Novel jet-type heat exchanger unit

A technology of heat exchange unit and jet heat pump, which is applied in the field of industrial waste heat recovery and solar energy, can solve the problems of high investment in pipe network, high energy consumption of pipe network transportation, and high cost of central heating, so as to reduce the temperature of return water and improve the efficiency of pipe network. The effect of increasing the transmission capacity of the road and increasing the temperature difference between the supply and return water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

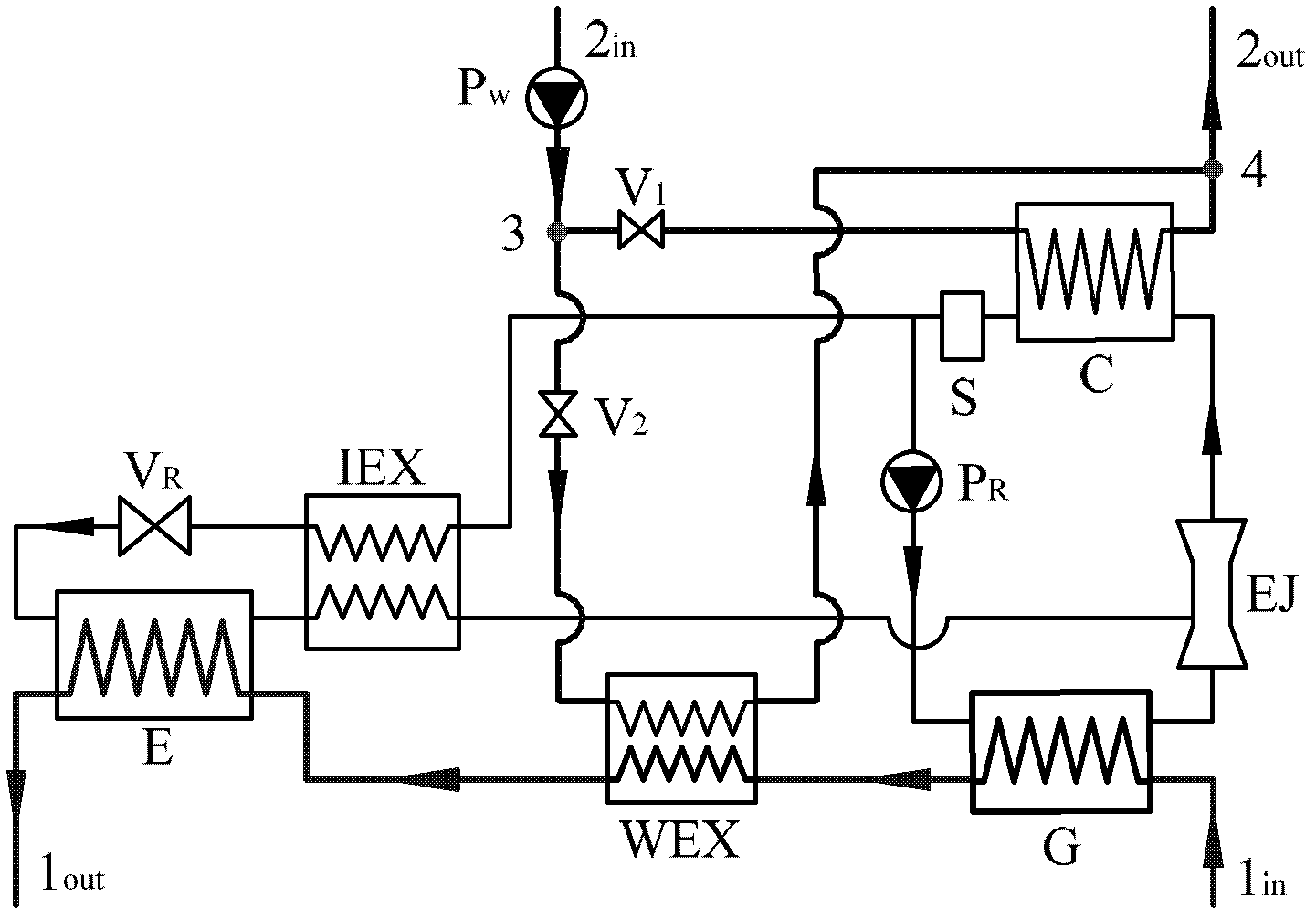

[0024] Embodiment 1: The first kind of system composition and connection mode, such as figure 1 As shown, a new jet heat exchange unit is mainly composed of a jet heat pump, a water-to-water heat exchanger WEX and a waterway system. The jet heat pump is mainly composed of a generator G, a condenser C, an evaporator E, an ejector EJ, Working fluid circulation pump P R , regenerator IEX, liquid storage tank S, throttling device V R and connecting pipelines.

