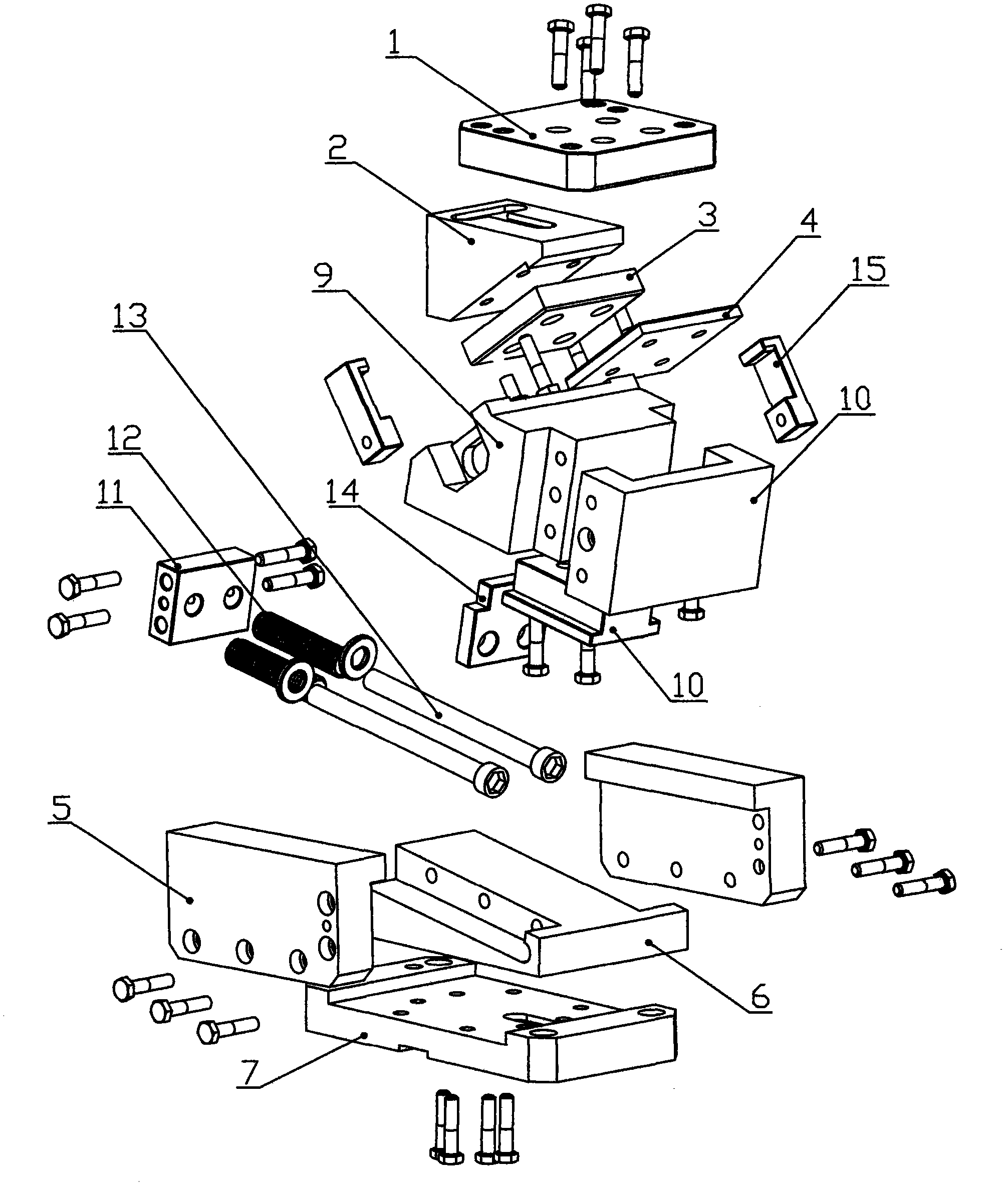

[0019] Specific implementation mode one: as figure 1 As shown in the figure, a multi-function assembling wedge for formal installation includes a driving block, a slider and a slider seat. It consists of standard parts for connecting and installing stamping dies and adjusting parts for adjusting the working angle of the wedge. The driving block includes a driving block mounting plate 1 and a working angle block 2. The driving block mounting plate 1 is a standard part, and the working angle block 2 is an adjustment part. The working angle block 1 is detachably installed on the driving block mounting plate 2. The working angle block 1 and The slider is equipped with a detachable guide plate relative to the sliding surface; the guide plate includes a driving block guide plate 3 and a slider guide plate 4, the driving block guide plate 3 is detachably installed on the bottom of the working angle block 2, and the slider guide plate 4 is installed on the upper part of the slider. ...

