Improved and not-easy-to-freeze air bathing gasifier

An air-bath and vaporizer technology, which is applied to the field of air-bath vaporizers that are not easy to freeze, can solve the problems such as the decline of heating and vaporizing effect, and achieves the advantages of not easy to freeze, good heating and vaporizing effect, and guaranteeing heating and vaporizing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

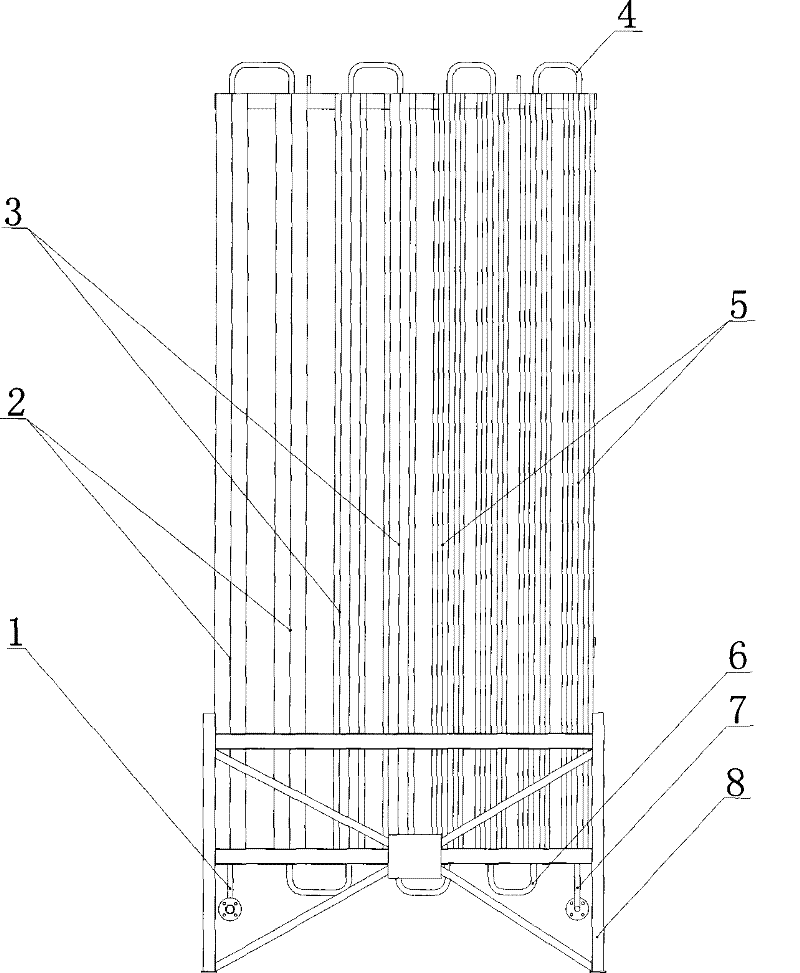

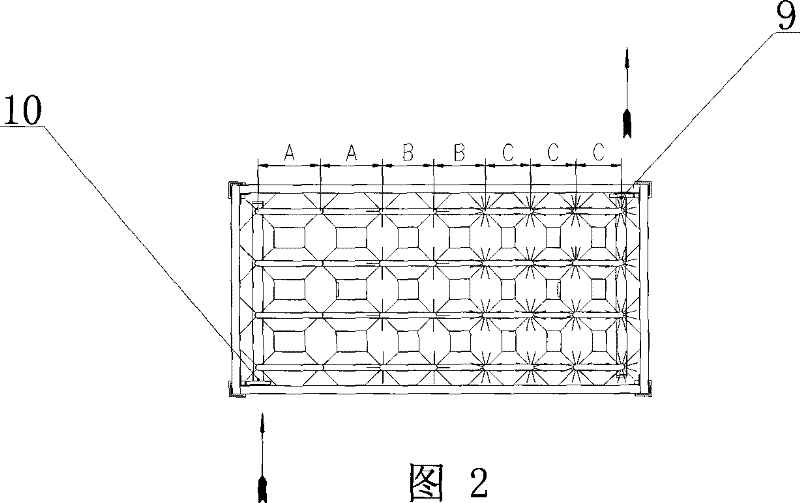

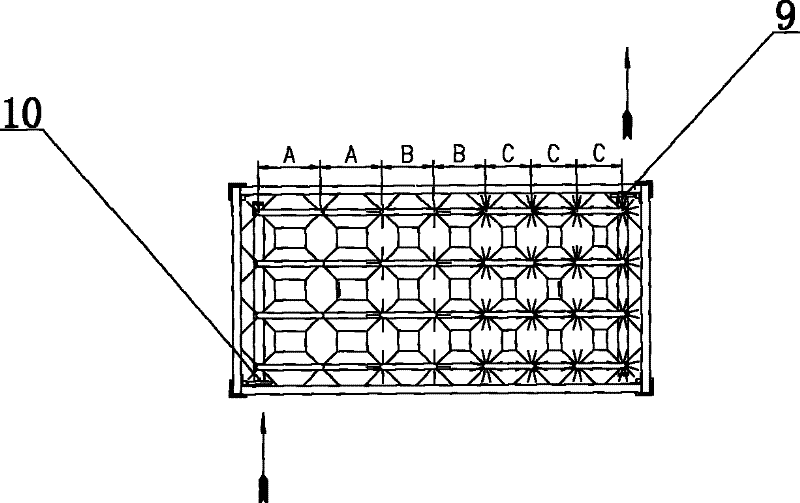

[0009] See figure 1 , figure 2 , the present invention includes a liquid inlet pipe 1, a finned heat exchange pipe, and an air outlet pipe 7. The finned heat exchange pipe is a multi-section finned heat exchange pipe section connected and conducted through connecting pipes 4 and 6. Along the flow direction of the liquid medium, the finned The spacing between fin heat exchange tube sections changes from large to small, and the number of fins increases from few to many. The finned heat exchange tube section includes heat exchange tube 2 with 4 fins, and the input of the heat exchange tube section with 4 fins The ends are connected in parallel with the liquid inlet pipe 1, and each heat exchange pipe section with 4 fins is connected to the heat exchange pipe section 3 with 8 fins and the heat exchange pipe section 5 with 12 fins through the connecting pipe respectively. 8 is a support, and 9 and 10 are flange covers respectively.

[0010] figure 2 The direction of the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com