[0025] Heat pump working fluid process: The heat pump liquid working medium is heated by the water supply of the primary side pipeline in the generator G to become the heat pump working medium vapor, and then enters the ejector EJ to speed up and reduce pressure, and injects the low-pressure superheating work from the regenerator IEX After the steam of the two working fluids is combined, decelerated and pressurized, it enters the condenser C and is condensed into a liquid by the return water from the secondary side pipeli...

Embodiment 2

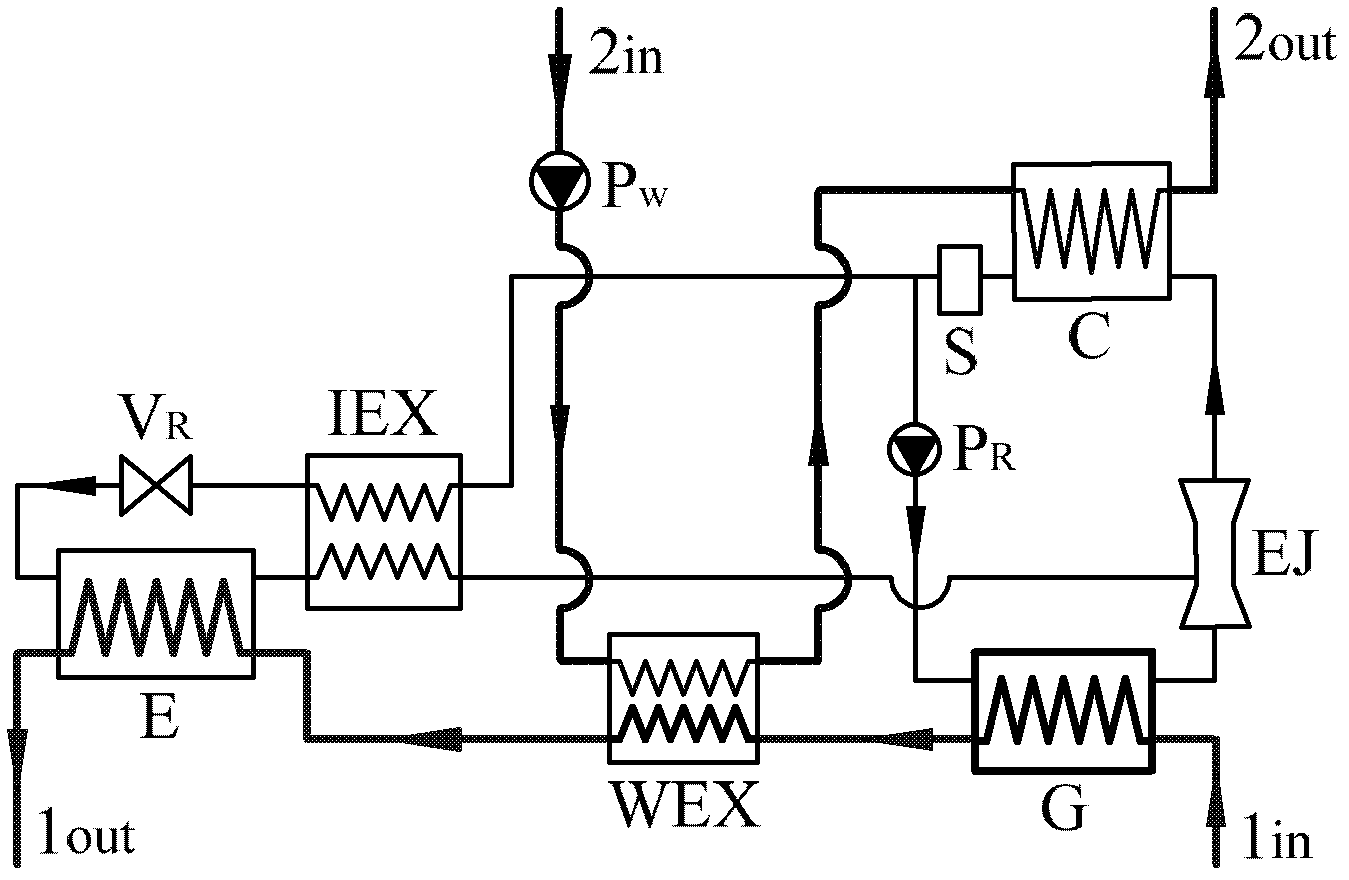

[0029] Embodiment 2: the second kind of system composition and connection mode, such as figure 2 As shown, a new jet heat exchange unit is mainly composed of a jet heat pump, a water-to-water heat exchanger WEX and a waterway system. The jet heat pump is mainly composed of a generator G, a condenser C, an evaporator E, an ejector EJ, Working fluid circulation pump P R , regenerator IEX, liquid storage tank S, throttling device V R and connecting pipelines.

[0030] Heat pump working fluid process: After the heat pump liquid working fluid is heated by the water supply in the primary side pipeline in the generator G and turned into working fluid vapor, it enters the ejector EJ to speed up and reduce pressure, and injects the low-pressure superheating working fluid from the regenerator IEX. After the two-way working medium steam merges, decelerates and pressurizes, it enters the condenser C and is condensed into a liquid by the return water from the secondary side pipeline, an...

