Large temperature-difference central heating system

A central heating and large temperature difference technology, which is applied in steam central heating systems, heating systems, hot water central heating systems, etc., can solve the problems of low energy utilization efficiency, achieve large heating temperature differences, increase transportation capacity, The effect of lowering the return water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

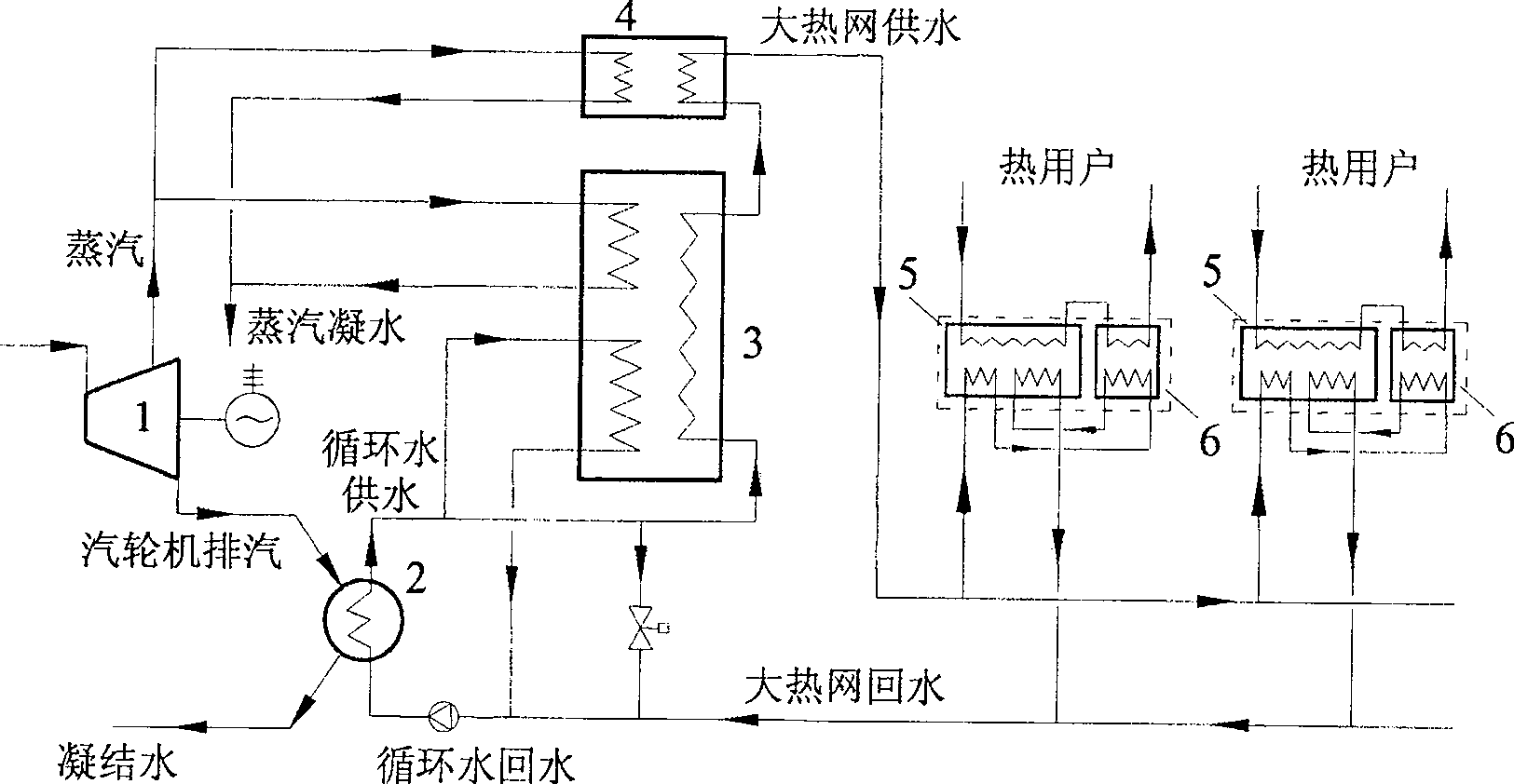

Embodiment 1

[0014] Example 1: Basic heating method. like figure 1 As shown, the system consists of steam turbine 1, condenser 2, steam absorption heat pump 3, steam-water heat exchanger 4, hot water absorption heat pump 5, water-water heat exchanger 6, connecting pipelines and accessories. The exhaust steam from the final stage of the steam turbine 1 enters the condenser 2 to heat the circulating water, and then returns to the boiler for heating after being cooled and condensed; the steam extracted from the steam turbine 1 is divided into two paths, and one path enters the steam absorption heat pump 3 as a driving heat source to recover the waste heat of the circulating water , and heat the large heat network, and the other way enters the steam-water heat exchanger 4, directly heats the large heat network, and the steam condenses and returns to the boiler for heating; the circulating cooling water enters the condenser 2, is sent out after being heated by the exhaust steam of the steam tur...

