Non-transparent film with controllable and reversible transparency and preparation method thereof

A transparent film and transparency technology, applied in the field of material engineering, can solve the problems of unchangeable transparency and poor toughness of PMMA, and achieve the effect of avoiding high cost and pollution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

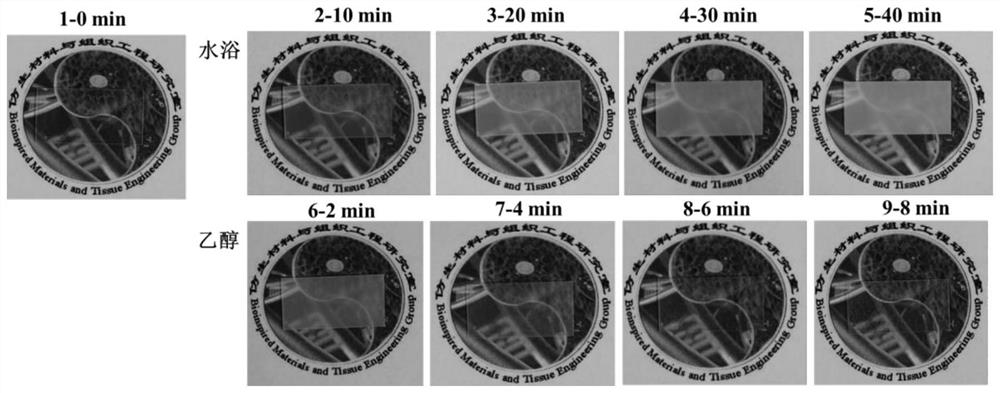

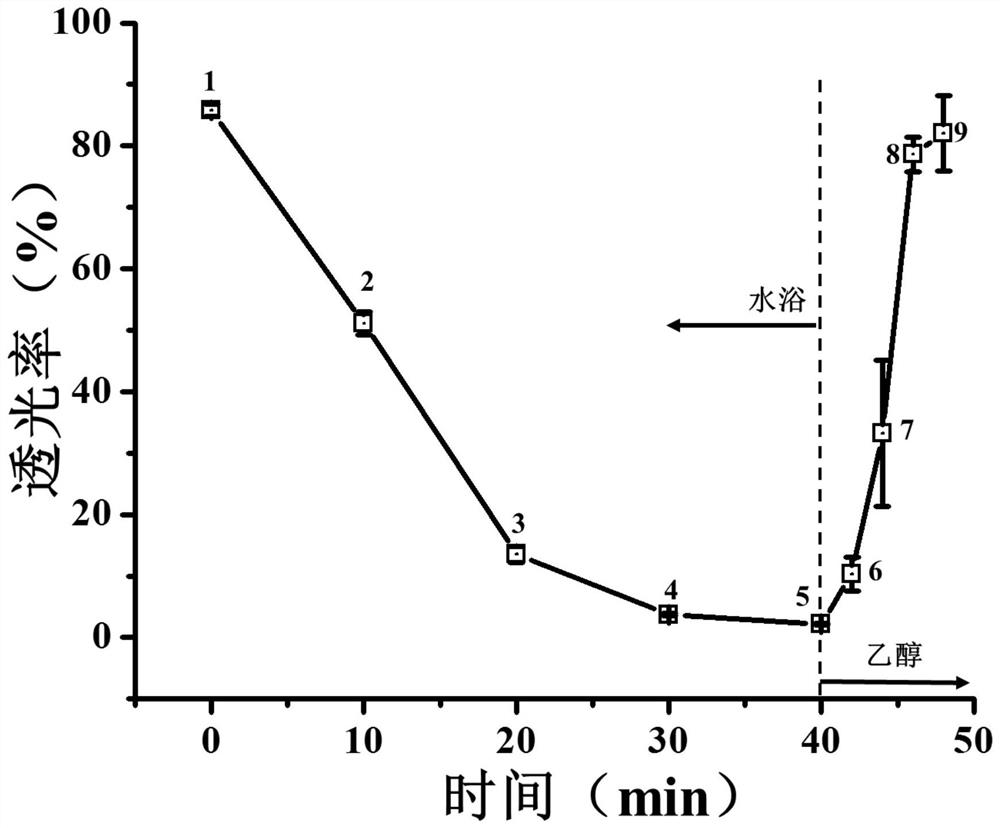

[0022] Take PMMA and PMAA by mass ratio 1:1, dissolve with 10mL acetone, its configuration concentration is 0.2g / mL, stir for 24 hours, inject the solution in the 2mL mold, treat that acetone volatilizes completely, prepare into PMMA / PMAA film (the The physical picture of the membrane is figure 1 In the picture corresponding to 1-0min, the transmittance is 86%, corresponding to figure 2 point in 1).

Embodiment 2

[0024] The PMMA / PMAA film that embodiment 1 obtains is immersed in water, and 50 ℃ of water-baths, heat 10min, obtain the opaque film (the physical figure of this film is that light transmittance is about 51%) figure 1 The picture corresponding to 2-10min in the middle, corresponding to figure 2 point 2).

Embodiment 3

[0026] The PMMA / PMAA film that embodiment 1 obtains is immersed in water, 50 ℃ of water-baths, heat 20min, obtain the opaque film (the physical figure of this film is that light transmittance is about 13%) figure 1 3-20min in the middle, corresponding to figure 2 in point 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com