Patents

Literature

70 results about "Airlift pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An airlift pump is a pump that has low suction and moderate discharge of liquid and entrained solids. The pump injects compressed air at the bottom of the discharge pipe which is immersed in the liquid. The compressed air mixes with the liquid causing the air-water mixture to be less dense than the rest of the liquid around it and therefore is displaced upwards through the discharge pipe by the surrounding liquid of higher density. Solids may be entrained in the flow and if small enough to fit through the pipe, will be discharged with the rest of the flow at a shallower depth or above the surface. Airlift pumps are widely used in aquaculture to pump, circulate and aerate water in closed, recirculating systems and ponds. Other applications include dredging, underwater archaeology, salvage operations and collection of scientific specimens.

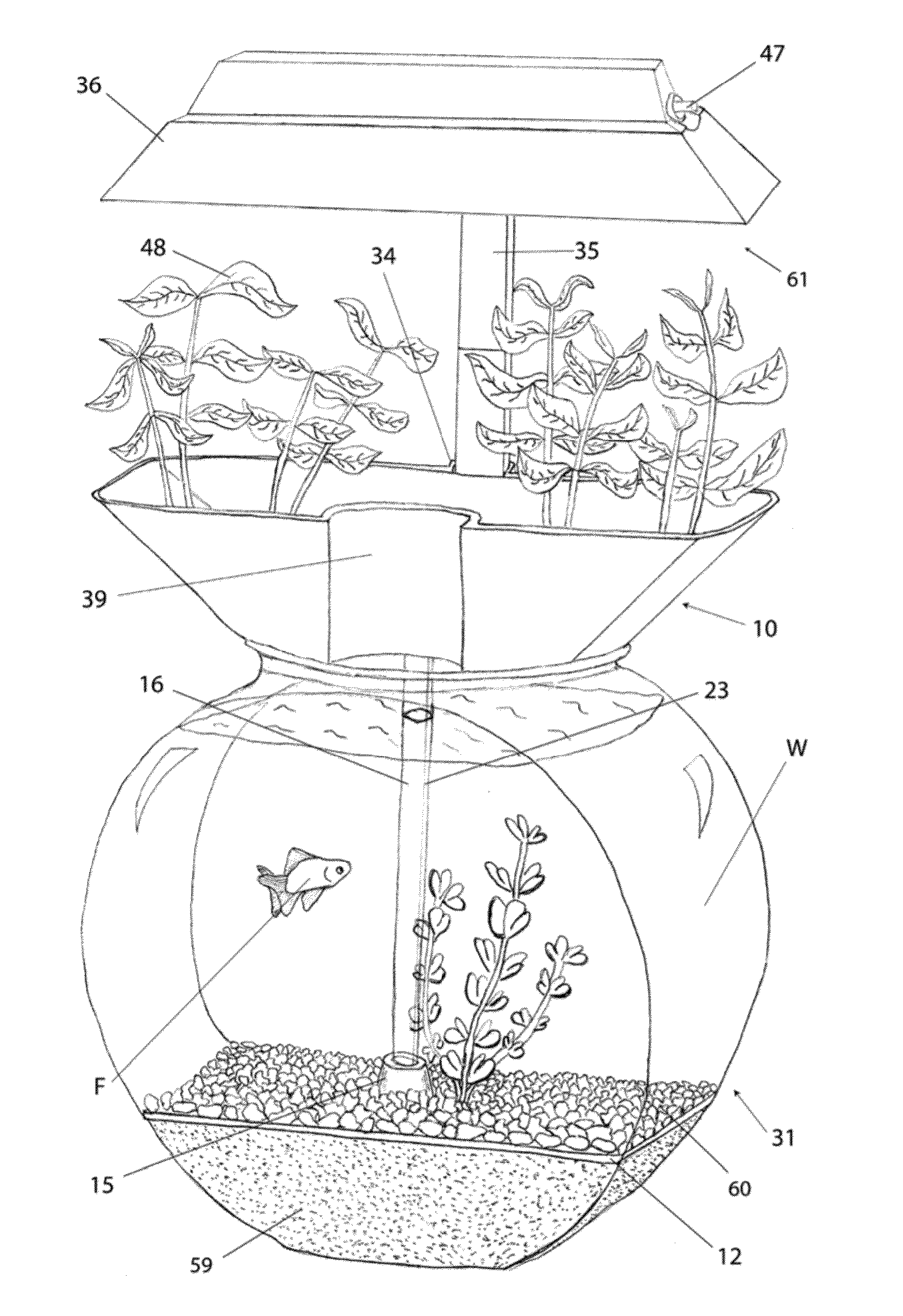

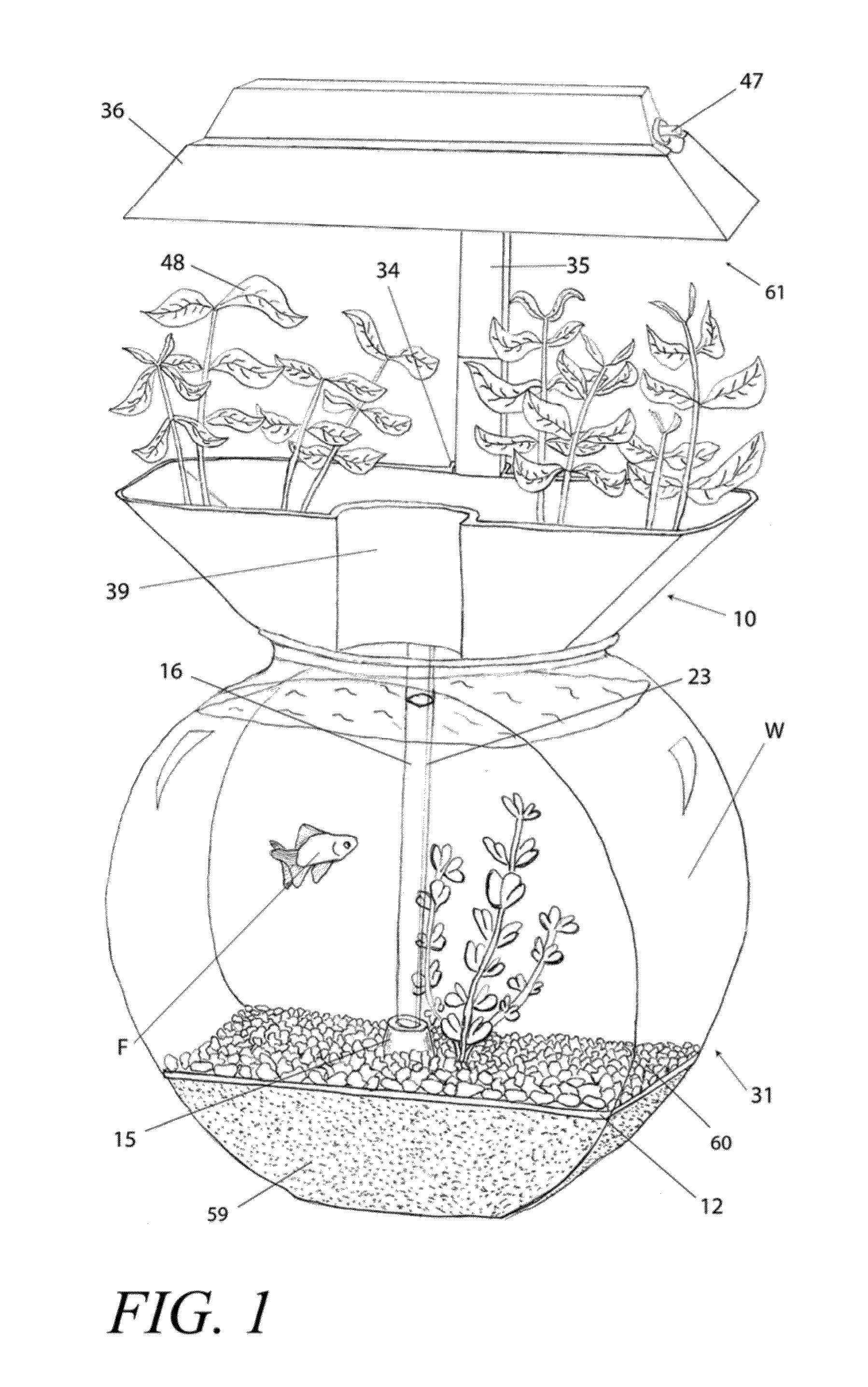

