Electric heating deicing method and device of air temperature type vaporizer and installation method of electric heating deicing device

An air-temperature vaporizer and electric heating technology, applied in deicing, lighting and heating equipment, heat exchange equipment, etc., can solve the problems of poor deicing effect and low efficiency, achieve rapid deicing, reduce renovation and Destruction, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The invention provides an electric heating deicing method for an air-temperature gasifier.

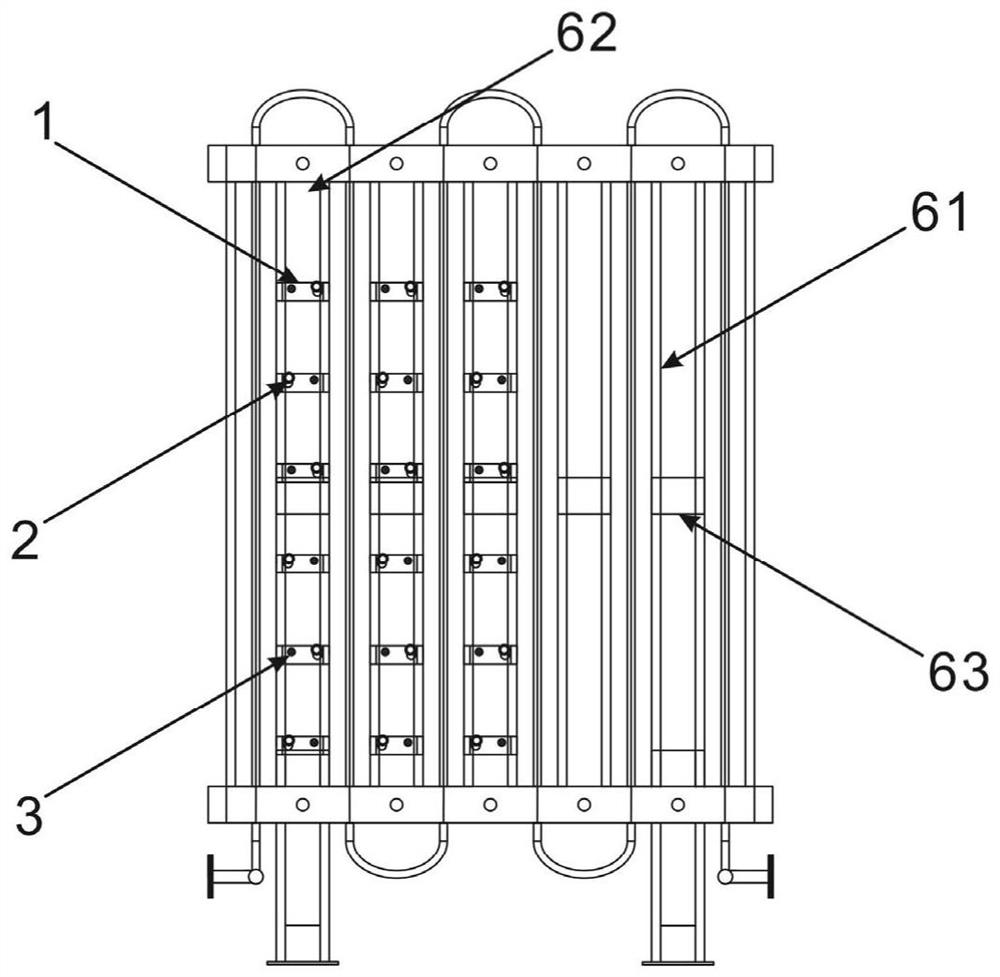

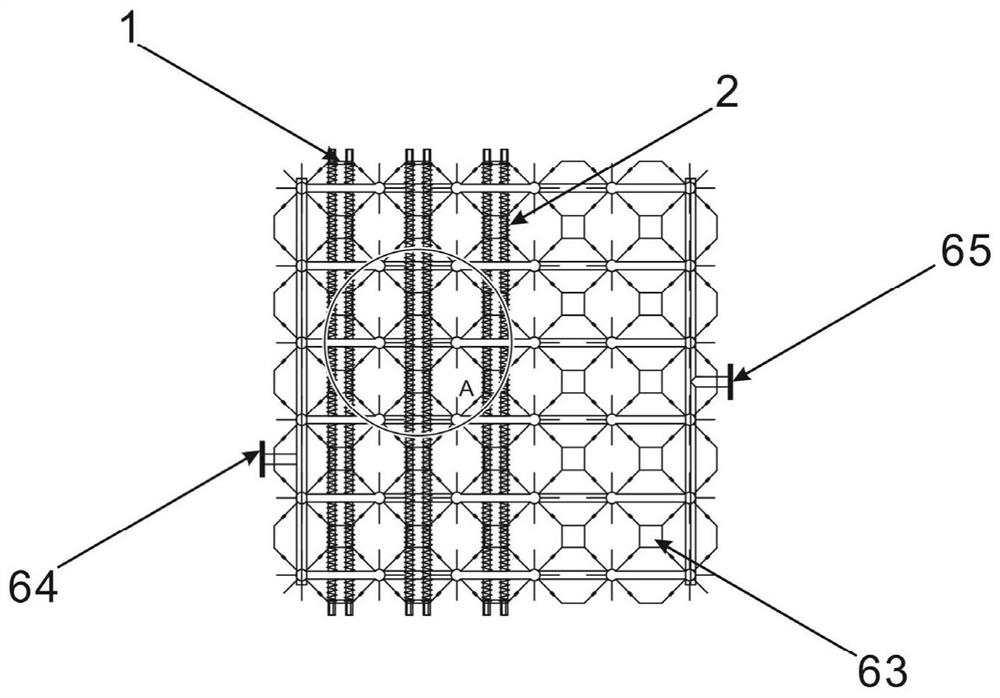

[0046] Such as Figure 1-Figure 5 As shown, the air-temperature vaporizer 6 is a vertical array of multiple rows and multiple columns composed of a plurality of star-shaped vertical finned tubes 61, and the space between the vertical arrays is the air circulation channel 62, preferably , the space between two adjacent horizontal rows or two vertical rows of vertical finned tubes 61 forms an air circulation channel 62 .