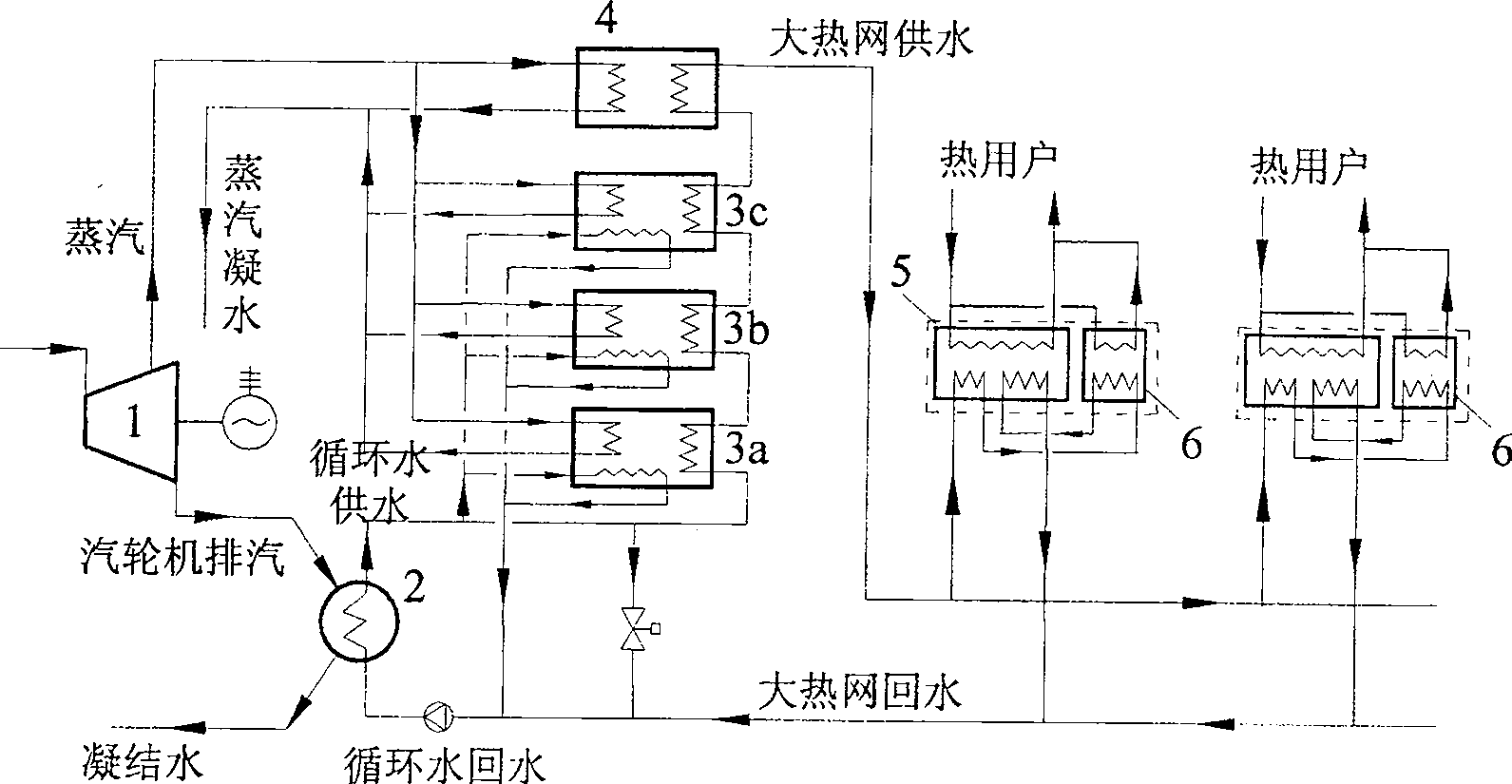

Embodiment 2

[0016] Example 2: Three-stage steam absorption heat pumps are used for heating in series. like figure 2 As shown, the system consists of a steam turbine 1, a condenser 2, a first-stage steam absorption heat pump 3a, a second-stage steam absorption heat pump 3b, a third-stage steam absorption heat pump 3c, a steam-water heat exchanger 4, and a hot water absorption heat pump 5. The water-water heat exchanger 6 is composed of connecting pipelines and accessories. The exhaust steam from the final stage of steam turbine 1 enters the condenser 2 to heat the circulating water, and after being cooled and condensed, it returns to the boiler for heating; the steam extracted from steam turbine 1 is divided into two paths, and one path is used as a driving heat source to enter the first-stage steam absorption heat pump 3a and the second stage respectively. The first-stage steam absorption heat pump 3b and the third-stage steam absorption heat pump 3c recover the waste heat of the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com