Patents

Literature

127results about How to "Lower return water temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

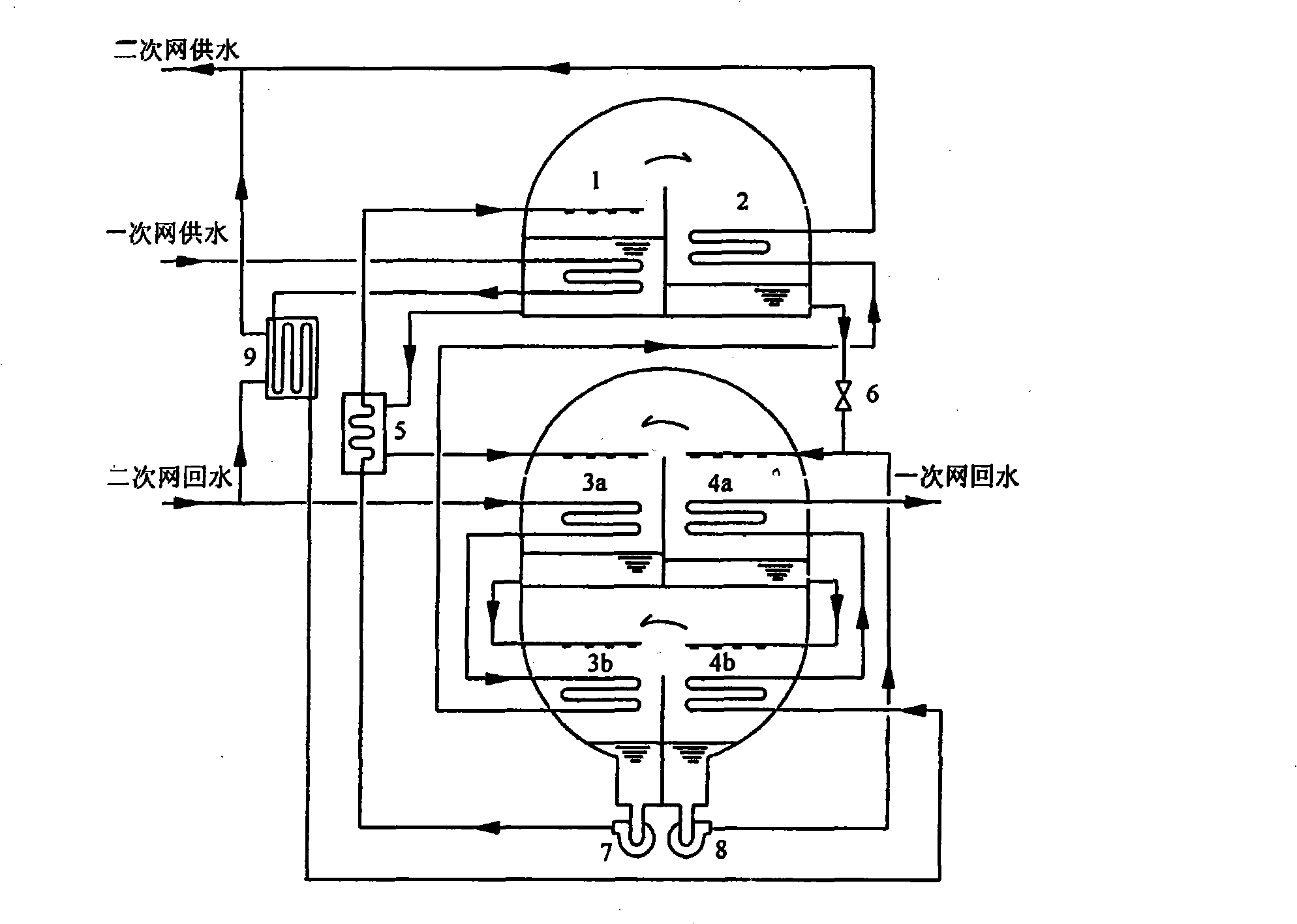

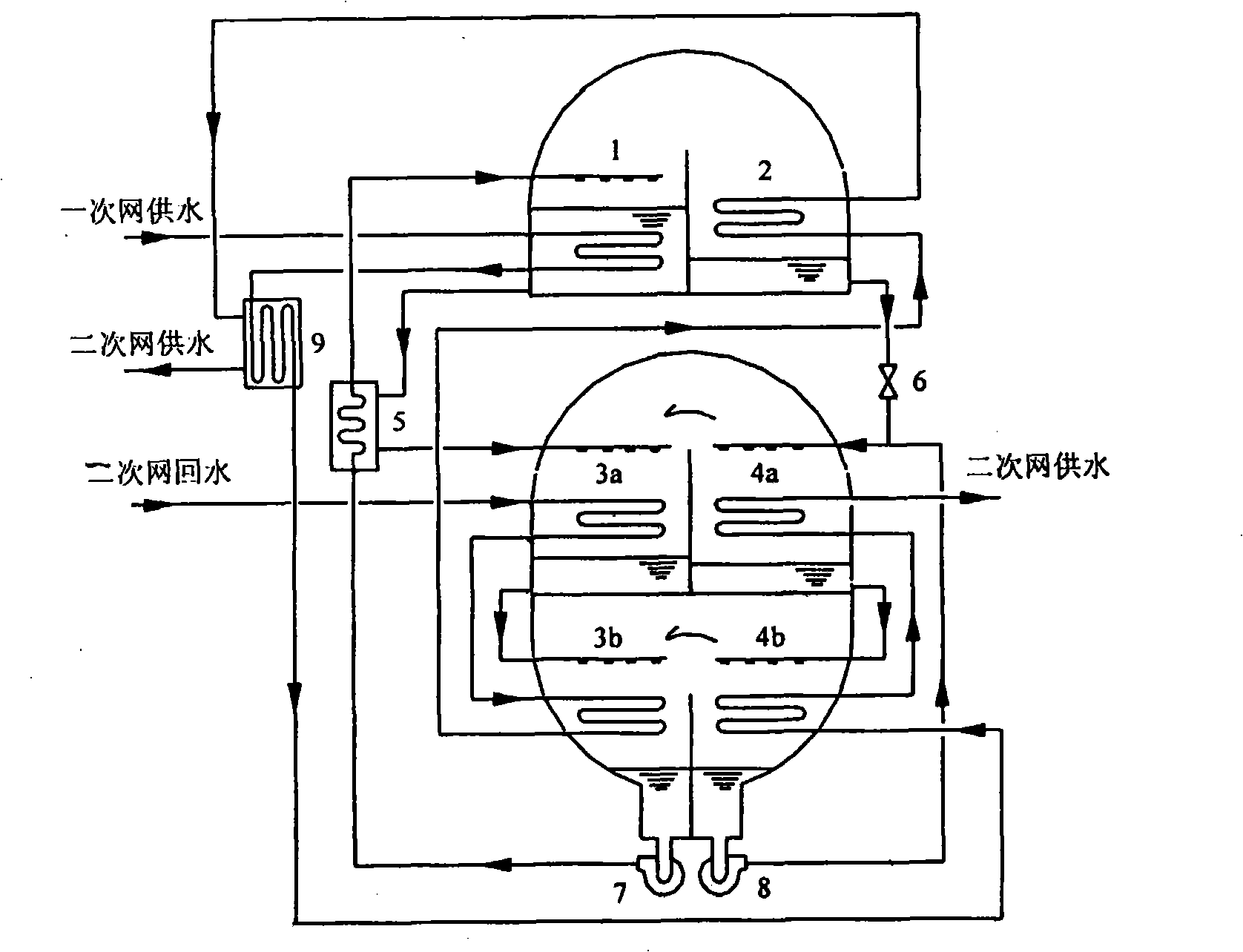

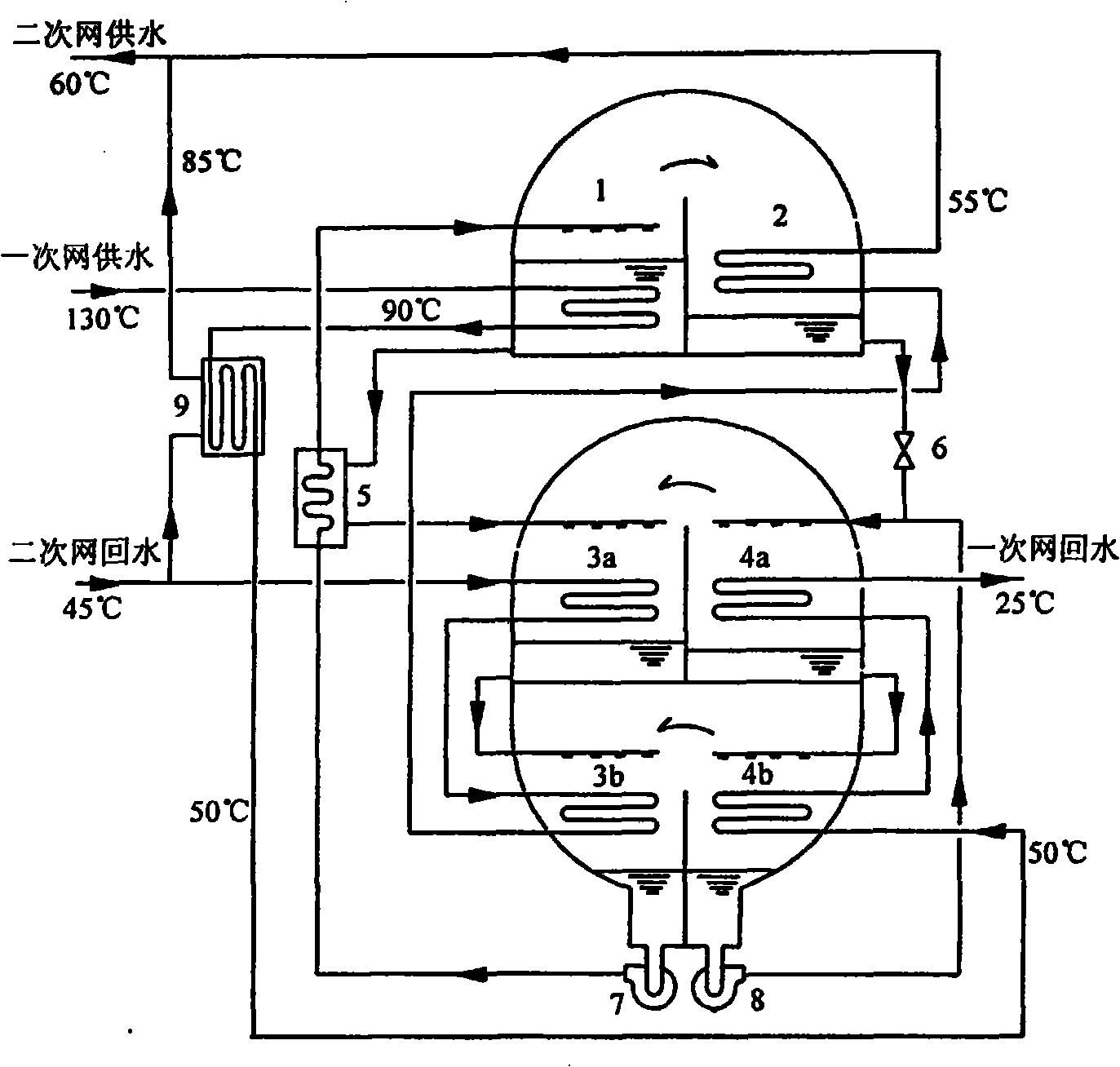

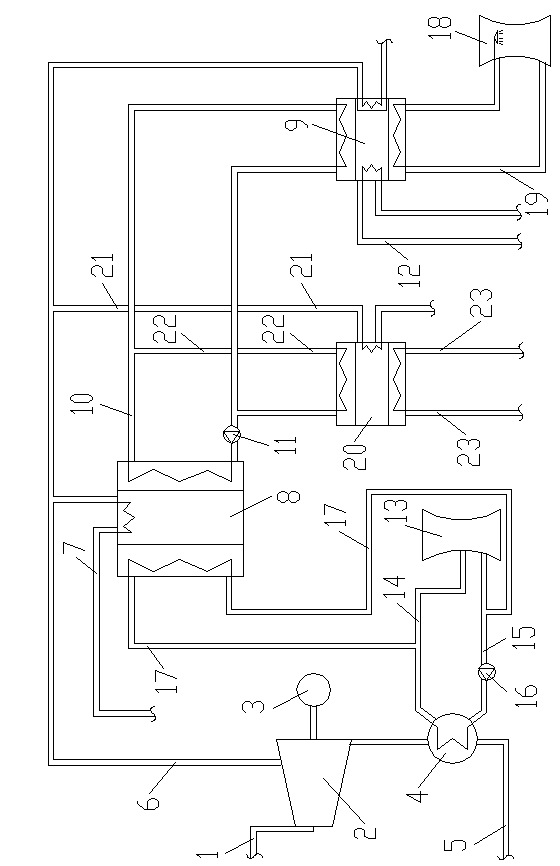

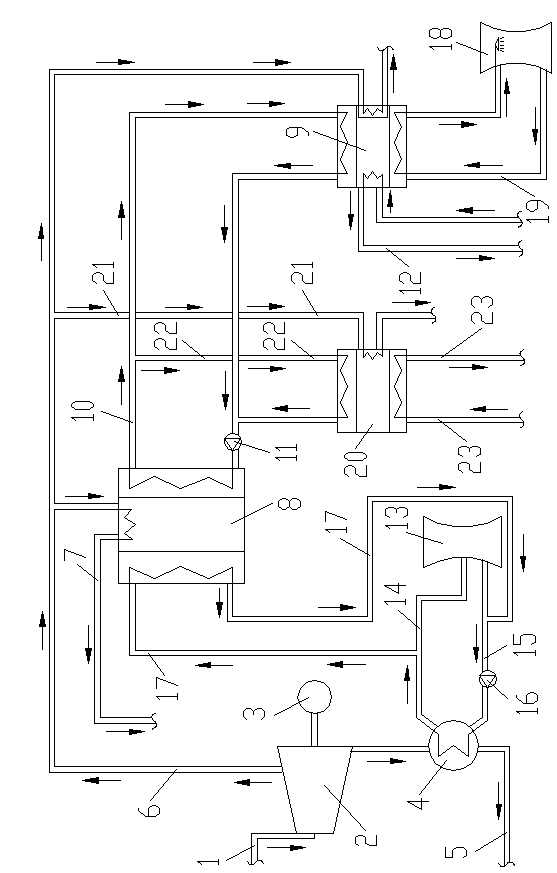

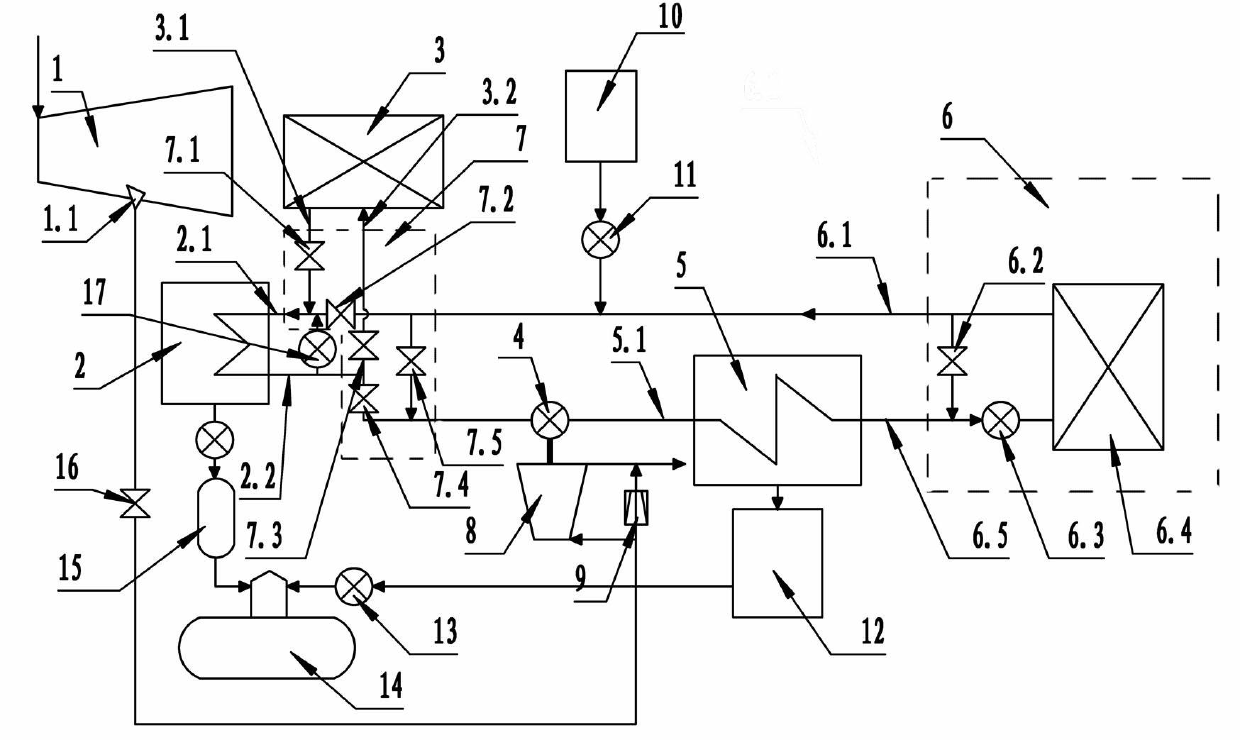

Integral type absorption type heat exchange machine unit

ActiveCN101329117ALower return water temperatureReduce initial investmentHeat pumpsClimate change adaptationThermal energyEvaporation

The invention relates to an integrated absorption heat-exchanging unit, belonging to the field of the heating and hot water supply devices and comprising a hot-water absorption heat-exchanger and a normal water-water heat exchanger which are combined, wherein, the hot-water absorption heat-exchanger adopts the means of two-level evaporation and two-level absorption. The unit comprises a generator, a condenser, a low-pressure absorber, a high-pressure absorber, a low-pressure evaporator, a high-pressure evaporator, a solution heat exchanger, a throttle device, a solution pump, a water-water heat exchanger and various connecting pipes and accessories. The invention can effectively reduce the backwater temperature of a first-time network of a collective heating system, thus greatly raising the temperature difference of between hot water supply and backwater of the first-time network, further greatly reducing the initial investment to the pipeline system and the power cost of the pump running, creating conditions for utilizing the low-quality heat energy even waste heat, etc., enhancing the comprehensive energy utilization efficiency of the system and reducing the heat supply cost.

Owner:北京华源泰盟节能设备有限公司

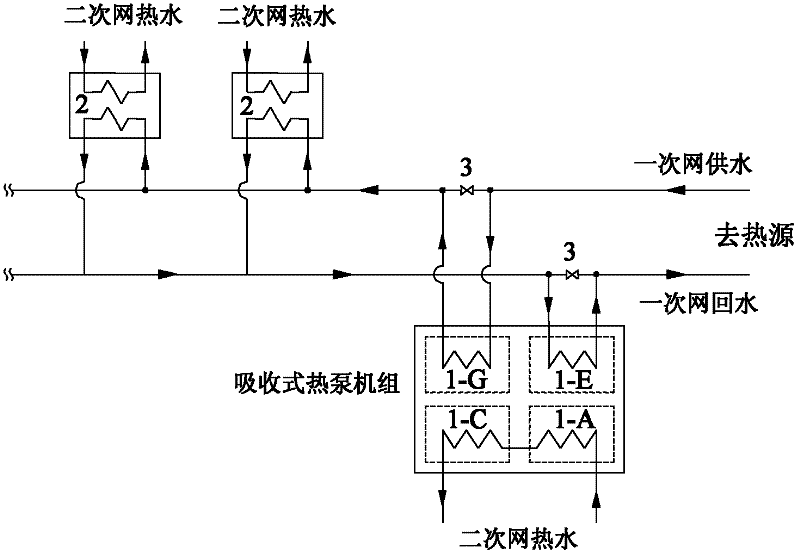

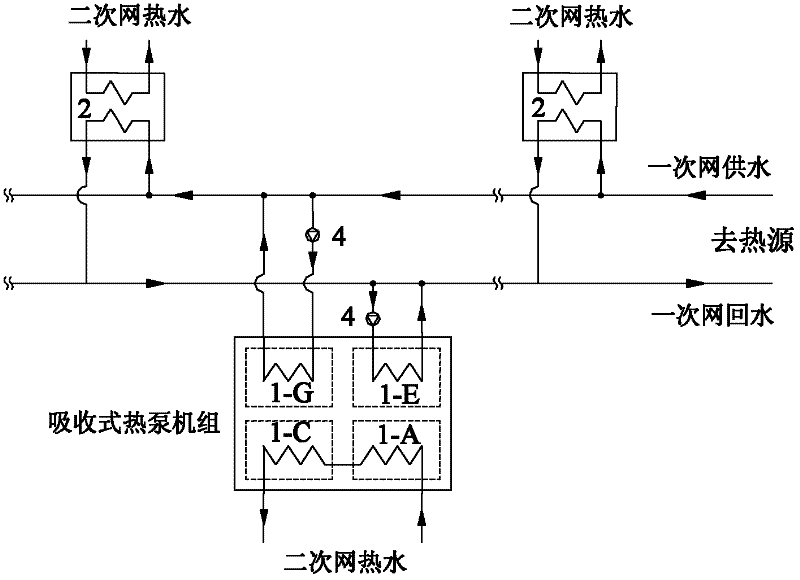

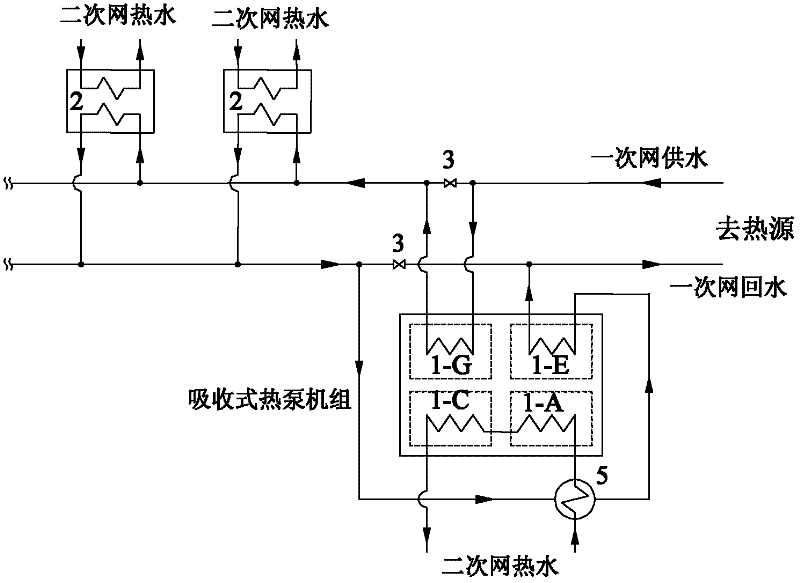

A heating system that uses heat pump technology to improve the heating capacity of central heating pipe networks

ActiveCN102269442ALower return water temperatureWater supply realizationLighting and heating apparatusEnergy efficient heating/coolingNet returnEngineering

The invention discloses a heating system utilizing a heat pump technology to improve the heat capacity of a central heating pipe network and belongs to the field of central heating. The heating system provided by the invention comprises the central heating pipe network, wherein the central heating pipe network is divided into a primary net and a secondary net; the heating system also comprises anabsorption heat pump set, a primary net water supply pipeline is connected with the generator of the absorption heat pump set by virtue of a pipeline, and the primary water supply is taken as the driving heat source of the absorption heat pump; a primary net return pipe is connected with the evaporator of the absorption heat pump set by virtue of a pipeline, and a primary net backwater is taken as the lower-temperature heat source of the absorption heat pump set; and a secondary net backwater enters into the absorber and condenser of the absorption heat pump set in turn so as to be heated, warmed and then output as a secondary water supply. The heating system provided by the invention has the advantages of further increasing the temperature difference of the water supply and backwater of the primary net, and improving the heat transfer capability of the heating pipe net.

Owner:TSINGHUA UNIV +1

Novel low-temperature combined cooling, heating and power (CCHP) system based on heat pump

ActiveCN103075841AIncrease profitSimple structureClimate change adaptationHeating and refrigeration combinationsThermal energyCooling tower

The invention relates to a novel low-temperature combined cooling, heating and power (CCHP) system based on a heat pump. Currently, no novel low-temperature CCHP system based on the heat pump with a simple structure and a reasonable design exists. The novel low-temperature CCHP system based on the heat pump comprises a high-pressure steam pipe, a steam turbine, a power generator, a condenser and a boiler connecting pipe, and is characterized by also consisting of a heating low-pressure steam pipe, a heating condensate pipe, a power plant after-heat single-effect heat pump unit, a refrigeration single-effect absorbing heat pump unit, a heat pump unit loop pipe, a loop circulating pump, a user refrigeration pipe, a cooling tower, a cooling tower water inlet pipe, a cooling tower water outlet pipe, a cooling water circulating pump, a power plant circulating cooling water pipe, a heat pump cooling tower, a cooling tower circulating pipe, a heating single-effect absorbing heat pump unit, a heating heating pipe, a heat pump circulating pipe and a user heating pipe; the heating low-pressure steam pipe is connected with the refrigeration single-effect absorbing heat pump unit; and the heating condensate pipe is connected with the power plant after-heat single-effect heat pump unit. The novel low-temperature CCHP system based on the heat pump has the advantages of reasonable structural design, energy saving, environmental friendliness and high heat utilization rate.