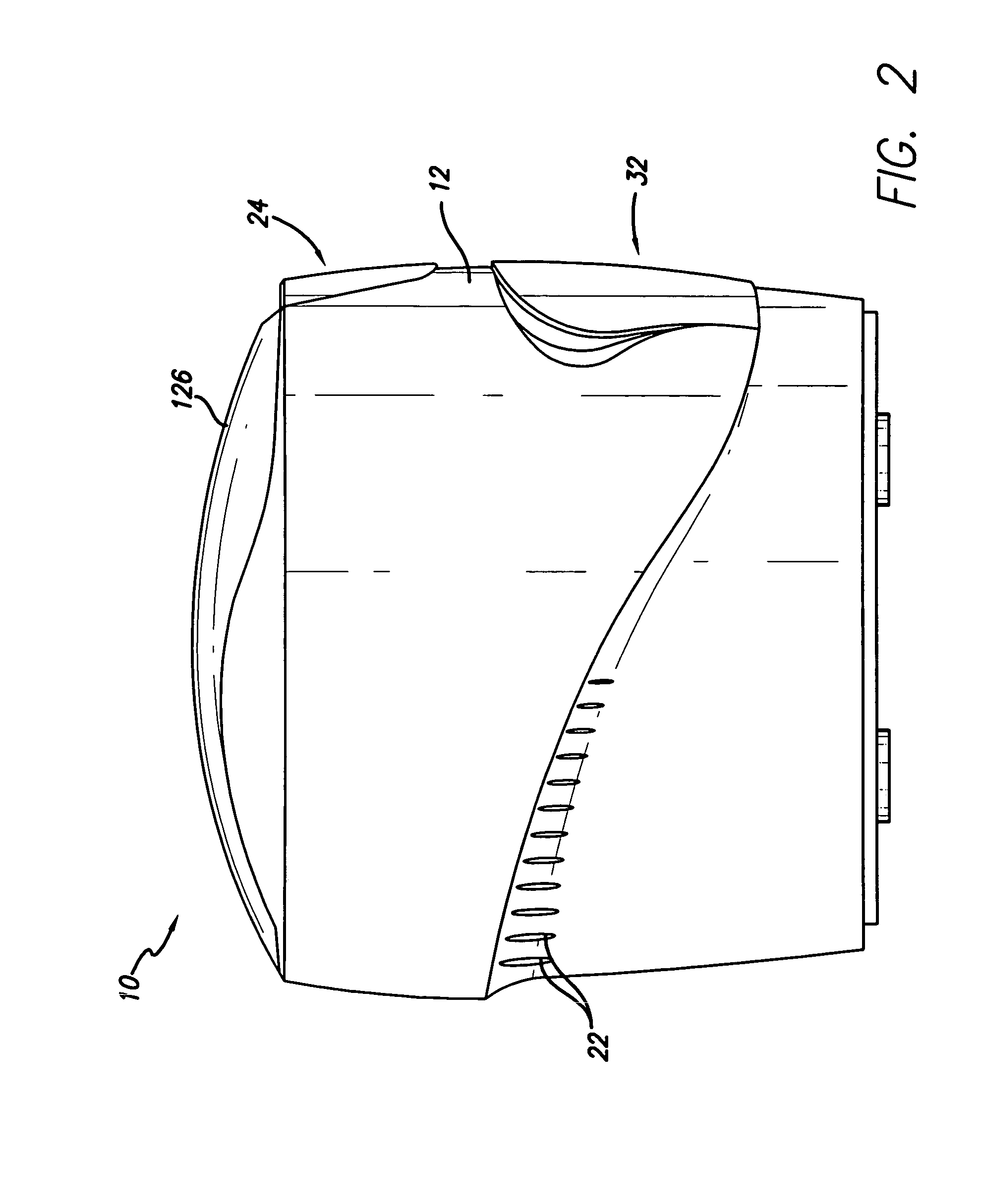

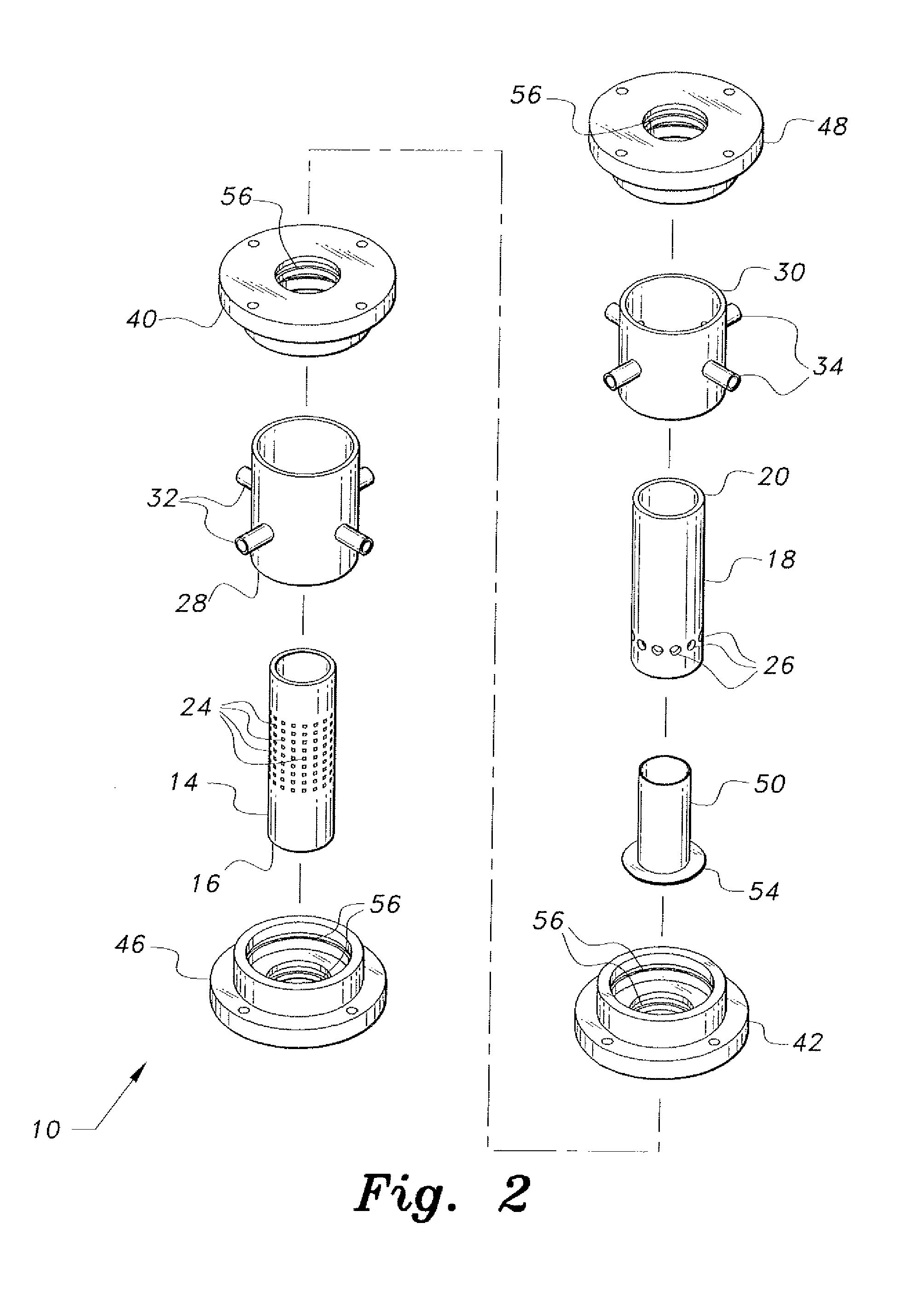

Filtration system for use in aquariums

InactiveUS20140223818A1Effective growth of plantGuaranteed efficient growthPisciculture and aquariaAgriculture gas emission reductionLiquid wasteActivated carbon

An inexpensive aquaponic conversion kit for aquariums that uses a combination of mechanical, biological, and chemical filtration components along with terrestrial plants to filter aquarium water. The system includes a funnel shaped undergravel filter that concentrates solid waste towards an airlift pump that transports solid and liquid waste into a planter containing terrestrial plants. These waste nutrients are trapped in the planter in layers of activated carbon and filamentous material that adsorb and trap waste particles where the roots of plants turn the waste into biological material and aid in cleaning the tank. A grow light and hood are able to be attached to a bracket at the back of the planter to grow healthy plants.

