Cleaning method for heat exchanger of heating power company

A heat exchanger, the company's technology, applied in the field of heat exchangers of thermal companies, can solve the problems affecting the normal use of equipment safety users, the reduction of heat exchange efficiency of plate heat exchangers, and the small flow section of plate heat exchangers, and achieve outstanding cleaning. effect, reduced maintenance, reduced corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

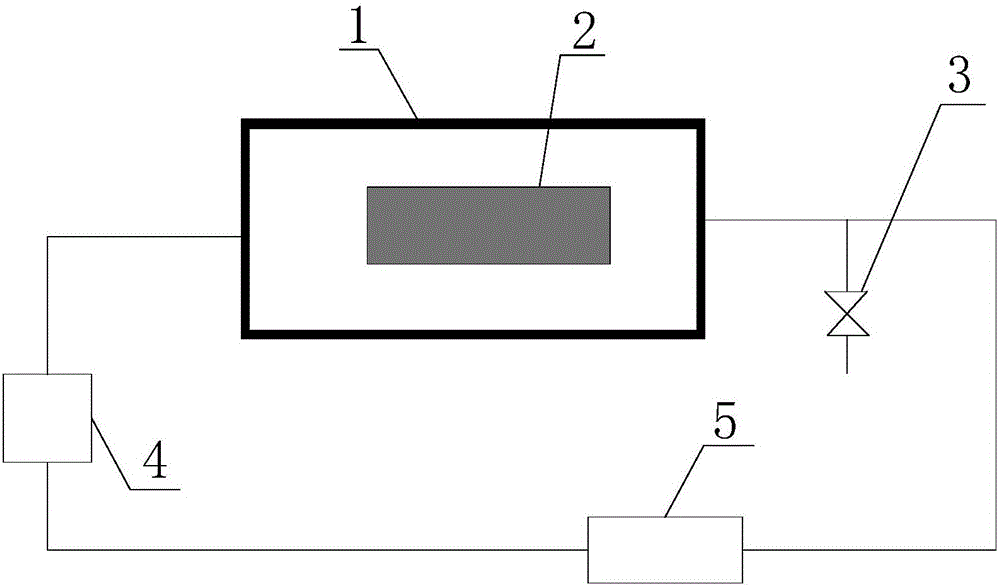

[0031] Embodiment 1 of the present invention: a cleaning method for a heat exchanger of a heat company. A cleaning system is used to clean the heat exchange fins 2 of the heat exchanger. The cleaning system includes a cleaning tank 1 connected in sequence through pipelines, and a circulation pump. 5 and heater 4, sampling pipe 3 is arranged on the pipeline downstream of cleaning tank 1, and described cleaning method comprises the following steps successively:

[0032] S100 washing with water: placing the heat exchange fins 2 of the heat exchanger in the cleaning tank 1, and washing the heat exchange fins 2 of the heat exchanger with clean water;

[0033] S200 Alkaline cleaning: Use an alkaline solution with a pH equal to 11 to wash the heat exchange plate 2 of the heat exchanger;

[0034] S300 water washing: use clean water to wash the heat exchange plate 2 of the heat exchanger until the pH of the cleaning solution in the cleaning tank 1 is reduced to 8.5;

[0035] S400 pick...

Embodiment 2

[0039] Example 2: A cleaning method for a heat exchanger of a thermal company, using a cleaning system to clean the heat exchanger fins 2 of the heat exchanger, the cleaning system includes a cleaning tank 1, a circulation pump 5 and a heating tank connected in sequence through pipelines Device 4, sampling pipe 3 is arranged on the pipeline downstream of cleaning tank 1, and described cleaning method comprises the following steps successively:

[0040] S100 washing with water: placing the heat exchange fins 2 of the heat exchanger in the cleaning tank 1, and washing the heat exchange fins 2 of the heat exchanger with clean water;

[0041] S200 Alkaline cleaning: use a trisodium phosphate solution with a concentration of 0.4%, and an alkaline solution with an alkalinity equal to 11 to rinse the heat exchange plate 2 of the heat exchanger; control the temperature of the cleaning solution in the cleaning tank 1 at about 40 degrees, The flow rate of the cleaning liquid is controll...

Embodiment 3

[0047] Example 3: A cleaning method for a heat exchanger of a thermal company, using a cleaning system to clean the heat exchanger fins 2 of the heat exchanger, the cleaning system includes a cleaning tank 1, a circulation pump 5 and a heating Device 4, sampling pipe 3 is arranged on the pipeline downstream of cleaning tank 1, and described cleaning method comprises the following steps successively:

[0048] S100 washing with water: placing the heat exchange fins 2 of the heat exchanger in the cleaning tank 1, and washing the heat exchange fins 2 of the heat exchanger with clean water;

[0049]S200 Alkaline cleaning: use a trisodium phosphate solution with a concentration of 0.4%, and an alkaline solution with an alkalinity equal to 11 to rinse the heat exchange plate 2 of the heat exchanger; control the temperature of the cleaning solution in the cleaning tank 1 above 30 degrees, The flow rate of the cleaning liquid is controlled at about 0.4m / s, and the heat exchange fins 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com