Owner:杭州全能星科技有限公司

300MW-capacity-level low vacuum heat supply steam turbine system and adjusting method thereof

InactiveCN103016082ASolve the problem that low vacuum heating cannot be performedLarge adjustment rangeSteam useEnergy industryEngineeringLow vacuum

The invention belongs to the technical field of thermoelectricity, and relates to a 300MW-capacity-level low vacuum heat supply steam turbine system and an adjusting method thereof. The system consists of a 300MW-capacity-level low vacuum heat supply steam turbine generator set and a power plant cold end and heat supply load coupling adjusting system. A steam turbine high-pressure cylinder, a steam turbine medium-pressure cylinder, a steam turbine low-pressure cylinder I, a steam turbine low-pressure cylinder II and a generator are uniaxially arranged in the steam turbine generator set. In the heating period, the back pressure of the two low-pressure cylinders rises, and a steam turbine set runs under low vacuum; steam is uniformly divided into two strands when entering a communicating pipe at the front of the two low-pressure cylinders, so that the flow of each low-pressure cylinder is half the flow of the low-pressure cylinder of the 300MW-capacity-level steam turbine in the prior art, and the flow is greatly reduced; the length of the last-stage blade is shortened, the adjusting range of back pressure is expanded, and the safety of the system is improved; and in the non-heating period, the steam turbine set runs under the straight condensing condition. The invention is applicable for a 300MW-capacity-level combined heat and power steam turbine set to implement low vacuum heat supply.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

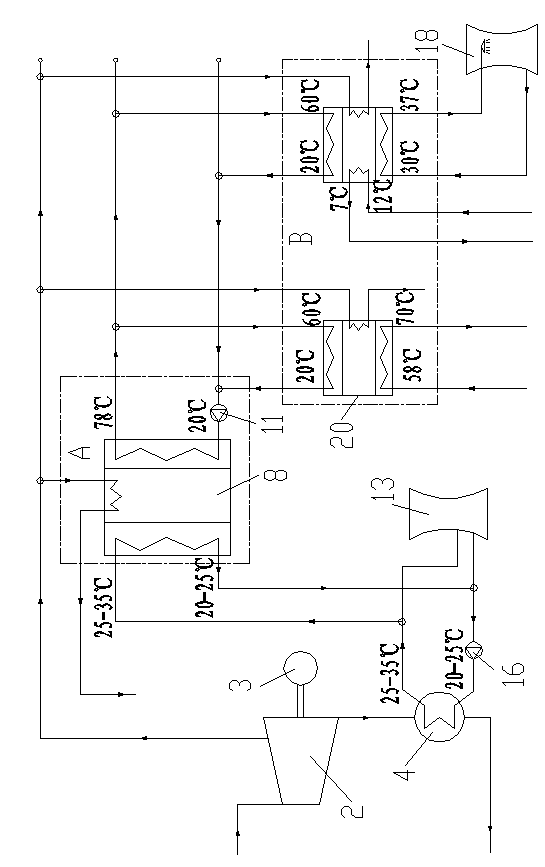

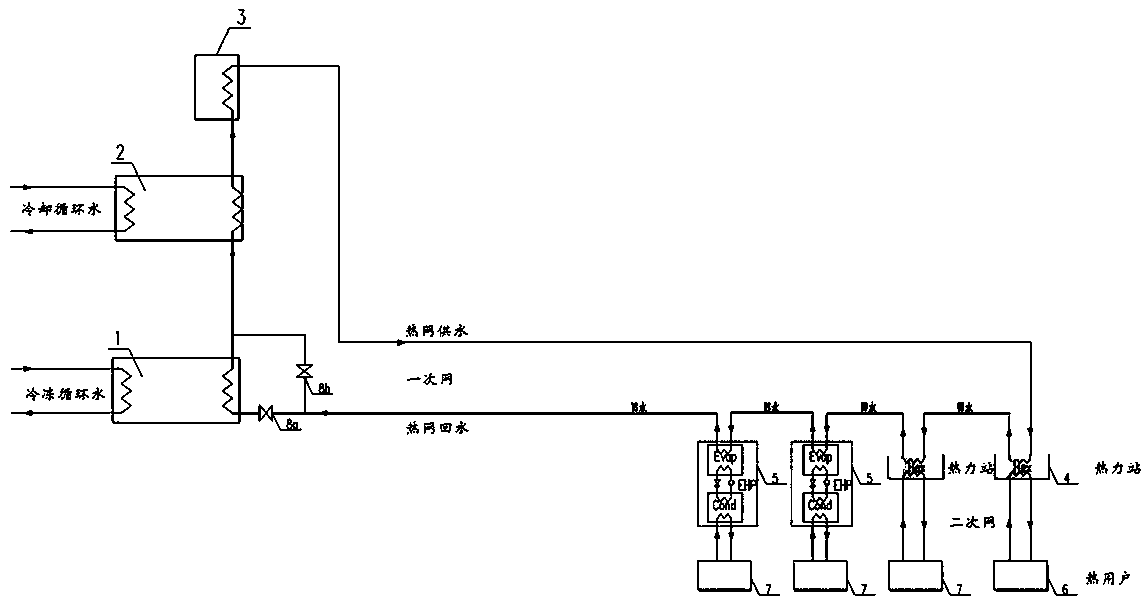

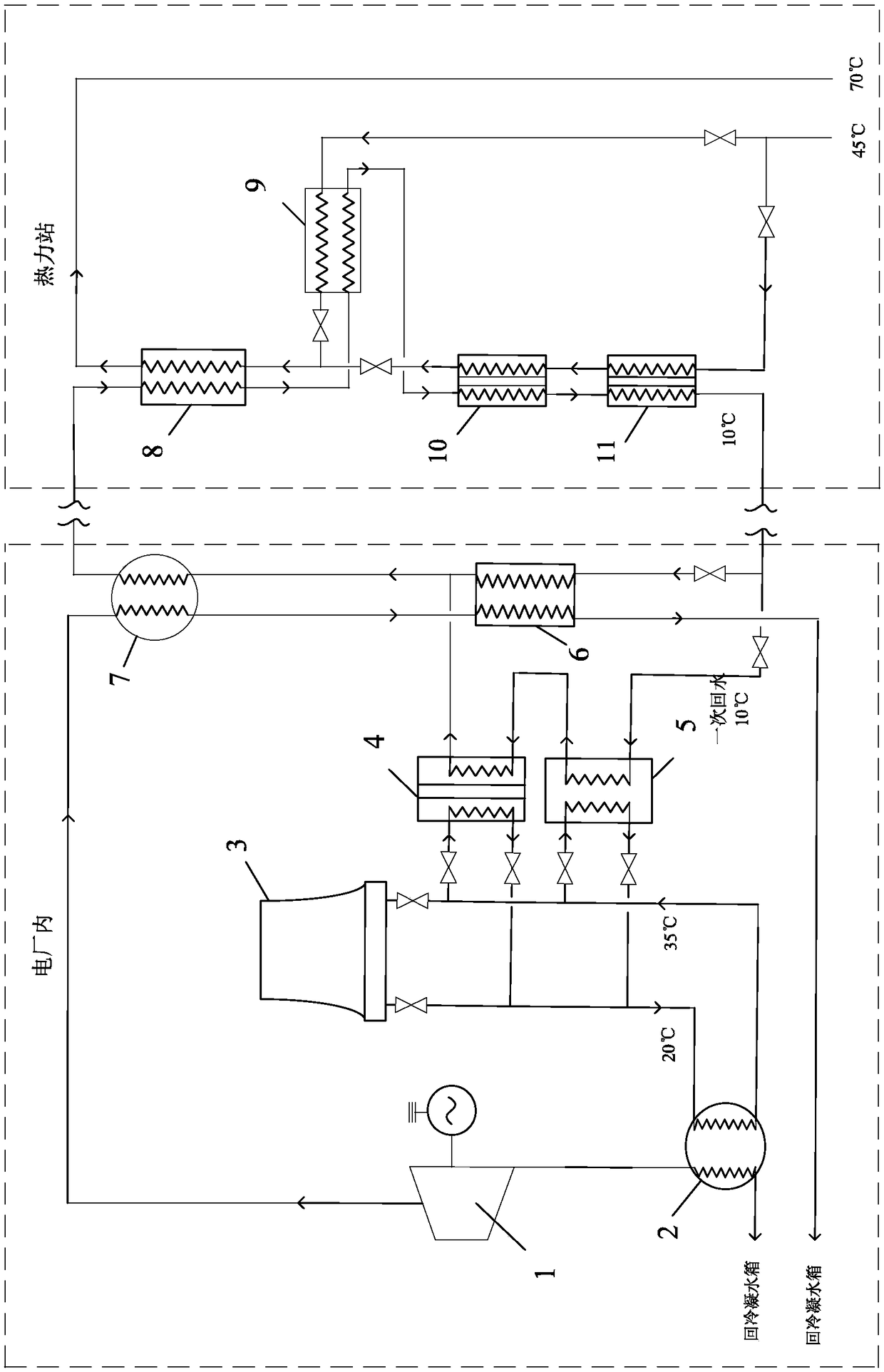

A central heating system with low temperature return water

InactiveCN102297467ALower return water temperatureImprove delivery capacityLighting and heating apparatusEnergy efficient heating/coolingNet returnEngineering

The invention discloses a low-temperature return water central heating system belonging to the field of central heating. The technical solution is to set up heat pump heat exchange units in each thermal station of the heat network to reduce the return water temperature of the primary network hot water, and first introduce the low-temperature primary network return water into the condenser in the power plant, and use the steam turbine exhaust Steam heating. The main features of the present invention are reflected in two aspects: first, a heat pump type heat exchange unit is installed in the heating network thermal station, which further reduces the return water temperature of the primary network compared with the conventional centralized heating mode, so that the hot water supply of the primary network 1. The temperature difference of the return water is further increased, which improves the transmission capacity of the heat network, and the low-temperature return water provides the possibility of recovering the exhaust heat of the steam turbine in the power plant; The heat supply capacity of the power plant is improved by reducing the exhaust heat of the steam turbine.

Owner:TSINGHUA UNIV +1

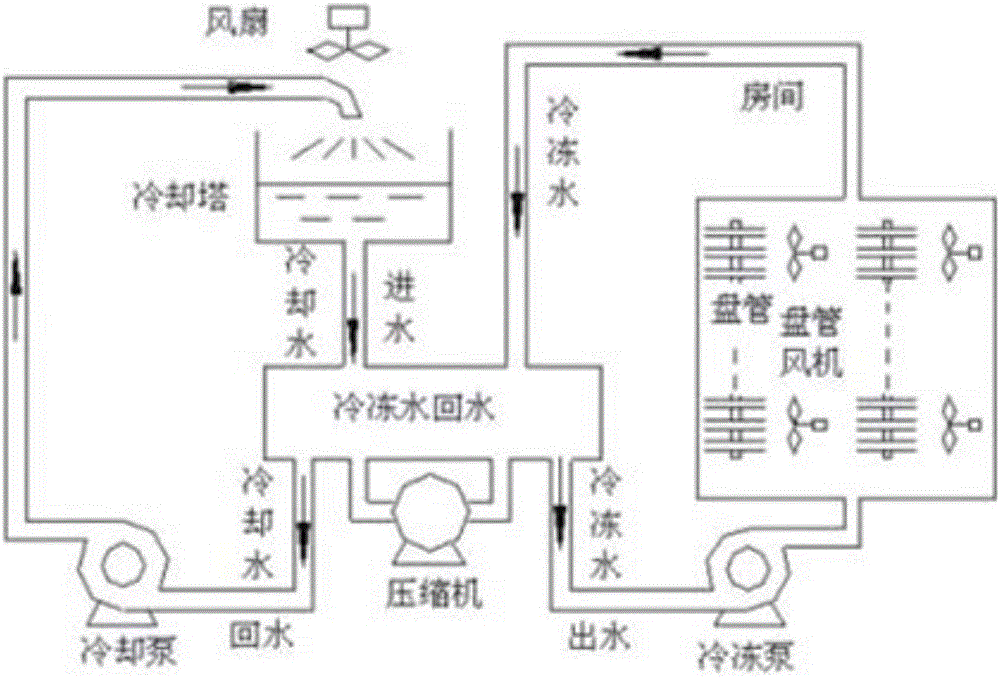

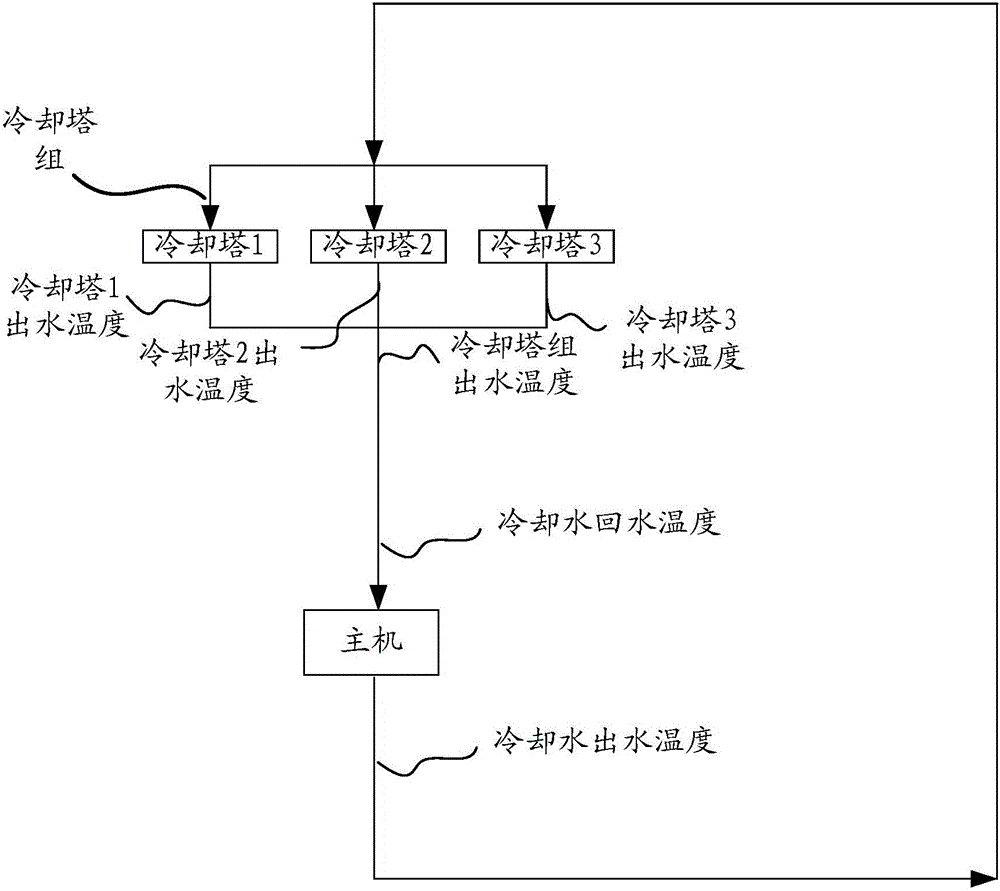

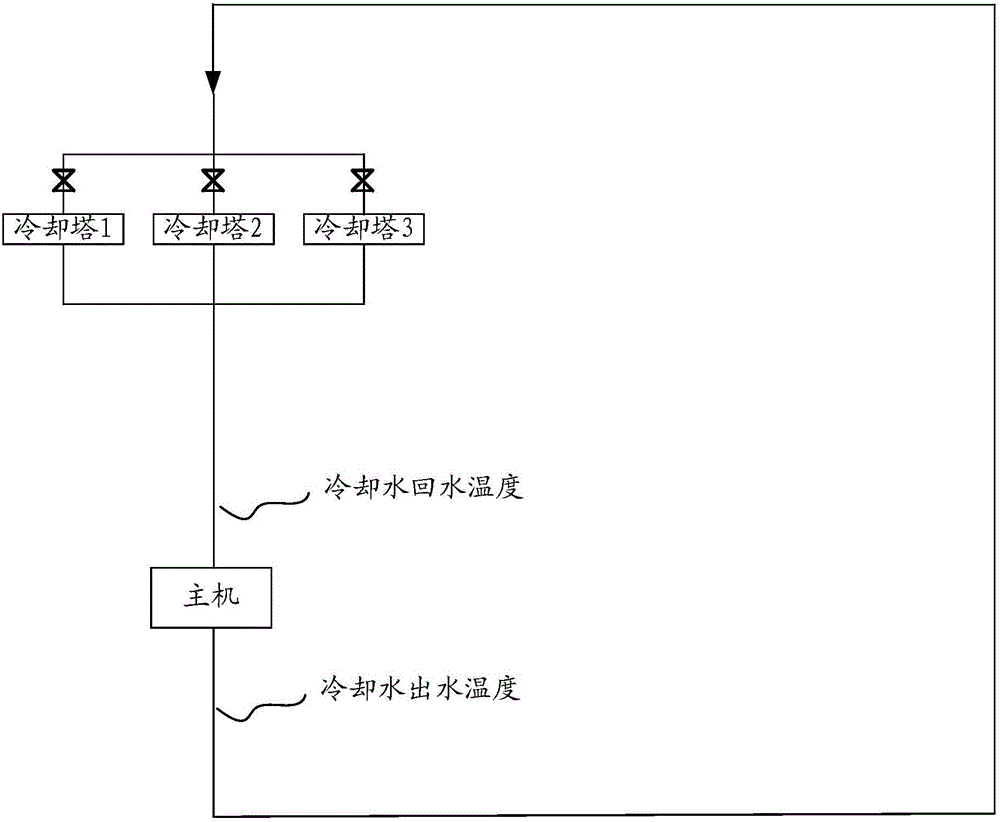

Air conditioner cooling water system control method and device

ActiveCN106123215ALower return water temperatureImprove cooling efficiencyMechanical apparatusSpace heating and ventilation safety systemsCooling towerTemperature difference

The invention relates to the technical field of air conditioner system control, in particular to an air conditioner cooling water system control method and device. The control method comprises the steps that the current cooling water return temperature is obtained, and the current outdoor wet bulb temperature is determined in an air conditioner cooling water system; and a first cooling tower is started according to the preset optimization sequence if the temperature difference between the current cooling water return temperature and the current outdoor wet bulb temperature is larger than a first temperature different threshold value and at least one un-started cooling tower exists, specifically, the first cooling tower is the cooling tower highest in cooling efficiency among the un-started cooling towers in the preset optimization sequence. According to the method, when the cooling tower needs to be started, the un-started cooling tower highest in cooling efficiency is selected to be started according to the preset optimization sequence, the cooling water return temperature can be lowered rapidly, and the cooling efficiency is improved; and in addition, by starting the cooling tower according to the strategy, the effect that preset control conditions can be met by starting a few cooling towers can be achieved, and therefore the system resources are saved.

Owner:石家庄新奥能源发展有限公司

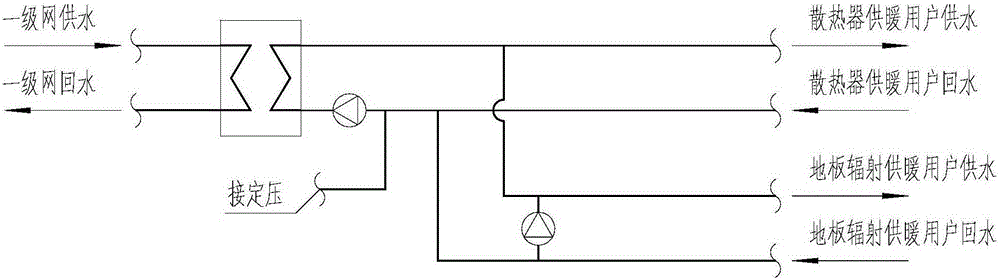

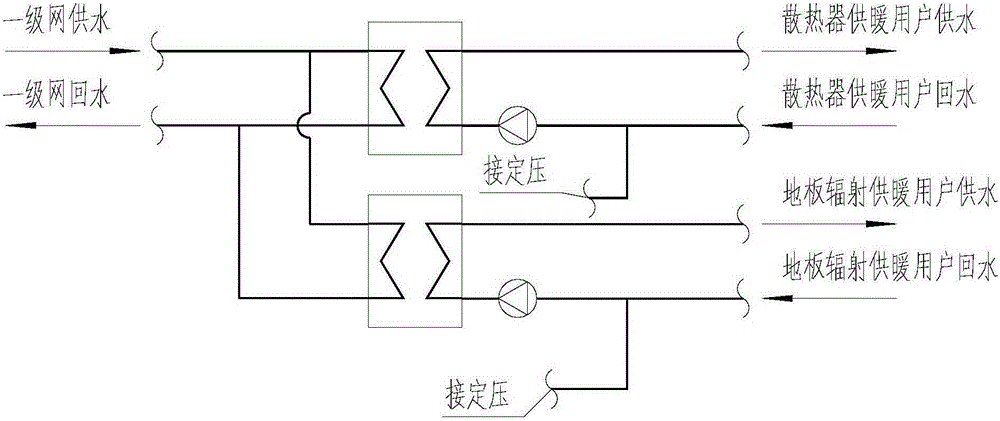

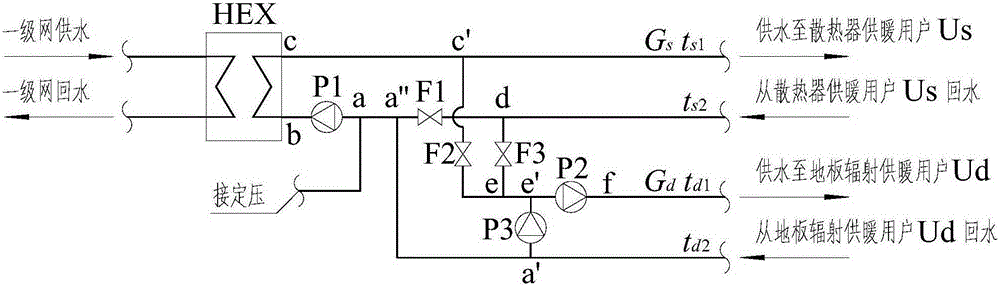

Radiator and floor radiation heating loop cascade heat exchange station system and heat gradient utilization method

ActiveCN105180244ASolve design problemsLower return water temperatureLighting and heating apparatusSpace heating and ventilation detailsEngineeringControl valves

The invention relates to a radiator and floor radiation heating loop cascade heat exchange station system and a heat gradient utilization method. The system and the method aim to solve the problems that an existing radiator heating and floor radiation heating second-class network parallel heat exchange station system and a radiator heating and floor radiation heating heat exchanger parallel heat exchange station system cannot effectively utilize the temperature of heating media, namely the second-class network return water temperature is high, and the investment of the radiator heating and floor radiation heating heat exchanger parallel heat exchange station system is excessively high. Particularly, the radiator and floor radiation heating loop cascade heat exchange station system comprises a heat exchanger unit, a second-class network circulating water pump unit P1, a second-class network circulating water pump unit P2, a water mixing pump unit P3, a control valve unit F1, a control valve unit F2 and a control valve unit F3. A radiator heating loop and a floor radiation heating loop are connected in series. The system and the method are applied to the field of heat-supply engineering.