specific Embodiment approach 2

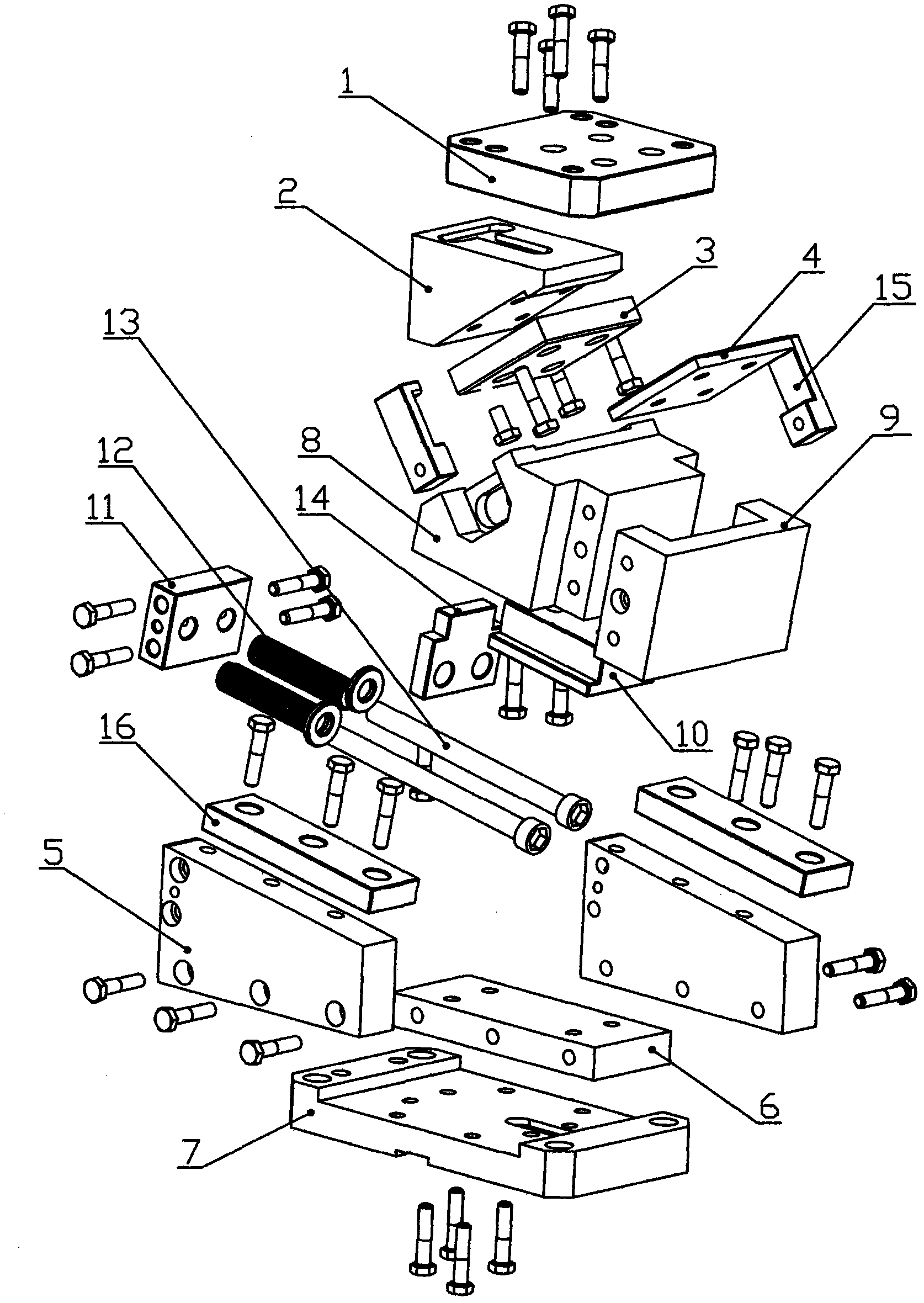

[0021] Specific implementation mode two: as figure 2 As shown in the figure, a multi-function assembling wedge for formal installation includes a driving block, a slider and a slider seat. It consists of standard parts for connecting and installing stamping dies and adjusting parts for adjusting the working angle of the wedge. The driving block includes a driving block mounting plate 1 and a working angle block 2. The driving block mounting plate 1 is a standard part, and the working angle block 2 is an adjustment part. The working angle block 1 is detachably installed on the driving block mounting plate 2. The working angle block 1 and The slider is equipped with a detachable guide plate relative to the sliding surface; the guide plate includes a driving block guide plate 3 and a slider guide plate 4, the driving block guide plate 3 is detachably installed on the bottom of the working angle block 2, and the slider guide plate 4 is installed on the upper part of the slider. ...