[0047] The electric heating deicing method of the air-temperature gasifier comprises the following steps:

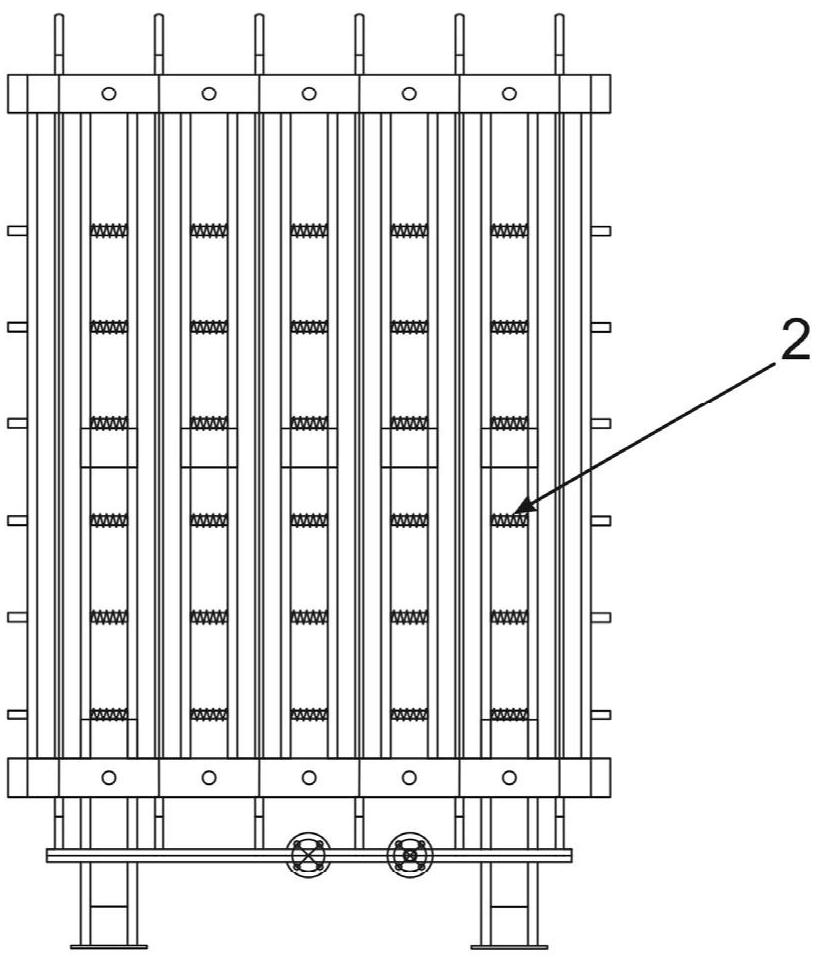

[0048] (i) In the air circulation channel 62 of the vertical finned tube of the air-heated vaporizer that is prone to frost and icing, multiple groups of horizontally arranged finned electric heating tubes 2 are installed close to the vertical finned tube 61, The distance between adjacent finned electric heating tubes 2 in the same air circulation channe...

Embodiment 2

[0055] The invention provides an electric heating deicing device for an air-temperature gasifier, such as figure 1 As shown, the electric heating and deicing device of the air-temperature gasifier includes a fixing device 1, a finned electric heating tube 2 and a detection device 3, wherein: the fixing device 1 is arranged on a phase outside the air-temperature gasifier Between the adjacent vertical finned tubes 61, preferably, the fixing device 1 is provided with a first installation part and a second installation part; the first installation part is arranged at one end of two rows of adjacent vertical finned tubes 61, so The second mounting part is horizontally arranged at the opposite end (such as image 3 shown); one end of the finned electric heating tube 2 is arranged on the first installation part, and the other end is arranged on the second installation part, for heating the ice accumulation in the air-heated vaporizer 6; The detection device 3 is arranged on the firs...

Embodiment 3

[0069] Embodiment 3 is based on Embodiment 2: the present invention provides an installation method for electric heating deicing of an air-temperature gasifier, which includes the following steps:

[0070] (i) Select two rows of adjacent vertical finned tubes 61 of the air-heated gasifier 6 according to actual needs, first install the fixing device 1 near the lower part of the adjacent vertical finned tubes 61 at both ends;

[0071] (ii) Install the finned electric heating tube 2 on the fixture 1, and make the finned electric heating tube 2 closely contact with the outer wall of the vertical finned tube 61; The heating tube 2 has a layer spacing of about 20cm to 150cm;

[0072]Repeat the above steps, and install the upper level until the finned electric heating tube 2 is installed at the position of about 40cm to 100cm on the top of the vertical finned tube 61. Each finned electric heating tube 2 is evenly distributed, and two adjacent finned electric heating tubes The spacin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com