Owner:HARBIN INST OF TECH

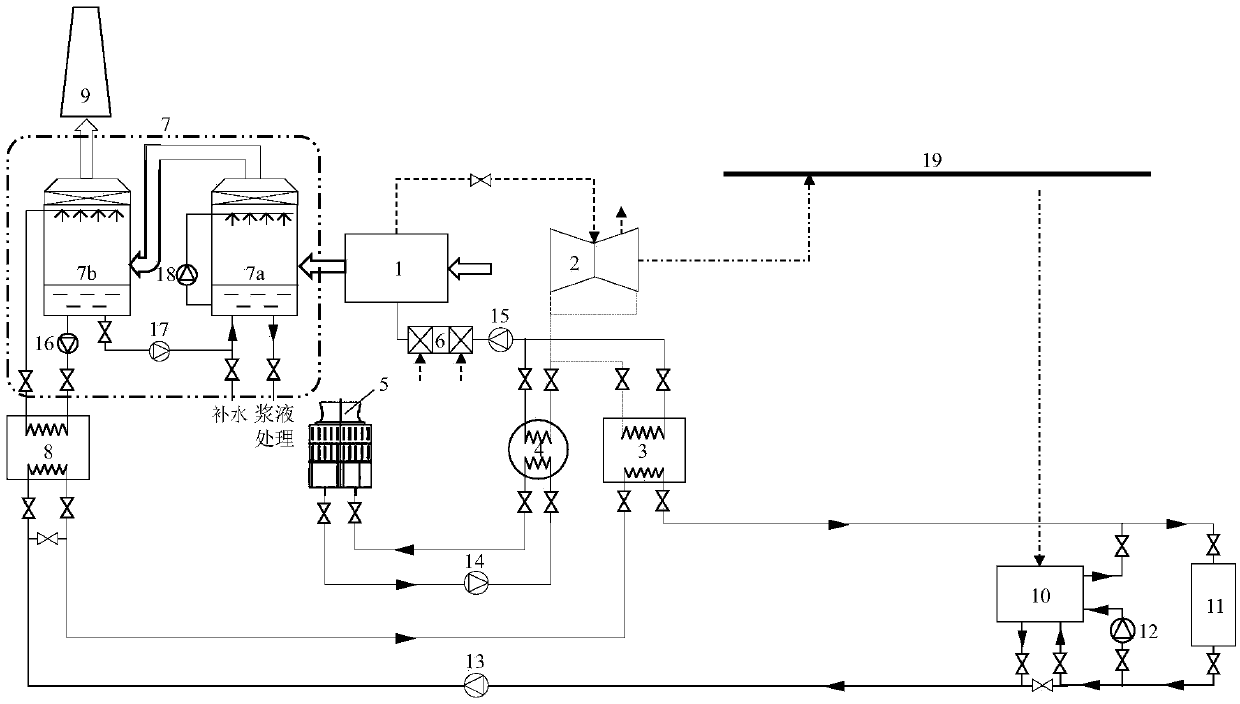

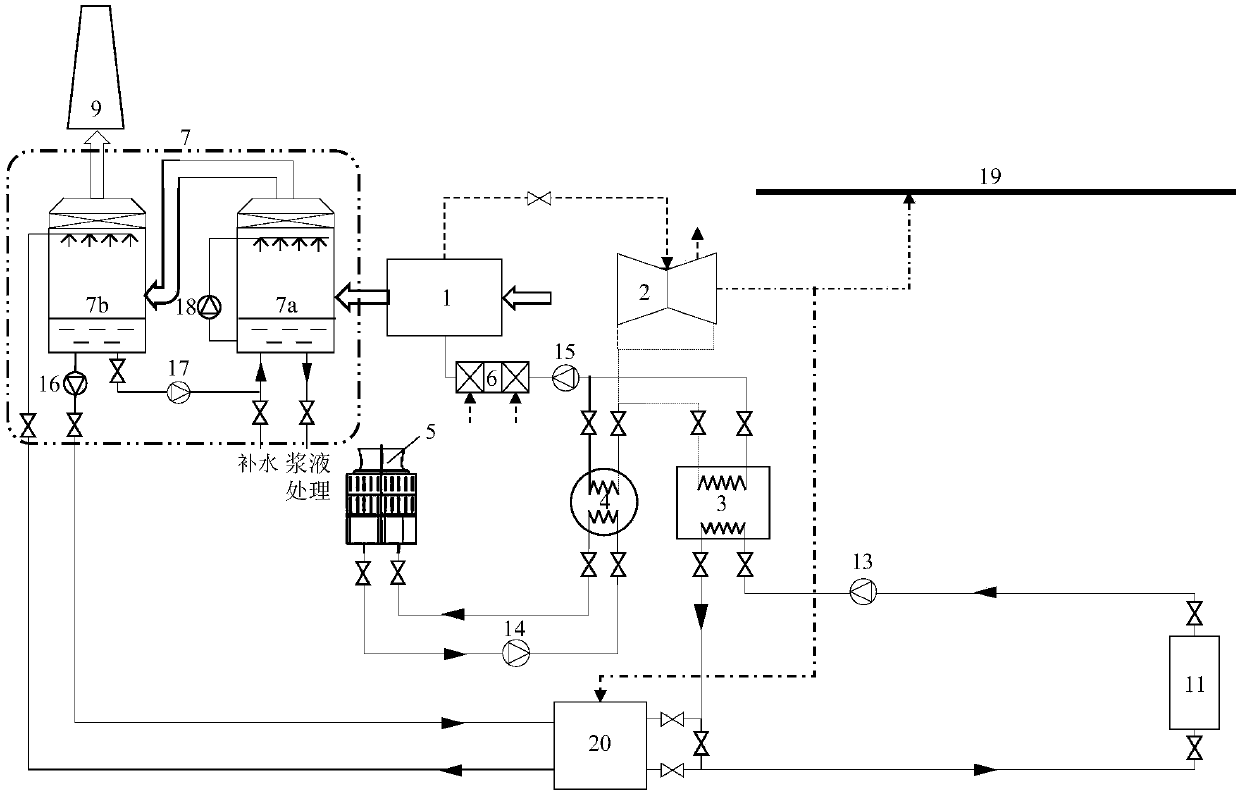

Data center cold and heat combined supply waste heat large-temperature-difference central heating system

PendingCN108317582AImprove utilization efficiencyLow running costLighting and heating apparatusHot-water central heatingCooling towerData center

The invention provides a data center cold and heat combined supply waste heat large-temperature-difference central heating system which comprises a conventional water cooling unit, compression heat pumps, a peak adjusting heat source, a water-water heat exchanger, electricity-driven compression heat pumps, a connecting pipeline and an accessory. Data center waste heat is extracted through frozen circulating water on the evaporator side, heat release is conducted in two ways on the evaporator side, heat of one of the two ways heats a primary heating network return water, heat of the other way is connected into all stages of compression heat pump evaporators to serve as low-level heat sources of the heat pumps, and surplus heat is discharged into the environment through a cooling tower. Thecompression heat pumps conduct heat release in a condenser to heat the primary heating network return water stage by stage. The peak adjusting heat source heats the heating network return water to theheating temperature finally, and then the heating network return water is sent out of the data center through a heating pipeline. The heating network supplied water passes through the water-water heat exchanger to heat a terminal radiator user firstly and then flows into the electricity-driven compression heat pumps in series to heat the tail end of a radiation floor. According to the central heating system, cold and heat combined supply and cascaded heating are adopted, the primary heating network temperature difference is large, and only electricity is needed to serve as driving energy of the heat pumps.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

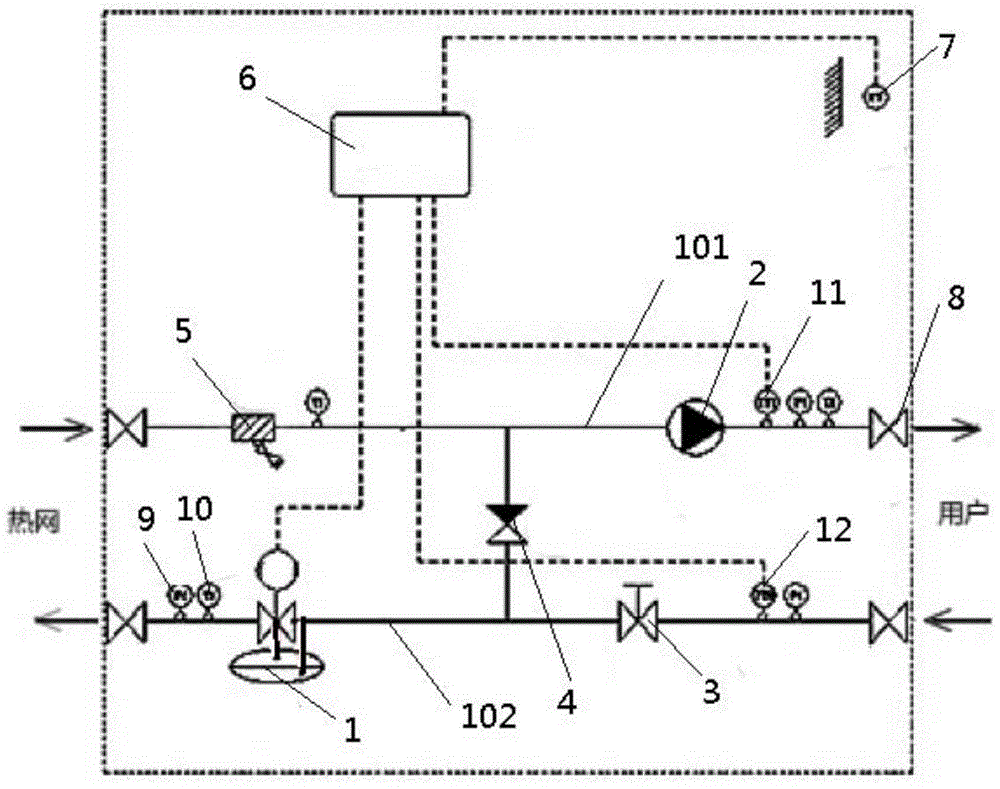

Heat supply network balancing system

InactiveCN104566596AReduce trafficReduce energy consumptionLighting and heating apparatusSpace heating and ventilation detailsEngineeringPressure difference

The invention discloses a heat supply network balancing system. The heat supply network balancing system comprises a water inlet pipe and a water return pipe; the water inlet pipe is provided with a filter, a water pump and a water inlet temperature sensor at a user side in sequence according to the water flow direction; the water return pipe is provided with a water return temperature sensor at the user side, a manual balance valve and a pressure difference control valve with a flow rate adjusting function in sequence according to the water flow direction; a check valve is arranged between the water inlet pipe and water return pipe; the water pump is provided with a transducer; the pressure difference control valve, water inlet temperature sensor at the user side, water return temperature sensor at the user side and outdoor temperature sensor are connected with a controller with a weather compensation function through circuits; each of the water inlet pipe and water return pipe is provided with a thermometer and a pressure gauge, and shut-off valves are arranged at two ends of each of the water inlet pipe and water return pipe. The heat supply network balancing system realizes the variable-flow rate intelligent heat usage of a secondary network of the heat supply network, the return water at the user side is mixed with the primary side inlet water of the system, the return water energy of the user side is completely used, the comfort is improved for the user, and the energy conservation and environment protection are realized.

Owner:董全意

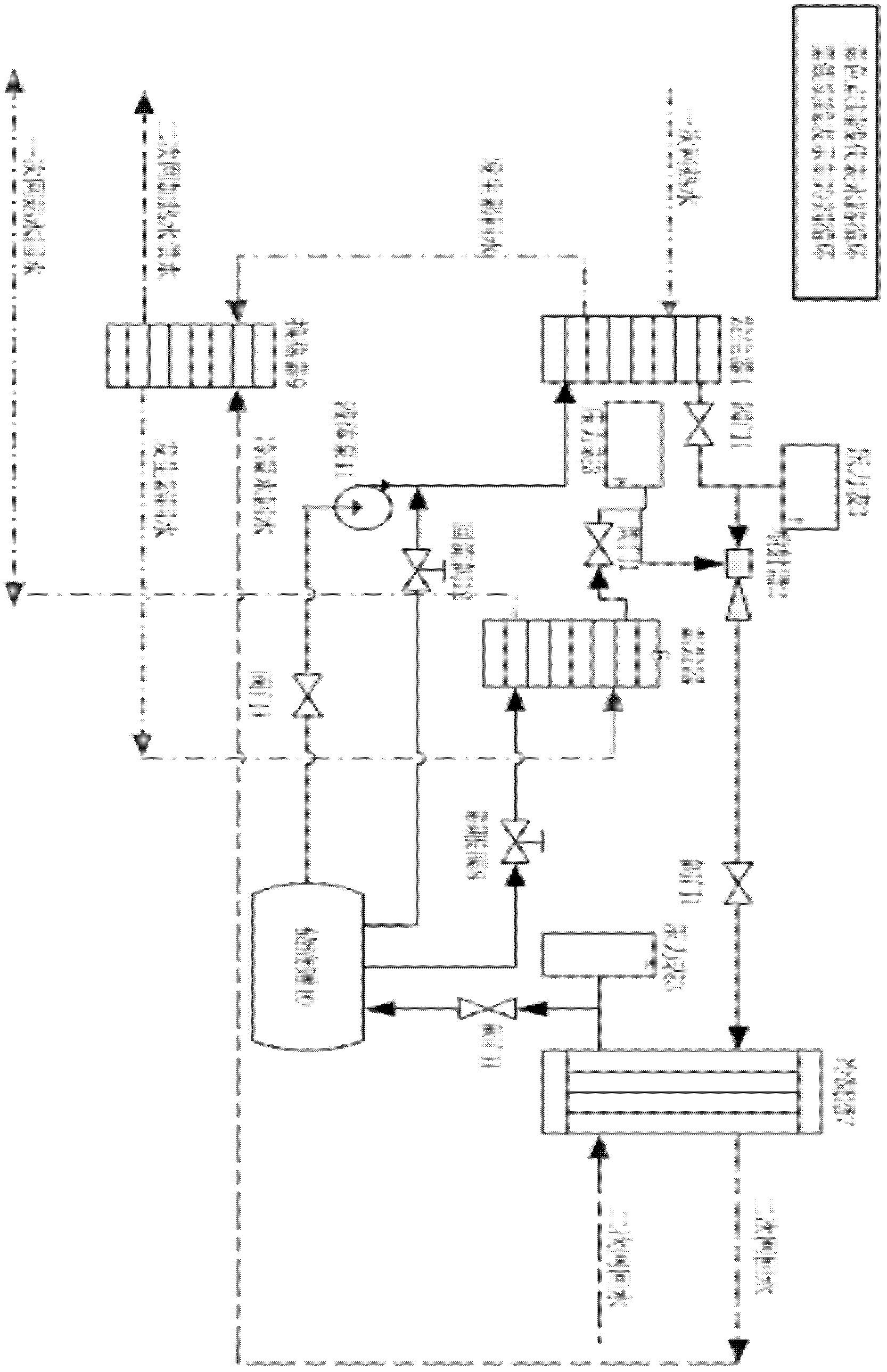

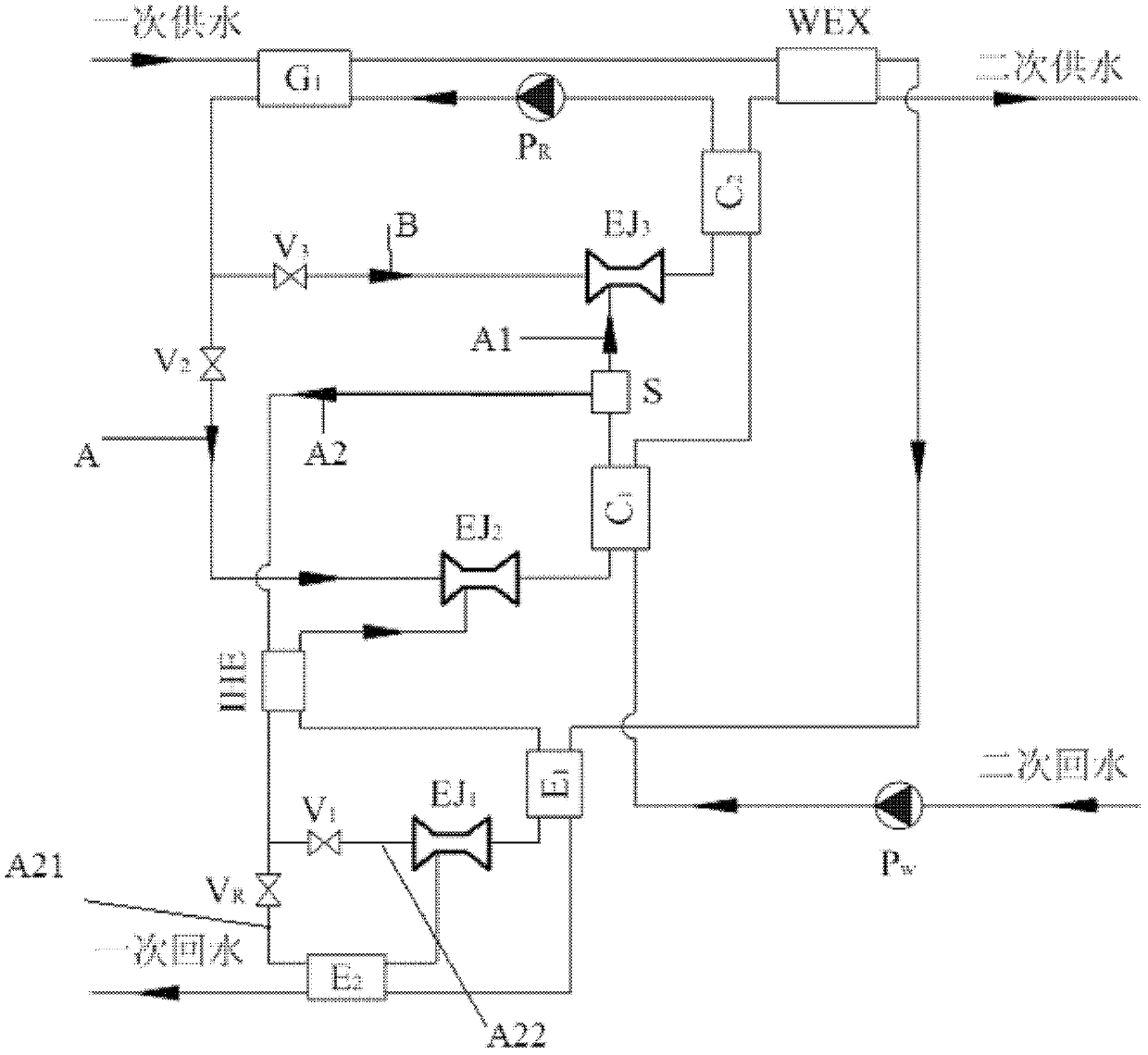

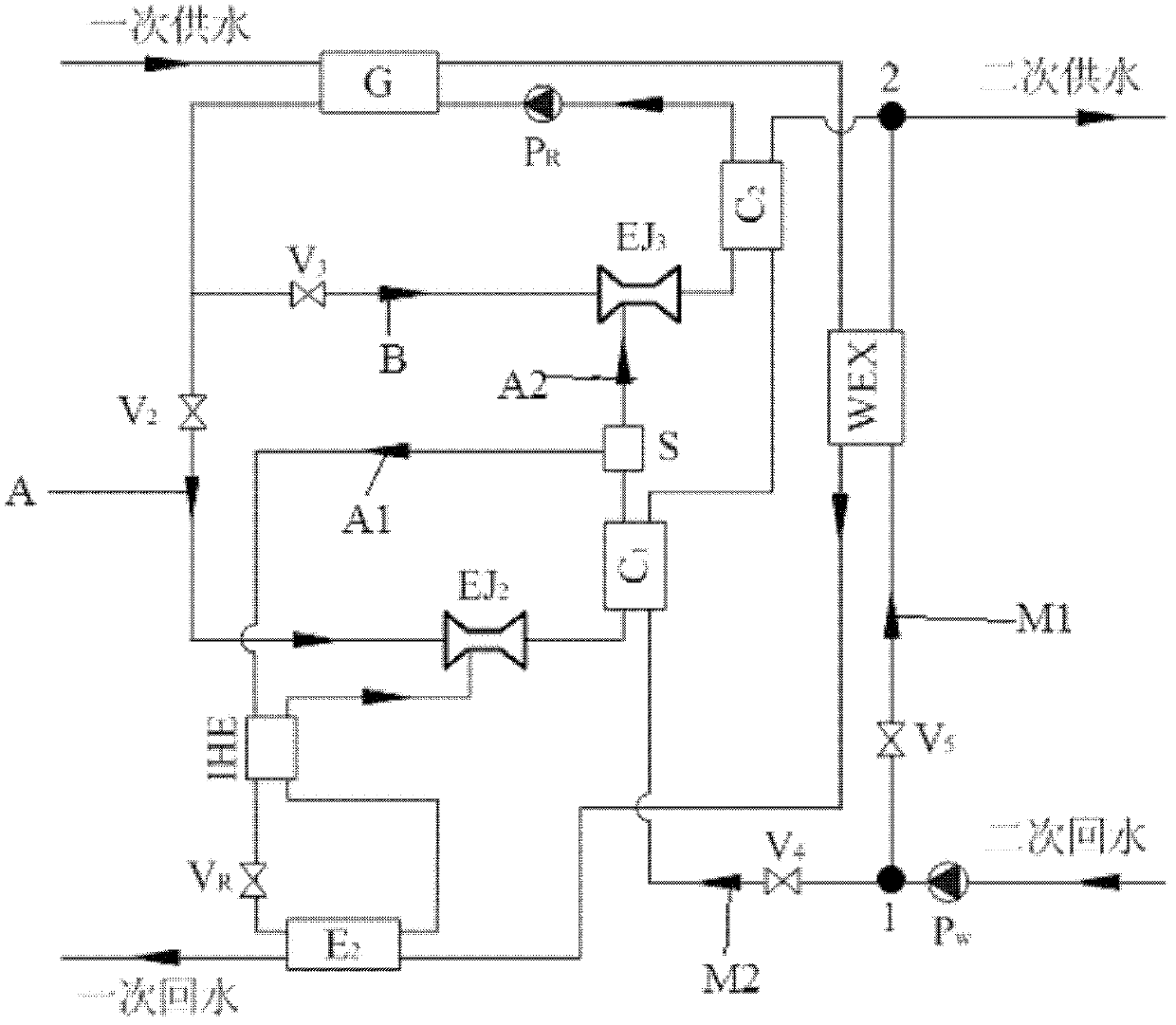

Secondary heat exchange station heating system based on jet type heat pump for recovering primary grid backwater complementary energy

ActiveCN102434907ALower return water temperatureIncrease total heating capacityLighting and heating apparatusEnergy efficient heating/coolingEngineeringHeating system

A secondary heat exchange station heating system based on jet type heat pump for recovering primary grid backwater complementary energy belongs to the energy technical field, and is characterized in that a heat exchanger is added on the base of a traditional jet type heat pump system. The system enables generator backwater and condenser backwater to exchange heat by using the heat exchanger in the system under the condition that total water supply of a primary grid is kept unchanged so as to lower primary grid backwater temperature, recover the primary grid complementary energy, improve secondary grid water supply temperature and increase total heat supplying capacity of a heat supply network. The system and the heat exchanger of an original heat exchange station adopt a parallel operation method, the heat pump system can safely quit operation at any time while achieving heating of secondary grid backwater, and original working conditions of the original heat exchange station can be recovered, thereby having reliable safety. The system does not need to change original primary grid pipelines, does not need to add primary grid pump work, and can increase by 60% of the total heat supplying capacity of the whole heat supply network to the maximum extent, and the primary grid backwater temperature is 30 DEG C.

Owner:DALIAN UNIV OF TECH

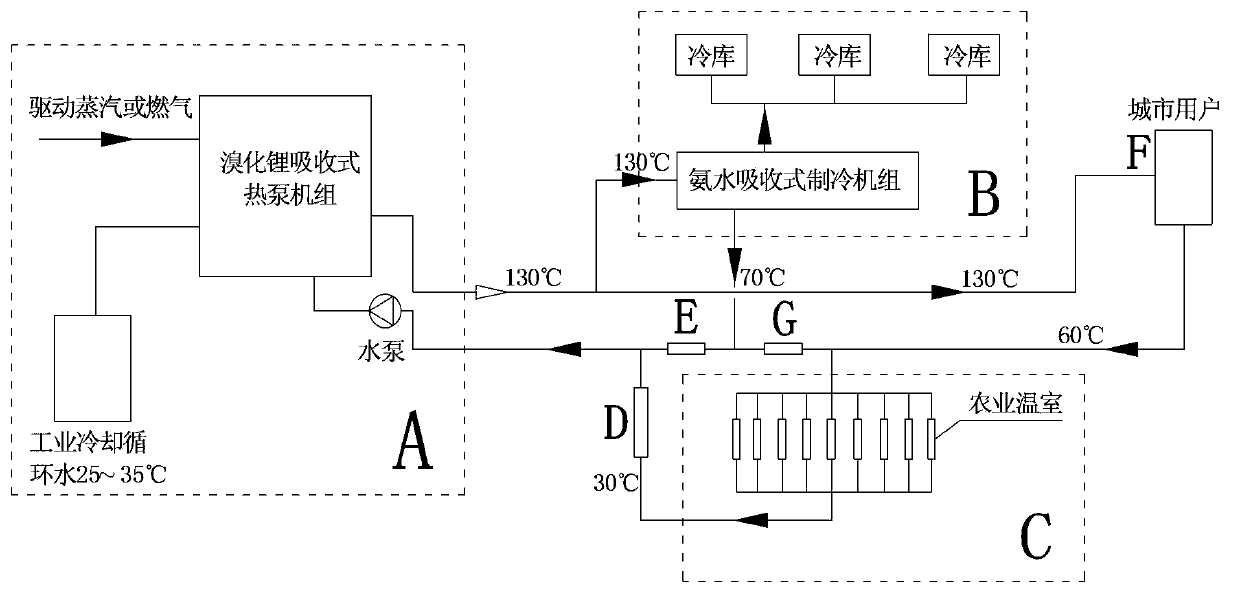

Large temperature difference centralized heating/cooling system

InactiveCN103968598ALower return water temperatureReduce power consumptionClimate change adaptationHeating and refrigeration combinationsAbsorption heat pumpElectric power

The invention discloses a large temperature difference centralized heating / cooling system. According to the large temperature difference centralized heating / cooling system, hot water output from a residual heat heating system can be divided into two ways: one way is connected with the cooling system through pipelines and the other way is connected with urban heat users through the pipelines; the cooling system is mixed with backwater of the heat supply users and then connected with heat users through the pipelines; the backwater of the heat supply users enters into an absorption heat pump in a heating system; the absorption heat pump is driven by steam or fuel gas to extract cooling circulating water residual heat; the residual heat is heated by a heater to the temperature of 130 DEG and heating water is discharged and enters into a next circulation. The large temperature difference centralized heating / cooling system has the benefits that as the back water of the system is recycled, the temperature of supply water / backwater reaches 130 / 30 DEG; as the temperature of the supply water / backwater is increased, the heat supply network delivery capacity is improved and the water pump power consumption in the system operation is reduced; moreover, an ammonium hydroxide absorption cooling unit can not only ensure cooling in winter, but also provide cold quantity for cold storages in spring, summer and autumn, power necessary for normal electric cooling is saved, the residual heat usage rate is improved and the energy conservation and emission reduction are facilitated.

Owner:DUNAN TIANJIN ENERGY SAVING SYST

Novel heating station system having both large-temperature-difference heat exchange and concentrated heat refrigeration functions

ActiveCN106123395ALower return water temperatureReduce condensing pressureHeating and refrigeration combinationsCooling towerAbsorption heat pump

The invention discloses a novel heating station system having both large-temperature-difference heat exchange and concentrated heat refrigeration functions, and relates to the technical field of heating devices. The novel heating station system comprises an absorption heat pump, a compression heat pump, a cooling tower, a first heat exchanger and a heat exchanger; the absorption heat pump includes a generator, a first evaporator, an absorber and a first condenser; the compression heat pump includes a second evaporator and a second condenser; under the working conditions in winter, the large-temperature-difference heat exchange is realized through the absorption heat pump and the compression heat pump, the heating network water return temperature is lowered, and the heating network conveying capacity is improved; under the working conditions in summer, high-temperature heating network water supplied by a concentrated heating resource is used for driving the absorption heat pump to realize concentrated heat refrigeration; meanwhile, the compression heat pump is converted to a refrigeration working condition; the absorber and the first condenser are connected with the second condenser in series for heating; the cooling tower is matched for cooling; and the first evaporator and the second evaporator are serially connected for cooling to realize frozen water supply of a cold supply terminal, so that the utilization rate of heat pump / refrigerator equipment is increased.

