Absorber

An absorber and absorbing liquid technology, applied in the field of absorbers, can solve problems such as low absorption efficiency, and achieve the effects of improved absorption efficiency, good handling, and reduced heat transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

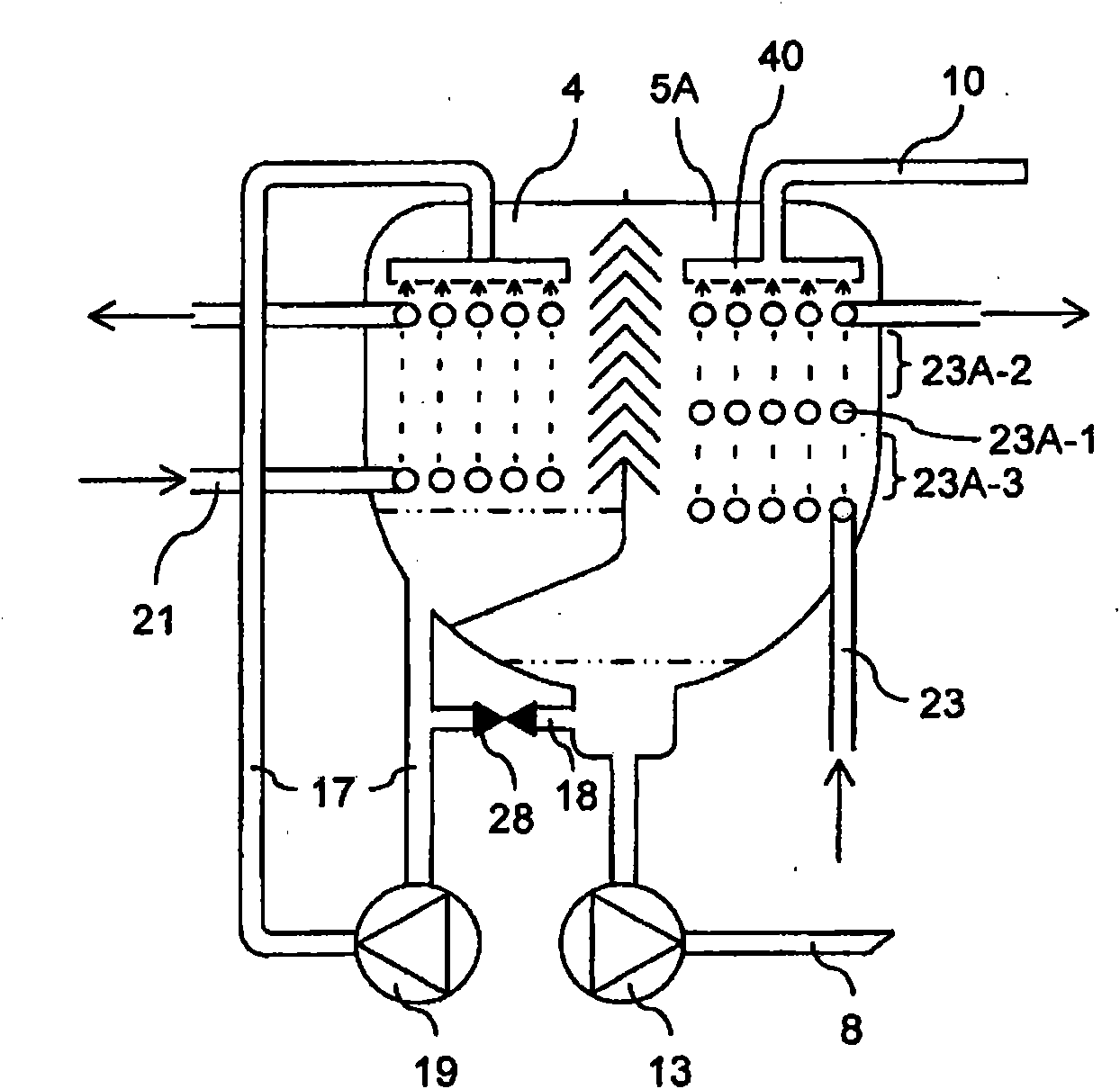

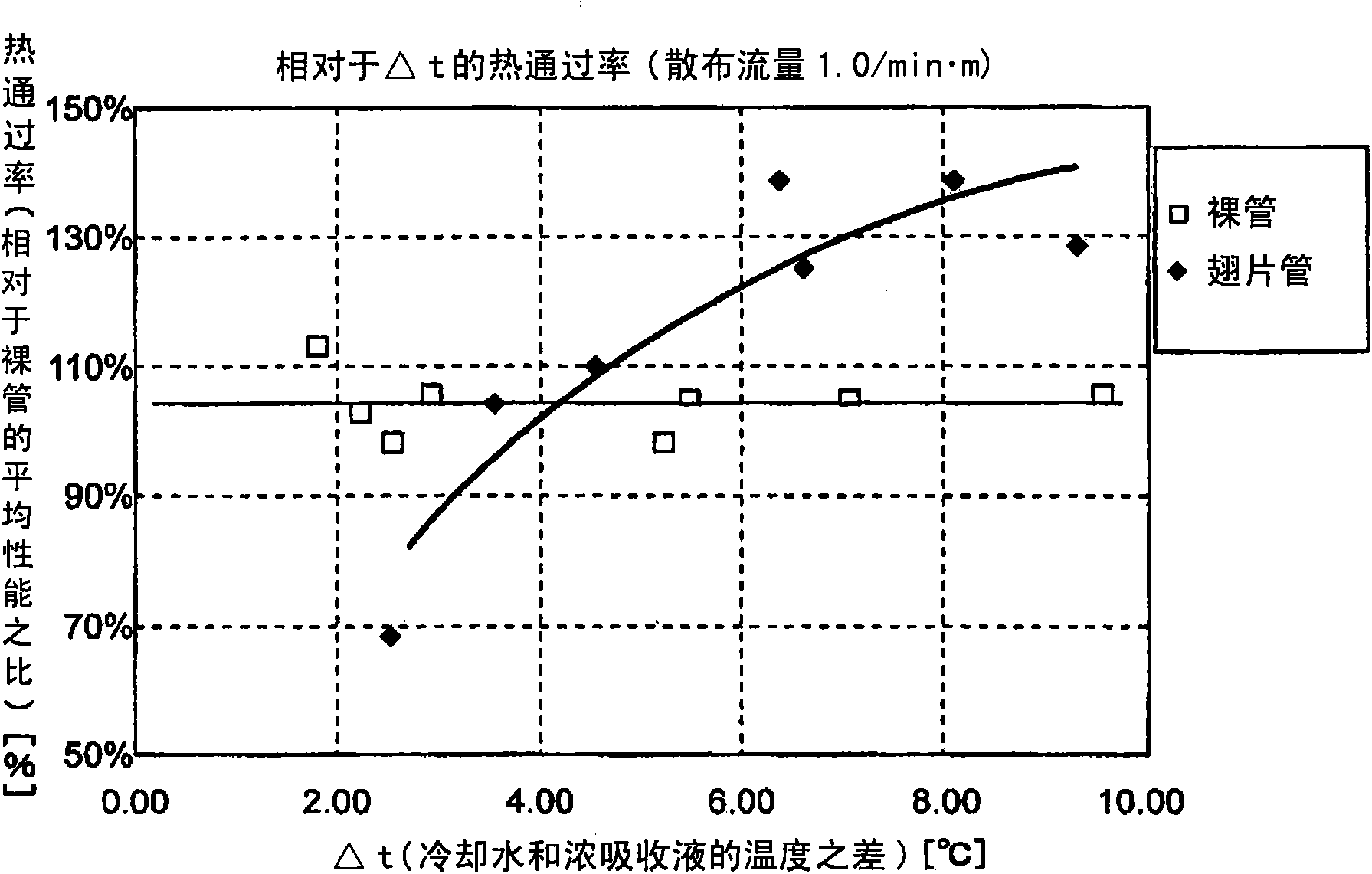

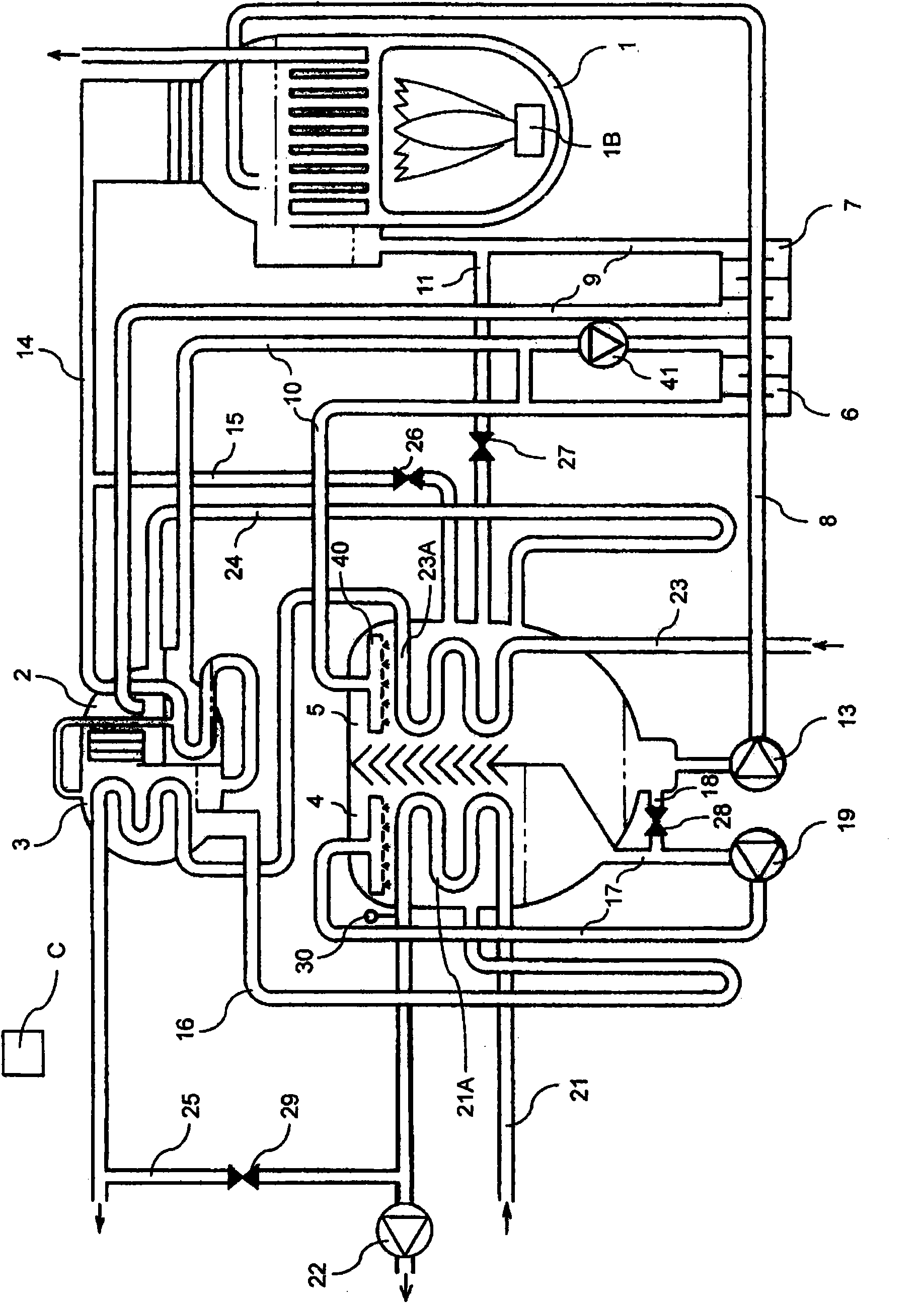

[0086] in possession of figure 1 The structure of the heat pipe shown in the absorber image 3 Among them, the finned heat pipes are used as the 70% of the heat pipes located in the upper part of the full heat pipe in the absorber 5, and the bare heat pipes are used as the remaining 30% of the heat pipes below, which will circulate in the cooling water pipe 23. The temperature of the cooling water is set at 32°C at the inlet of the absorber and at the outlet of the condenser at 37.5°C, and the temperature of the cold and hot water circulated by the hot and cold water pump 22 to the unillustrated cooling / heating load is set at the temperature returned from the load The temperature at the outlet of the evaporator 4 was 12°C and the outlet temperature from the evaporator 4 was 7°C, and the cooling operation was performed. As a result, the result was the same as the case where all the heat transfer tubes installed in the absorber 5 as a comparative example were all bare heat trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com