Pit toilet flushing method and system

A technology of toilets and urinals, which is applied in flushing toilets, household utensils, buildings, etc., and can solve problems such as moving pistons and being prone to freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

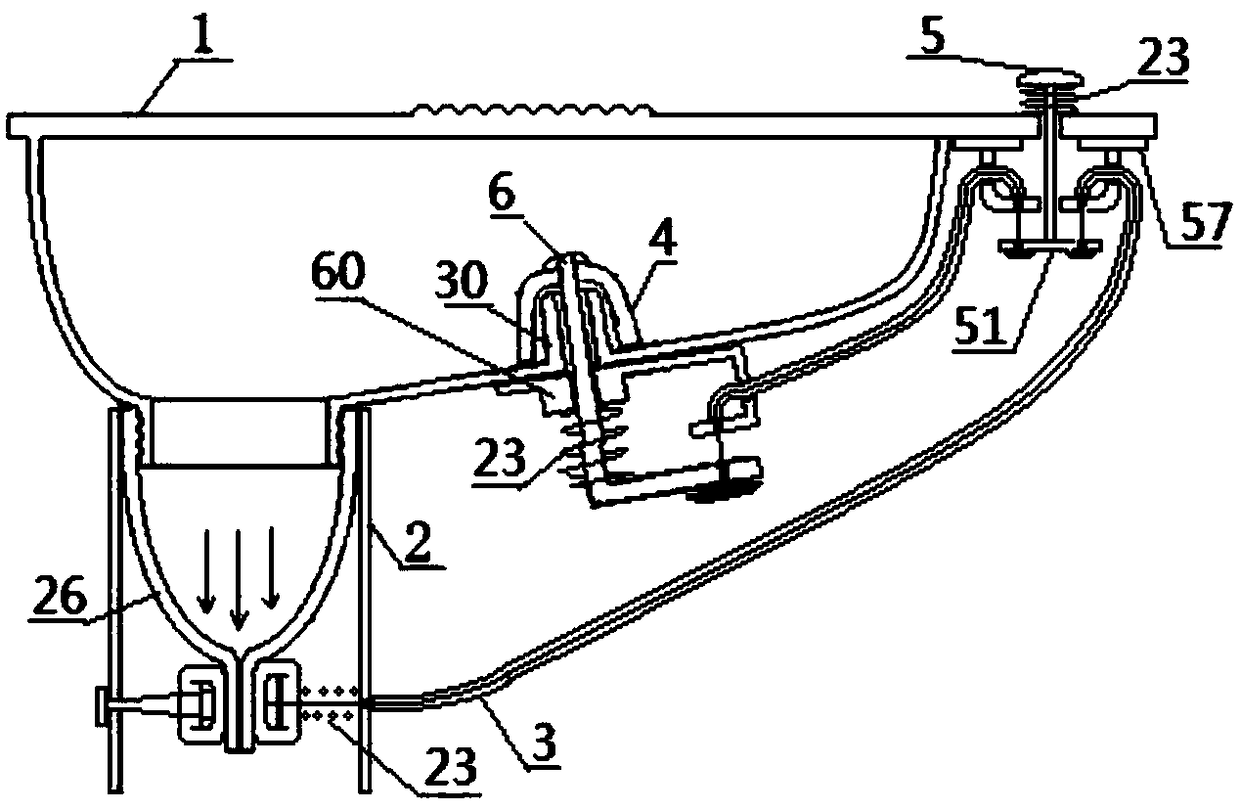

Method used

Image

Examples

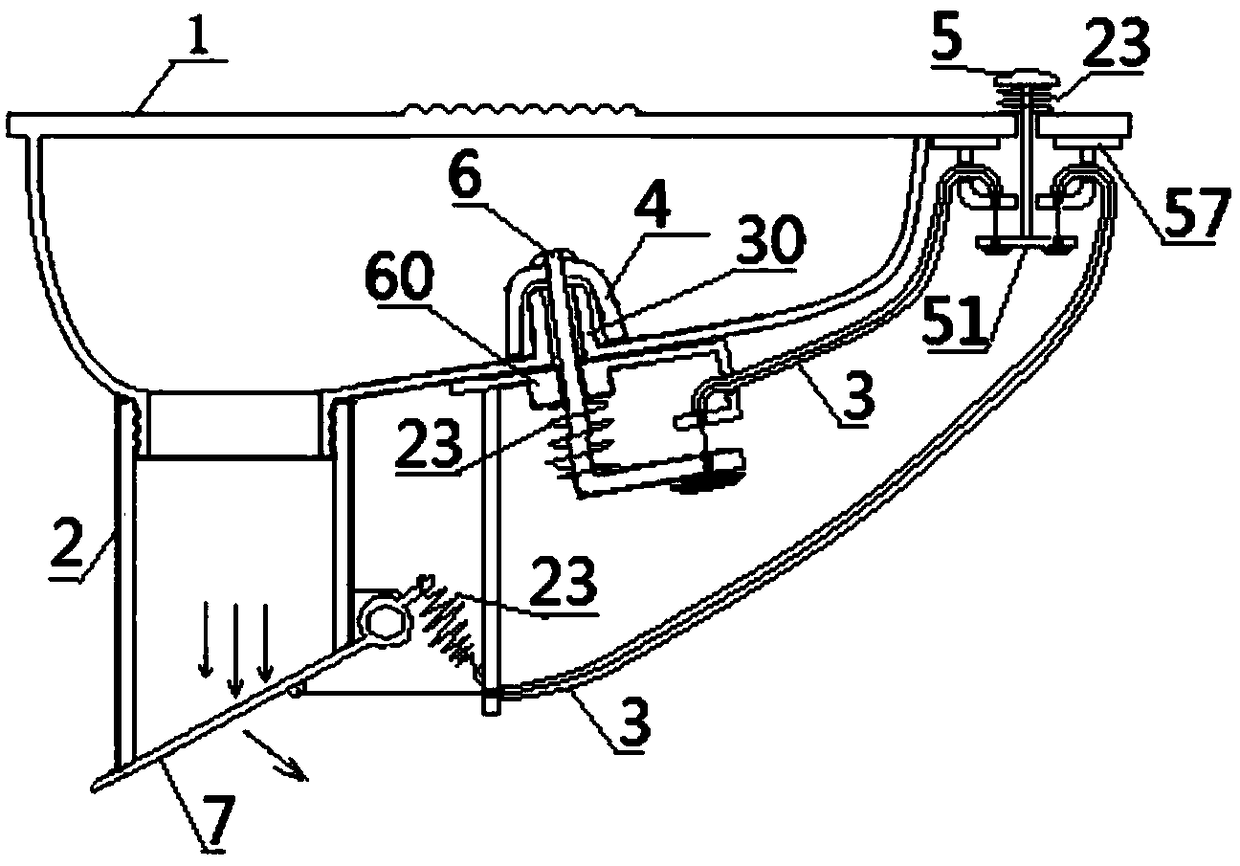

Embodiment 2

[0091] Embodiment two, such as image 3 As shown, the difference between the flushing method and system of the dry toilet of the present invention and the first embodiment is that the lower end of the discharge pipe 2 is hinged with a sealing flap 7 equipped with a return spring. The lower end of the discharge pipe 2 is an oblique opening, and the outer edge of the upper end of the oblique opening at the lower end of the discharge pipe 2 is fixed with a hinged seat. A tensile return spring 23 is fixedly connected between the extension part and the bracket fixed under the slope of the slope flow bottom groove at the front part or other fixed parts. The lower end, the plugging flap 7 are fixedly connected to the core wire lower end of the odor-proof control casing gate line 3. The blocking flap 7 is connected with the lifting pedal 5 through a push-pull transmission control mechanism.