Owner:COGHLAN RYAN

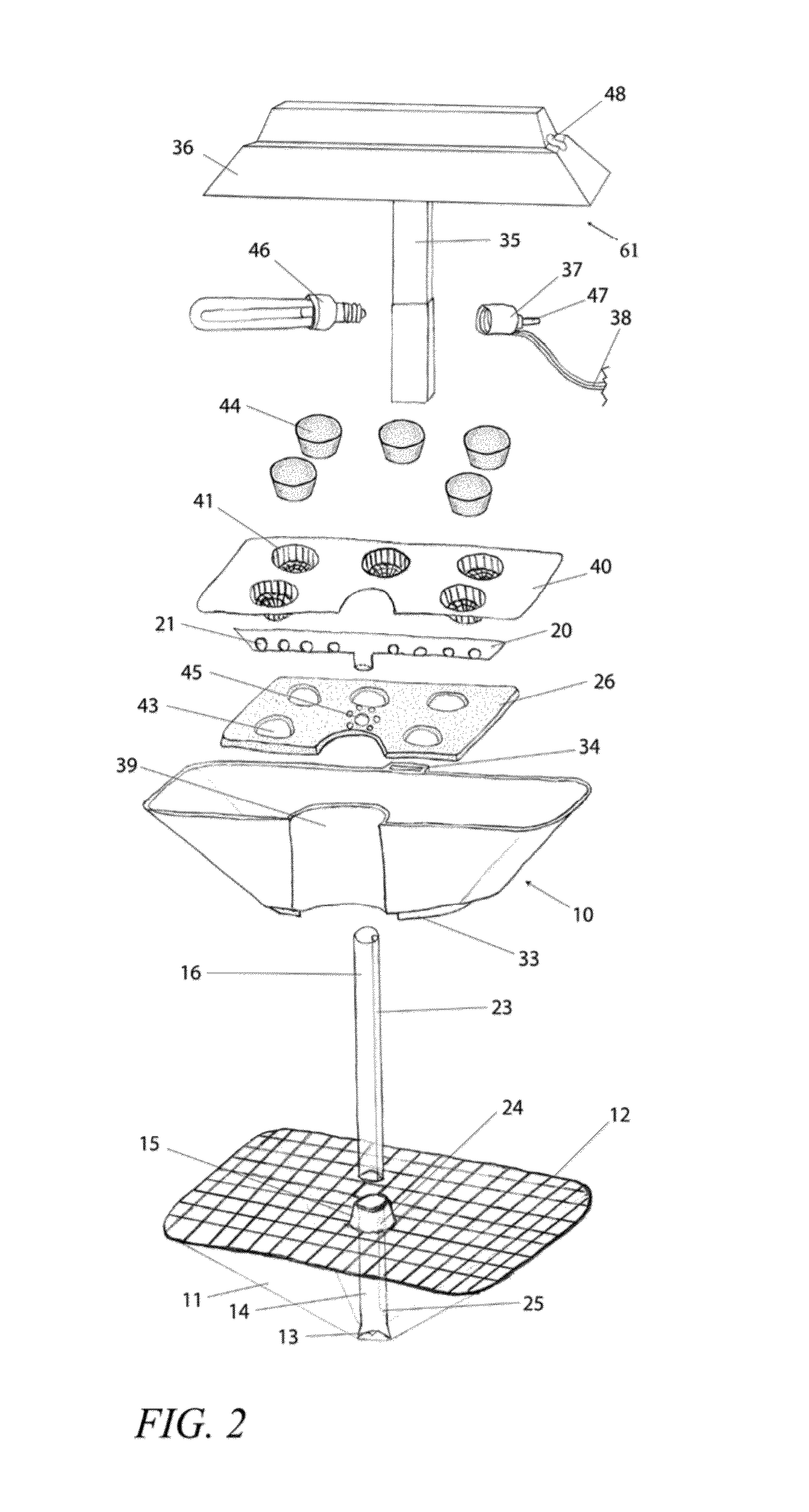

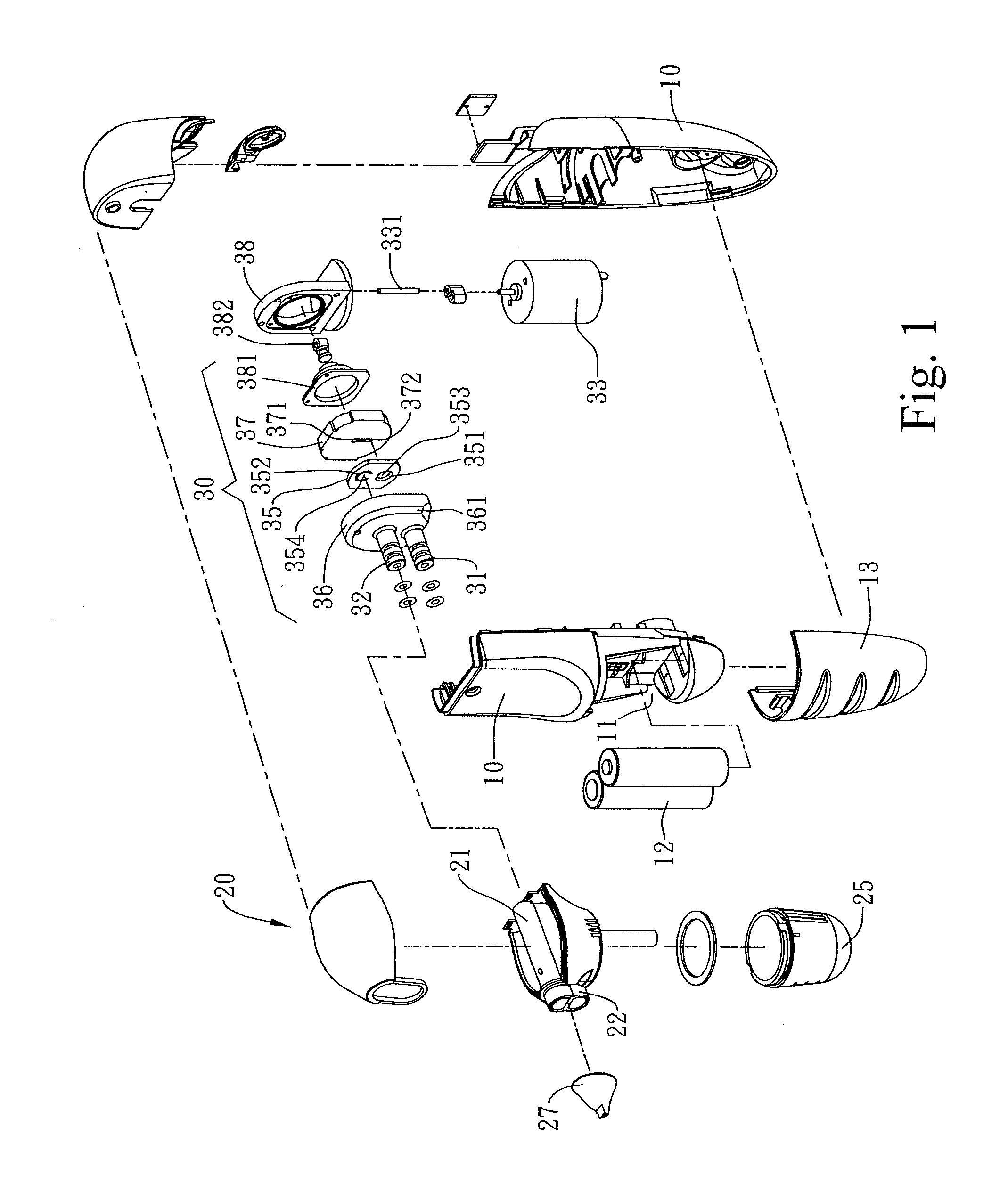

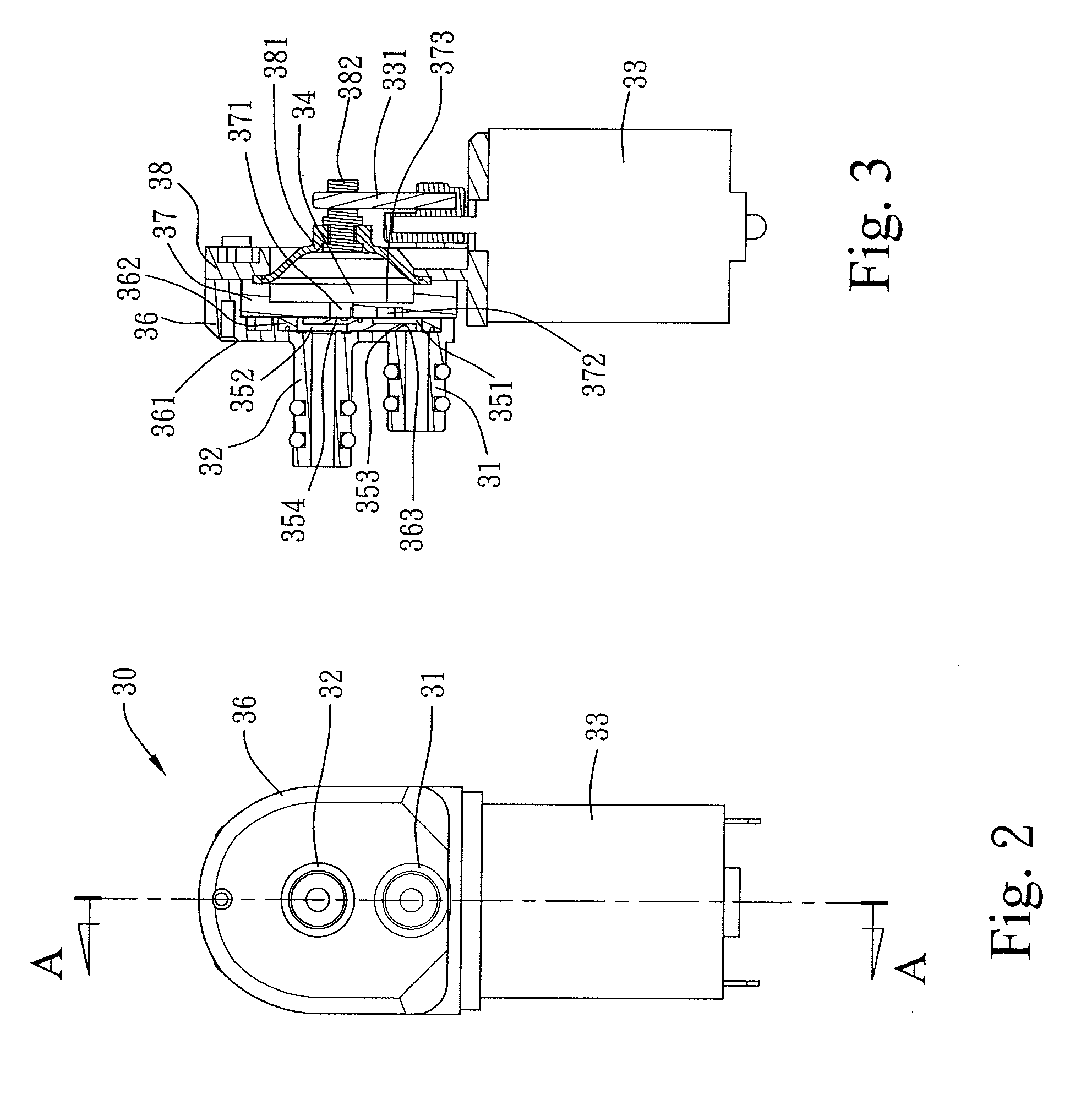

Combined nasal spray and aspirator device

ActiveUS20080312674A1Good for healthPresent invention is physically more favorable for usersEar treatmentCannulasNasal cavityNebulizer

A combined nasal spray and aspirator device includes an air pump disposed within a housing and comprises a spray and aspirator assembly. The air pump, at which an air suction connector and an air discharge connector are disposed, is driven by a driving component to perform air suction and discharge actions. The spray and aspirator assembly, mounted to the air suction connector and the air discharge connector, comprises a spray conduit and a first aspiration conduit; the spray conduit connects to an atomizer which is provided with liquids from a liquid storage container, and the first aspiration conduit connects to a mucus collector so that when some air carrying mucus enters the mucus collector, the mucus is left behind and the air enters the air pump through a second aspiration conduit. The device of the present invention integrates the operations of a nasal spray and a nasal aspirator, sucking the mucus away right after it sprays and liquefies the mucus, with said actions occurring almost simultaneously. The present invention is physically more favorable for users.

