Adjustable tubular bus fitting

An adjustable and pipe-feed technology, which is applied in the direction of open busbar installation, busbar installation, electrical components, etc., can solve the problems of unable to adjust the installation distance, equipment damage, etc., achieve simple structure, reduce failure rate, and ensure normal operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

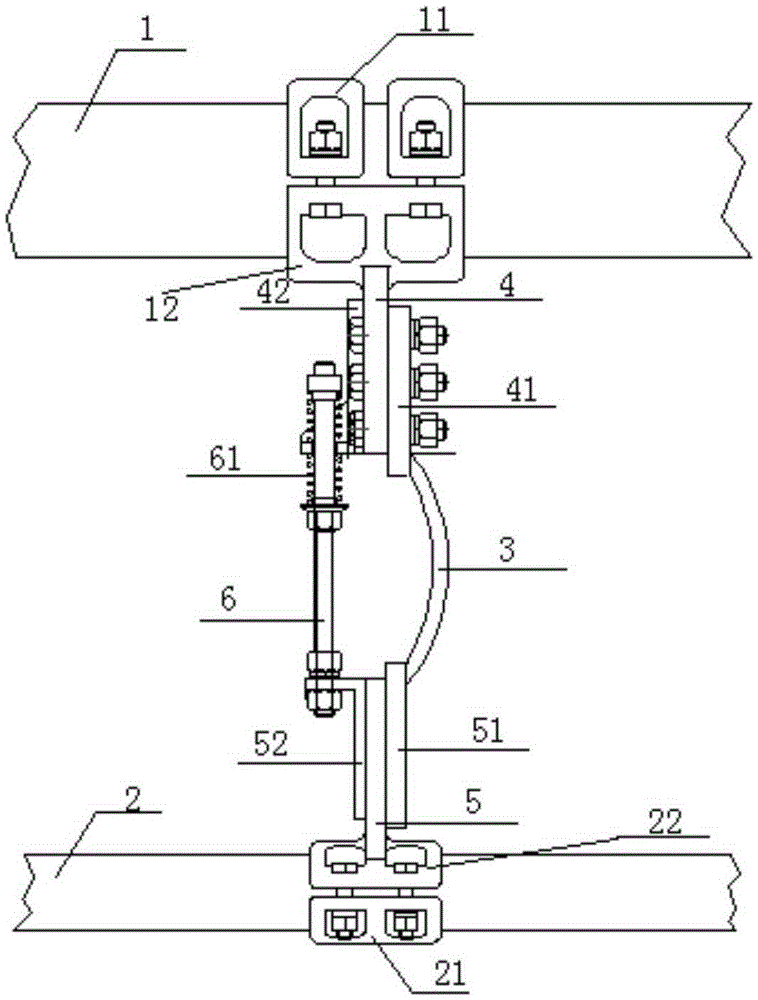

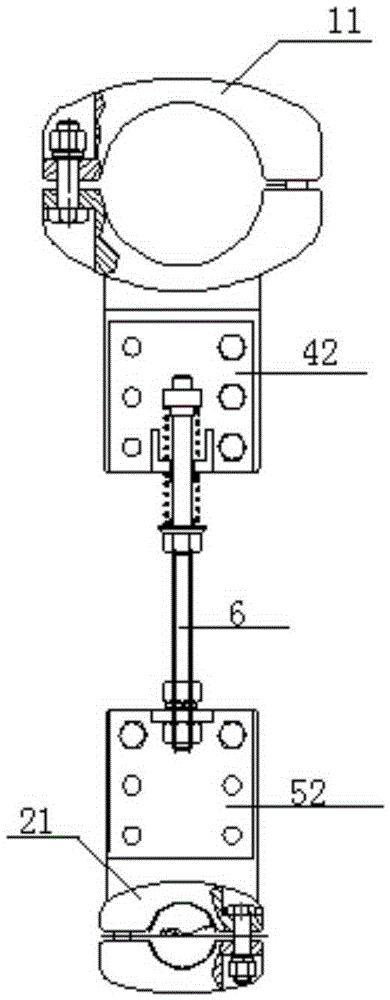

[0031] combine Figure 1-2 , a kind of adjustable pipe bus fittings, including pipe bus clamp, guide rod 6, expansion joint, aluminum section 3, upper splint 4 and lower splint 5, wherein, the upper pipe bus 1 and the lower pipe bus 2 are connected with the pipe bus clamp The two ends of the aluminum section 3 are respectively connected to one side of the expansion joint, and the two ends of the guide rod 6 are respectively connected to the other side of the expansion joint. The aluminum section 3 is made of laminated aluminum sheets with a thickness of 0.5mm. Can be bent into an arc. For example, when the ampacity is 1000A, the aluminum section 3 is formed by stacking 20 aluminum sheets with a thickness of 0.5mm; when the ampacity is 2000A, the aluminum section 3 is formed by laminating 40 aluminum sheets with a thickness of 0.5mm. When the distance between the pipe busbars is long, the aluminum section 3 can be straightened to increase the length of the aluminum section 3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com