A semitransparent perovskite solar cell and a preparation method thereof

A solar cell and perovskite technology, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve problems that hinder the development and utilization of semi-transparent perovskite solar cells, and achieve transparency easily, increase transmittance, The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

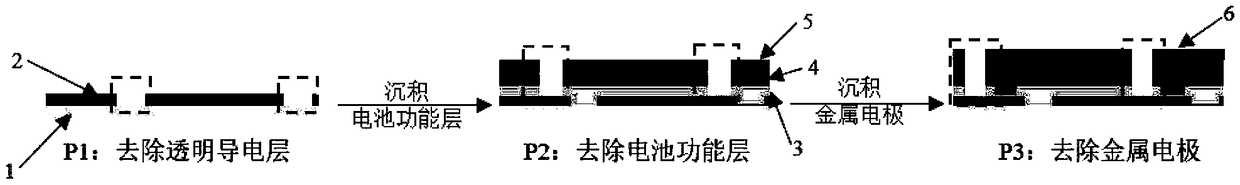

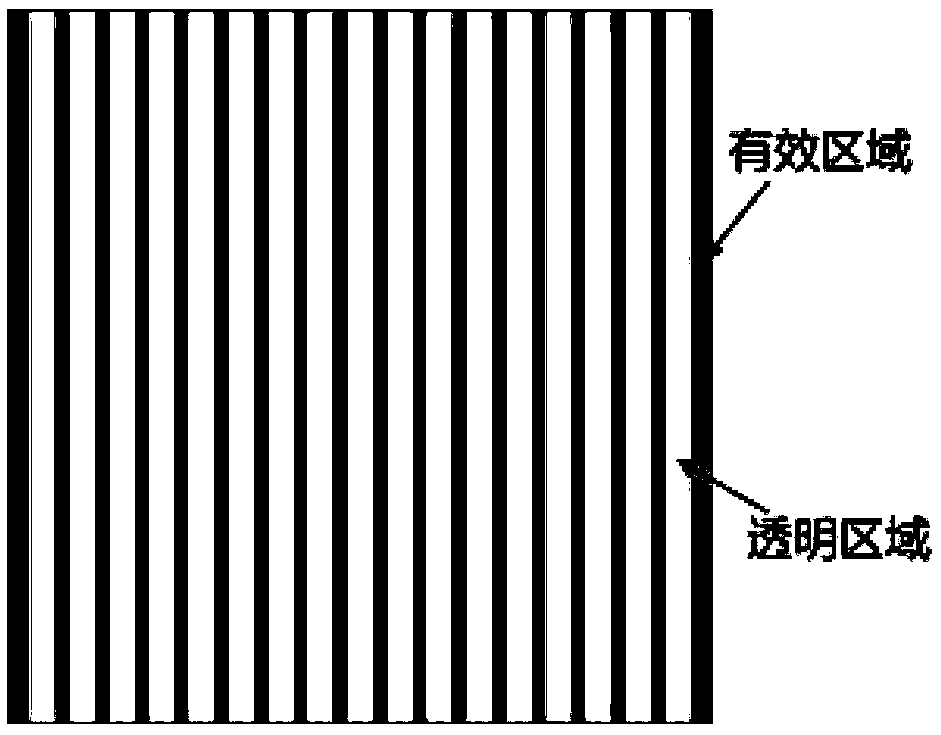

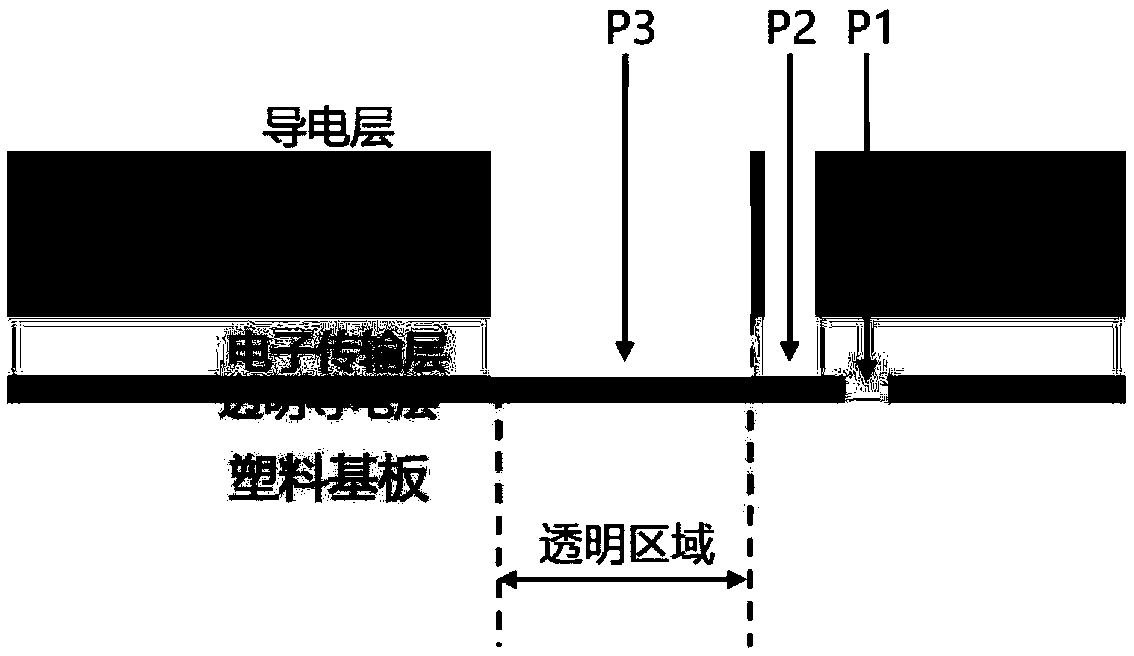

[0026] Such as figure 1 Shown, a kind of preparation method of translucent perovskite solar cell comprises the steps:

[0027] (1) Utilize an ultrafast laser to draw a line on a 5cm*5cm glass substrate containing an ITO transparent conductive layer, and cut the transparent conductive layer (P1). The tangent distance is 0.5mm, and the width of a single small battery is 0.5mm. The tangent processing parameters are: picosecond mode, repetition frequency of 200k Hz, laser power of 15W, galvanometer scanning speed of 1000mm / s, etching line width of 30μm; the substrate is cleaned after cutting;

[0028] (2) Scrape-coating a layer of tin oxide electron transport layer by Slot-die on the cleaned substrate;

[0029] (3) spin-coating perovskite and spiro-OMeTAD hole transport layer on the tin oxide electron transport layer;

[0030] (4) The functional layer (electron transport layer, perovskite light-absorbing layer and hole transport layer) is cut by ultrafast laser, but the transpar...

Embodiment 2

[0036] Such as figure 1 Shown, a kind of preparation method of translucent perovskite solar cell comprises the steps:

[0037] (1) Scribe a 10cm*10cm glass substrate containing an FTO transparent conductive layer with an ultrafast laser, and cut the transparent conductive layer (P1). The tangent distance is 0.4mm, and the width of a single small battery is 0.4mm. The tangent processing parameters are: picosecond mode, repetition frequency of 500k Hz, laser power of 14W, galvanometer scanning speed of 900mm / s, etching line width of 30μm; the substrate is cleaned after cutting;

[0038] (2) preparing a layer of tin oxide electron transport layer by chemical bath deposition on the cleaned substrate;

[0039] (3) Spin-coat perovskite light-absorbing layer and spiro-OMeTAD hole-transporting layer on the tin oxide electron-transporting layer;

[0040] (4) The functional layer (electron transport layer, perovskite light-absorbing layer and hole transport layer) is cut by ultrafast ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com