Owner:YANSHAN UNIV

High temperature difference heating system combined with peak shaving boiler and method

ActiveCN108167915ATake advantage ofLower return water temperatureHot-water central heatingRefrigeration machinesEngineeringAbsorption heat pump

The invention belongs to the technical field of heat supply energy sources, and discloses a high temperature difference heating system combined with a peak shaving boiler and a method. The high temperature difference heating system is provided with a steam boiler, a turbine, a compression type heat pump, an absorption type heat pump, a steam water heat exchanger, a steam system and a hot water system; and the steam system and the hot water system are connected with the steam boiler, the turbine, the compression type heat pump, the absorption type heat pump and the steam water heat exchanger. With the combination of the compression type heat pump and the absorption type heat pump, deep cooling on the return water temperature of a heating network can be realized, the temperature difference between supply water and the return water of the heating network is increased, the pipe network investment and running cost is reduced, and favorable working conditions are created for recovery of lowtemperature waste heat of a thermoelectric power plant; steam generated by the peak shaving boiler enters the turbine to do work to drive the compression type heat pump, the turbine subjected to pressure reduction exhausts steam to act as a driving heat source of the absorption type heat pump, so that available energy of a boiler heat source is used fully; and the return water of the heating network is sequentially subjected to step cooling by an evaporator of the absorption type heat pump and an evaporator of the compression type heat pump.

Owner:YANSHAN UNIV

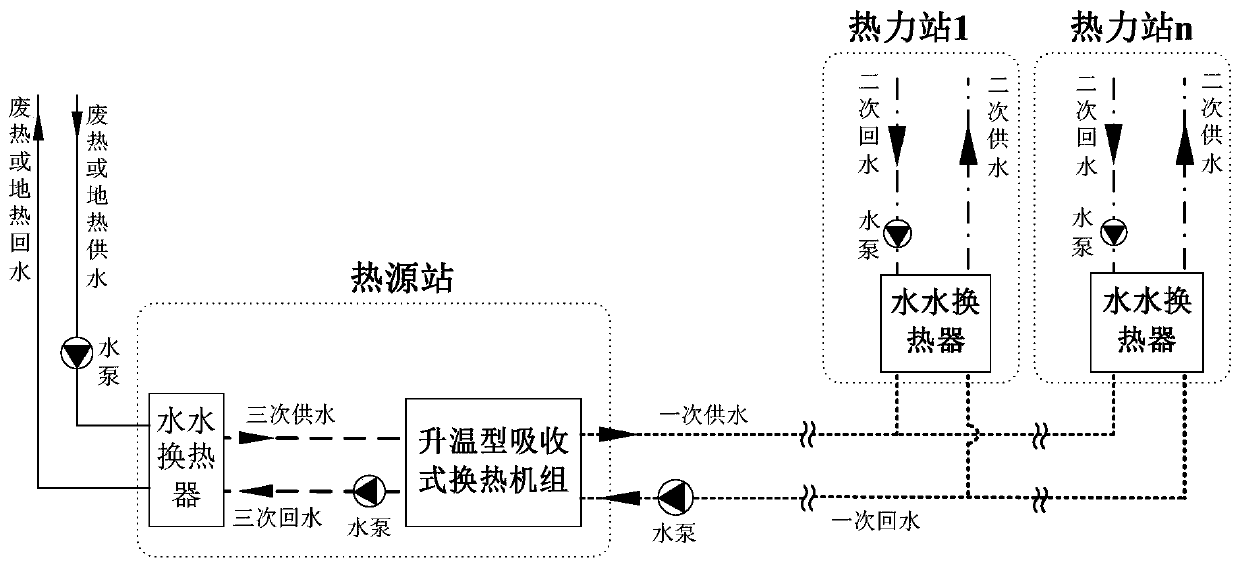

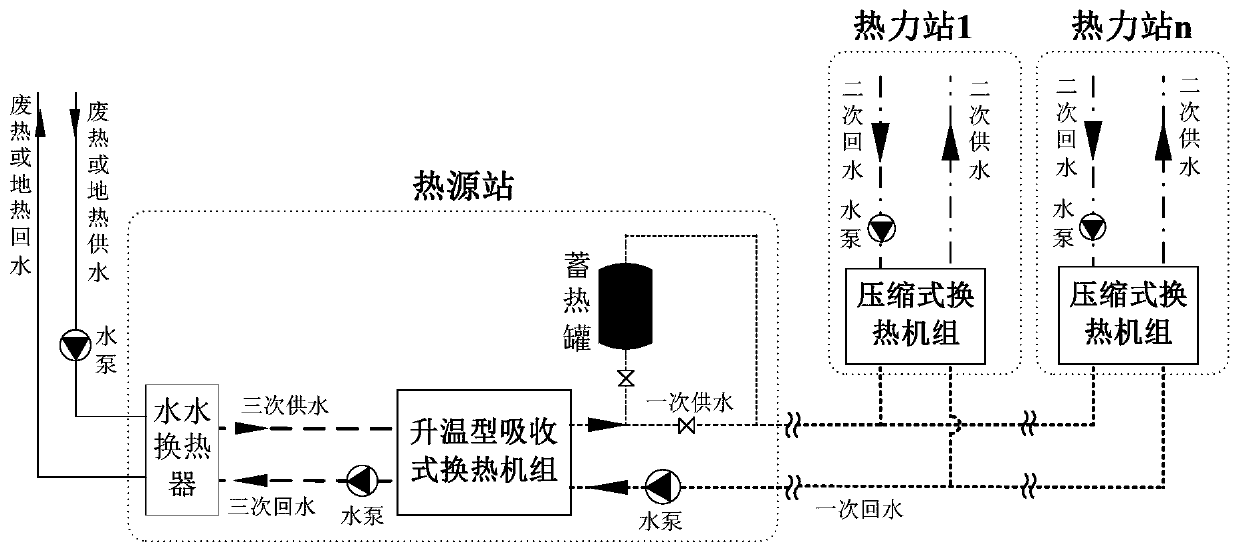

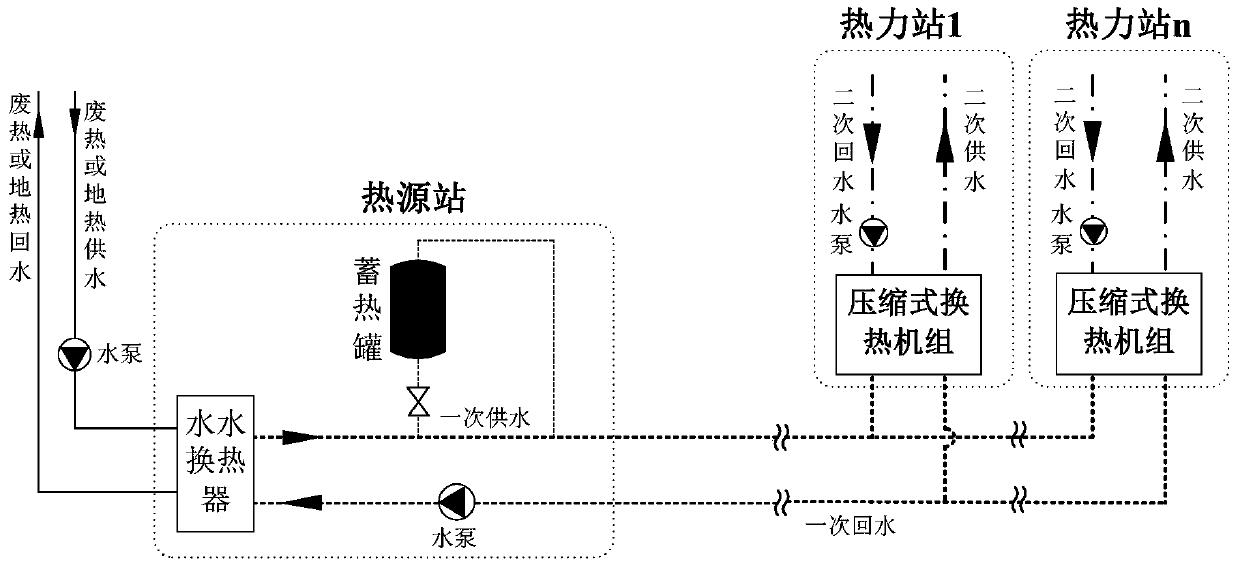

Medium and low temperature heat energy heat supply system based on heating type absorption-compression type heat exchange

ActiveCN110030769AIncrease economic heat transfer distanceLower return water temperatureMechanical apparatusHeat pumpsThermal energyAbsorption compression

The invention belongs to the technical field of heating and ventilation air conditioners, and particularly relates to a medium and low temperature heat energy heat supply system based on heating typeabsorption-compression type heat exchange. The system comprises a medium and low temperature heat source, a heat source station, a primary net, a heat station and a secondary net which are connected in sequence; the heat source station is a first water-water heat exchanger, and the heat station is a compression type heat exchange unit or a second water-water heat exchanger; and the medium and lowtemperature heat source is medium and low temperature industrial waste heat, or medium-and-deep geothermal heat, or medium and low temperature circulating water from a solar heat collector. Accordingto the medium and low temperature heat energy carrier characteristics, the heat exchanger is reasonably configured in the medium and low temperature heat source station, the compression type heat exchange unit is reasonably configured in the heat station according to the characteristics of the heat user so that the water return temperature of a primary heat network can be greatly reduced and the primary water supply temperature can be increased, and the industrial waste heat economic heat transfer distance is greatly improved; and high-efficiency utilization of the medium and low temperature heat energy is facilitated so that a heat supply heat source support is provided for surrounding towns, and the fossil energy consumption of the heat supply system and the discharge amount of pollutants are reduced.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

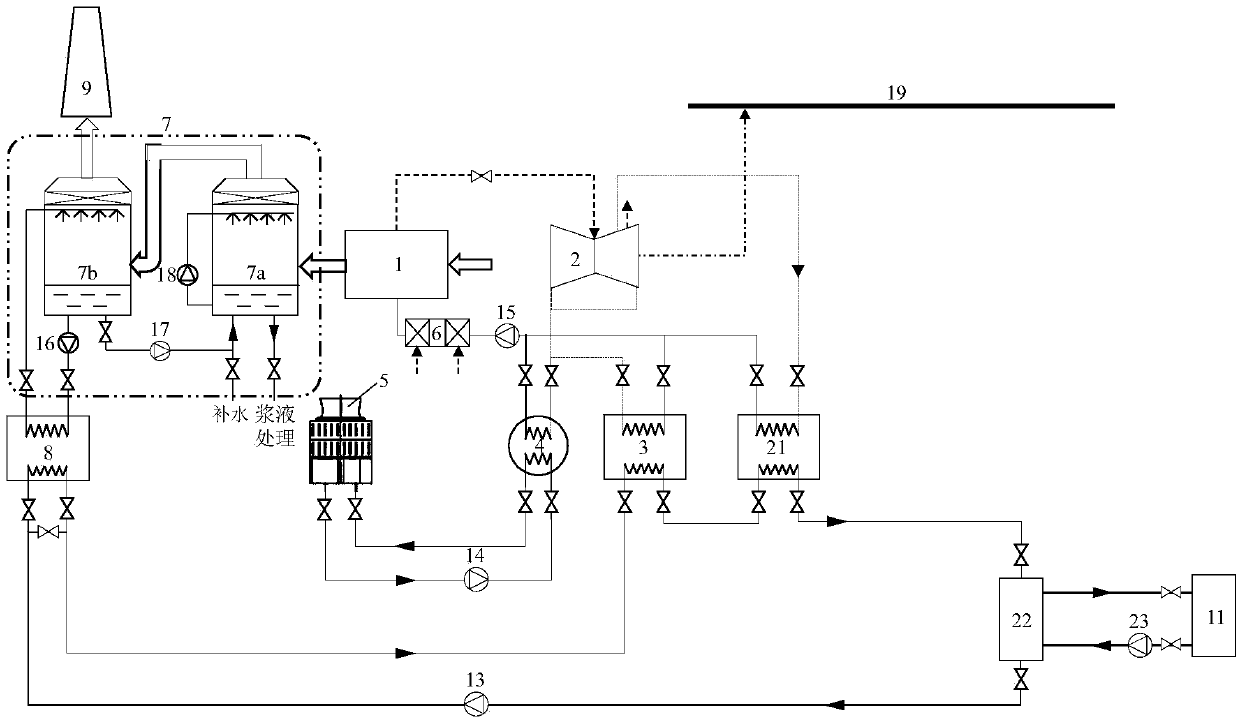

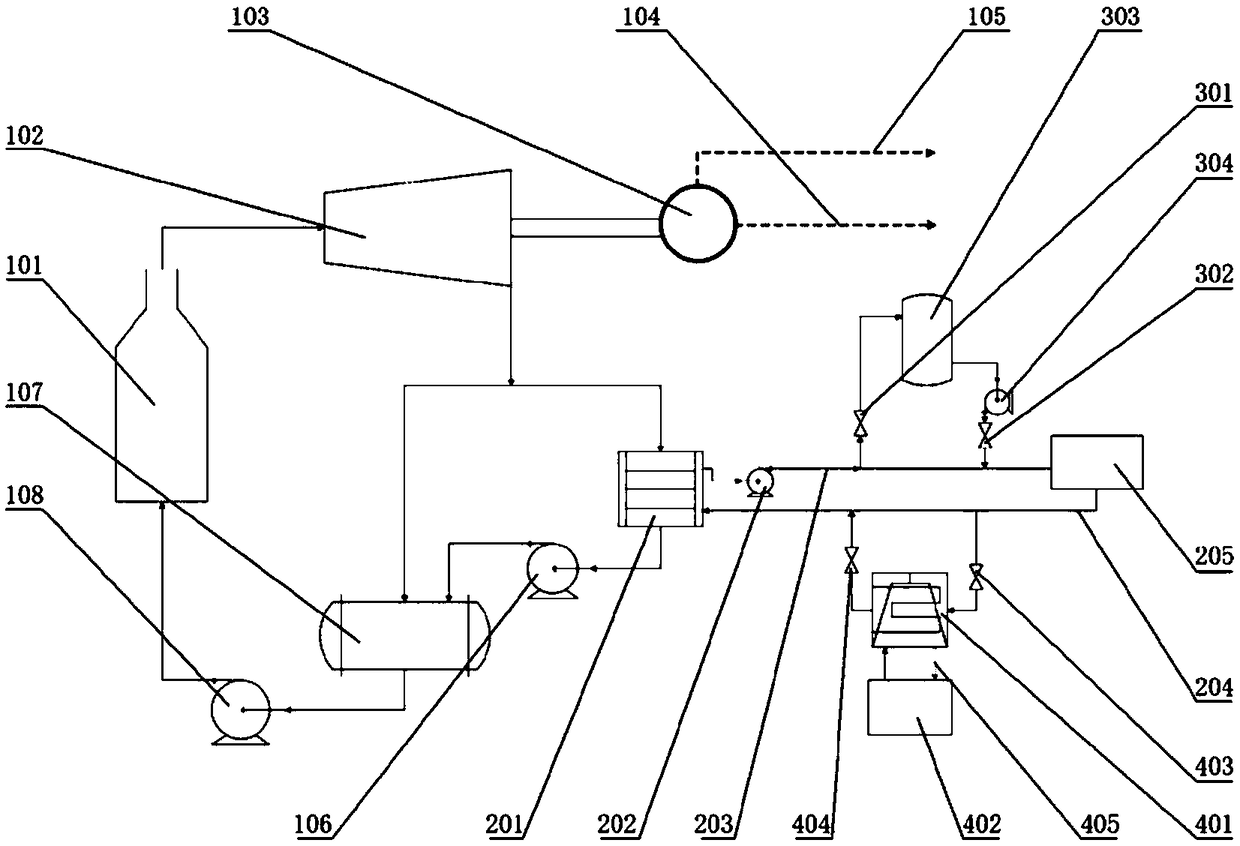

Biomass combined heat and power generation system capable of recycling steam exhaust and smoke waste heat at the same time

PendingCN109681281AAchieve optimal utilizationReduce water consumptionHeat recovery systemsLighting and heating apparatusCooling towerEngineering

The invention provides a biomass combined heat and power generation system capable of recycling steam exhaust and smoke waste heat at the same time, and belongs to the technical field of biomass energy use. The system comprises a biomass boiler, a steam turbine, a steam exhaust heat exchanger, a condenser, a cooling tower, a boiler water supply heater, a smoke emission reduction and waste heat recycling integrated unit, a smoke spraying water heat exchanger, a chimney, a power grid, an end electric heat pump, a user heat exchanger, a connecting pipeline and a valve. The smoke emission reduction and waste heat recycling integrated unit comprises a desulfurizing tower and a waste heat recycling tower; the electric heat pump mixed water heat supply manner is adopted on the user side to reducethe heat supply network water returning temperature, through direct heat exchange, smoke condensation latent heat and steam exhaust waste heat in a power plant can be recycled in a gradient manner, the heat supply capacity of a biomass power plant can be increased, and the optimal biomass energy comprehensive use efficiency is obtained.

Owner:TSINGHUA UNIV

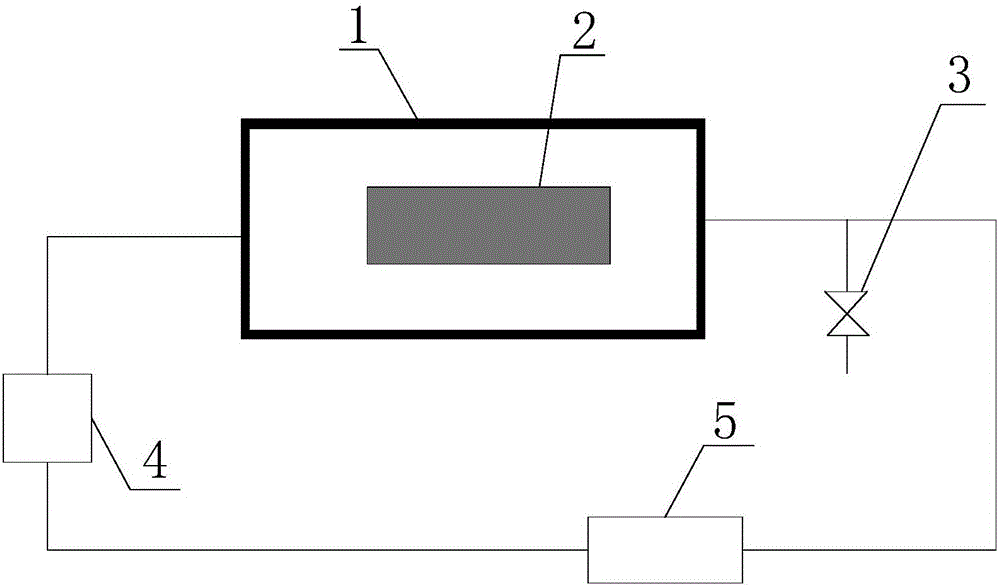

Cleaning method for heat exchanger of heating power company

InactiveCN106197139ARestore the heat transfer effectReduce corrosionMetallic material coating processesFlush cleaningChemical cleaningHeating power

The invention discloses a cleaning method for a heat exchanger of a heating power company. A cleaning system is adopted for cleaning a heat exchange sheet of the heat exchanger and comprises a cleaning tank, a circulation pump and a heater which are sequentially connected through a pipeline. A sampling pipe is arranged at the position, on the downstream portion of the cleaning tank, of the pipeline. The cleaning method sequentially comprises the following steps of S100 water washing, S200 alkali washing, S300 water washing, S400 acid pickling, S500 water washing, S600 passivation and S700 water washing. The heat exchange plate sheet is cleaned through the chemical cleaning method, the cleaned heat exchange plate sheet is bright as a new one, and the original heat exchange capacity of the heat exchanger is restored; and the plate sheet is cleaned through organic acid sulfamic acid, the sulfamic acid is weak acid, it is found that the effect is the best when a sulfamic acid adding corrosion inhibitor is selected as cleaning liquid through trial and errors, the prominent cleaning effect is achieved compared with other reagents, and the corrosion of the cleaning liquid to the plate sheet can be reduced.

Owner:HUADIAN ENERGY COMPANY LIMITED

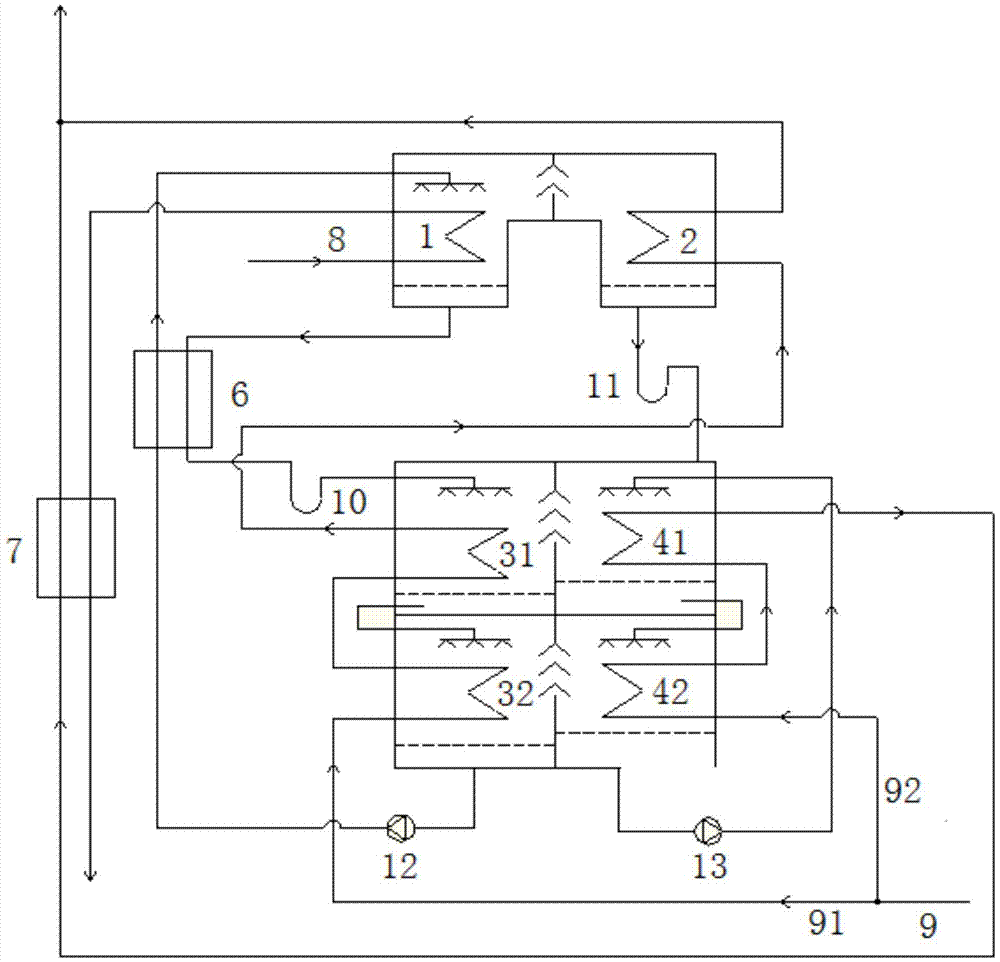

Absorption heat pump unit, heat exchanger unit and heat supply system

InactiveCN104764244AImprove overall thermal sophisticationLower return water temperatureHeating fuelClimate change adaptationEvaporatorEngineering

The invention relates to an absorption heat pump unit, a heat exchanger unit and a heat supply system. The absorption heat pump unit comprises a generator, a condenser, an absorber, an evaporator and a solution heat exchanger. The absorber at least comprises a first absorber body and a second absorber body, the evaporator at least comprises a first evaporator body and a second evaporator body, a solution outlet of the first absorber body is communicated with a solution inlet of the second absorber body, and a refrigerant water outlet of the first evaporator body is communicated with a refrigerant water inlet of the second evaporator body. The absorber bodies and the evaporator bodies are arranged, and therefore the overall heat power perfectness degree can be improved, and primary water return temperature can be lowered.

