Method for cleaning optical glass

An optical glass and glass technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning flexible objects, etc., can solve the problems of optical glass damage, affecting the life of optical glass, affecting the optical performance and light transmittance of optical glass, etc. To achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

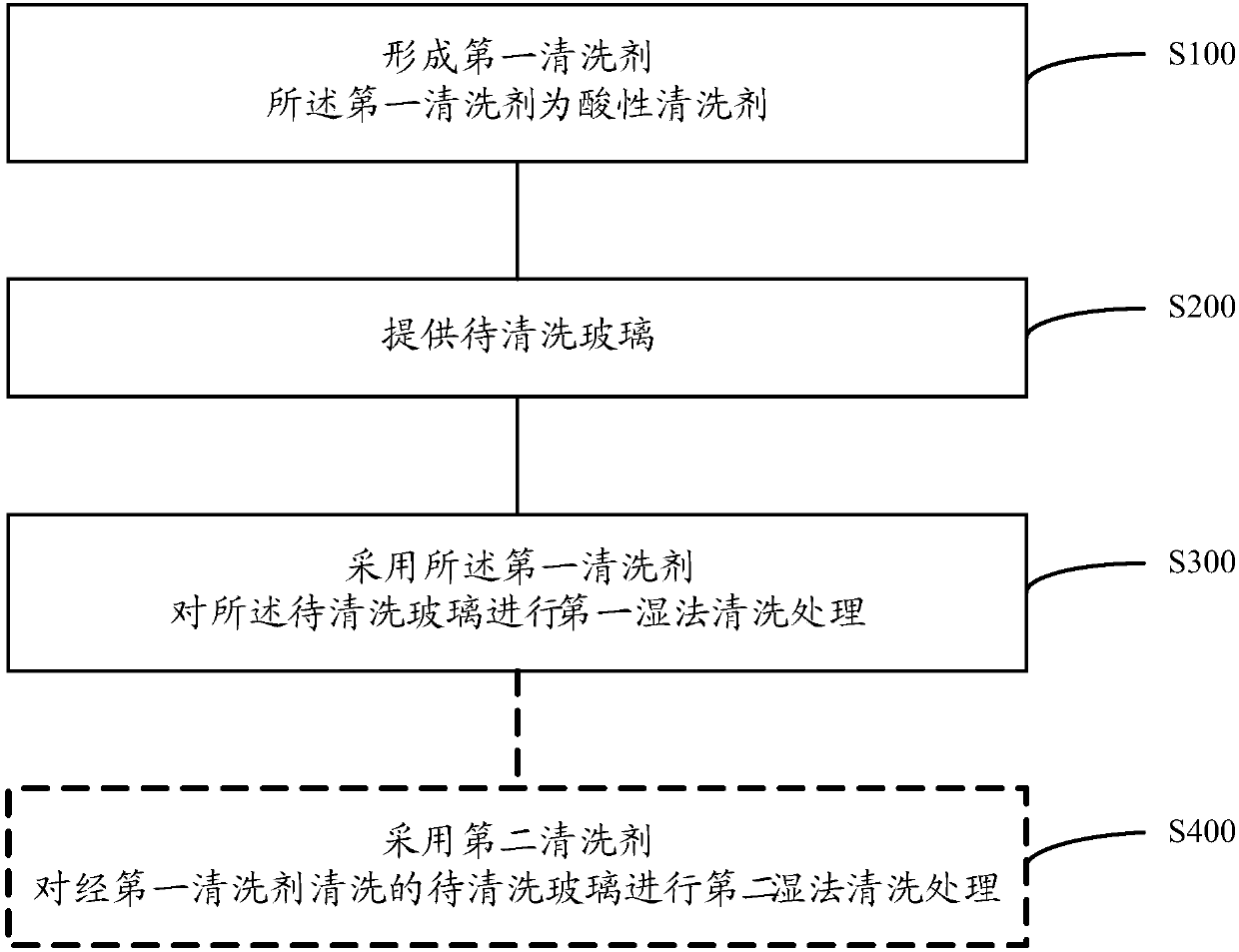

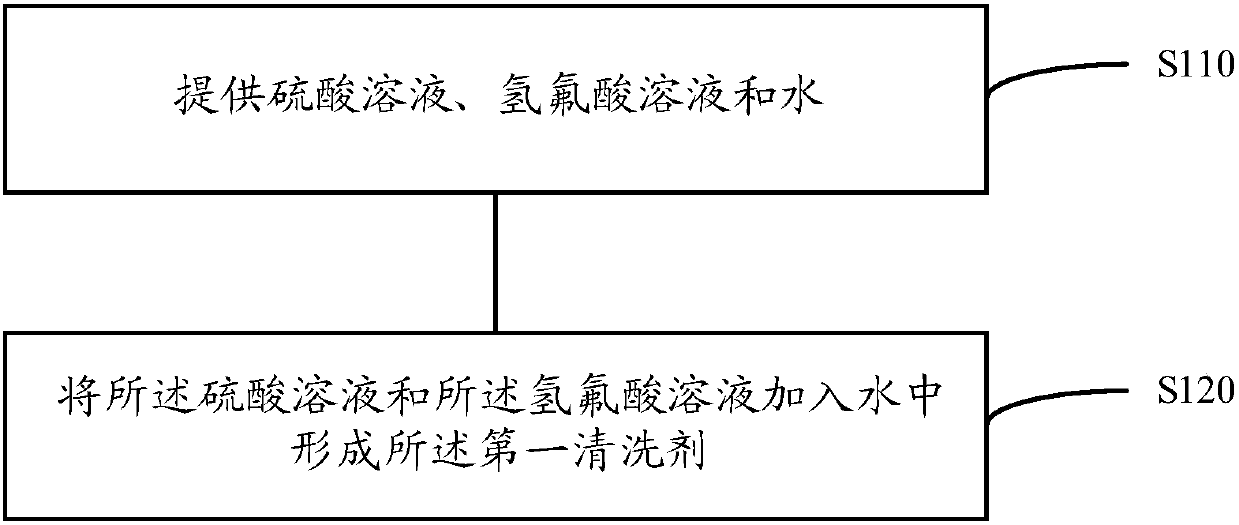

Method used

Image

Examples

Embodiment Construction

[0026] It can be known from the background art that the cleaning method of optical glass in the prior art has the problem of causing damage to the glass. Now combined with a cleaning method of optical glass to analyze the cause of its damage:

[0027] The shape of metal impurities is relatively stable, and it is difficult to remove them by general cleaning methods. Therefore, in the prior art, the dry method of scraping with sandpaper is often used to remove the volatile matter. However, the method of removing volatiles by scraping with sandpaper often causes damage to the surface of the optical glass, leaving scratches on the surface of the optical glass, which will affect the optical performance of the optical glass.

[0028] In addition, sandpaper scratches will also increase the surface roughness of the optical glass, thereby enhancing the surface adsorption capacity of the optical glass, resulting in the re-formation of impurities on the surface of the optical glass duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com