Embodiment 3

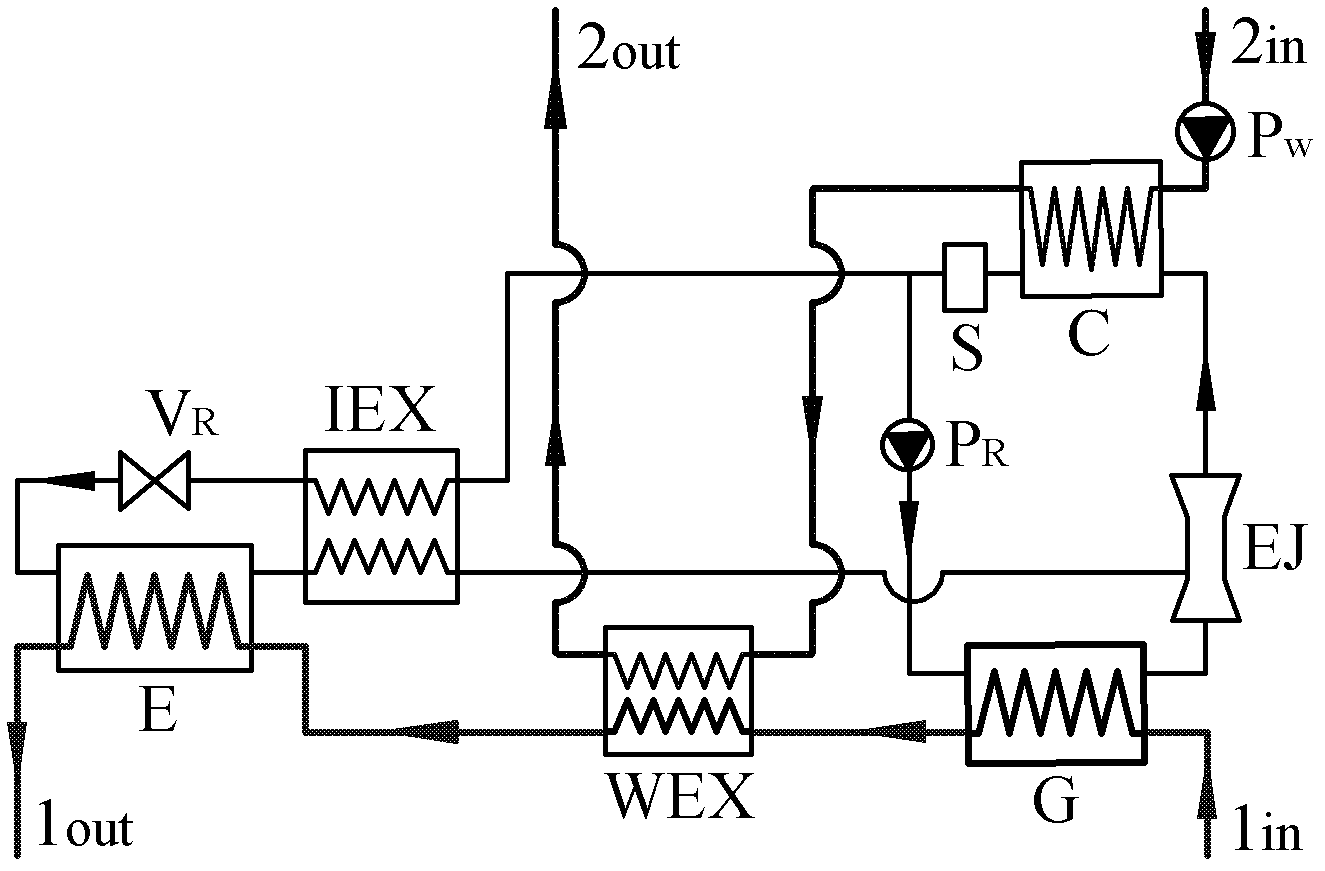

[0034] Embodiment 3: the third kind of system composition and connection mode, such as image 3 As shown, a new jet heat exchange unit is mainly composed of a jet heat pump, a water-to-water heat exchanger WEX and a waterway system. The jet heat pump is mainly composed of a generator G, a condenser C, an evaporator E, an ejector EJ, Working fluid circulation pump P R , regenerator IEX, liquid storage tank S, throttling device V R and connecting pipelines.

[0035] Heat pump working fluid process: After the heat pump liquid working fluid is heated by the water supply in the primary side pipeline in the generator G and turned into working fluid vapor, it enters the ejector EJ to speed up and reduce pressure, and injects the low-pressure superheating working fluid from the regenerator IEX. After the steam of the two working fluids merges, decelerates and pressurizes, it enters the condenser C and is condensed into a liquid by the hot water from the secondary side pipeline, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com