Owner:GREE ELECTRIC APPLIANCES INC

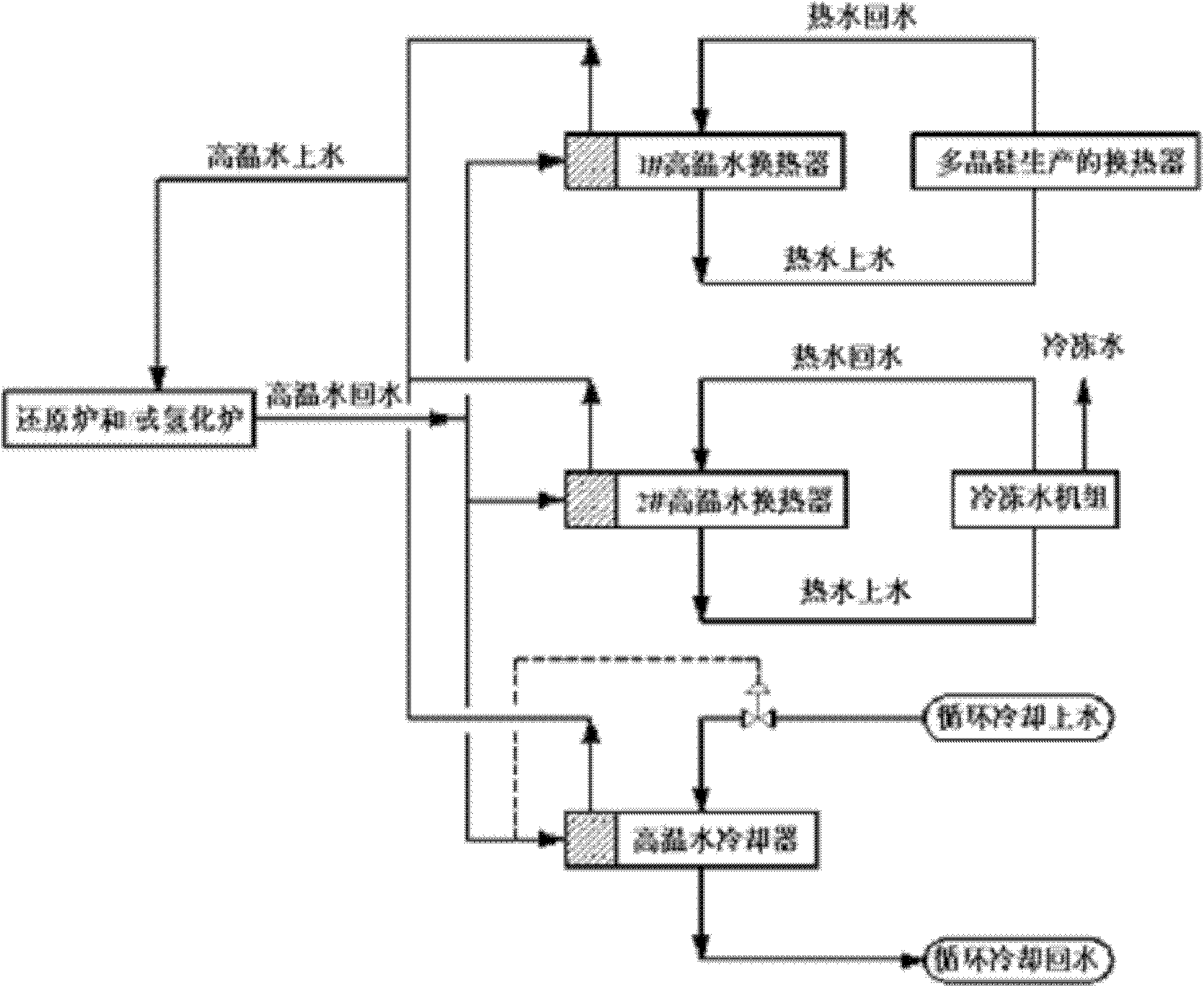

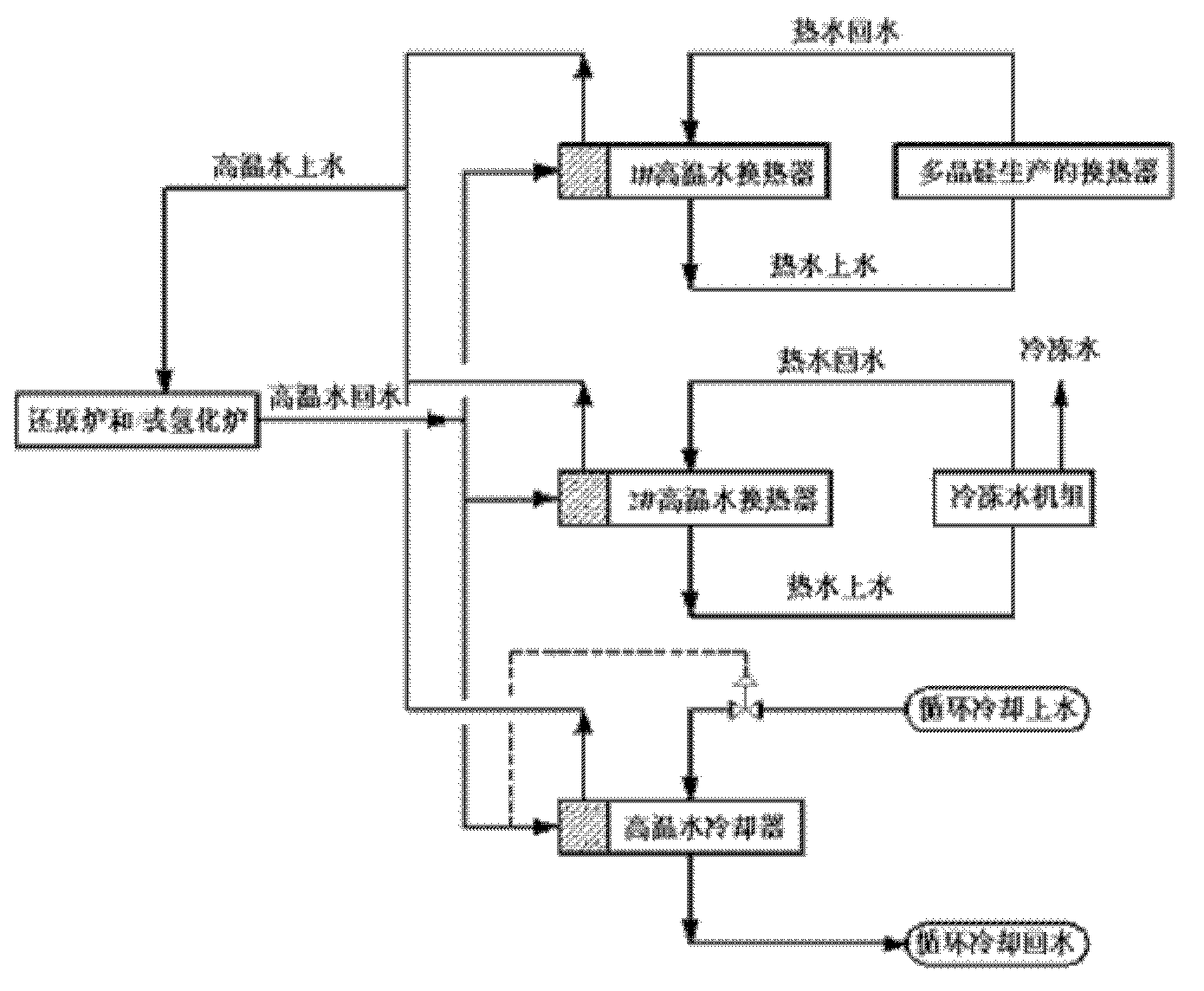

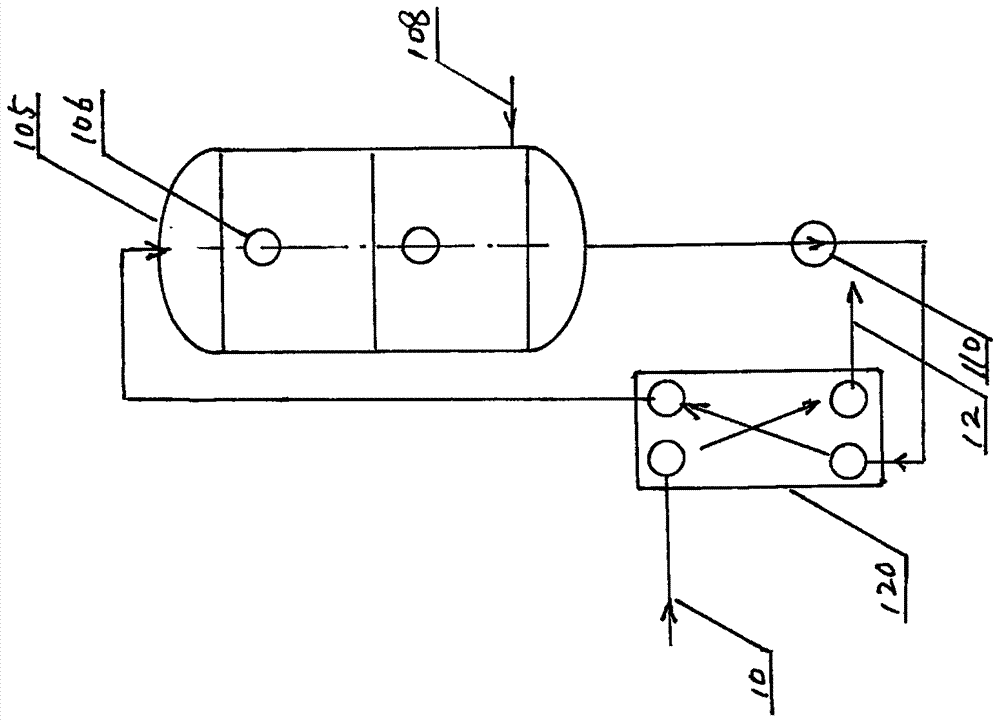

Method for comprehensively utilizing heat energy of high-temperature water of reduction furnace and/or hydrogenation furnace

InactiveCN101786626AWill not corrodeCause corrosion damagePolycrystalline material growthSiliconThermal waterHeat energy

The invention discloses a method for comprehensively utilizing heat energy of high-temperature water of a reduction furnace and / or a hydrogenation furnace, comprising the following steps of: respectively introducing high-temperature water backwater from the reduction furnace and / or the hydrogenation furnace to a #1 high-temperature water heat exchanger, a #2 high-temperature water heat exchanger and a high-temperature water cooler so that the high-temperature water backwater in the #1 high-temperature water heat exchanger and hot water backwater from a heat exchanger produced by polysilicon perform heat exchange; carrying out heat exchange on the high-temperature water backwater in the #2 high-temperature water heat exchanger and hot water backwater from a frozen water unit; carrying out heat exchange on the high-temperature water backwater and circulation cooling water supply on the high-temperature water cooler for adjusting the temperature of the high-temperature water backwater; and reducing the temperature of the high-temperature water backwater when the high-temperature water backwater carries out the heat exchange through the #1 high-temperature water heat exchanger, the #2 high-temperature water heat exchanger and the high-temperature water cooler for cooling the reduction furnace and / or the hydrogenation furnace. The method can avoid corrosion destroy on precious equipment due to leakage of the heat exchanger produced by the polysilicon, can reduce the temperature of the high-temperature water backwater, is beneficial to safe operation of the reduction furnace and / or the hydrogenation furnace and saves the energy.

Owner:CHINA TIANCHEN ENG

High-efficiency and energy-saving heating method and heating system

ActiveCN102607088AAvoid lostImprove heat utilization efficiencyLighting and heating apparatusSteam useEngineeringWater cooling

The invention provides a high-efficiency and energy-saving heating method and a heating system using the same. The heating system comprises a steam extraction and condensation type steam turbine, a condenser, a power plant circulating water cooling system, a heat supply network circulating pump, a heat supply network circulating heater and a low-temperature heat supply network. Return water of the low-temperature heat supply network is used as refrigerant of the cooling water system of the condenser when the heating system is used for heating in winter, and is primarily heated in the condenser, in the heating system using the heating method, the power plant circulating water cooling system and the low-temperature heat supply network are respectively connected into the condenser and the heat supply network heater by pipelines, a switch valve unit is further arranged between the power plant circulating water cooling system and the low-temperature heat supply network by a pipeline, and the condenser can selectively use return water of the power plant circulating cooling system or the return water of the low-temperature heat supply network as cooling water via the valve unit in a switching manner. The high-efficiency and energy-saving heating method and the heating system thereof have the advantages of high heat efficiency and low energy consumption.

Owner:兖矿能源集团股份有限公司 +1

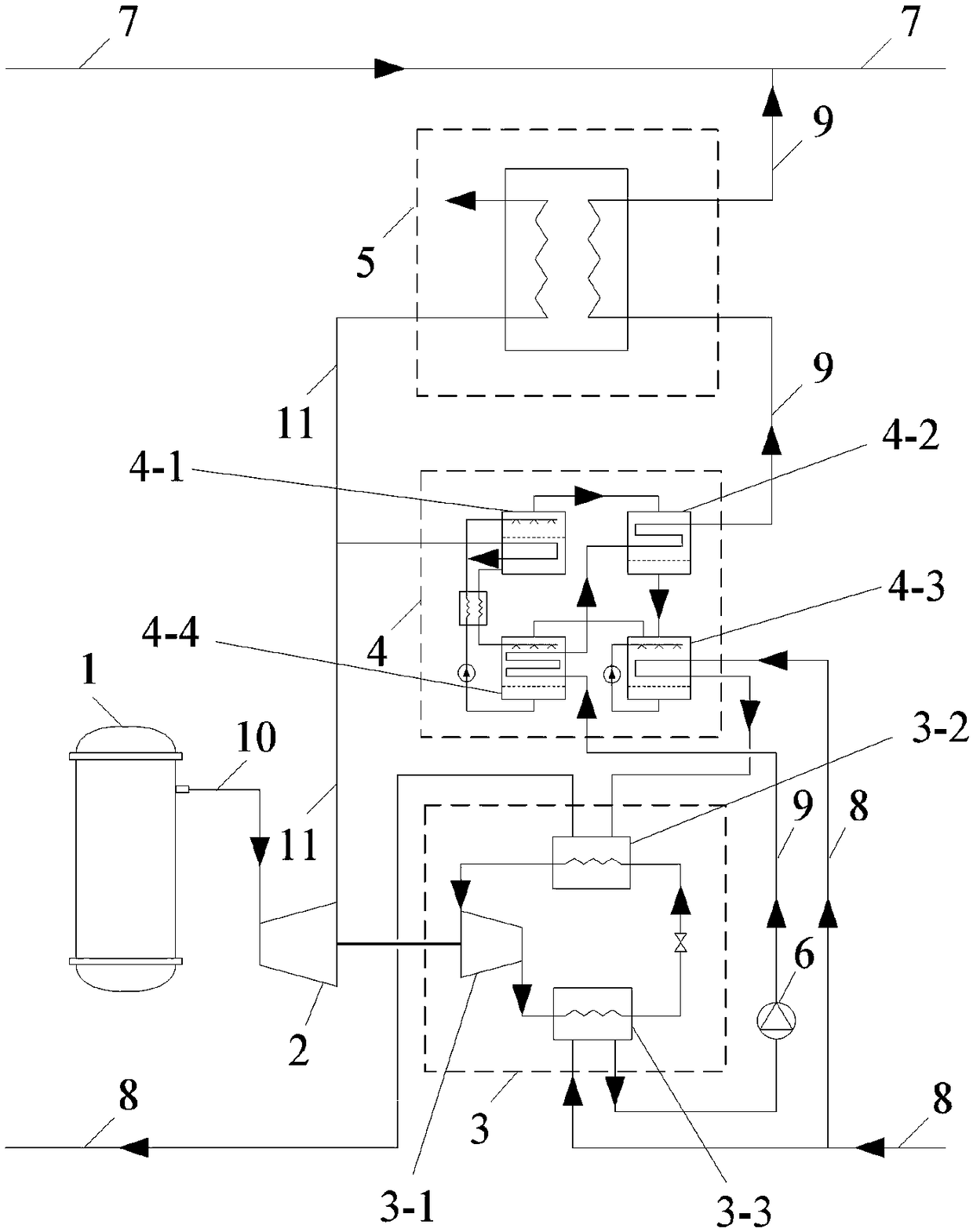

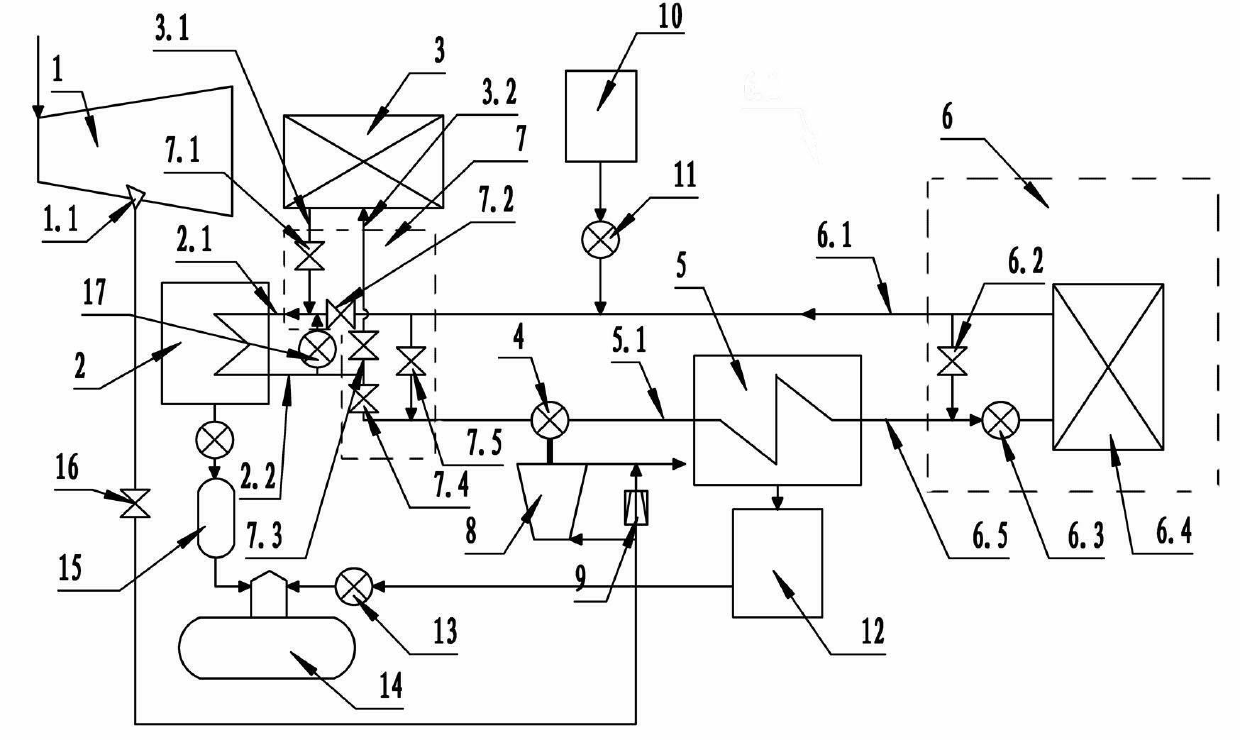

Interference-free middle-deep-stratum geothermal resource gradient utilization heating system

PendingCN109931651AImprove energy efficiency ratio and heating loadSmall heat transfer temperature differenceHeat pumpsGeothermal energy generationThree levelHeating system

The invention discloses an interference-free middle-deep-stratum geothermal resource gradient utilization heating system. The interference-free middle-deep-stratum geothermal resource gradient utilization heating system comprises a casing pipe (1), a heat insulation pipe (2), a heat exchanger (7), a high-temperature heat pump (8) and a low-temperature heat pump (9). According to the interference-free middle-deep-stratum geothermal resource gradient utilization heating system, through a three-level system including the heat exchanger, the high-temperature heat pump and the low-temperature heatpump, the high-grade portion, the middle-grade portion and the low-grade portion in geothermal energy can be sequentially absorbed and utilized, the middle-deep-stratum geothermal resource gradient utilization heating purpose is finally achieved, and the energy efficiency ratio and the heating load of the heating system are significantly increased. The heat insulation pipe (especially a vacuum heat insulation pipe) is taken as a central pipe, therefore, the heat dissipation capacity of water in the central pipe can be effectively reduced, and the grade of the geothermal energy can be effectively kept. Meanwhile, the advantages of an interference-free geothermal exploitation mode adopting the vacuum heat insulation pipe and the geothermal resource gradient utilization heating system are combined, and therefore the characteristics of being efficient, environmentally friendly and capable of achieving sustainable utilization are achieved.

Owner:XI'AN PETROLEUM UNIVERSITY +1

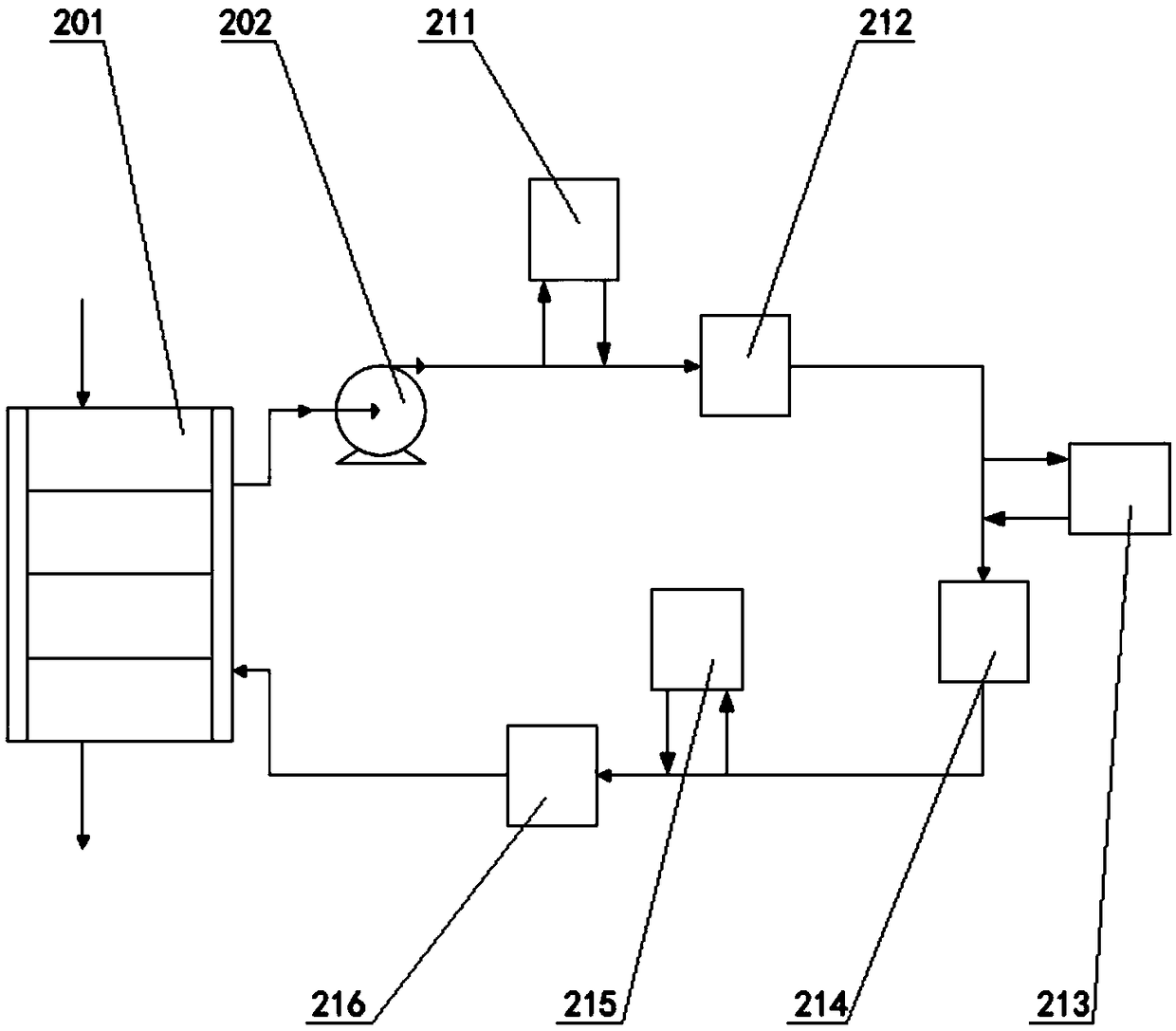

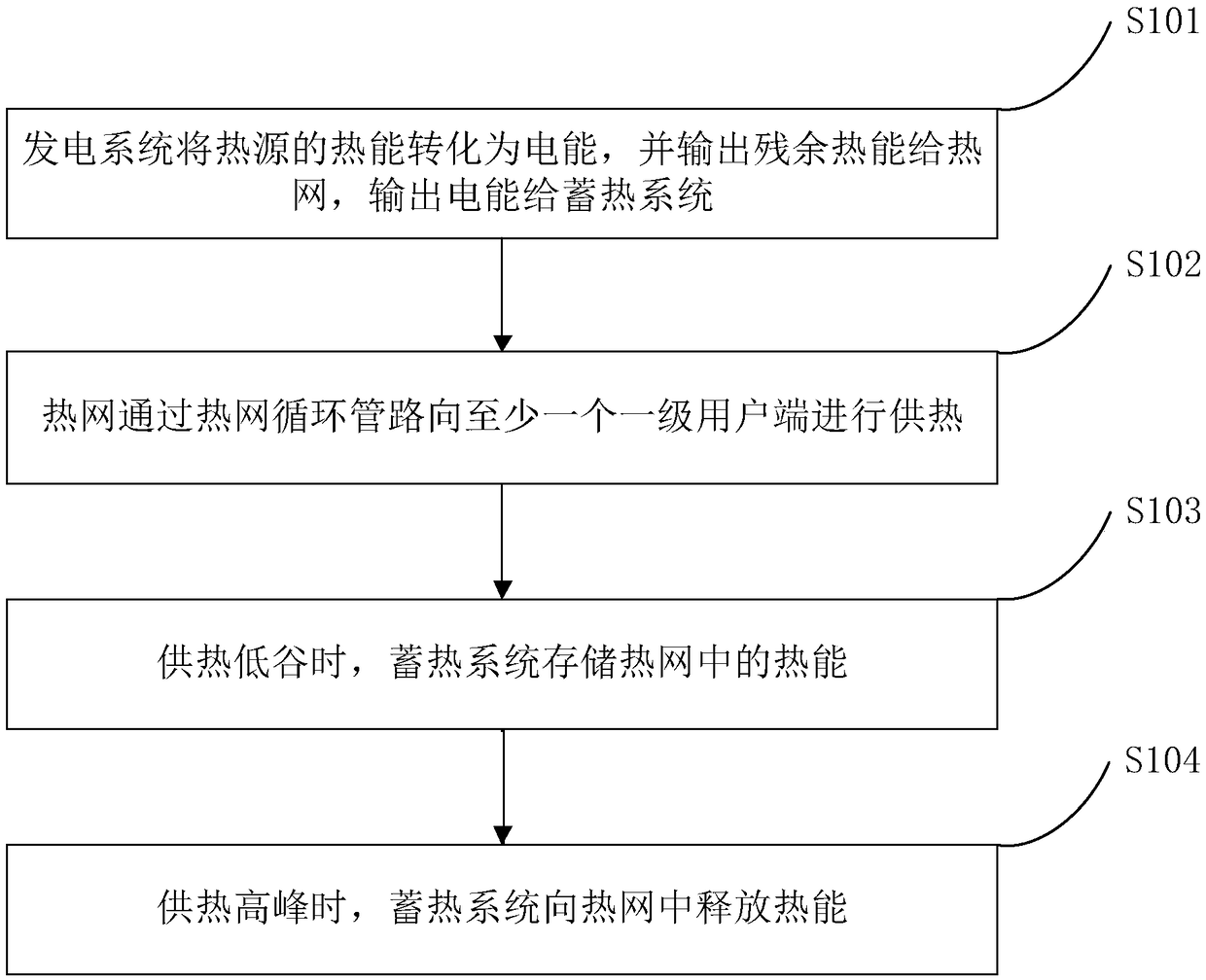

Heat supply system and method suitable for thermal power plant peak adjustment

PendingCN108692352AReduce installed capacitySolve the problem of uneven heating and coolingHeating fuelLiquid degasificationProcess engineeringPeak load

The invention relates to a heat supply system of a thermal power plant, in particular to a heat supply system and method suitable for thermal power plant peak adjustment. The system comprises a powergeneration system and a heat supply network, wherein the power generation system is used for converting heat energy into electric energy, and outputting partial residual heat energy to the heat supplynetwork through a pipeline; the heat supply network comprises a circulation loop; and a heat exchanger, at least one heat storage system and at least one first-grade user side are arranged on the circulation loop of the heat supply network. The heat supply network exchanges heat with the residual heat energy of the power generation system through the heat exchanger; the heat storage system is parallelly connected onto the circulation loop of the heat supply network, and is used for storing the heat energy at the heat supply trough period and releasing the heat energy at the heat supply peak time; and the first-grade user side is distributed on the heat supply network, and is used for utilizing heat energy in the heat supply network and returning the heat energy to the heat supply network.The heat supply system and method suitable for thermal power plant peak adjustment provided by the invention aims to solve the problems that the heat supply system carries out peak-load shifting so as to cause uneven cold and hot at far and near ends under the situations with the quick increase of a heat supply area and the great demand of heat supply.