Embodiment 3

[0092] Embodiment three, such as Figure 4As shown, the difference between the flushing method and system of the dry toilet of the present invention and the first embodiment is that the movable sealing of the odor barrier is that the lower part of the discharge pipe 2 is slidingly equipped with a horizontally reciprocating blocking gate 8 equipped with a return spring 23 . The urine delay discharge gate is provided with a hinged seat 61 through a vertical through hole, and the hinged seat 61 is hinged to a vertically inclined oblique rod 66 through a horizontal axis. The overturning dam 40 for the temporary liquid level of urine, at least the lower edge and both side edges of the overturning dam 40 are soft resin sealing edges, and the soft resin sealing sleeve 44 is sealed and connected between the vertical through hole and the oblique rod; The lower end of the inclined rod 66 is connected with the lifting pedal 5 through a push-pull transmission control mechanism. Urinary d...

Embodiment 4

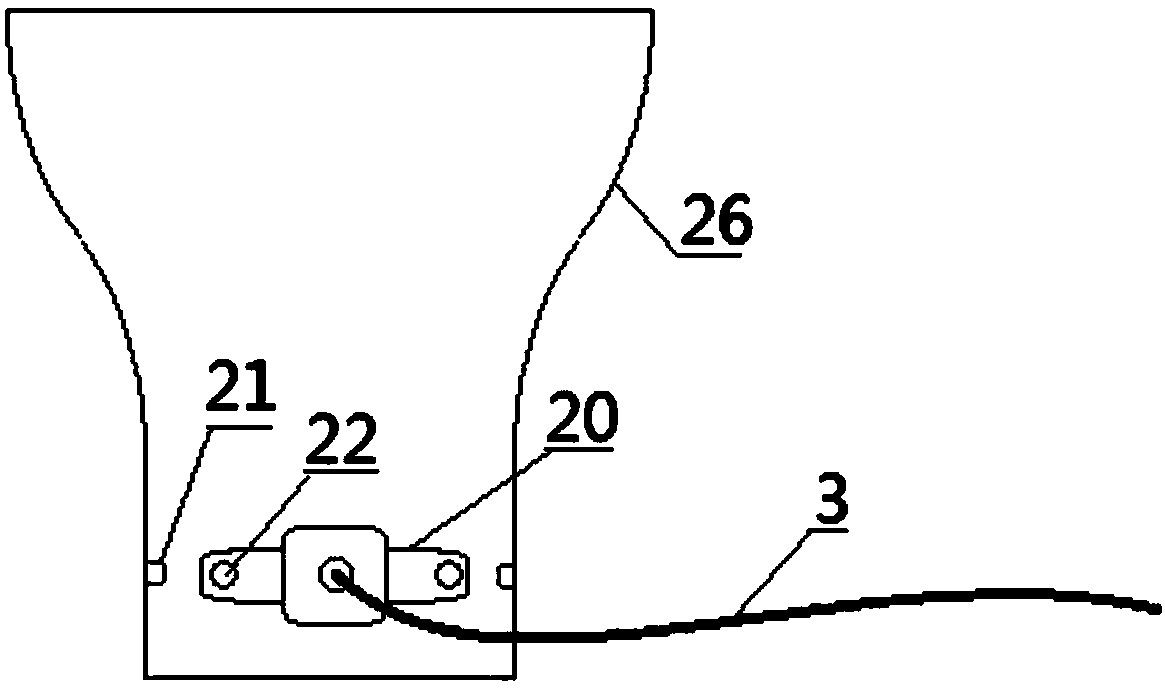

[0093] Embodiment four, such as Figure 5 As shown, the difference between the flushing method and system of the dry type toilet of the present invention and the first embodiment is that the upper end surface of the ground box provided under the ground where the toilet is installed is formed with a vertical through hole, and the vertical through hole is vertically slidable on the upper end. L-shaped vertical shaft 59 with pedal 5, back-moving spring 23 (or return extension spring) is sleeved between the vertical through hole peripheral wall and the upper end (or lower end) of the T-shaped vertical shaft, and the backguy 31 connected to the lower end of L-shaped vertical shaft 59 The front end bypasses the fixed pulley 88 backwards and is extended to connect the middle part of the active horizontally long splint 20, which is fixedly connected horizontally and slidingly fitted with the horizontal push shaft 85 passing through the wall of the discharge pipe 2, and is arranged betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com