Biomass combined heat and power generation system capable of recycling steam exhaust and smoke waste heat at the same time

A technology for co-generation of heat and power and waste heat from flue gas is applied in heat recovery systems, heating systems, and hot water central heating systems. The effect of reducing water consumption and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

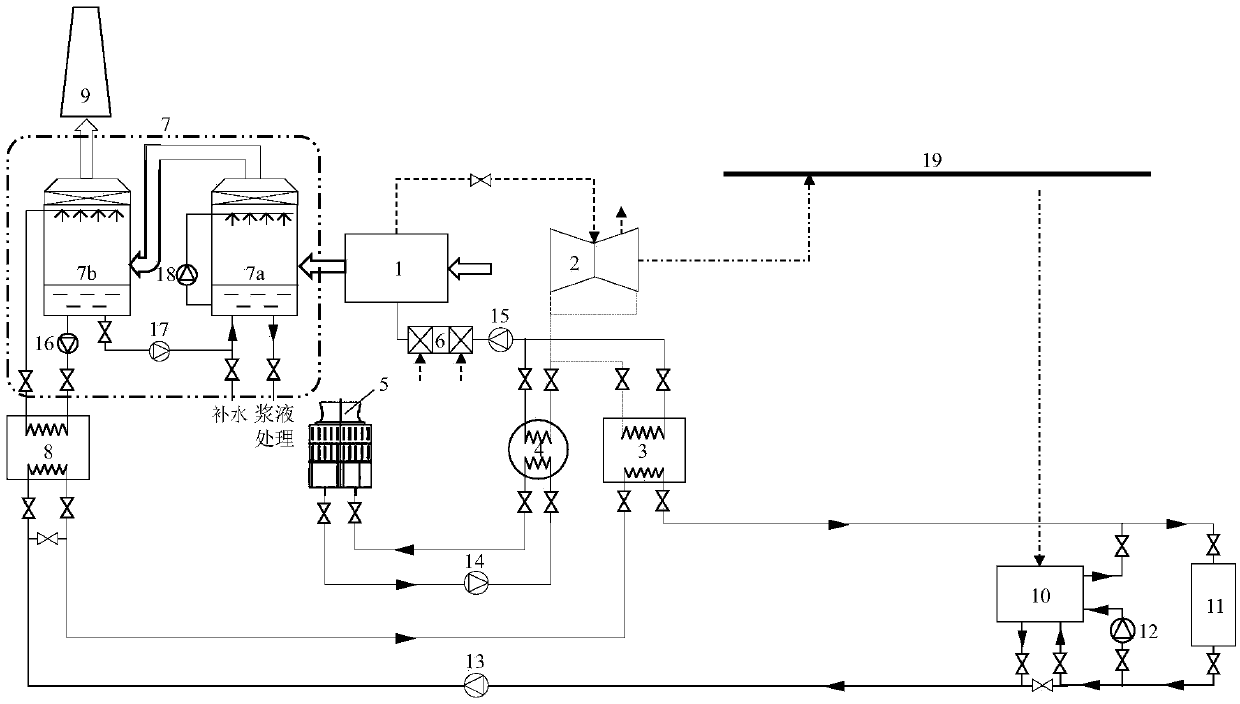

[0034] Example 1: In the factory, flue gas spray water heat exchanger and spent steam heat exchanger are used to heat the hot network water in a cascade, and an electric heat pump is used at the end to reduce the temperature of the return water, and the basic process of supplying heat to users after mixing with water

[0035] A biomass cogeneration system that can simultaneously recover spent steam and flue gas waste heat according to Embodiment 1 of the present invention, such as figure 1 As shown, the system includes biomass boiler 1, steam turbine 2, spent steam heat exchanger 3, condenser 4, cooling tower 5, boiler feed water heater 6, flue gas emission reduction and waste heat recovery integrated unit 7, flue gas injection Water shower heat exchanger 8, chimney 9, power grid 19, terminal electric heat pump 10, user heat exchanger 11 and connecting pipelines and valves; flue gas emission reduction and waste heat recovery integrated unit 7 includes desulfurization tower 7a a...