Owner:AVITA

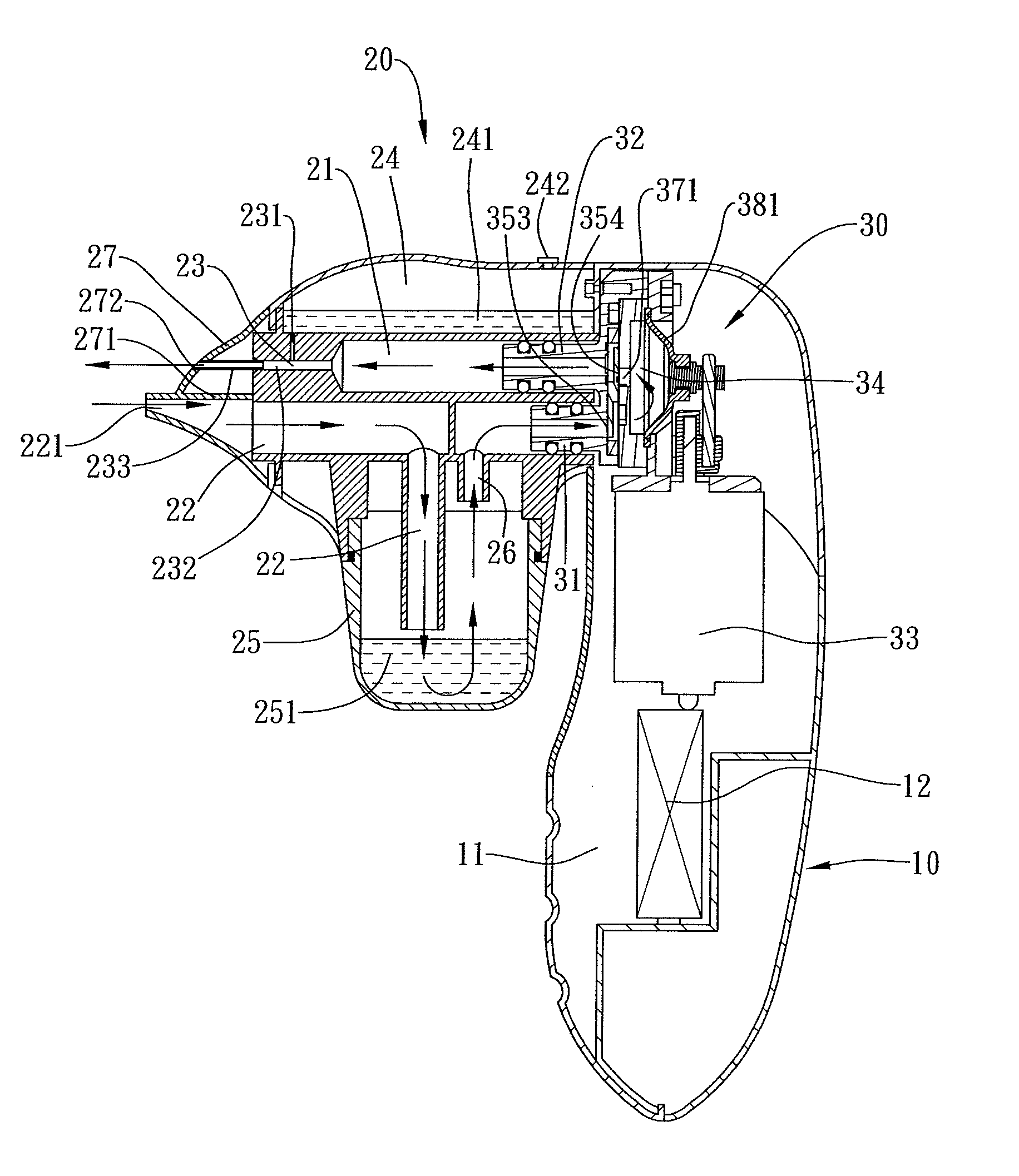

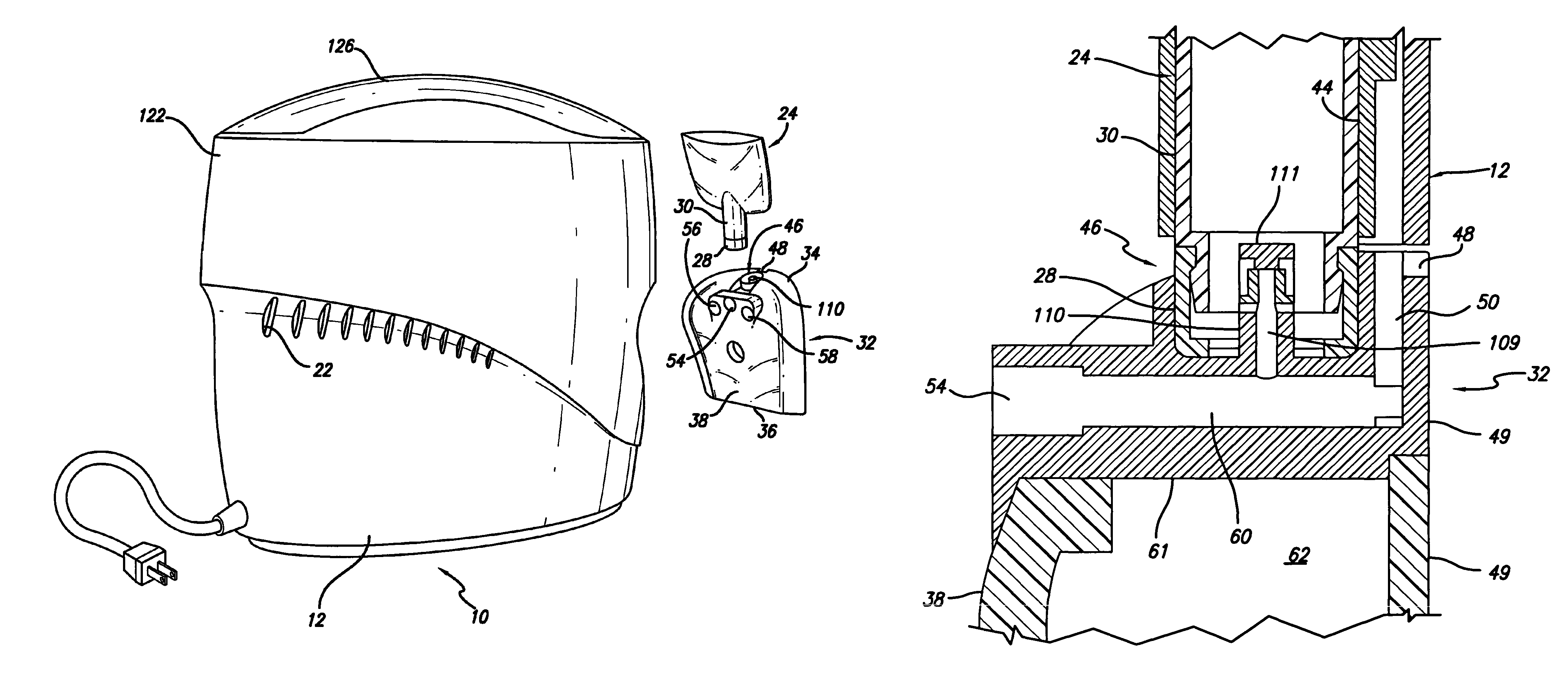

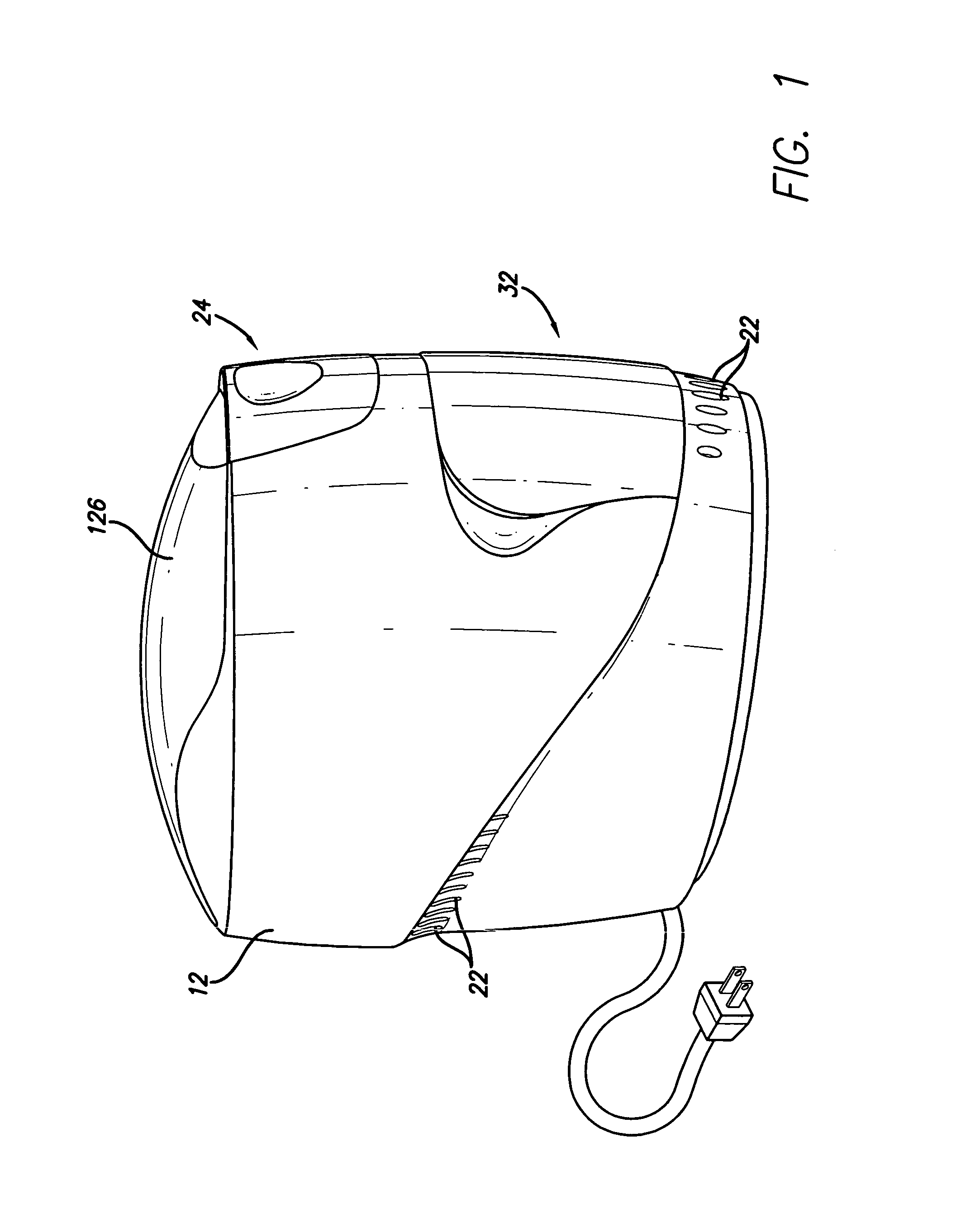

Portable microderm abrasion device

InactiveUS8025669B1Easy to operateEasy to serviceSurgeryAbrasive machine appurtenancesParticulatesLine tubing

A portable microderm abrasion device is comprised of a hollow housing containing an electric motor that operates an air pump having air suction and air exhaust ports. A hollow, disposable exfoliation grit supply cartridge is removably located within an upper bay, while a separate hollow, disposable waste collection cartridge is also located within a lower bay in the housing directly beneath the grit supply cartridge. The two cartridges are separately removable from the housing. Grit from the supply cartridge is mixed with air drawn by a vacuum created by the air pump into a grit entrainment duct located within the waste collection cartridge and carried to a movable wand. A particulate filter located in the waste collection cartridge allows air, but prevents solid waste material, from being discharged to ambient atmosphere. Safety features include a timer and / or a motion sensor to reduce or cut off vacuum in the line if the grit dispensing and retrieval tip of the wand remains in a static condition or exerts a vacuum for too long a period of time upon the skin of the subject.

Owner:BIORENEW LABS

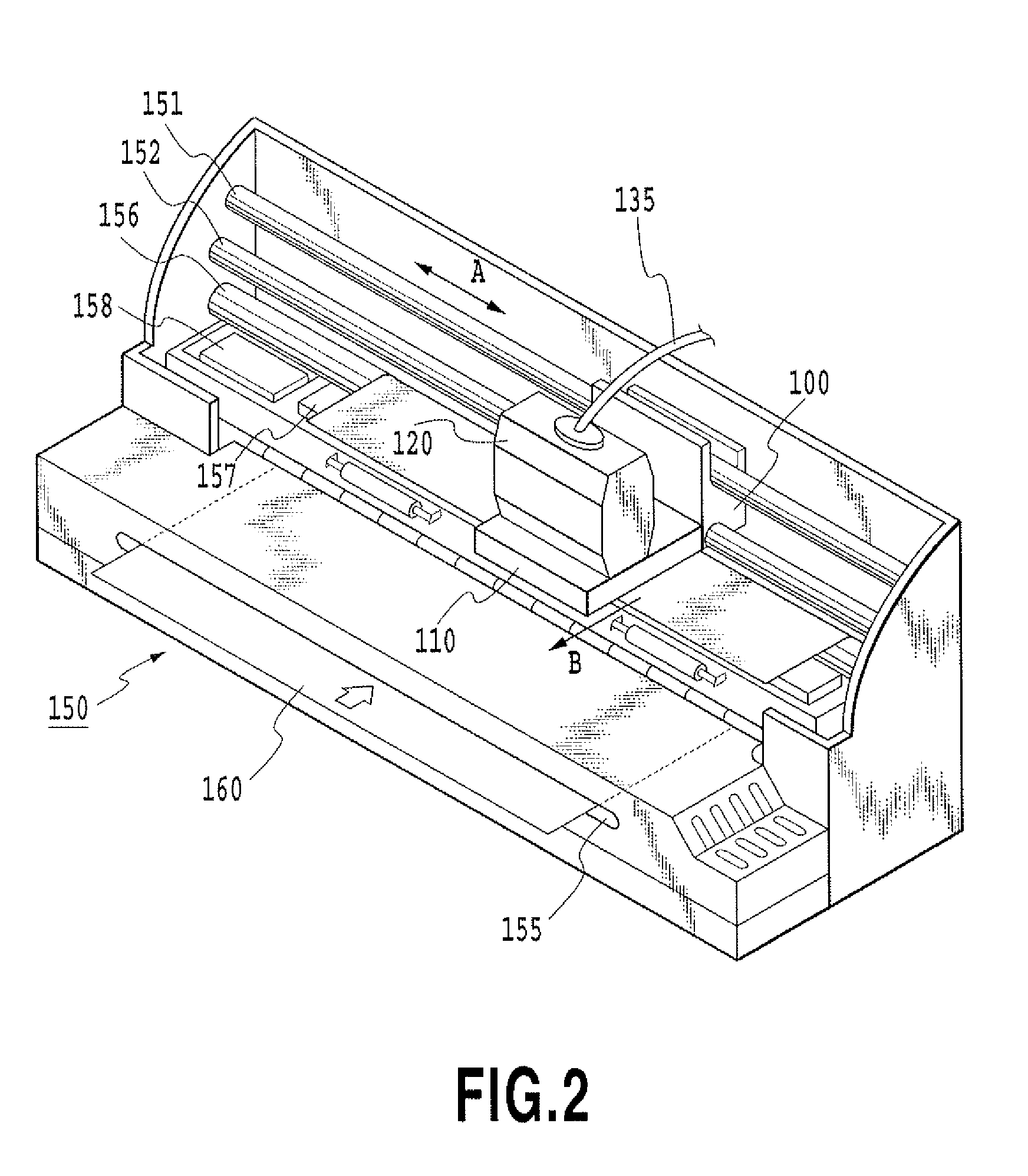

Ink jet printing apparatus

InactiveUS20090262150A1Not complicated in structureLow production costOther printing apparatusAir pumpAirlift pump

An air pump is driven to supply air via an air supply tube to a sub tank, by which a predetermined quantity of the air is mixed inside the sub tank via a gas-liquid separation membrane. Next, a carriage is swayed to agitate the ink by using the air mixed inside the sub tank. Then, the air pump is driven to discharge the air inside the sub tank via the gas-liquid separation membrane. In the above-described agitating motions, since the air utilized for the agitation is discharged from an ink tank after agitation processing, it is possible to prevent the air from remaining inside the ink tank to inflate, thereby adversely influencing the pressure relationship with a printing head.

