Self-lubricating hydrophilic coating and preparation method thereof

A self-lubricating and hydrophilic technology, applied in coatings and other directions, can solve the problems of coatings without self-lubricating function, hydrophilicity or low self-lubricating property, low heat conduction efficiency, etc., and achieve low surface friction coefficient and hydrophilicity and high self-lubricating performance and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

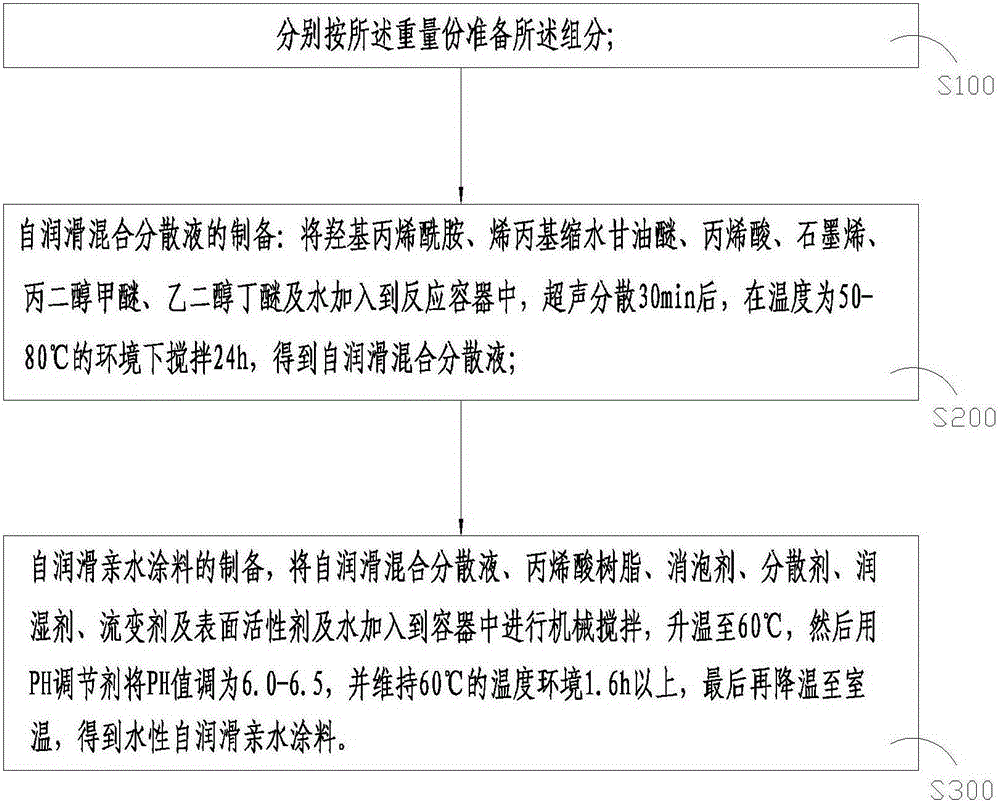

[0028] refer to figure 1 , the present invention also provides a kind of preparation method of self-lubricating hydrophilic coating, this method comprises the steps:

[0029] Step 1 S100, preparing the components according to the parts by weight respectively;

[0030] Step 2 S200, preparation of self-lubricating mixed dispersion: add hydroxyacrylamide, allyl glycidyl ether, acrylic acid, graphene, propylene glycol methyl ether, ethylene glycol butyl ether and water into the reaction vessel, and ultrasonically disperse for 30 minutes , stirring for 24 hours at a temperature of 50-80°C to obtain a self-lubricating mixed dispersion;

[0031] Step 3 S300, preparation of self-lubricating hydrophilic coating, adding self-lubricating mixed dispersion liquid, acrylic resin, defoamer, dispersant, wetting agent, rheological agent, surfactant and water into the container for mechanical stirring, Raise the temperature to 60°C, then adjust the pH value to 6.0-6.5 with a pH regulator, and...

Embodiment 1

[0040] A self-lubricating hydrophilic coating, comprising the following components by weight: 45 parts of self-lubricating mixed dispersion liquid, 75 parts of acrylic resin, 80 parts of water, 1 part of defoamer, 6 parts of dispersant, 1 part of wetting agent, 1.2 parts of PH regulator, 0.5 parts of rheological agent, and 1.3 parts of surfactant, wherein the self-lubricating mixed dispersion liquid includes the following components in parts by weight: 20 parts of hydroxyacrylamide, 30 parts of allyl glycidyl ether, 25 parts of acrylic acid 40 parts, 40 parts of graphene, 80 parts of water, 20 parts of propylene glycol methyl ether, 50 parts of ethylene glycol butyl ether.

[0041] The preparation method step of above-mentioned self-lubricating hydrophilic coating is as follows:

[0042] Prepare the components according to the above parts by weight respectively;

[0043] Preparation of self-lubricating mixed dispersion: 20 parts of hydroxyacrylamide, 30 parts of allyl, 25 par...

Embodiment 2

[0048] A self-lubricating hydrophilic coating, which includes the following components by weight: 40 parts of self-lubricating mixed dispersion liquid, 80 parts of acrylic resin, 60 parts of water, 2 parts of defoaming agent, 5 parts of dispersant, and 0.5 part of wetting agent , 1.6 parts of PH regulator, 0.7 part of rheological agent, 2 parts of surfactant, wherein, the self-lubricating mixed dispersion liquid comprises the following components by weight: 50 parts of hydroxyacrylamide, 45 parts of allyl glycidyl ether, acrylic acid 50 parts, 80 parts of graphene, 120 parts of water, 50 parts of propylene glycol methyl ether, and 80 parts of ethylene glycol butyl ether.

[0049] The preparation method step of above-mentioned self-lubricating hydrophilic coating is as follows:

[0050] Prepare the components according to the parts by weight respectively;

[0051] Preparation of self-lubricating mixed dispersion: 50 parts of hydroxyacrylamide, 45 parts of allyl glycidyl ether,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com