Embodiment 2

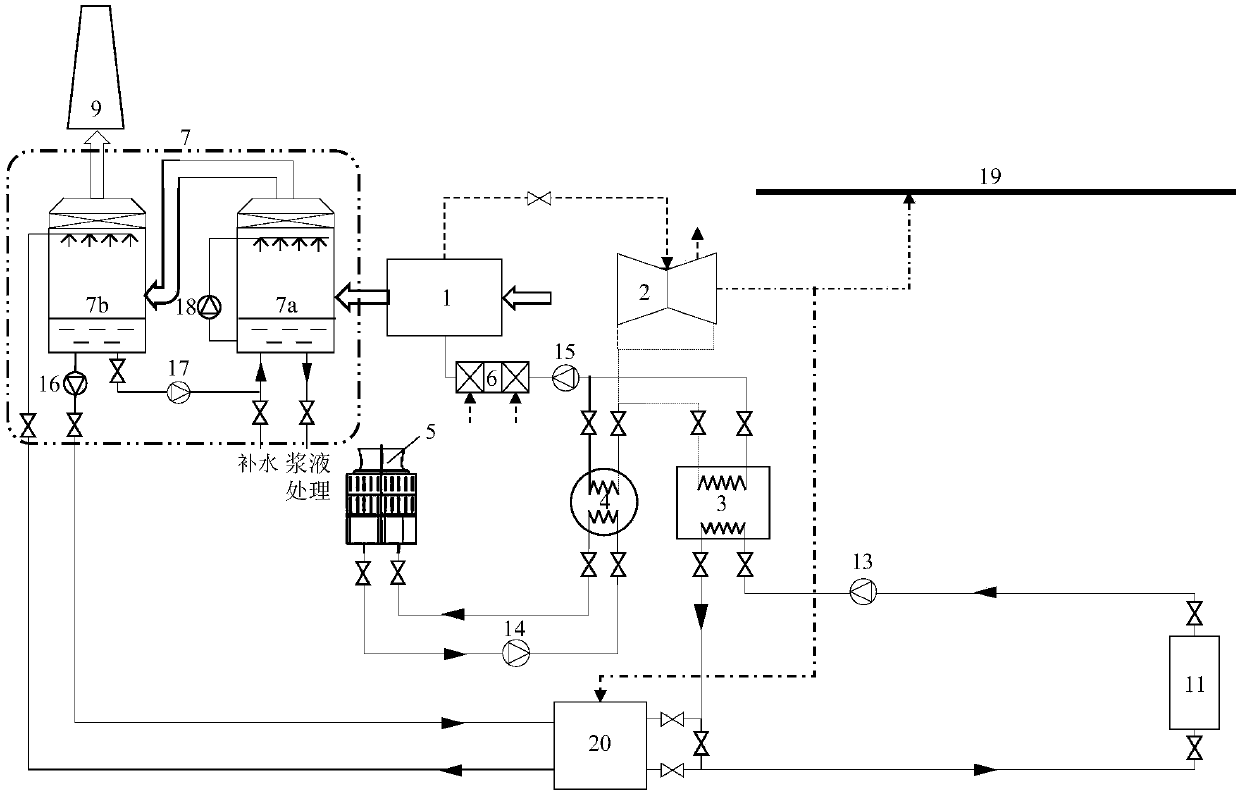

[0042] Example 2: The process of using the spent steam heat exchanger and the electric heat pump in the plant to heat the hot network water and directly supply it to the terminal heat users

[0043] A biomass cogeneration system that can simultaneously recover spent steam and flue gas waste heat according to the second embodiment of the present invention, such as figure 2 As shown, the system includes biomass boiler 1, steam turbine 2, spent steam heat exchanger 3, condenser 4, cooling tower 5, boiler feed water heater 6, flue gas emission reduction and waste heat recovery integrated unit 7, chimney 9, The power grid 19, the electric heat pump 20 of the power plant, the user heat exchanger 11 and the connecting pipelines and valves; the integrated unit 7 of flue gas emission reduction and waste heat recovery includes a desulfurization tower 7a and a waste heat recovery tower 7b; the connection relationship of each equipment is:

[0044]The high-temperature steam outlet of bio...