Owner:CANON KK

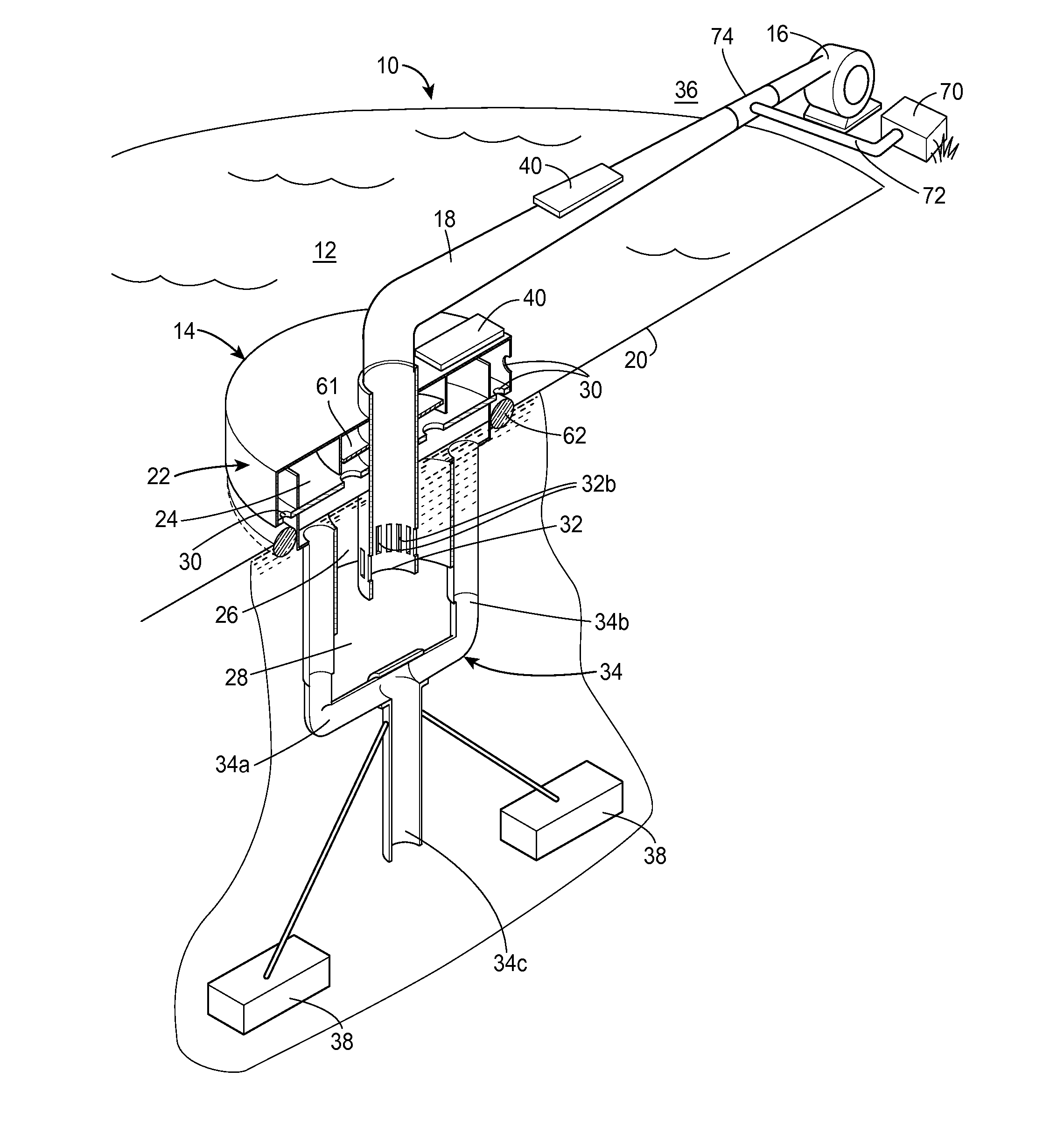

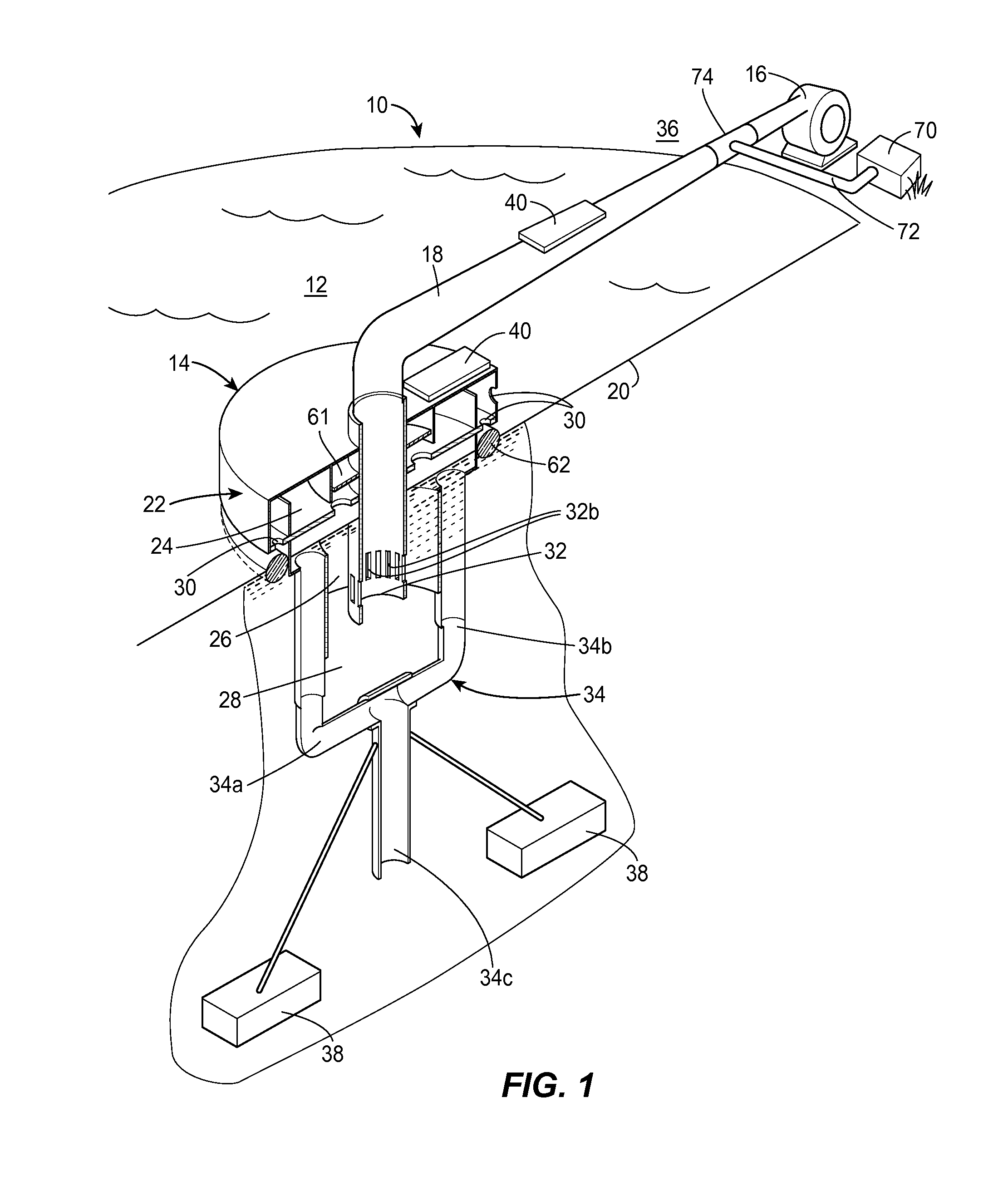

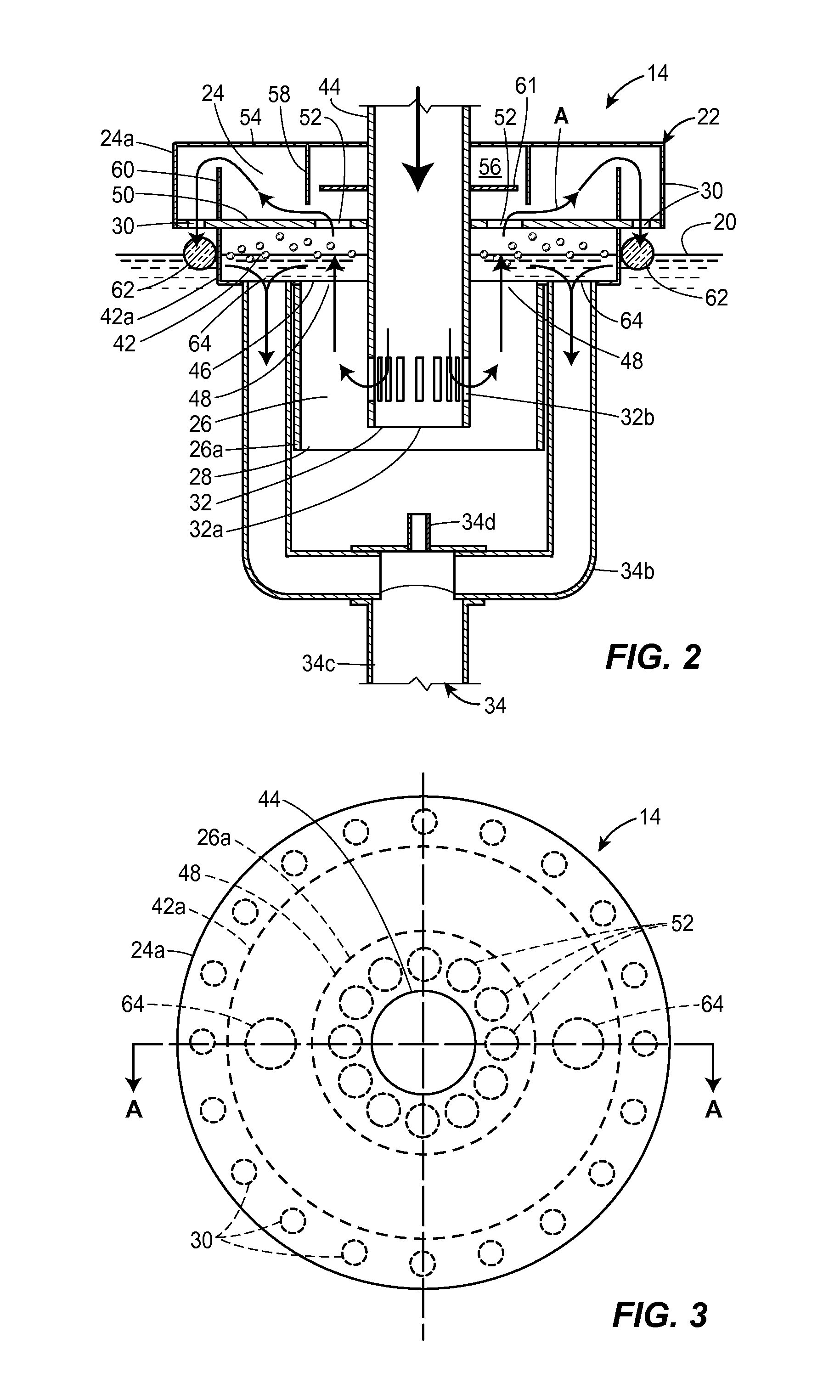

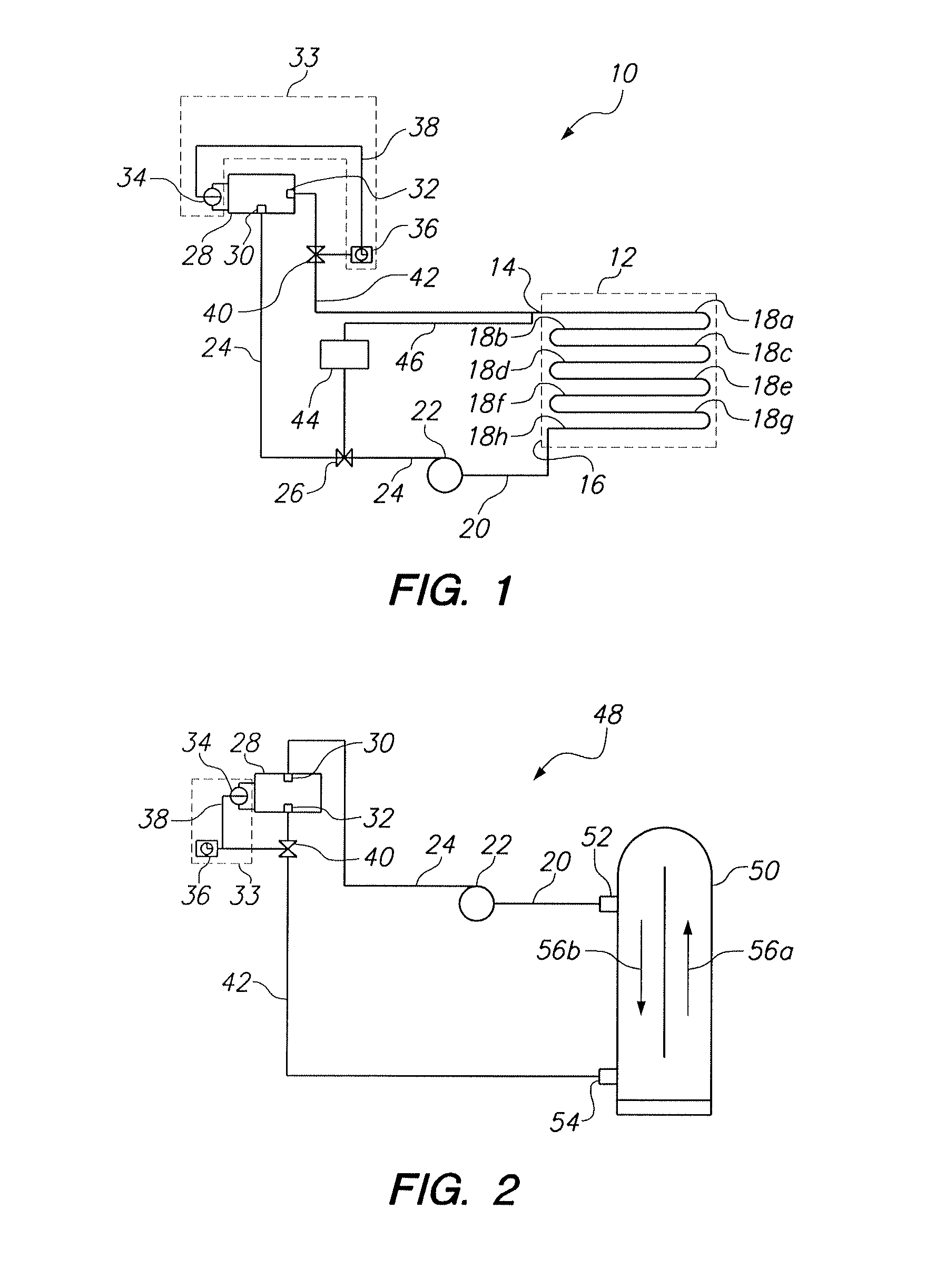

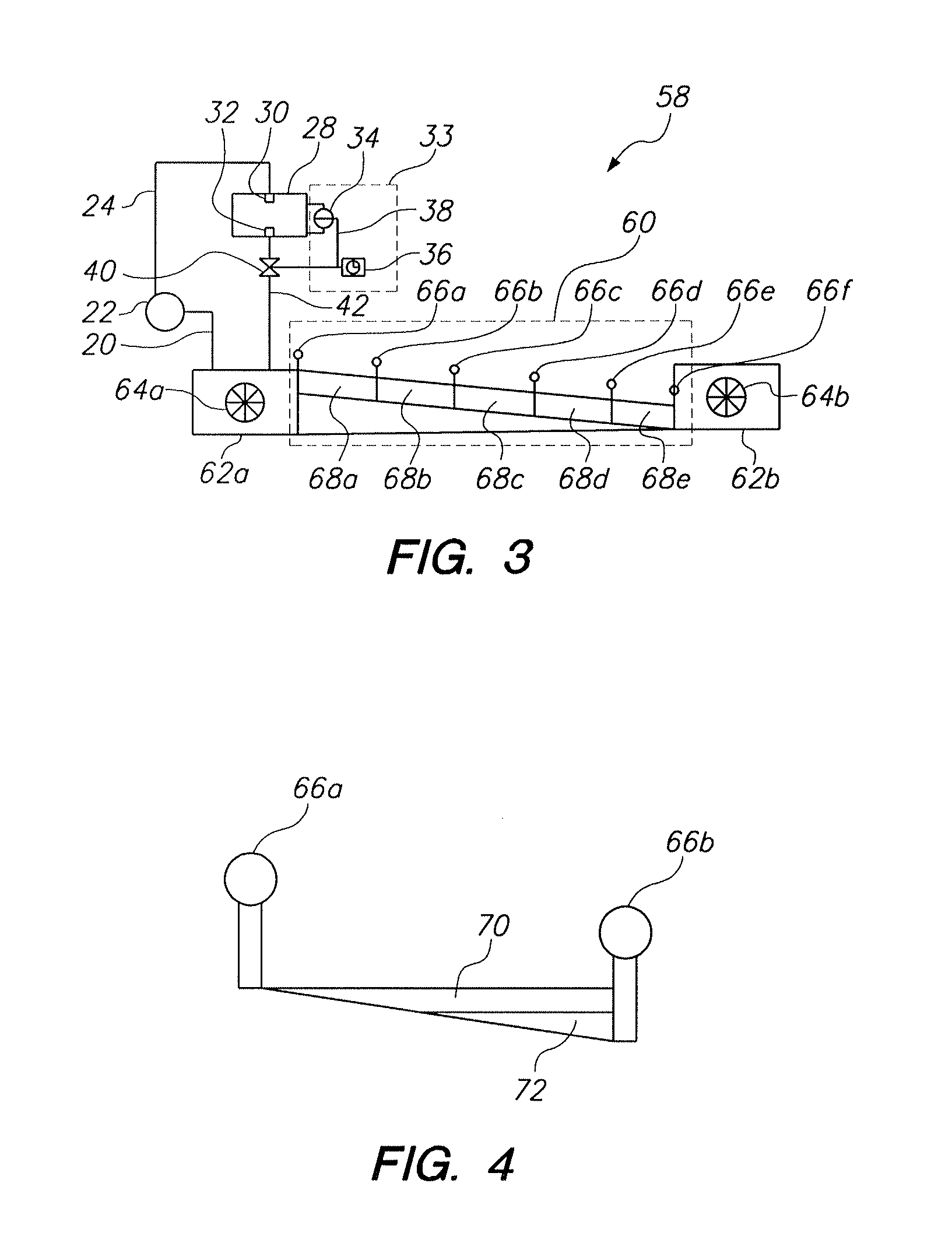

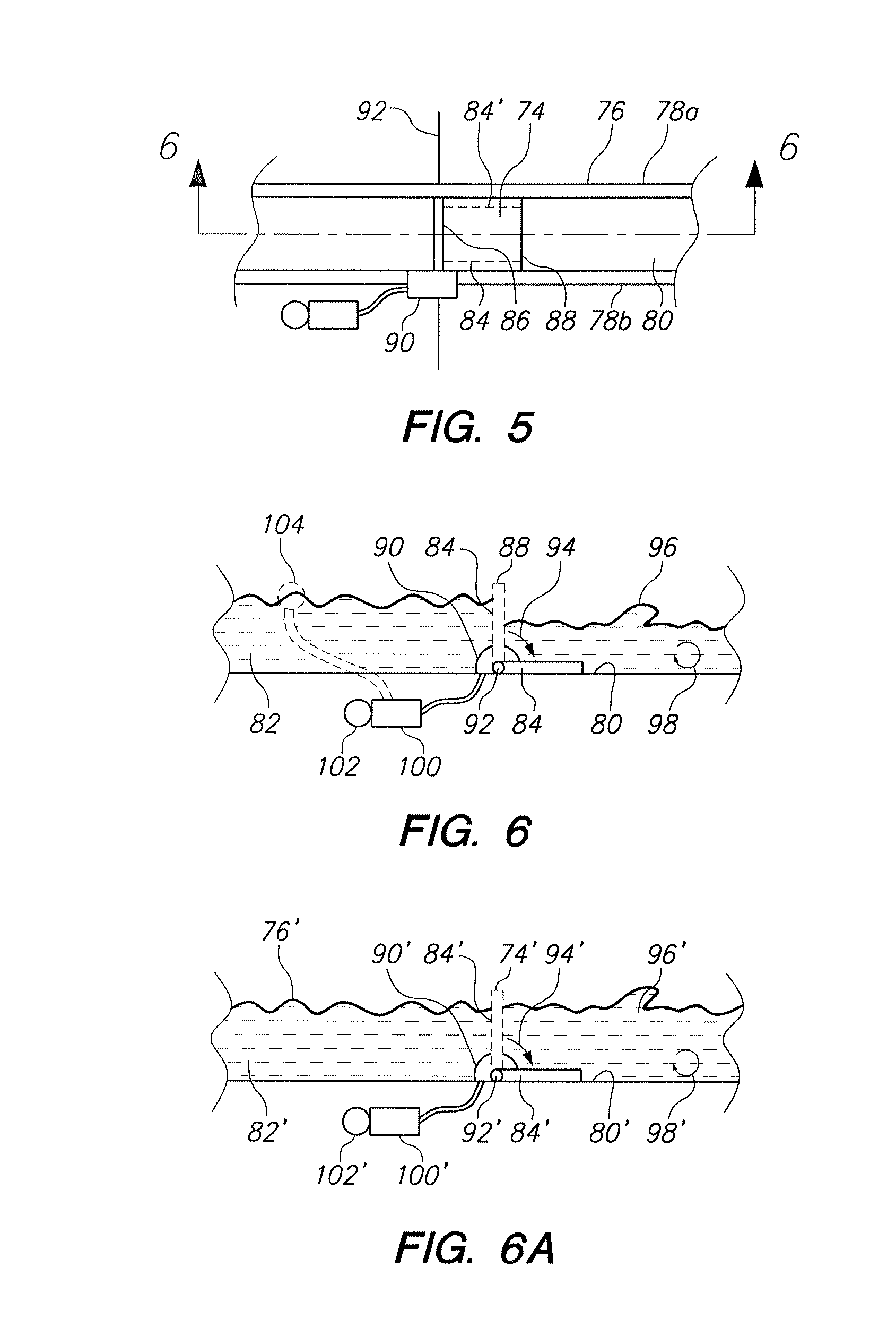

Fluid evaporator for an open fluid reservoir

ActiveUS20130248122A1Drying using combination processesEvaporator accessoriesControl mannerEvaporation

A reservoir evaporation system for evaporating fluid from an open reservoir of effluent containing a contaminant includes a fluid evaporator, an air pump, and an air supply conduit functionally connecting the fluid evaporator with the air pump. The fluid evaporator includes a vessel adapted to be positioned in an operative position partially submerged on the top surface of the effluent in the reservoir with a lower chamber submerged in the effluent and an upper chamber extending above the top surface of the effluent. In operation, air from the air pump mixes with the effluent inside the fluid evaporator and subsequently is discharged through exhaust openings. A fluid discharge pipe can also simultaneously discharge aerated effluent back down into the reservoir. Fluid is thereby separated from the effluent in the lower chamber by evaporation in a controlled manner that minimizes spread of contaminants to surrounding environments by wind.