Owner:GUODIAN LONGYUAN POWER TECH ENG

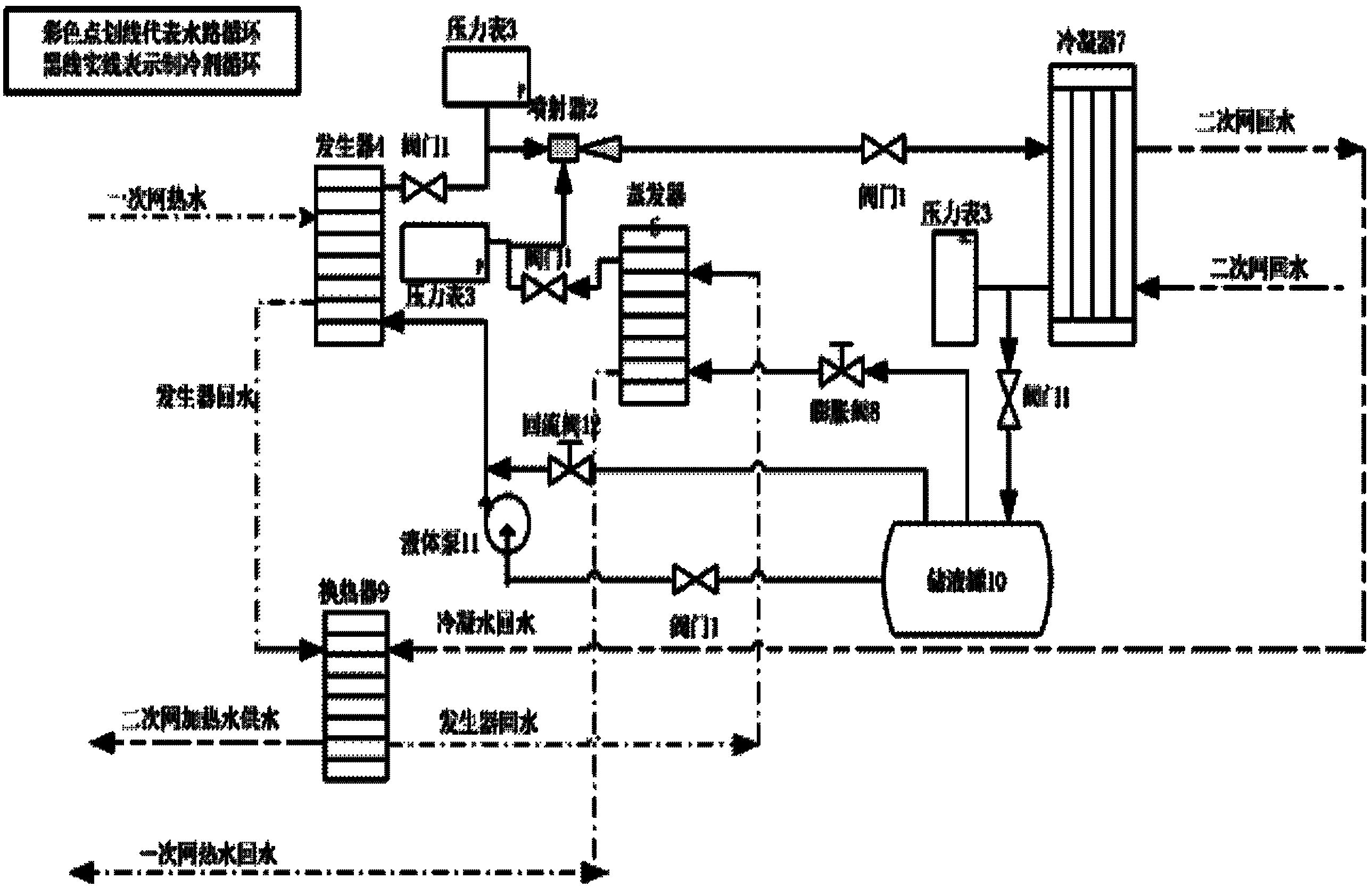

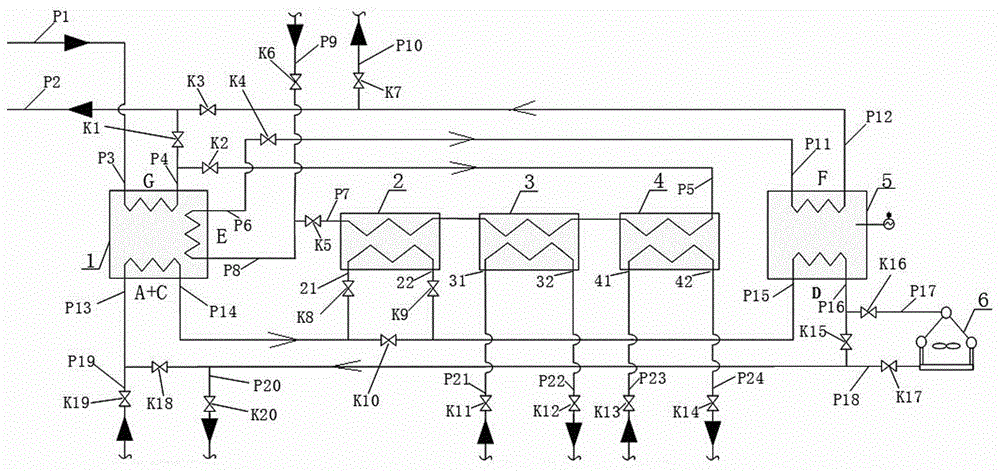

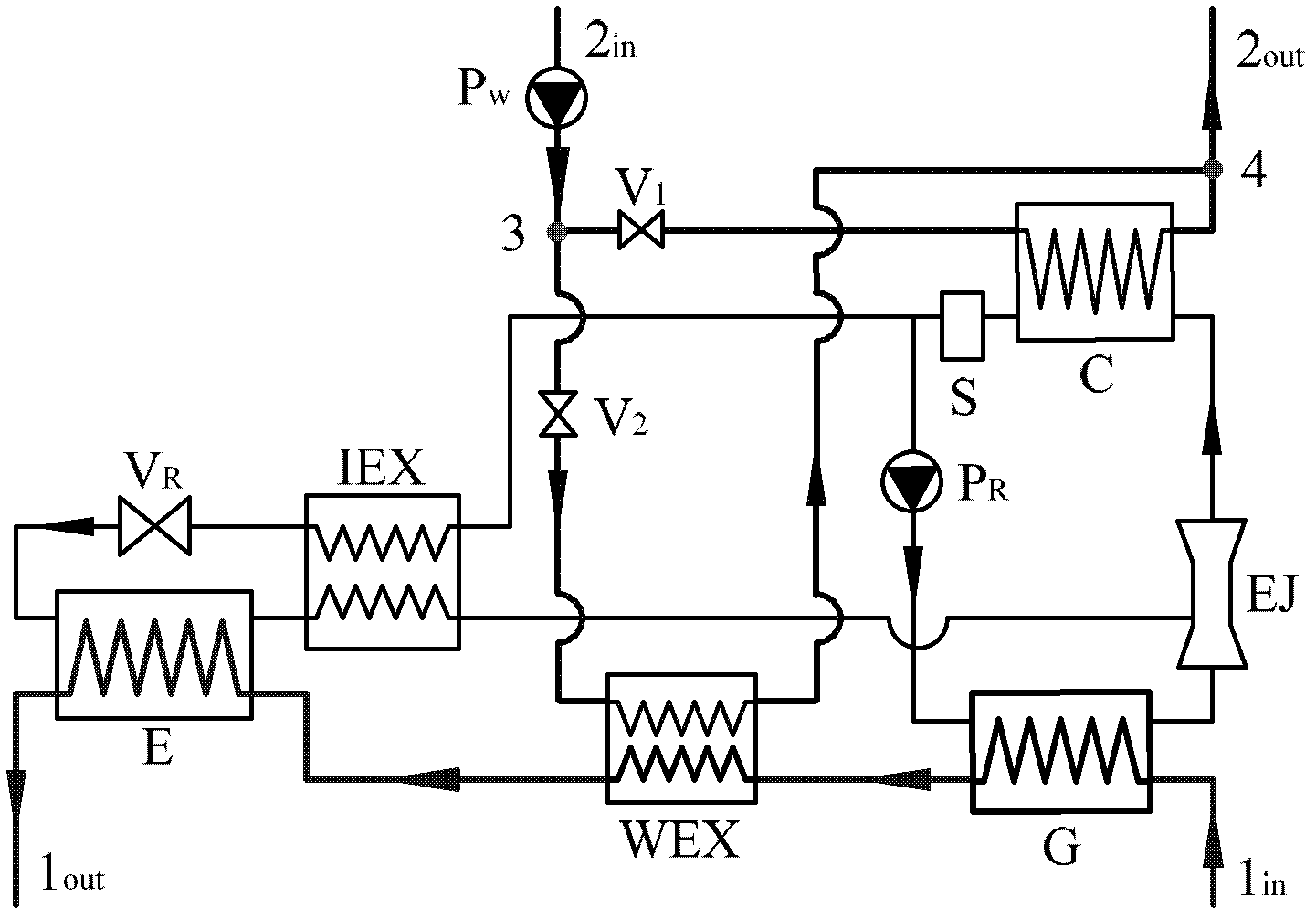

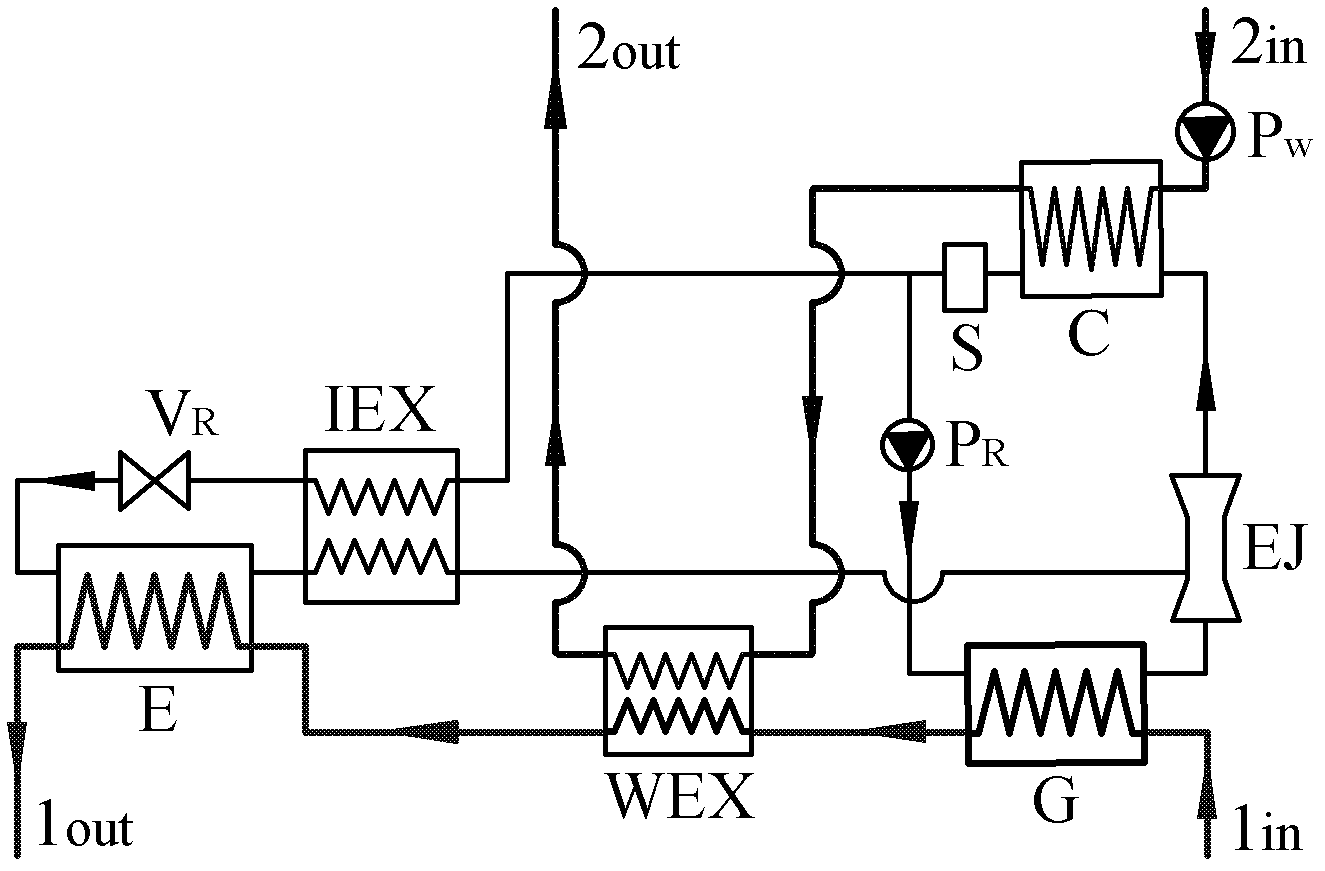

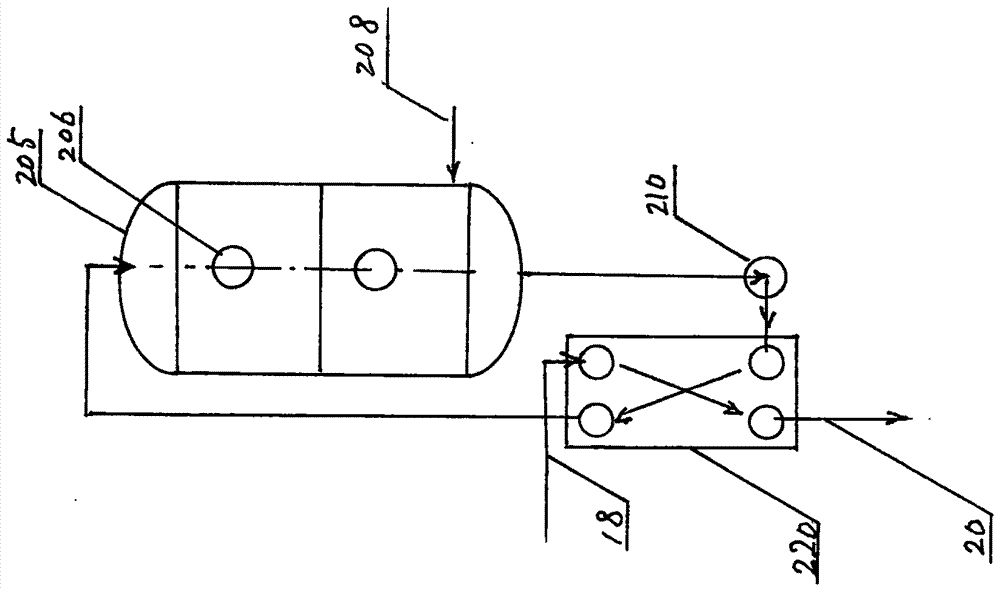

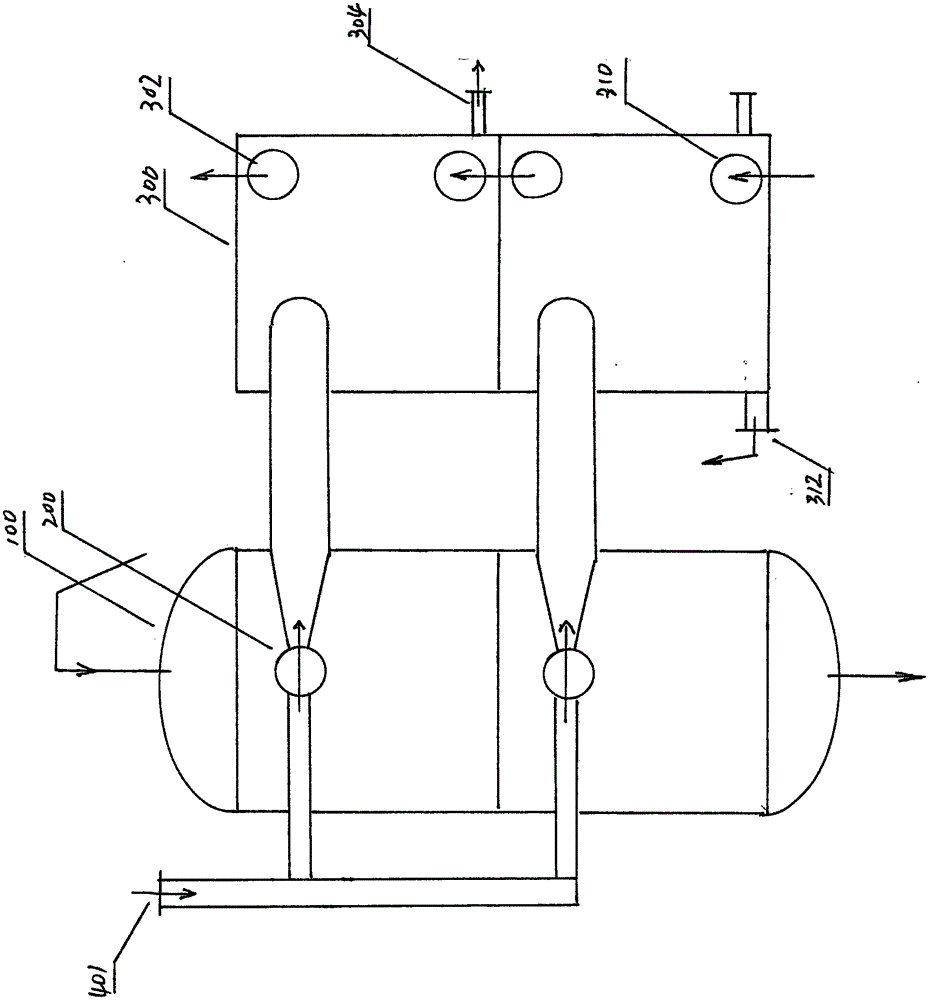

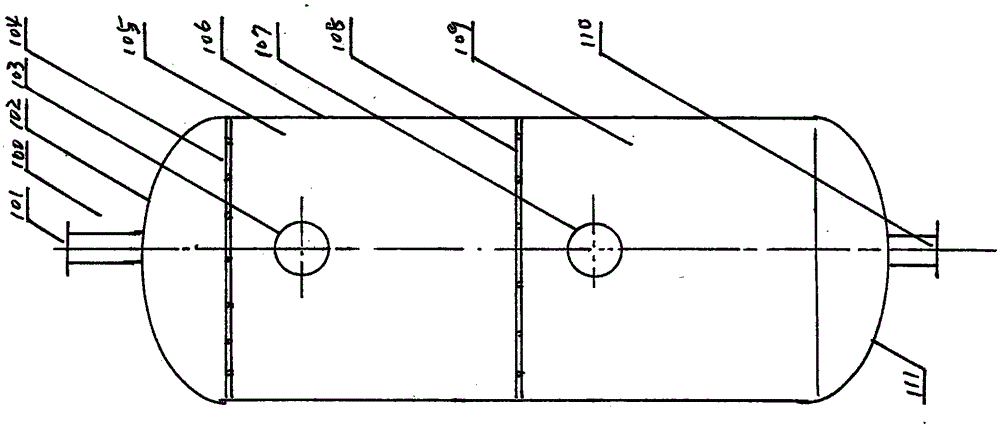

Novel jet-type heat exchanger unit

InactiveCN102538052ALower return water temperatureIncrease the temperature difference between supply and return waterLighting and heating apparatusEnergy efficient heating/coolingLiquid storage tankEngineering

The invention discloses a novel jet-type heat exchanger unit belonging to the technical field of energy sources. The unit mainly consists of a jet-type heat pump, a water-water heat exchanger and a waterway system, wherein the jet-type heat pump consists of a generator, a condenser, an evaporator, an injector, a working medium circulating pump, a heat regenerator, a liquid storage tank, a throttling device and a connecting pipeline; the waterway system of the jet-type heat exchanger unit is divided into a primary side pipeline and a secondary side pipeline. By means of a jet-type refrigeration technology, the heat of hot water of the primary side pipeline is utilized in a cascade manner, the temperature of return water of the primary side pipeline is reduced greatly, the temperature difference between supply water and return water of the primary side pipeline is increased, the heat transmission capacity of the primary side pipeline is improved by a large margin, and the heat transfer capacity of hot water in the primary side pipeline and the secondary side pipeline is improved greatly. The novel jet-type heat exchanger unit provided by the invention can be used for recovering industrial exhaust heat, solar energy and the like, and is also applicable to the substations of a central heating system so as to improve the delivery capacity of a primary heat supply network pipeline.

Owner:北京建筑工程学院

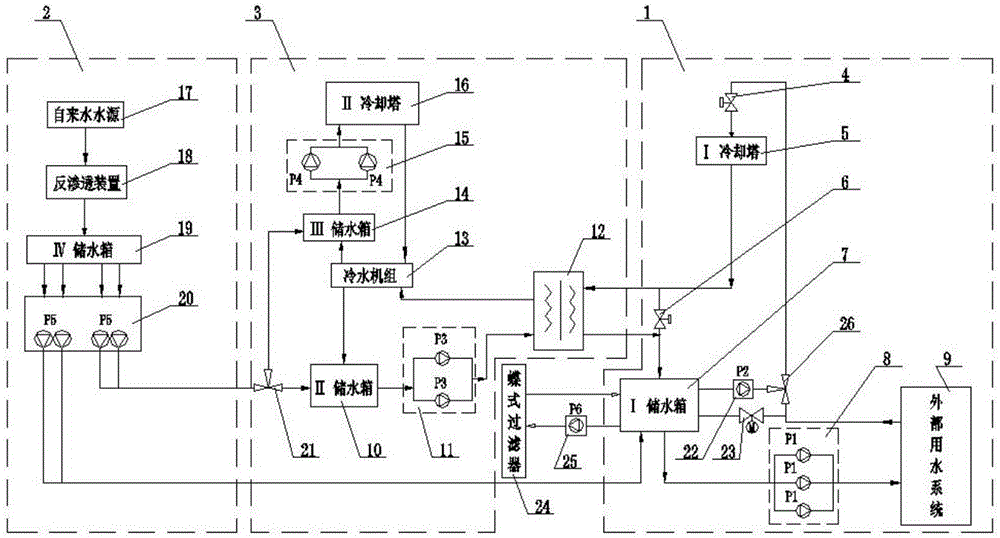

Small-temperature-variation combined type circulation cooling water system

InactiveCN105066544AImprove cooling effectReduce energy consumptionDomestic cooling apparatusLighting and heating apparatusPlate heat exchangerCooling tower

The invention relates to a small-temperature-variation combined type circulation cooling water system. The system comprises a basic circulation cooling water system and a water supplementing system and further comprises an adjusting circulation cooling water system. The water supplementing system carries out water supplementing work on the basic circulation cooling water system and the adjusting circulation cooling water system. The adjusting circulation cooling water system is connected to a return water pipeline of a cooling tower I in the basic circulation cooling water system in parallel, the temperature of return water is controlled through the function of a plate heat exchanger, a cooling water II and a water chilling unit in the adjusting circulation cooling water system are used for adjusting the water inlet temperature of the plate heat exchanger, the refrigerating capacity of the plate heat exchanger is enhanced, and a variable frequency pump is adopted in the whole system for supplying water. According to the small-temperature-variation combined type circulation cooling water system, the temperature of the return water can be precisely controlled, and the energy consumption of the system can also be reduced.

Owner:中核动力设备有限公司 +1

Large-temperature-difference heat exchange method and large-temperature-difference heat exchange device

InactiveCN107166475ASolve the shortage of heat supplyLarge heat supplyLighting and heating apparatusSpace heating and ventilation detailsInjectorSteam condensation

The present invention provides a large temperature difference heat exchange method and a large temperature difference heat exchange device capable of reducing the return water temperature of the heating network. Its working process is: (1) the high-temperature hot water for heating from the heating network enters the high-temperature evaporator The device releases heat, so that the high-temperature circulating water in it is heated and evaporated to produce high-temperature water vapor to flow out, and the high-temperature water vapor enters the steam injector as driving steam; (2) The incoming water from the heating network flows out from the high-temperature evaporator device and enters the heating heat exchanger to release heat , used for heating; (3) The incoming water from the heating network flows out from the heating heat exchanger, enters the low-temperature evaporator device to release heat, and the low-temperature circulating water is heated and evaporated to produce low-temperature steam to flow out; The return water pipe of the heating network; (4) The low-temperature water vapor generated by the heating and evaporation of the low-temperature circulating water in the low-temperature evaporator device is injected into the absorption chamber of the steam ejector, and the two are mixed into the diffuser tube of the ejector, and then enter To the condensing heat exchanger to release heat for heating.

