Solar evacuated tube collector for heat exchange in micro-channel

A technology of vacuum tube heat collector and micro-channel, applied in the field of solar energy utilization, can solve the problems of little cooling or heating, heat exchange efficiency of heat sink and low heat collection temperature, etc., to avoid freezing of pipeline water and light weight. , the effect of high heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

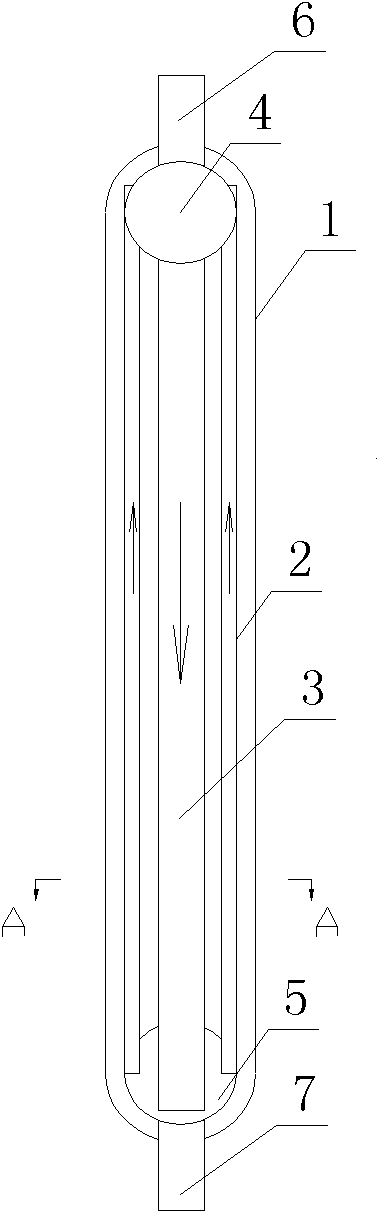

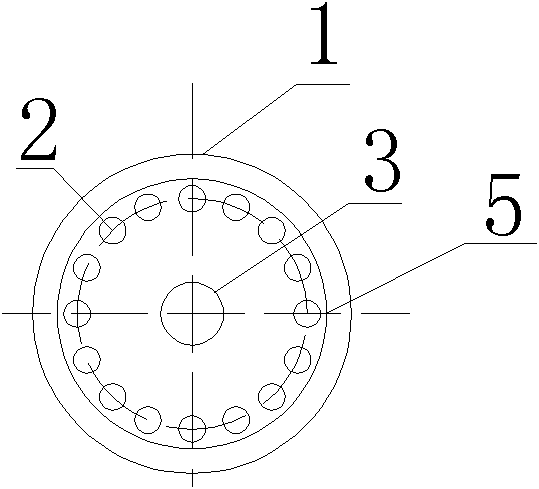

[0035] Such as Figure 1~5 As shown, a solar vacuum tube heat collector with micro-channel heat exchange includes: glass tube 1, micro-channel tube bundle 2, liquid return pipe 3, gas collection chamber 4, liquid collection chamber 5, air guide tube 6, and liquid guide tube 7 , and the external gas collection main pipe 8, gas connecting pipe 9, condensation section 10, liquid connecting pipe 11, and liquid collecting main pipe 12 form a separate circulation pipe;

[0036]Wherein the gas outlet at the upper end of the tiny channel tube bundle 2 is inserted into the gas collecting chamber 4 and the end surface of the gas outlet is higher than the bottom surface of the inner cavity of the gas collecting chamber 4, and the liquid inlet at the lower end of the micro channel tube bundle 2 is inserted into the liquid collecting chamber 5 and its liquid outlet end face is close to the bottom surface of the liquid collection chamber 4 inner cavity; the air outlet at the upper end of th...

Embodiment 2

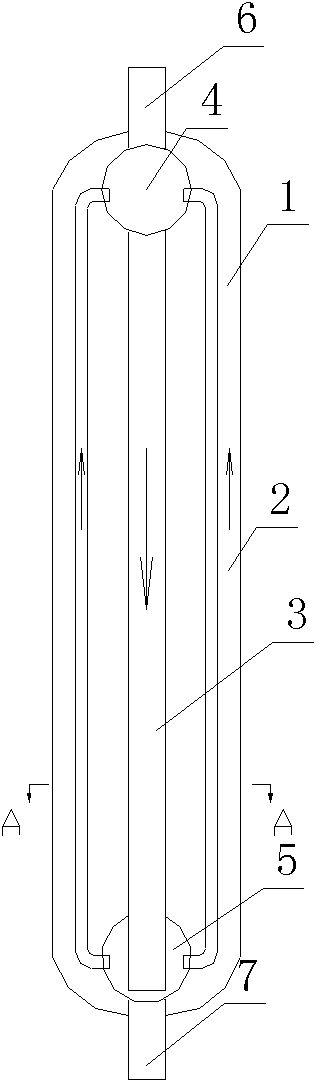

[0046] Such as figure 2 The solar vacuum tube heat collector of another kind of tiny channel heat exchange shown, its structure is identical with embodiment 1, and the sectional view of its A-A face is image 3 with Figure 4 , the difference is that: the two ends of the micro-channel tube bundle 2 in the glass tube 1 are respectively bent toward the central axis of the glass tube 1, and the upper and lower bent ends respectively form the upper gas outlet and the lower liquid outlet of the micro-channel tube bundle 2, which are respectively connected to the collector The air cavity 4 communicates with the liquid collecting cavity 5 .

Embodiment 3

[0048] Such as Image 6 Another kind of solar vacuum tube heat collector with micro-channel heat exchange is shown, and its single-tube elevation is figure 1 , the profile is image 3 with Figure 4 ; The only difference from Embodiment 1 is that a liquid pump 15 is provided on the liquid connecting pipe 11 . The capillary force in the tiny channel tube bundle 2 and the liquid pump 15 jointly drive the circulating working medium to work, which is generally applied to the occasion where the condensing section 10 is on the lower glass tube 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com