Owner:HEARTLAND WATER TECH INC

System and Method for Using a Pulse Flow Circulation for Algae Cultivation

InactiveUS20140322805A1Large specific surface areaGreat culture productivityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringAlgae

A device for generating a pulsed flow in a channel containing a circulating algal culture can include a plate that is pivotably mounted on the channel and an activator. A pulsed flow is generated in the channel by first positioning the plate to impede the flow of circulating algal culture and then rotating the plate to a submerged position. The pulsed flow can be employed to counteract the negative effects of bio-fouling on algae cultivation equipment. In another arrangement, a device for generating a pulsed flow in a sloped raceway that is in fluid communication with a sump can include a gate. In different embodiments, the gate can operate as a so-called “pinch gate” or as a so-called “overflow gate.” In another aspect, a variable rate pump, such as a centrifugal pump, a screw pump or an airlift pump, is described for establishing a pulsed flow in a channel.

Owner:GENERAL ATOMICS

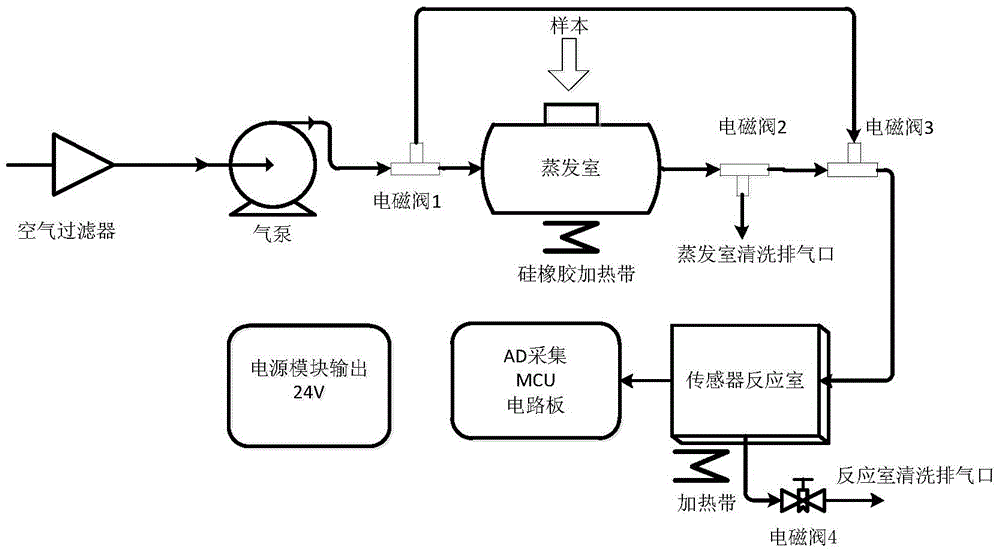

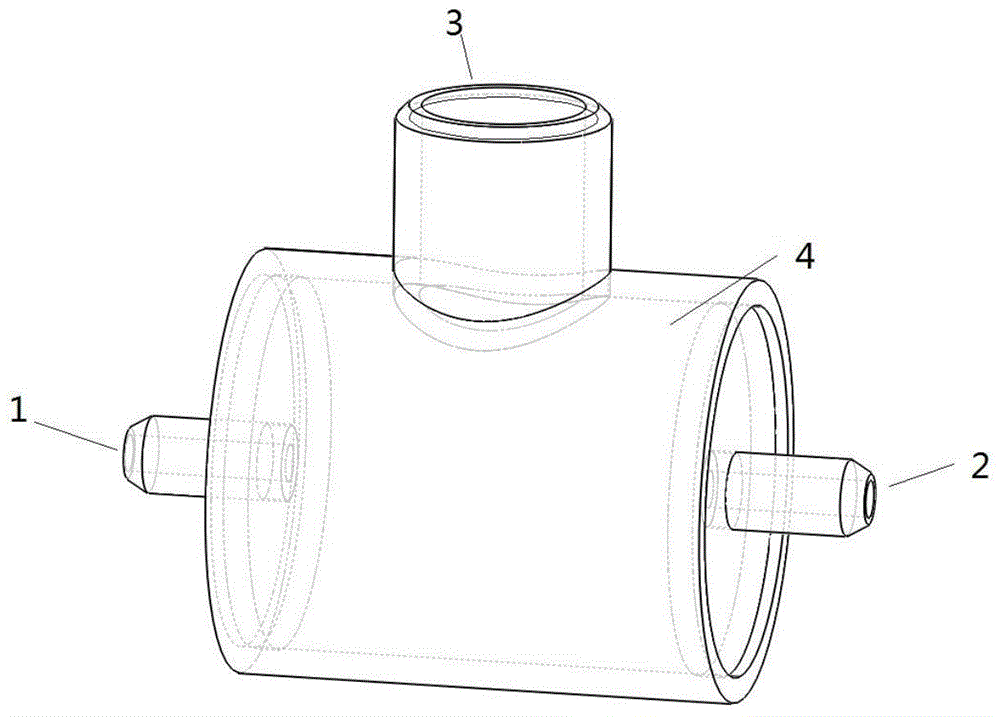

White spirit recognition method based on electric nose technology

ActiveCN104535618AConvenient Evaporative SamplingGood repeatabilityMaterial analysis by electric/magnetic meansFeature vectorFeature extraction

The invention relates to a white spirit recognition method based on an electric nose technology. An adopted device comprises an air pump, an evaporation chamber, a reaction chamber, a microprocessor and electromagnetic valves. The air pump is connected with an air inlet of the evaporation chamber through the first electromagnetic valve and connected with the reaction chamber through the third electromagnetic valve. The evaporation chamber is a cylindrical cavity arranged transversely, and an air inlet and an exhaust port are formed in the two sides of the cylindrical cavity. A heating strip is wound around the outer wall of the evaporation chamber, the top and the bottom of the reaction chamber are in a slightly protrusive cone shape, and signals collected by gas sensors are fed into the microprocessor. The recognition method includes the steps that for a specific kind of white spirits, sample collecting is performed repeatedly, the signals collected by the gas sensors are preprocessed, a usable characteristic vector used for training of a one-class classifier is obtained through characteristic extraction and selection, and finally the one-class classifier for the kind of white spirits is obtained through training learning on the characteristic vector. The recognition method for the white spirits is suitable for recognizing on-site and outdoor white spirits.

Owner:TIANJIN UNIV

Double-tube type electromagnetic induction RH device and method for heating molten steel and removing inclusions

The invention provides a double-tube type electromagnetic induction RH device and method for heating molten steel and removing inclusions. The device comprises a steel ladle, a vacuum chamber, an ascending pipe, a descending pipe, an iron core and an induction coil, wherein the ascending pipe and the descending pipe are arranged at the bottom of the vacuum chamber, lower ports of the ascending pipe and the descending pipe are communicated with the steel ladle, and the iron core is of a solid structure and is arranged in the manner of surrounding the ascending pipe or the descending pipe; and parts, close to the outer side of the ascending pipe or the outer side of the descending pipe, of the iron core are wound with the coil, and the axis of the coil keeps to be perpendicular to the axis of the ascending pipe or the descending pipe. The method includes the process steps that (1) the molten steel generates circulation motion in the vacuum chamber, the ascending pipe and the descending pipe according to the airlift pump principle; (2) a forced air cooling or water cooling device is started, alternating current is led into the induction coil, and the inclusions are continuously removed; and (3) after the temperature of the molten steel rises to the temperature which is 10 DEG C to 300 DEG C higher than the liquid phase line, electrification is stopped, the forced air cooling or water cooling device is stopped, and the molten steel is led into a next working procedure.