specific Embodiment approach 3

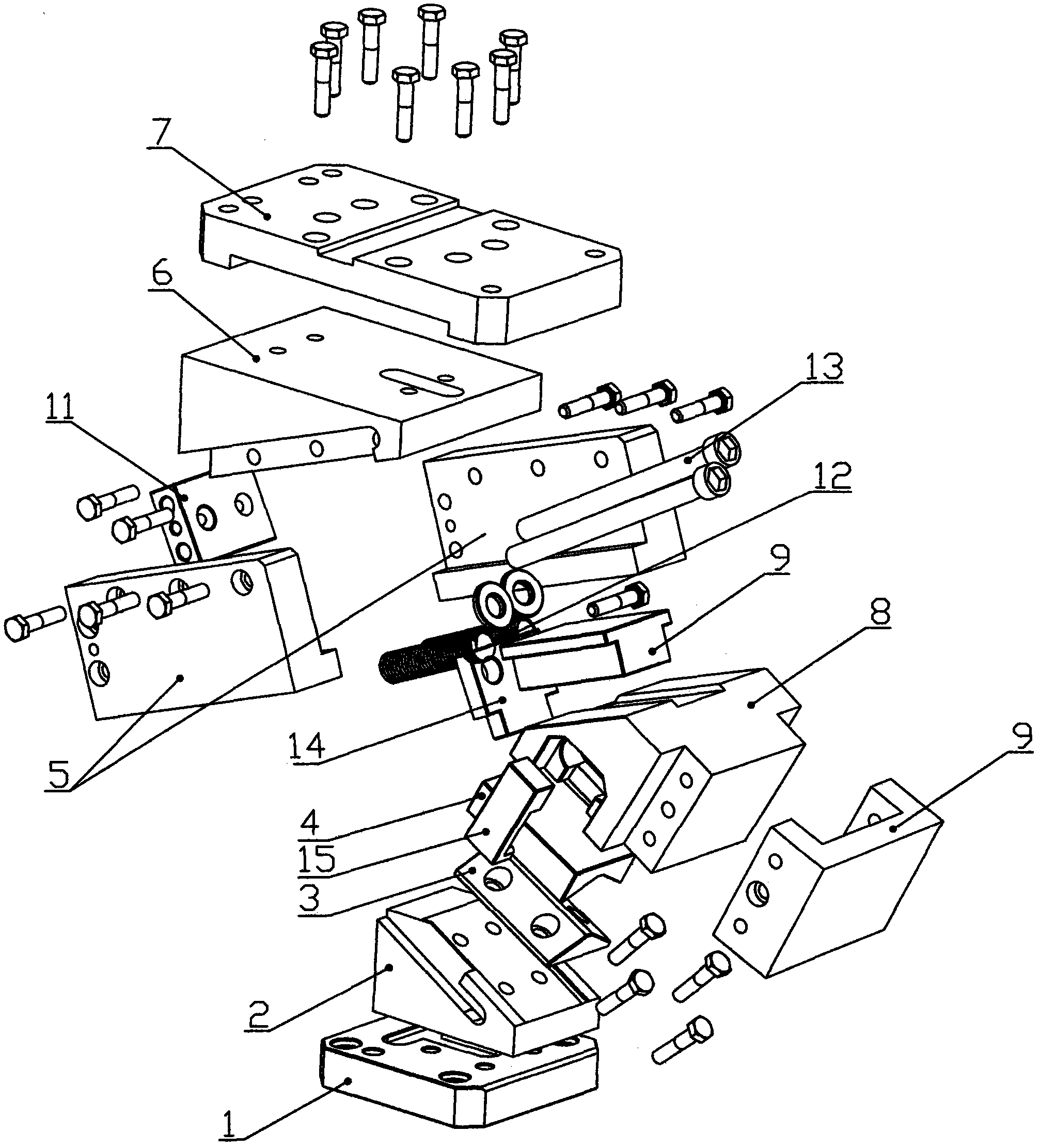

[0023] Specific implementation mode three: as image 3As shown, a hoisting multifunctional assembled wedge includes a driving block, a slider and a slider seat. It consists of standard parts for connecting and installing stamping dies and adjusting parts for adjusting the working angle of the wedge. The driving block includes a driving block mounting plate 1 and a working angle block 2. The driving block mounting plate 1 is a standard part, and the working angle block 2 is an adjustment part. The working angle block 1 is detachably installed on the driving block mounting plate 2. The working angle block 1 and The slider is equipped with a detachable guide plate relative to the sliding surface; the guide plate includes a driving block guide plate 3 and a slider guide plate 4, the driving block guide plate 3 is detachably installed on the upper part of the working angle block 2, and the slider guide plate 4 is installed on the bottom of the slider. The driving block guide plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com