Embodiment 3

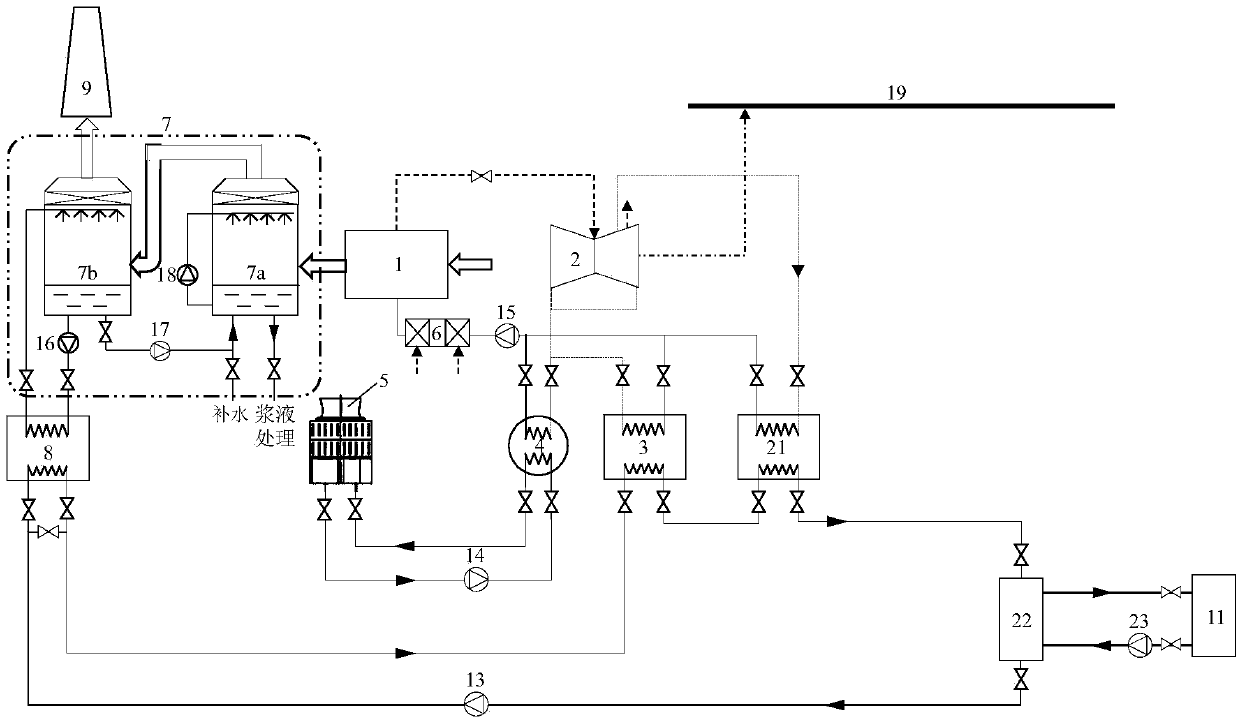

[0050] Example 3: The process of using the flue gas spray water heat exchanger, the spent steam heat exchanger and the extraction steam heater in the factory to heat the hot network water, and the end thermal station adopts the absorption heat exchange unit to supply the heat users through the secondary network

[0051] A biomass cogeneration system that can simultaneously recover spent steam and flue gas waste heat according to Embodiment 3 of the present invention, such as image 3 As shown, the system includes biomass boiler 1, steam turbine 2, spent steam heat exchanger 3, condenser 4, cooling tower 5, boiler feed water heater 6, flue gas emission reduction and waste heat recovery integrated unit 7, flue gas injection Water shower heat exchanger 8, chimney 9, power grid 19, extraction steam heater 21, absorption heat exchange unit 22, user heat exchanger 11 and connecting pipelines and valves; flue gas emission reduction and waste heat recovery integrated unit 7 includes de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com