Owner:HIT HARBIN INST OF TECH KINT TECH

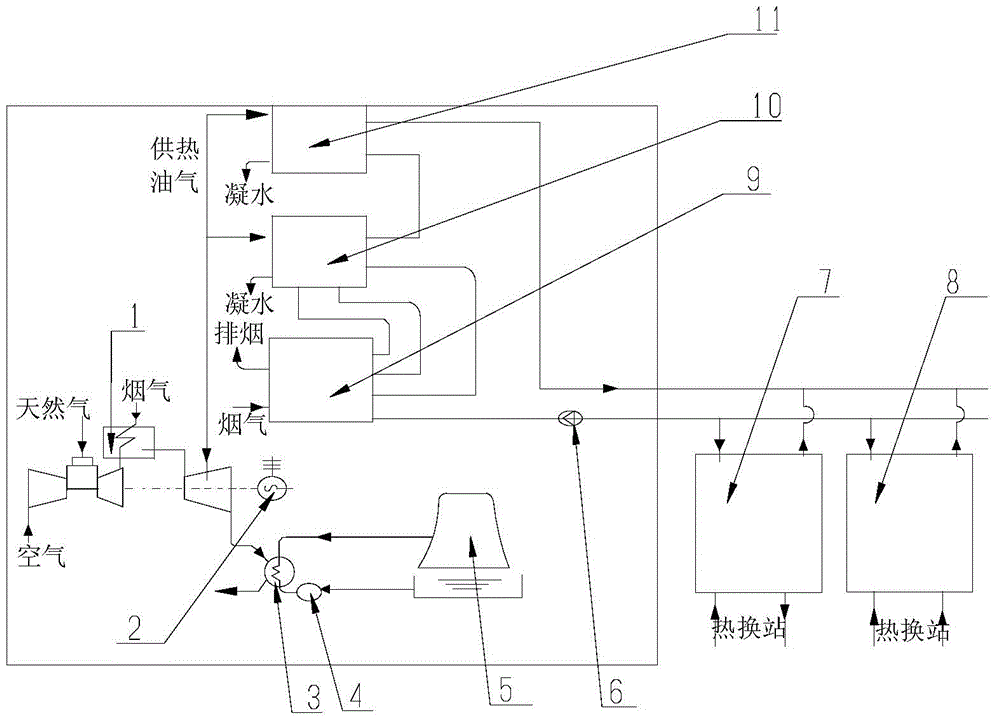

Fuel gas combined heat and power generation heating supply system based on absorption-type heat exchange

InactiveCN104964479ALower return water temperatureReduce the temperature difference between supply and return waterClimate change adaptationEnergy industryCooling towerPower station

The invention discloses a fuel gas combined heat and power generation heating supply system based on absorption-type heat exchange. The fuel gas combined heat and power generation heating supply system comprises a waste heat boiler, an electric generator, a condenser, a cooling circulation pump, a cooling tower, a heat supply network circulating pump, a first absorption-type heat exchange unit, a second absorption-type heat exchange unit, a smoke ventilation device, an absorption-type heat pump and a gas and water heat exchanger; a steam turbine is installed on one side of the waste heat boiler, and the steam turbine is connected with the electric generator; the condenser and the steam turbine are connected with pipelines of the cooling tower; the smoke ventilation device is connected with pipelines of the first absorption-type heat exchange unit and the second absorption-type heat exchange unit. According to the fuel gas combined heat and power generation heating supply system based on the absorption-type heat exchange, in a heating station, by means of an absorption-type heat exchange technology, a conventional plate heat exchanger is replaced with the absorption-type heat exchange units, actual supply water temperature of a heat supply network is 120 DEG C, the return water temperature of 25 DEG C of the heat supply network is achieved so as to recycle a large number of waste heat of power stations, and the energy utilization efficiency of the system is improved.

Owner:ZHONGNENG SHIHUA BEIJING ENERGY SAVING SCI & TECH

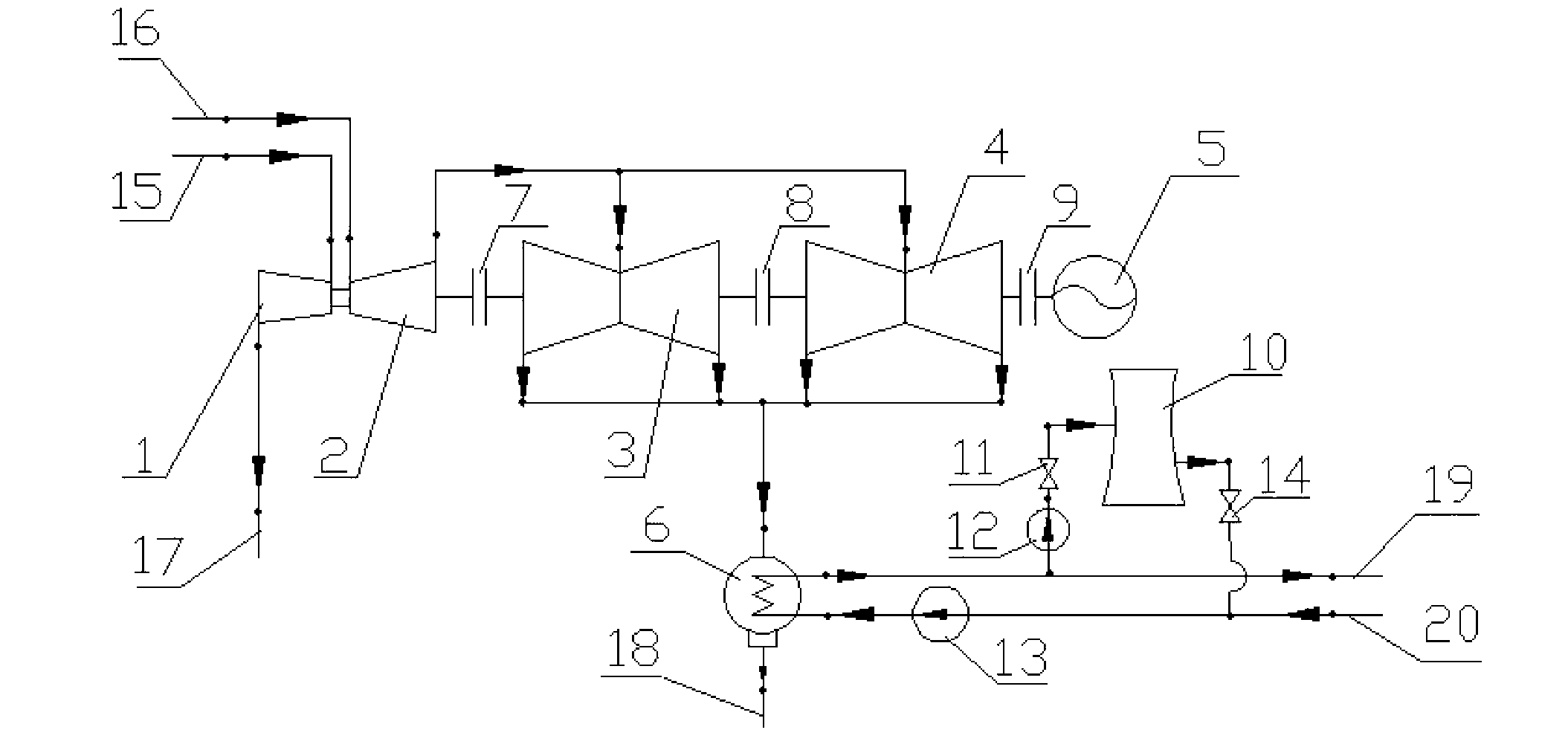

Large temperature difference centralized heating system using power plant waste heat and work method

ActiveCN108800275ALower return water temperatureImprove heat utilizationHeat recovery systemsLighting and heating apparatusTemperature differenceProcess engineering

The invention discloses a large temperature difference centralized heating system using power plant waste heat and a work method. A two-stage water-water heat exchanger and a two-stage power drive heat pump unit are arranged in a two-stage net heat exchange station, a circular cooling water waste heat recycling heat exchanger, a circular cooling water waste heat recycling electric heat pump unit,steam-water heat exchanger and a water-water heat exchanger are arranged in a first-stage pipe network heat exchange station, on the premise of ensuring the secondary network normal water supply temperature, water supply temperature of a primary heat network can be greatly reduced, steam consumption of a heat supply system is greatly reduced, and the use proportion of thermal power plant circularwater waste heat is greatly improved. Meanwhile, it is ensured that a secondary pipe network has the normal water supply temperature and water supply and returning temperature difference, the water supply temperature of the primary heat network is reduced to 80 DEG C, the water supply temperature of a secondary pipe network reaches about 70 DEG C, and the normal running flow of the secondary pipenetwork and energy-saving running of the circular water pump are ensured.

