Operation switching adjusting device for heat exchangers and circulating pumps of heat exchange station and working method

An adjustment device and operation switching technology, applied in the direction of heating mode, high-efficiency adjustment technology, space heating and ventilation details, etc., can solve the problem of not being able to dynamically and accurately match the heat supply and demand, and the heat supply adjustment range of the heat exchange station Small size, excess heat supply of heat exchange stations, etc., to achieve the effect of reducing control uncertainty, reducing operating energy consumption, and improving effective heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

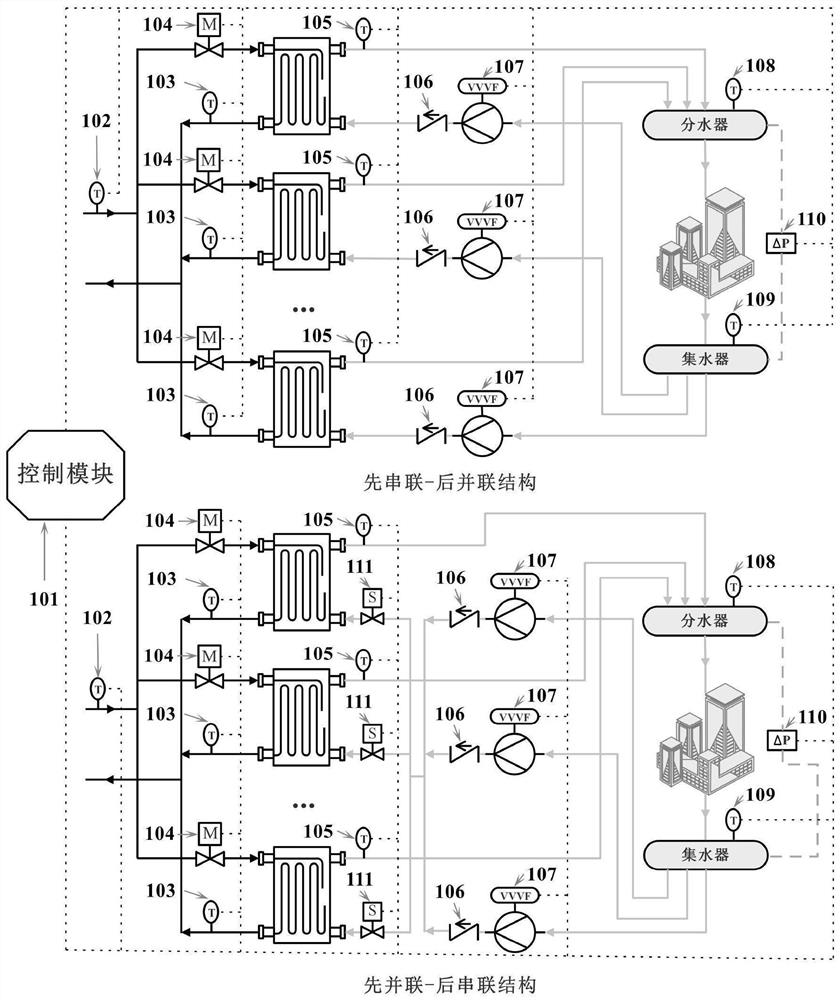

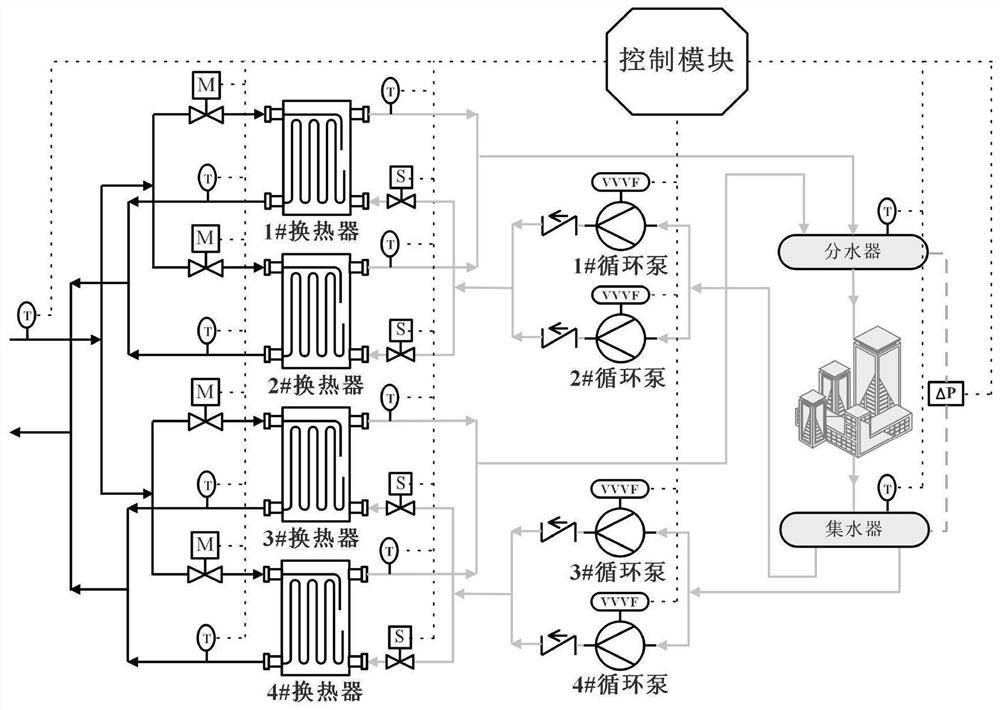

[0021] Such as figure 1 As shown, a heat exchange station heat exchanger and circulating pump operation switching adjustment device, including a control module 101, a water temperature sensor 102 of the main water inlet pipe of the heat exchange station, a water temperature sensor 103 of the primary outlet pipe of the heat exchanger, and a primary water inlet pipe of the heat exchanger Electric regulating valve 104, water temperature sensor 105 of secondary outlet pipe of heat exchanger, check valve 106, frequency conversion speed controller of circulating pump 107, water temperature sensor 108 of water separator, water temperature sensor 109 of water collector, differential pressure sensor 110 of water collector And the solenoid valve 111 of the secondary return pipe of the heat exchanger; the solenoid valve 111 of the secondary return pipe of the heat exchanger is only installed in the heat exchange station of the "parallel first-then series structure" of the heat exchanger a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com