A wet cooling unit condenser economic back pressure calculation method based on logarithmic average temperature difference and a genetic algorithm

A technology of average temperature difference and genetic algorithm, which is applied in the field of economic optimization of the cold end system of thermal power plants, and can solve the problem that the most economical back pressure of the condenser of the wet cooling unit cannot be obtained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

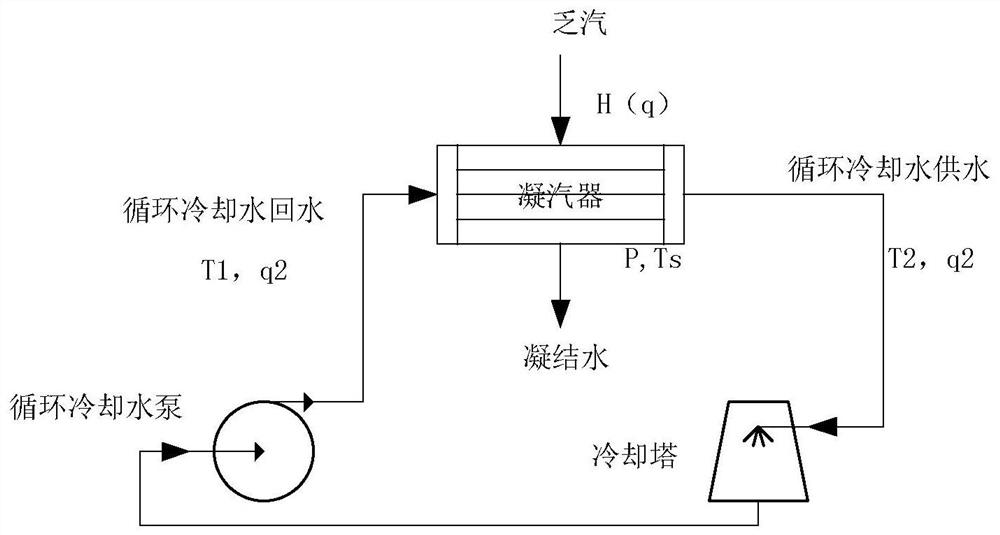

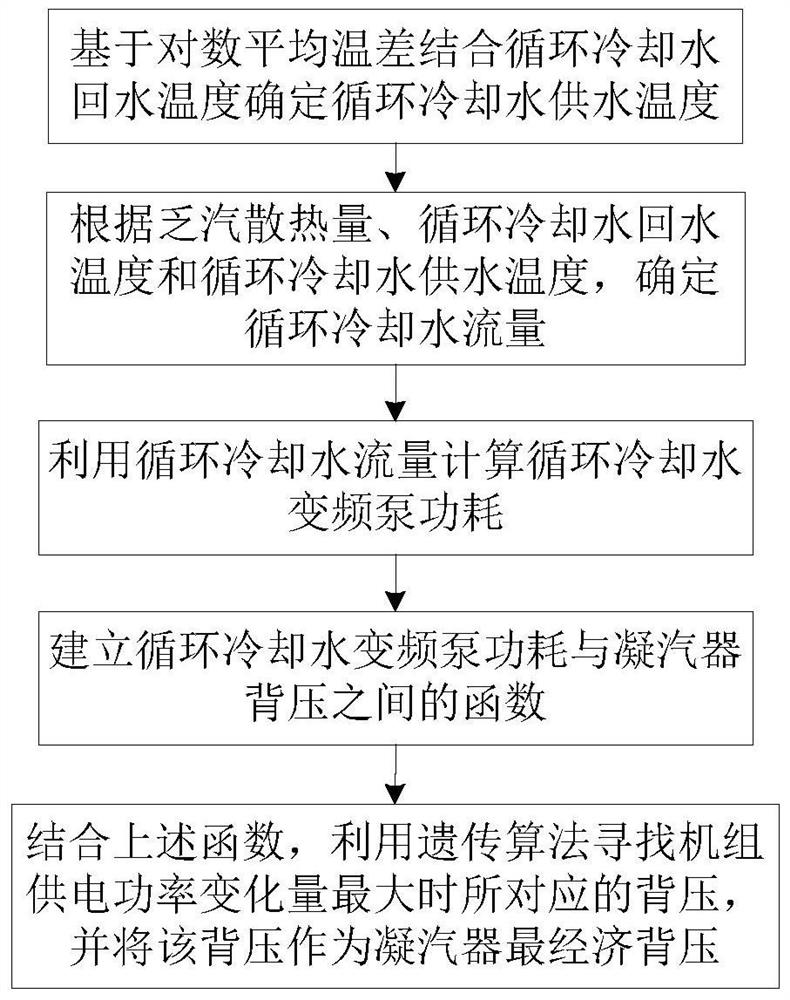

[0052] Specific implementation mode one: combine figure 2This embodiment is specifically described. The method for calculating the economic back pressure of the condenser of the wet cooling unit based on the logarithmic mean temperature difference and the genetic algorithm described in this embodiment is specifically:

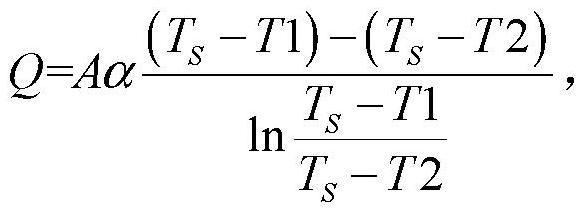

[0053] Firstly, the mechanism model of the condenser is established, which is used to calculate the back pressure p c The corresponding functional relationship between the circulating cooling water variable frequency pump power consumption W:

[0054] 1) Confirm the working environment, select the main steam flow q, and the condenser back pressure p c , Heat transfer area A of the hot and cold ends of the condenser, return temperature T1 of circulating cooling water and heat transfer coefficient α.

[0055] 2) According to the condenser back pressure p c , query the physical property function table of water to obtain the corresponding latent heat of vaporiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com