Radiator and floor radiation heating loop cascade heat exchange station system and heat gradient utilization method

A radiant heating and radiator technology, applied in hot water central heating systems, heating systems, heating methods, etc., can solve the problem of ineffective use of heat medium temperature, high return water temperature of secondary network, radiator heating and floor radiation High investment of heating and heat exchanger parallel heat exchange station system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

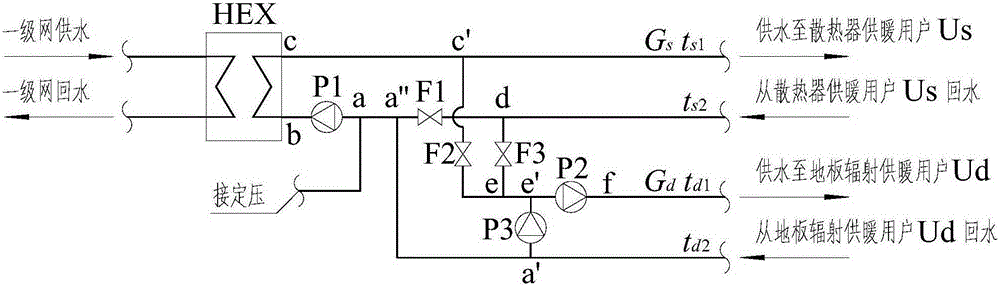

[0087] Embodiment 1: A radiator and floor radiant heating loop cascaded heat exchange station system in this embodiment includes a heat exchanger unit HEX, a secondary network circulating water pump unit P1, a secondary network circulating water pump unit P2, and a water mixing pump Unit P3, control valve unit F1, control valve unit F2 and control valve unit F3; image 3 ;

[0088] One end c of the water supply pipe cc' of the heat exchanger unit is connected to the heat exchanger unit HEX, and the other end c' of the water supply pipe cc' of the heat exchanger unit is respectively connected to the water supply pipe of the radiator heating loop and the water supply pipe of the floor radiant heating loop ee';

[0089] Wherein, the other end c' of the water supply pipe cc' of the heat exchanger unit is connected to the water supply pipe ee' of the floor radiant heating loop through the control valve unit F2;

[0090] The water supply pipe of the radiator heating loop is connec...

specific Embodiment approach 2

[0099] Specific embodiment 2. The difference between this embodiment and specific embodiment 1 is that one end a of the return pipe a"a of the heat exchanger unit is connected to the constant pressure equipment of the secondary network through a pipeline.

[0100] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0101] Specific Embodiment Three: The heat cascade utilization method of a radiator and floor radiant heating loop cascaded heat exchange station system in this embodiment is characterized in that it is a radiator and floor radiant heating loop cascaded heat exchange station The specific process of the heat cascade utilization method of the system is as follows: image 3 ;

[0102] 1. When the flow G of the radiator heating loop s Equal to the flow G of the radiant floor heating loop d , there are 3 situations:

[0103] 1.1) When the return water temperature of the radiator heating loop is t s2 Equal to the supply water temperature t of the radiant floor heating loop d1 ; The specific process is:

[0104] The water supply of the secondary network reaches the water supply pipe node c of the heat exchanger unit through the heat exchanger unit HEX, from the water supply pipe node c of the heat exchanger unit to the water supply pipe node c' of the heat exchanger unit, and fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com