Sludge viscosity reduction drying method

A sludge and drying technology, applied in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high energy consumption, easy to produce sticky wall effect, easy to produce harmful and toxic gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Source of sludge: belt filter dewatered sludge from Nanchang Honggutan Wastewater Treatment Plant;

[0065] After the sludge is concentrated and digested, the initial weight reduction (centrifugal dewatering) is performed to obtain sludge with a moisture content of 83.2%;

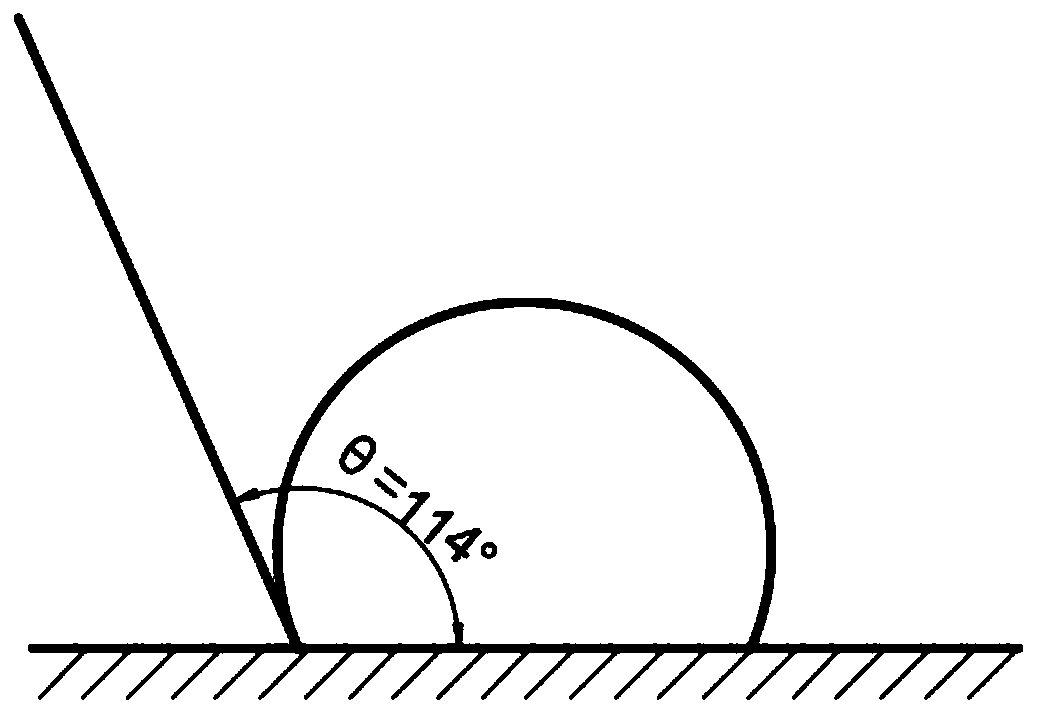

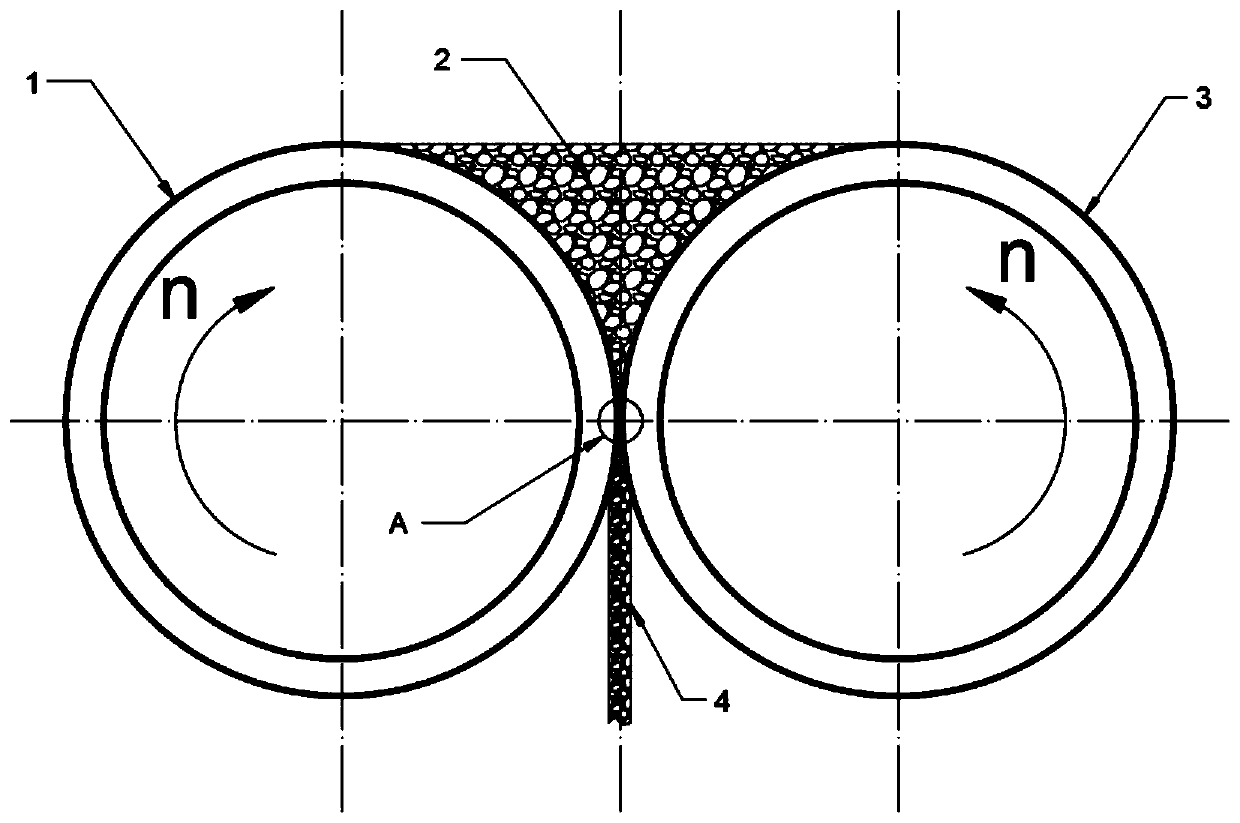

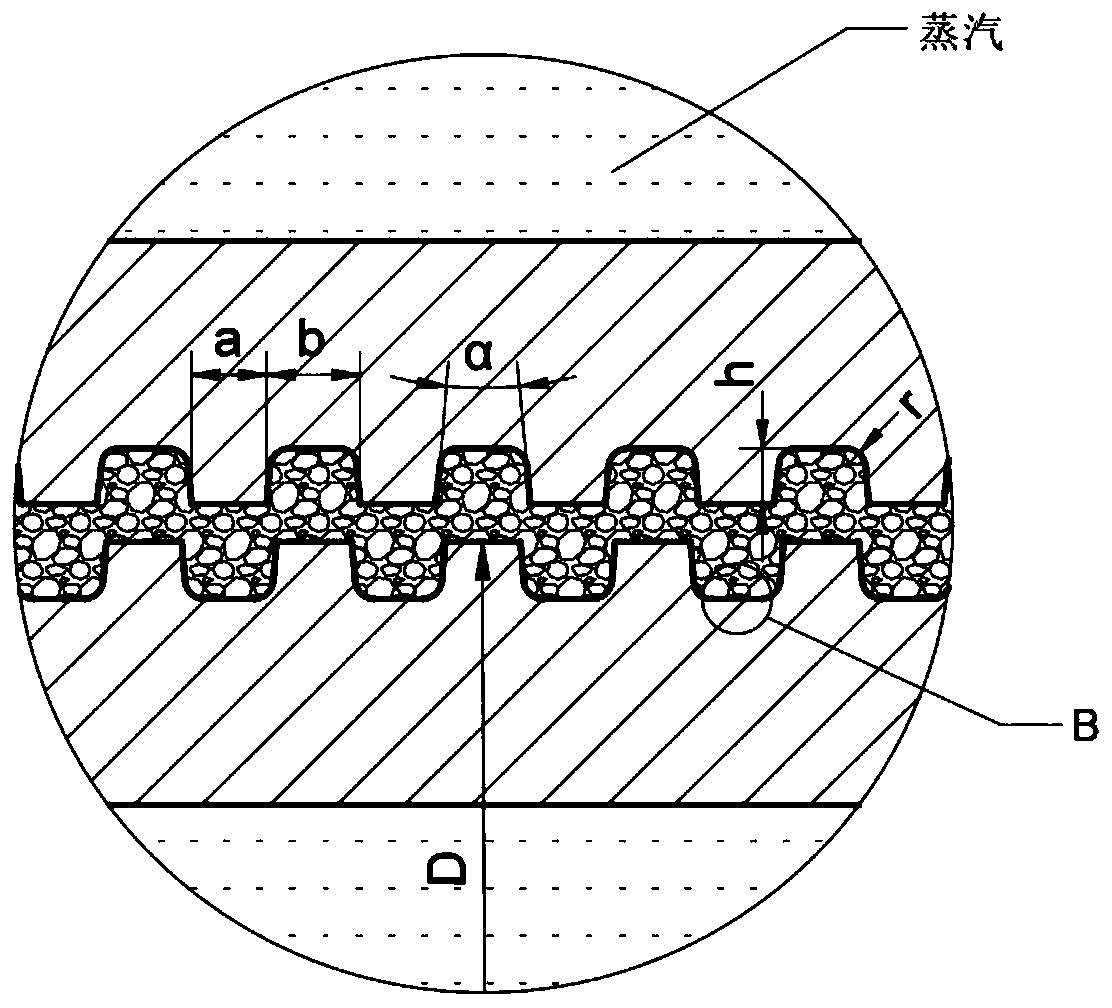

[0066] From the heating roller (structure such as Figure 2~3 Shown) One end perpendicular to the radial direction is preheated by steaming, and after the temperature of the outer cylinder wall of the heating roller reaches 150°C, the sludge with a moisture content of 83.2% is passed through the heating roller for heating Rotary extrusion (rotating speed of the heating roller is 3 rpm) to obtain sludge with a moisture content of 40%.

[0067] The viscosity-reducing characteristics of the sludge drying process are expressed by the quality of the sticky wall sludge per unit area, that is, the amount of sticky wall; the test of the sticky wall amount adopts the scraping method (scraping 3 times on the heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com