Owner:HENAN POLYTECHNIC UNIV

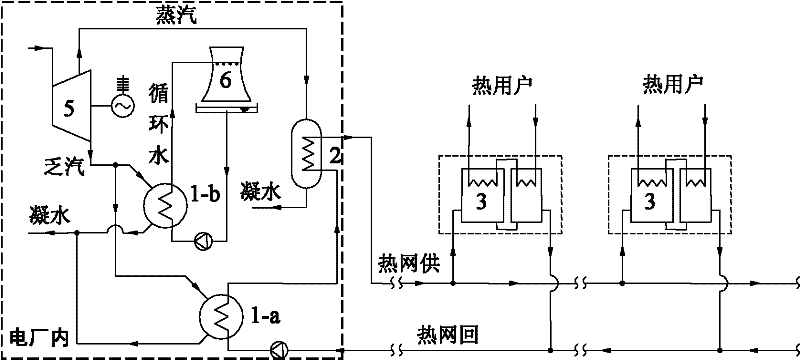

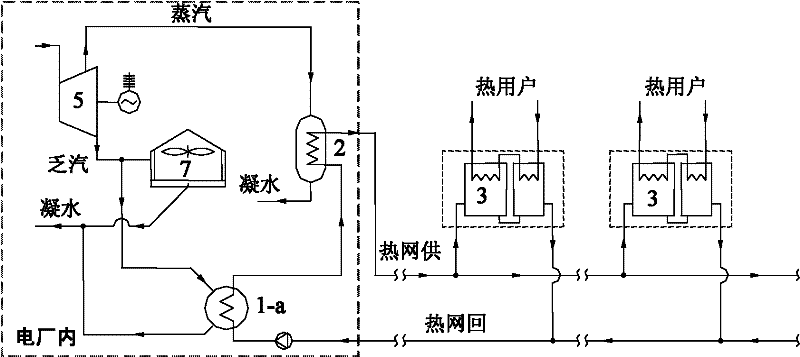

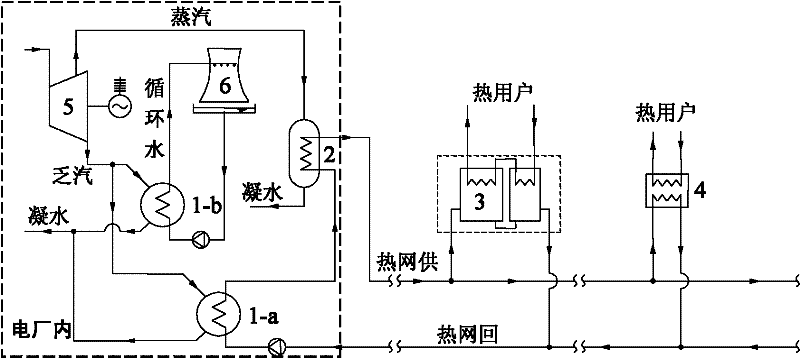

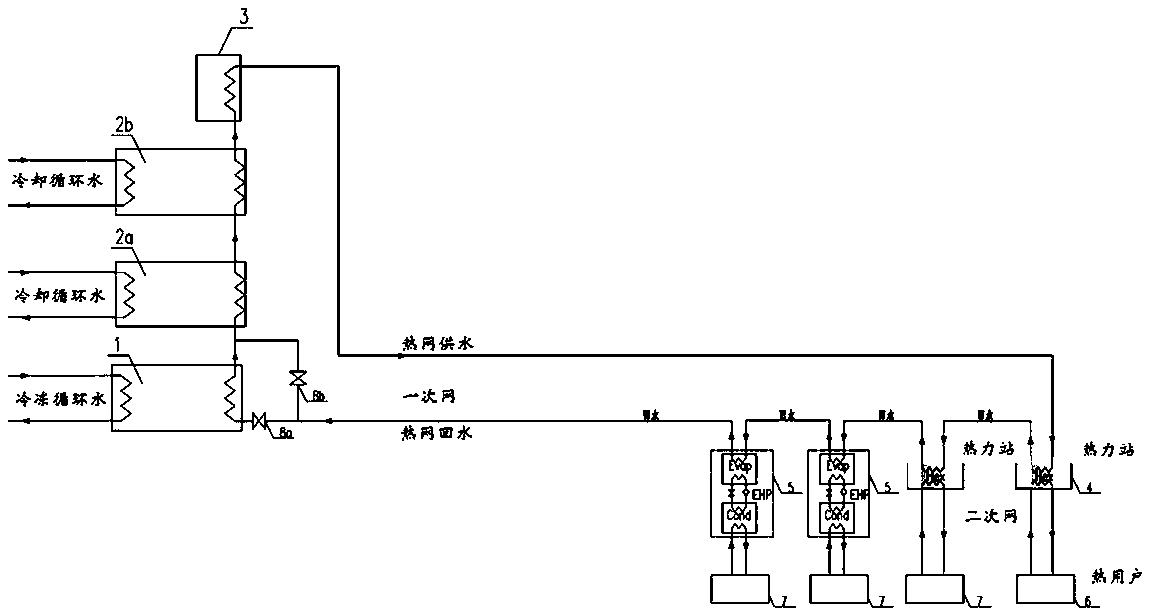

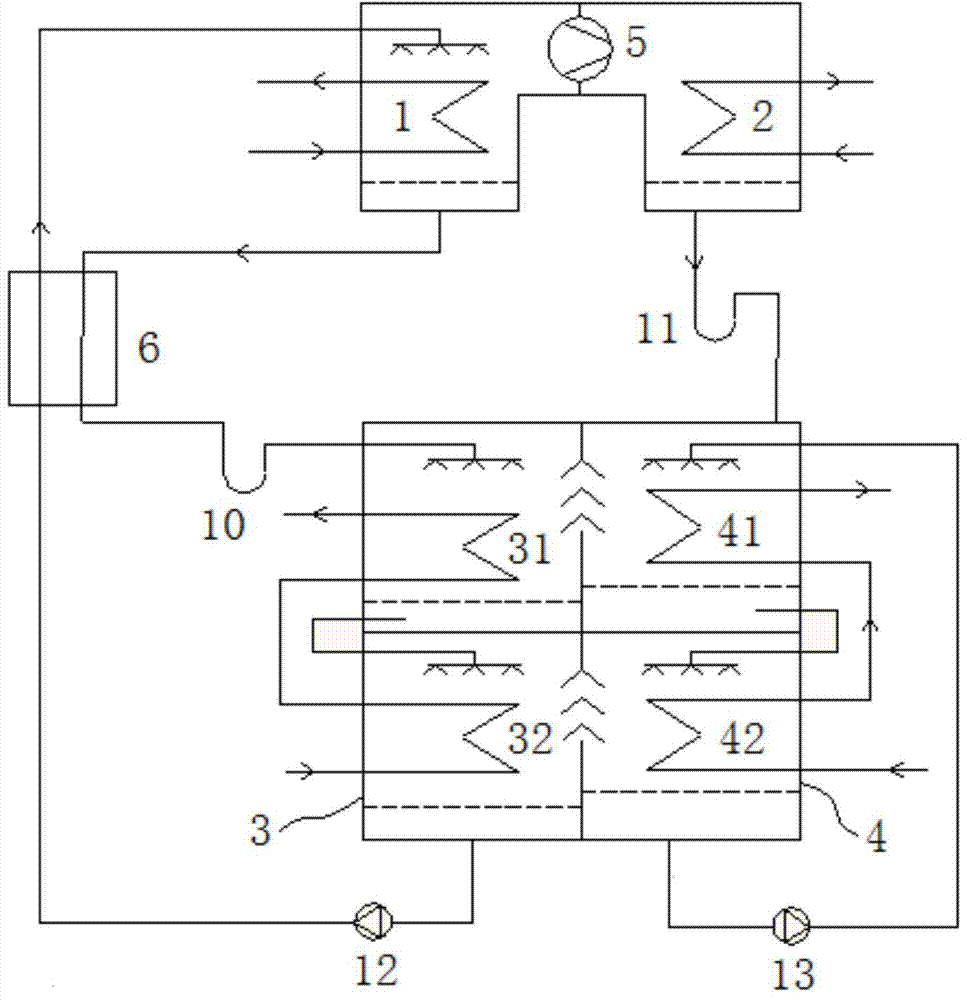

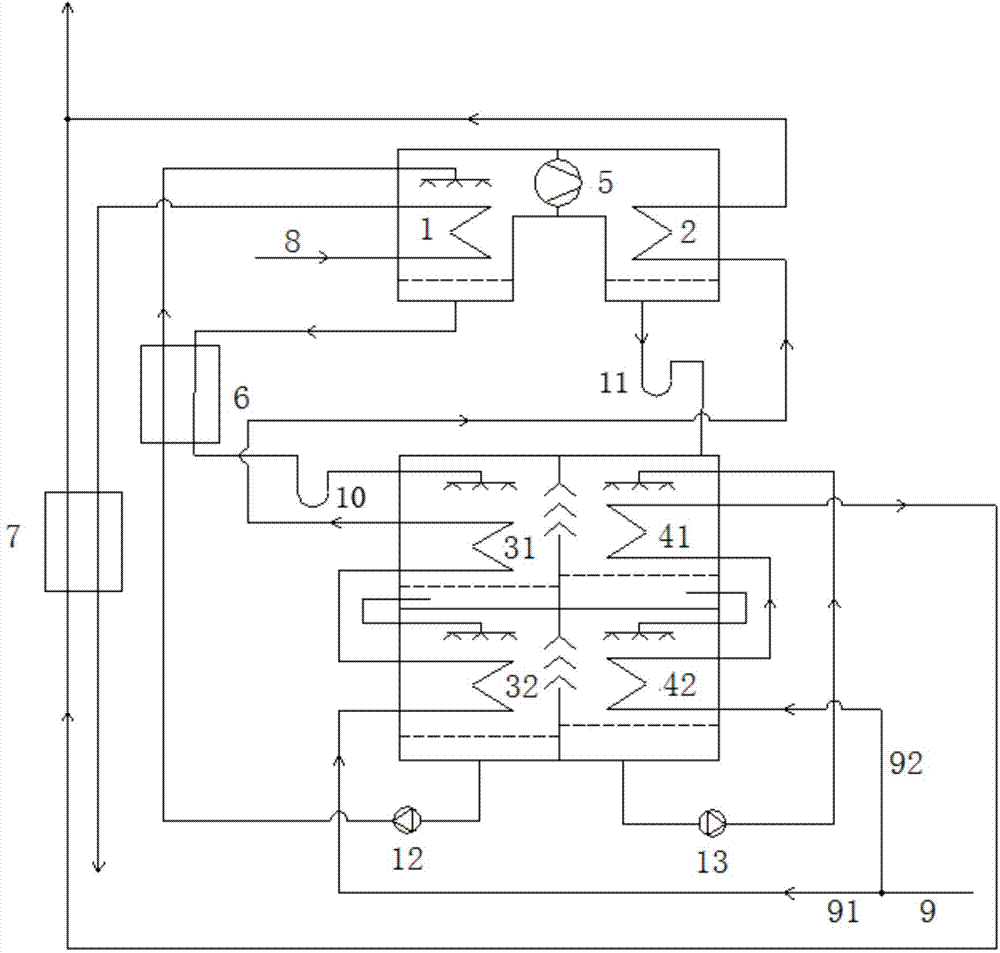

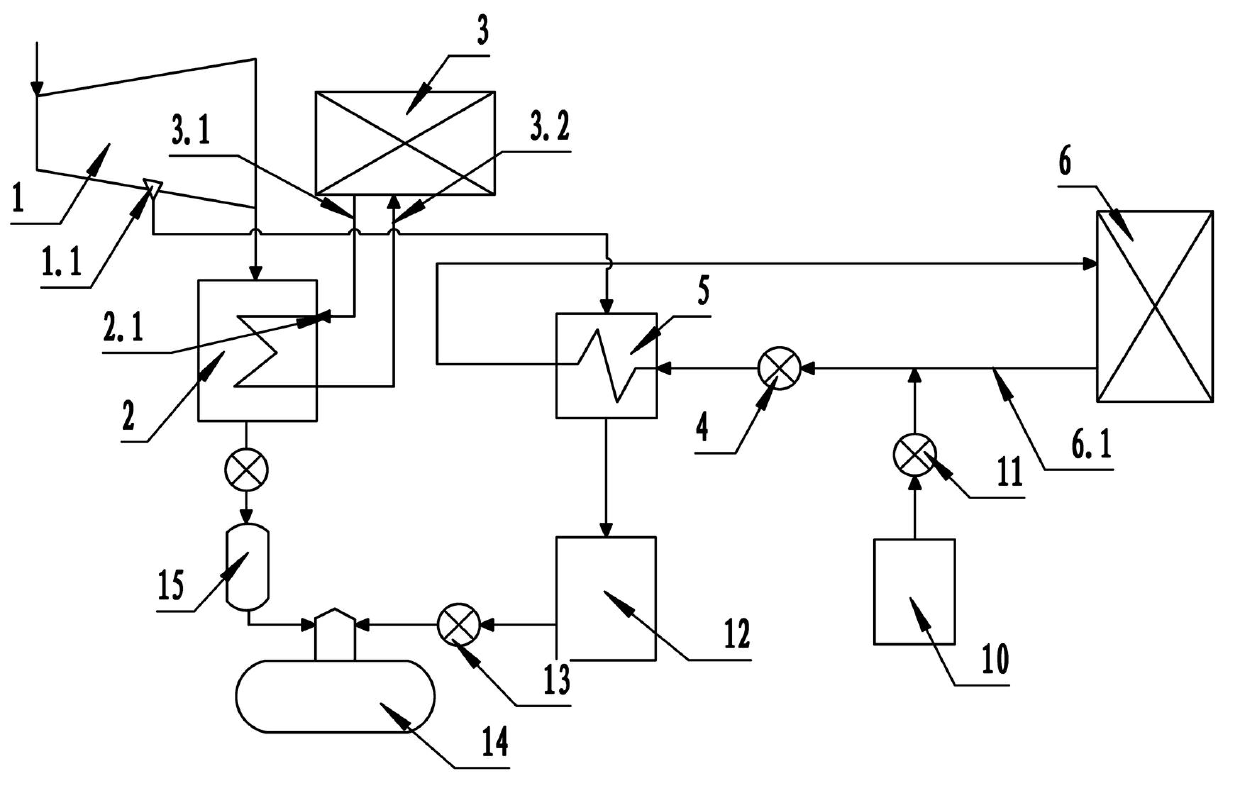

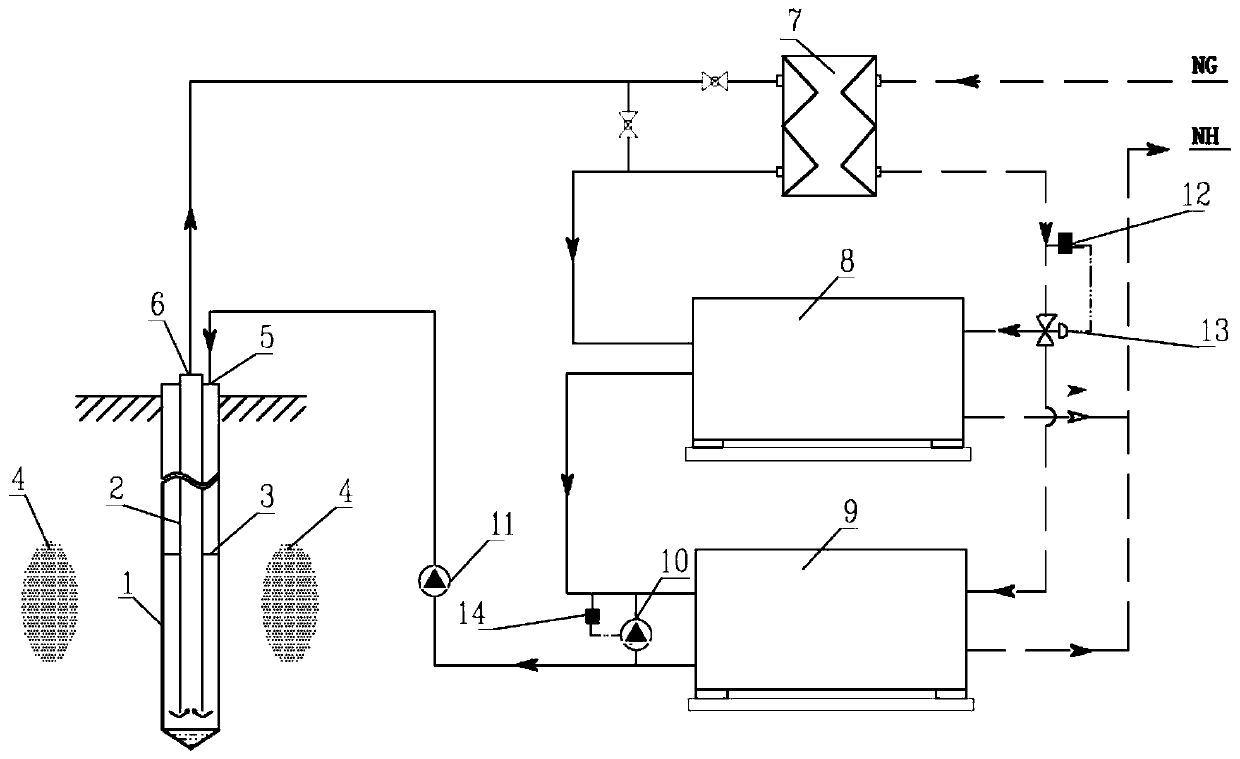

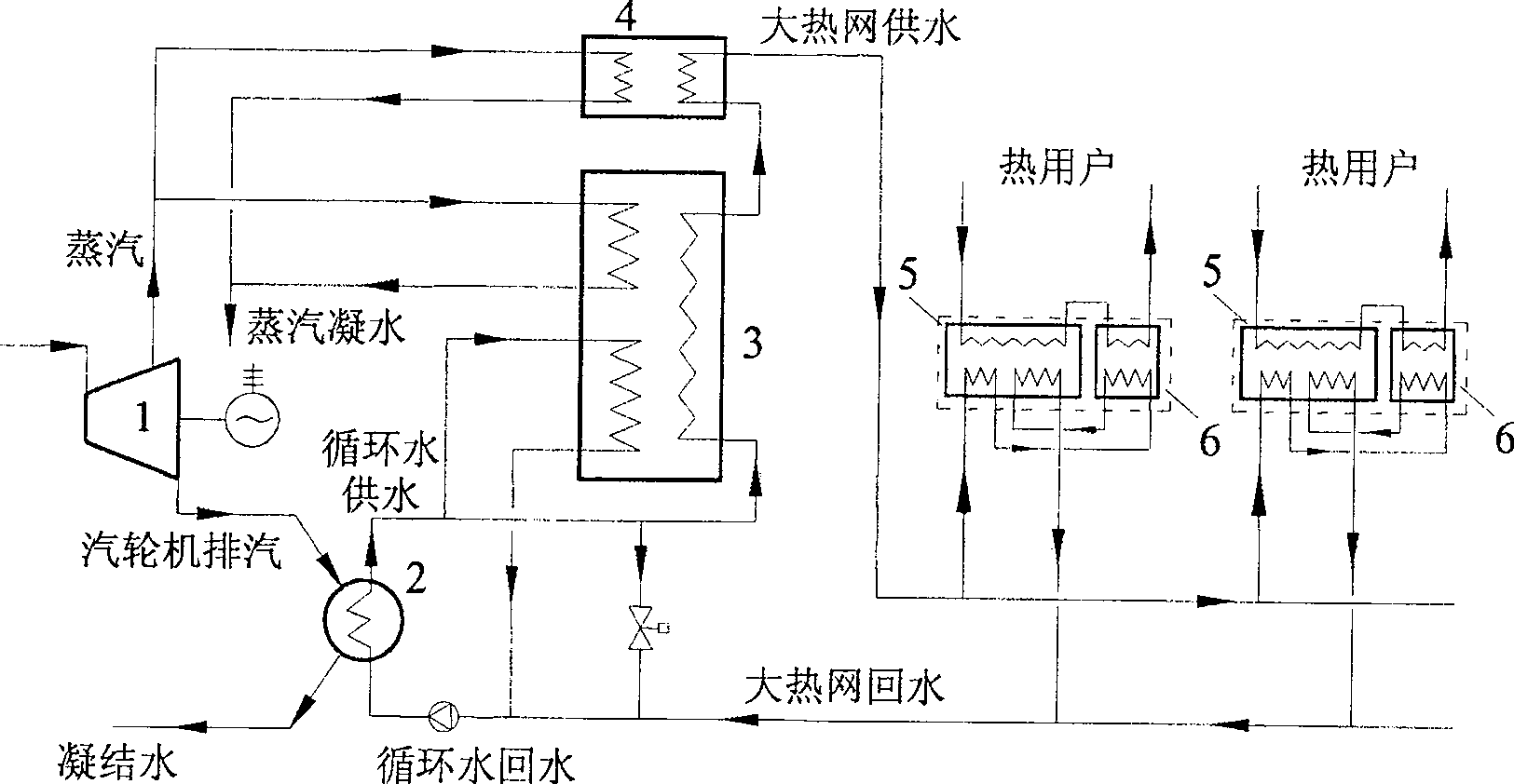

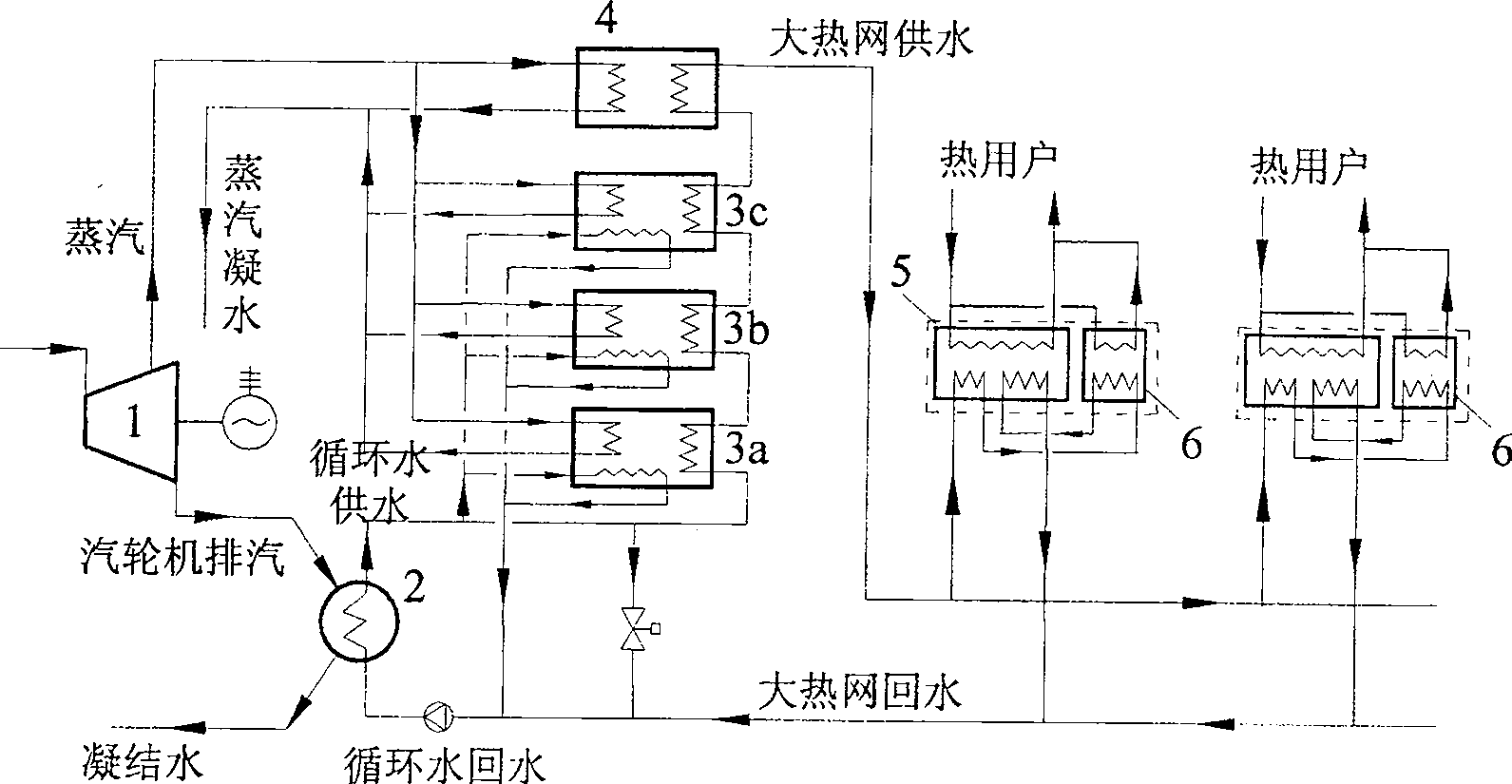

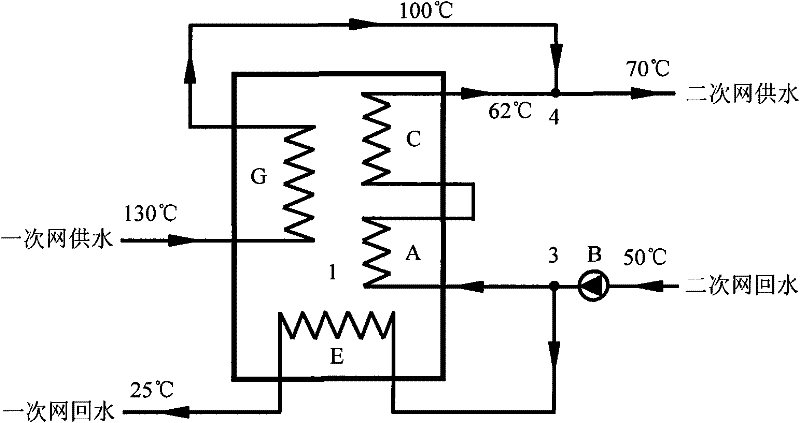

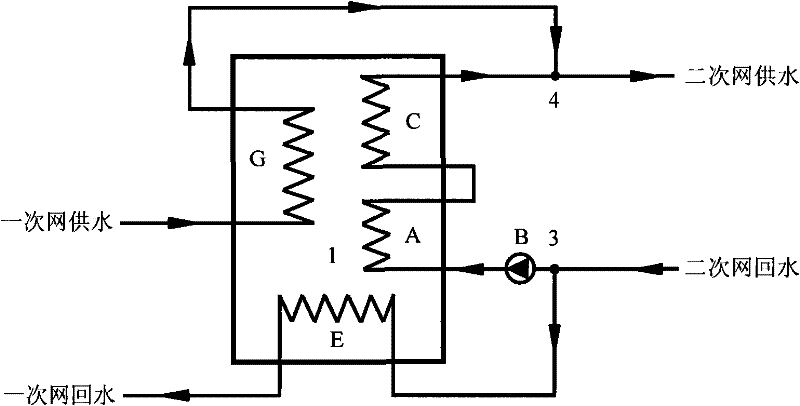

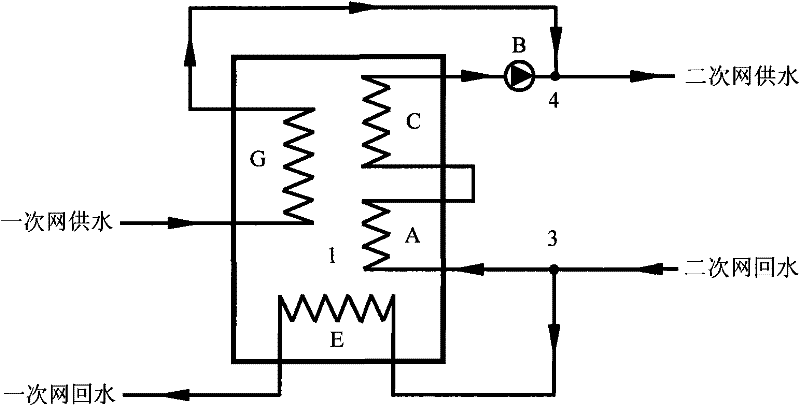

Large temperature-difference central heating system

ActiveCN100507375CLarge heating temperature differenceImprove delivery capacityHeat recovery systemsLighting and heating apparatusTemperature differenceEngineering

A kind of concentrated heat-supply system includes a steam turbine (1), which has a condenser (2), at least a steam absorption type heat pump (3), a steam-water heat exchanger (4) and pipes (7, 8, 9). The exhausted steam of the steam turbine (1) is used to pre-heat the back-water of the first heat network, and drive the steam absorption type heat pump (3). The hot water of the heat network is heated by the condenser (2), the steam absorption type heat pump (3) and the steam-water heat exchanger (4) for three times. At the end, the heat-supply hot water of the second network is heated by a hot water absorption type heat pump (5) and a water-water heat exchanger (6) in a combination form.

Owner:TSINGHUA UNIV +1

Method for reducing return water temperature of heat supply pipeline

ActiveCN101629733BLower return water temperatureReduce initial investmentLighting and heating apparatusEnergy efficient heating/coolingEnergy technologyAbsorption heat pump

Owner:TSINGHUA UNIV +1

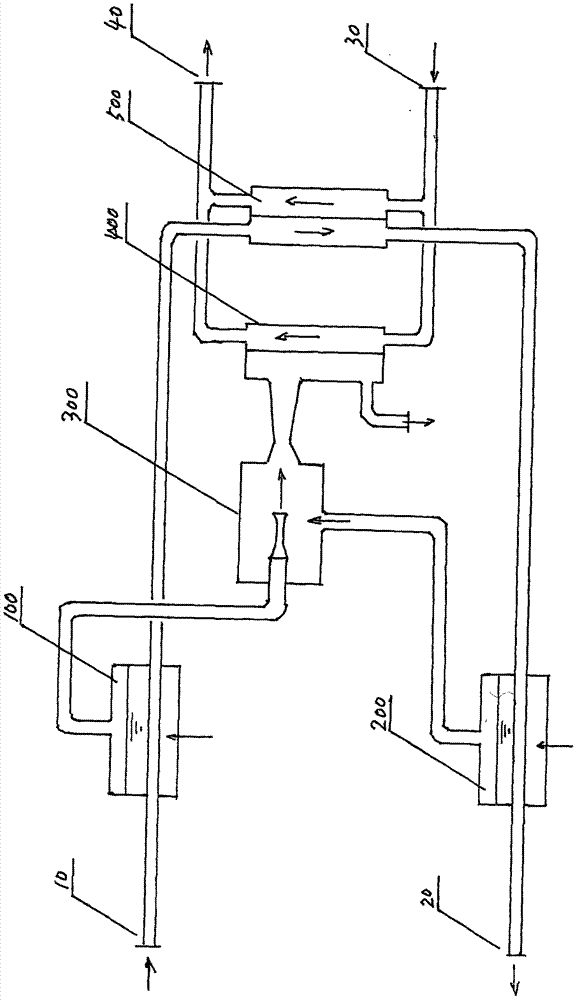

Jet type large temperature difference heat exchange method and device

InactiveCN106839049AGuaranteed to workSolve the shortage of heat supplyLighting and heating apparatusHot-water central heatingWater dischargeWater flow

The invention discloses a jet type large temperature difference heat exchange method and device. The device structurally comprises an evaporator, jetting devices, a condenser and connecting pipelines. The device is divided into the left portion, the middle portion and the right portion, the upright multi-stage evaporator is arranged on the left portion, the upright multi-stage condenser is arranged on the right portion, and each steam jetting device is arranged between the corresponding stage of the evaporator and the corresponding stage of the condenser for connection; the jetting devices jet low-pressure water steam in the evaporator by means of high-temperature water, with certain pressure, coming from a heat supply pipe network, and a steam-water mixture with the medium pressure is formed and enters the condenser; the steam-water mixture entering the condenser heats heat supply circulating water, the steam is condensed and dissolved in the rest of water to form medium-temperature water, and the medium-temperature water flows out of a water outlet of the condenser and flows into the evaporator; and through stage-by-stage evaporation of several evaporation chambers from top to bottom, the medium-temperature water is cooled to form low-temperature water, and the low-temperature water is discharged out of a water discharging outlet in the bottom of the evaporator and flows back to a water return pipeline of the heat supply pipe network.

Owner:HIT HARBIN INST OF TECH KINT TECH

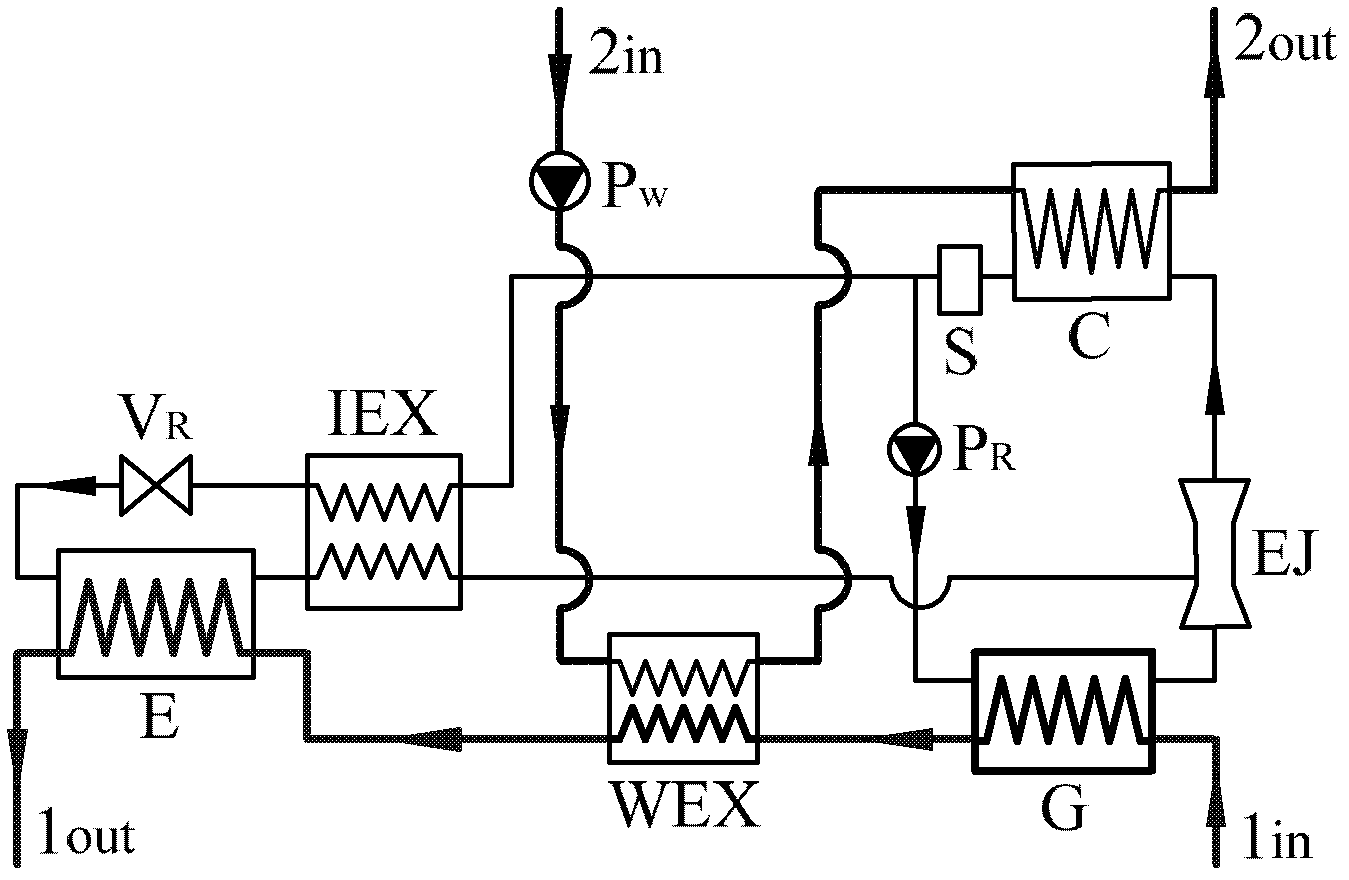

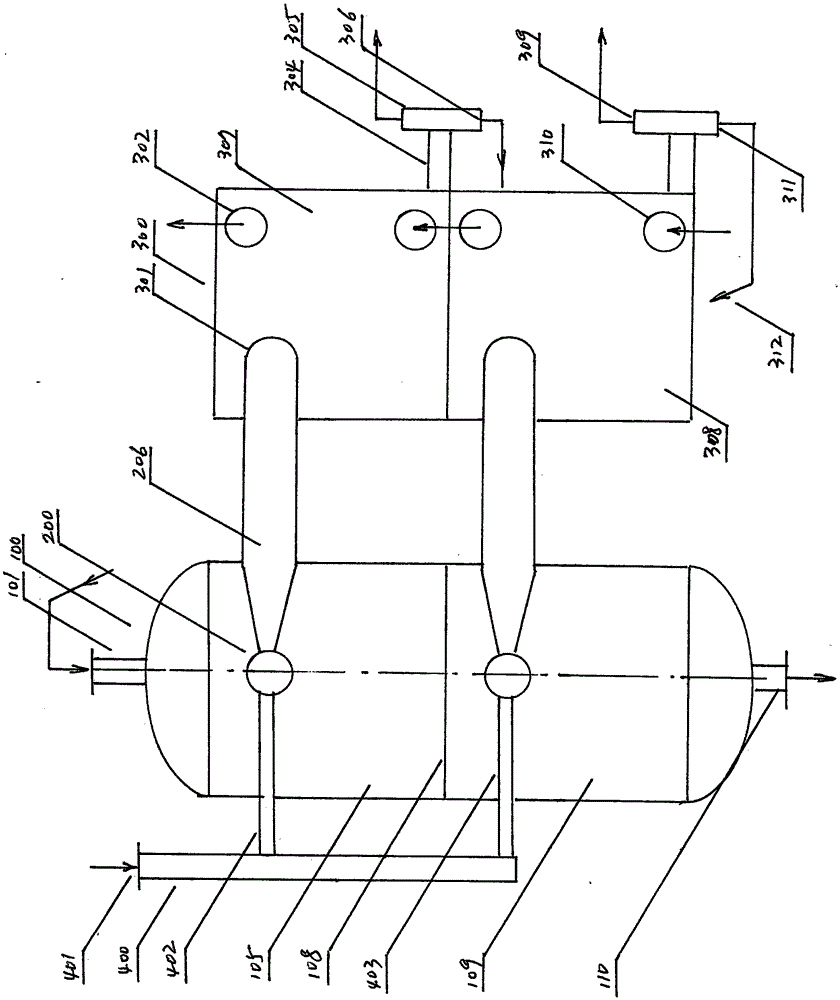

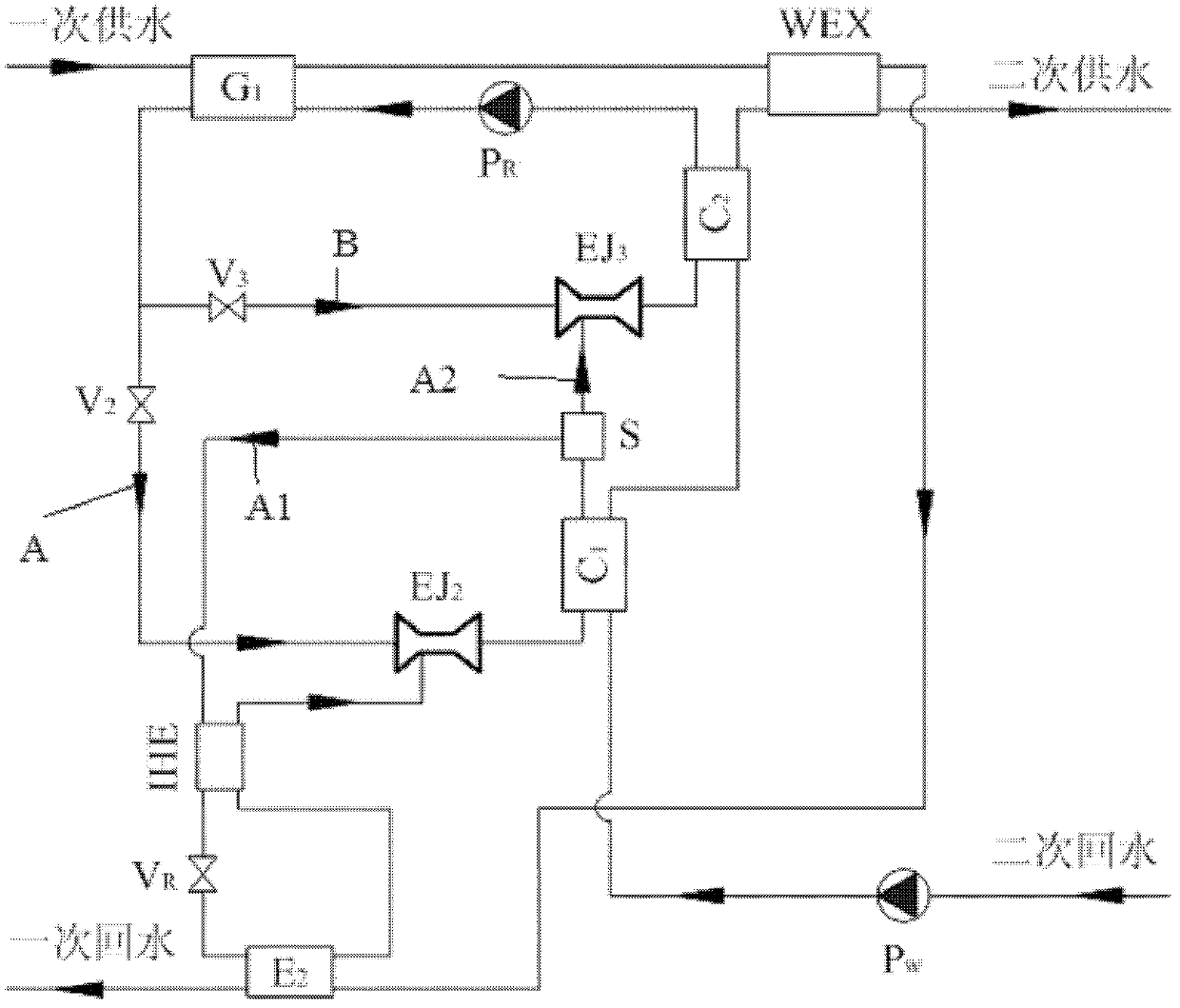

High-efficiency jetting type heat exchange machine set

ActiveCN102589043AImprove hot water heat transfer capacityIncreased heat transfer capabilityLighting and heating apparatusSpace heating and ventilation detailsEngineeringWater supply

The invention discloses a high-efficiency jetting type heat exchange machine set, belonging to the technical field of energy source utilization. The high-efficiency jetting type heat exchange machine set consists of a high-efficiency jetting type heat pump, a water-water heat exchanger, a circulating water pump, a connection pipe, a valve and other accessories, wherein the high-efficiency jetting type heat pump is of a two-stage condensation and two-stage evaporation structure or a two-stage condensation and one-stage evaporation structure, and the connection pipe is divided into a working medium system pipe and a water system pipe, wherein the water system pipe is divided into primary side pipes and secondary side pipes, the primary side pipes are connected in series, and the secondary side pipes are connected in parallel and series. Depending on the jetting type heat pump technique, the high-efficiency jetting type heat exchange machine set disclosed by the invention can perform cascade utilization to the water supply heat of the primary side pipes through certain pipe connection manners, therefore, returned water temperature of the primary side pipes is greatly reduced, so that the returned water supply temperature difference of the primary side pipes is increased, and heat transfer capability of hot water of the primary side pipes and the secondary side pipes is greatly improved.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com