Owner:NORTHEASTERN UNIV

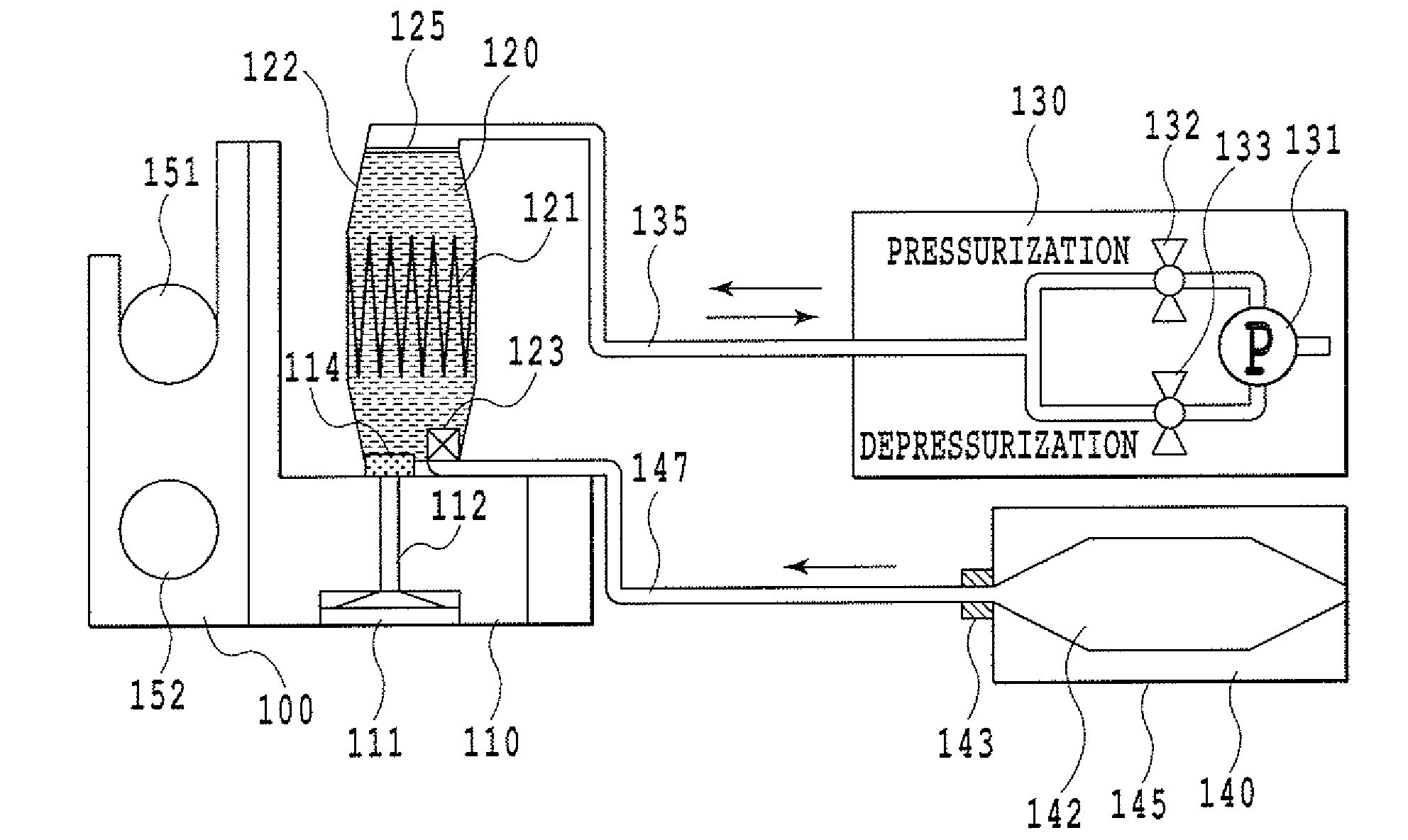

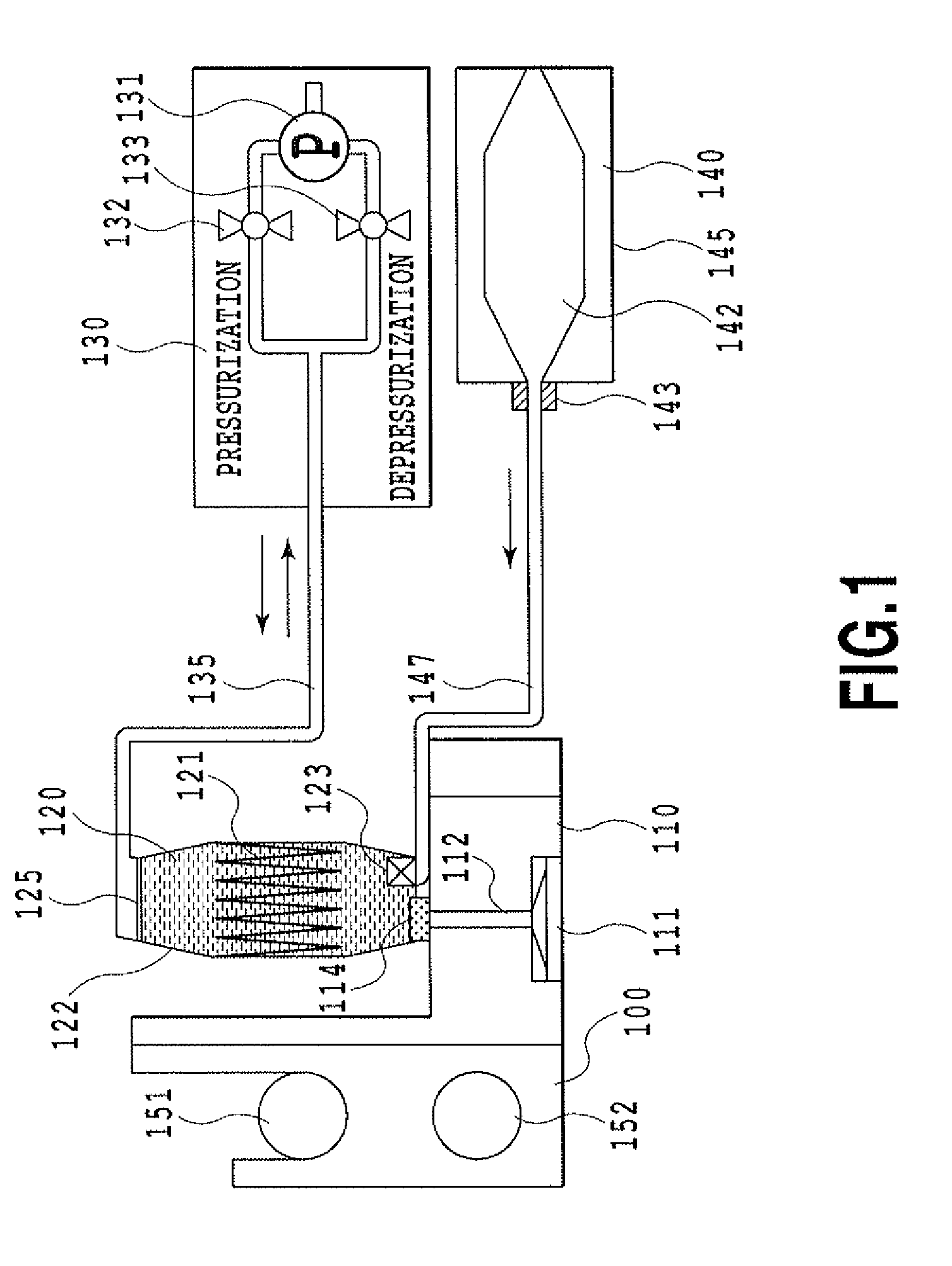

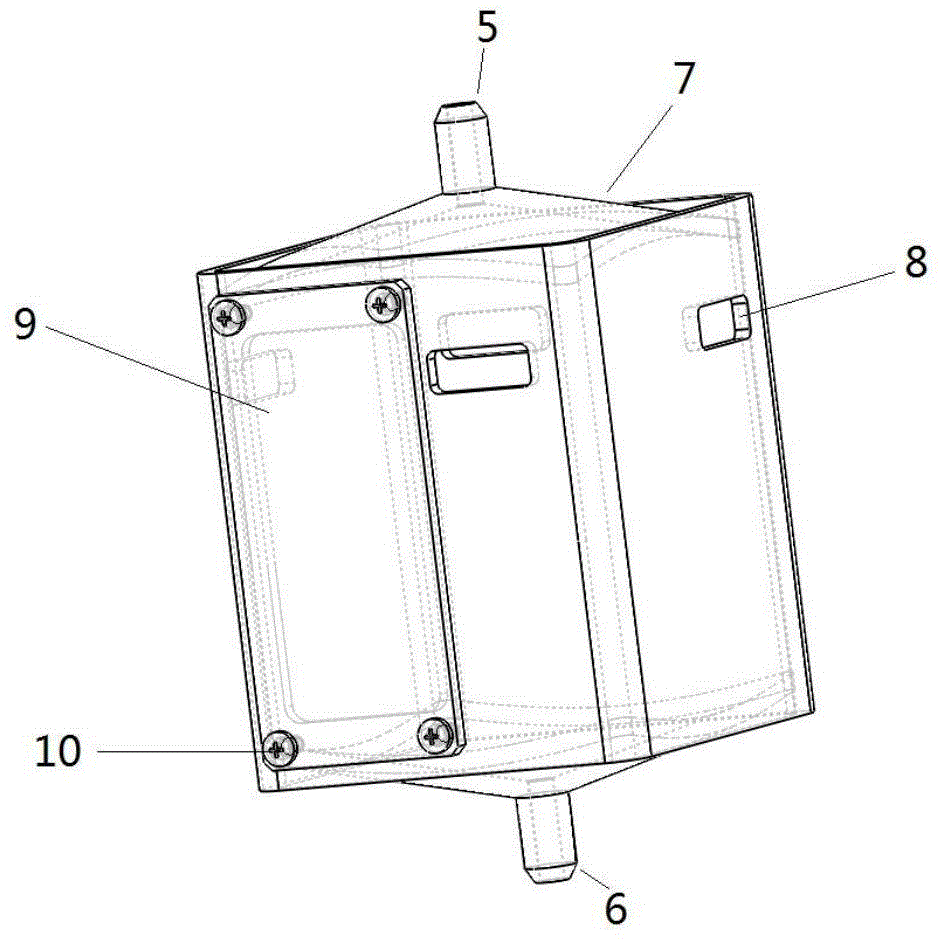

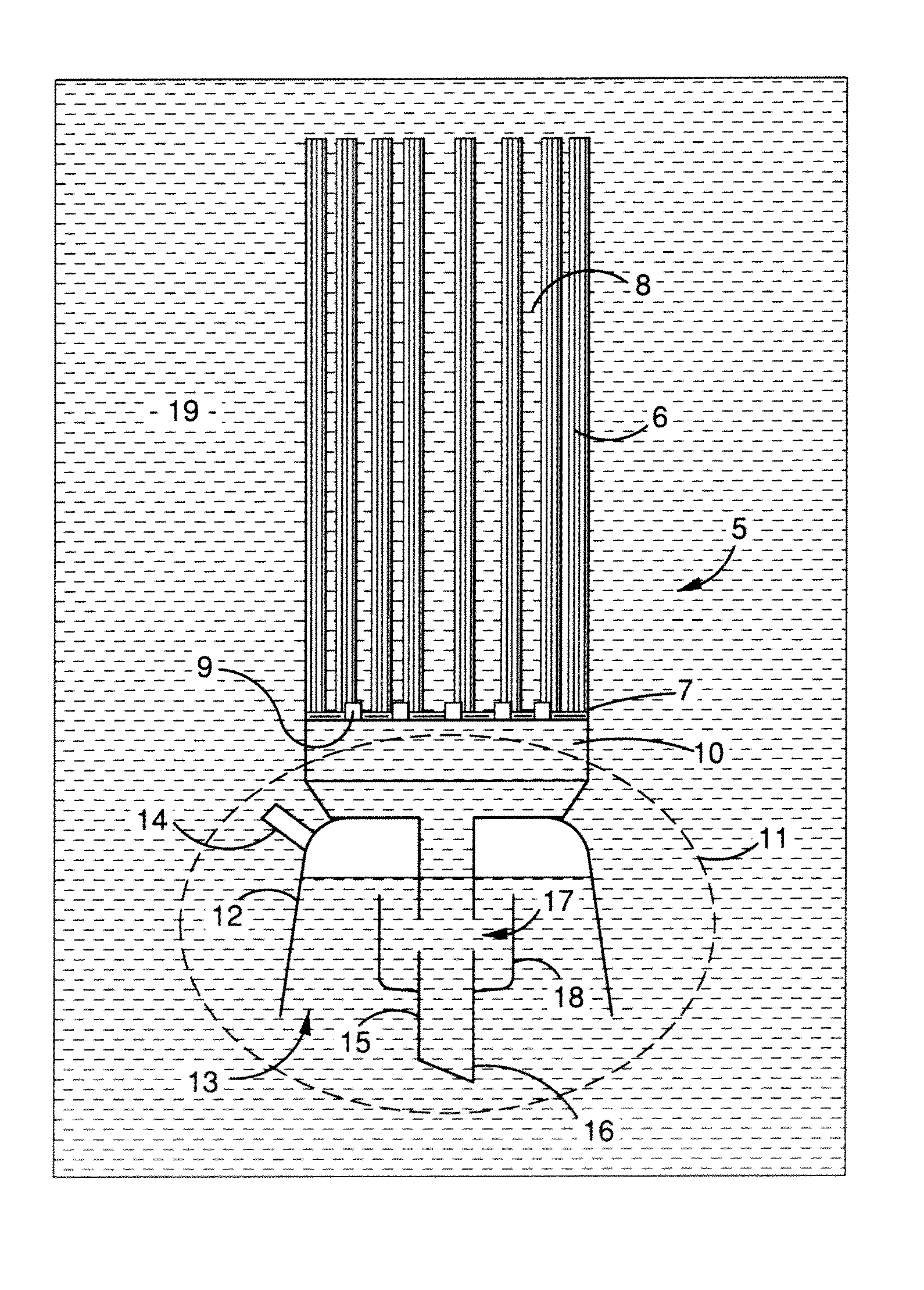

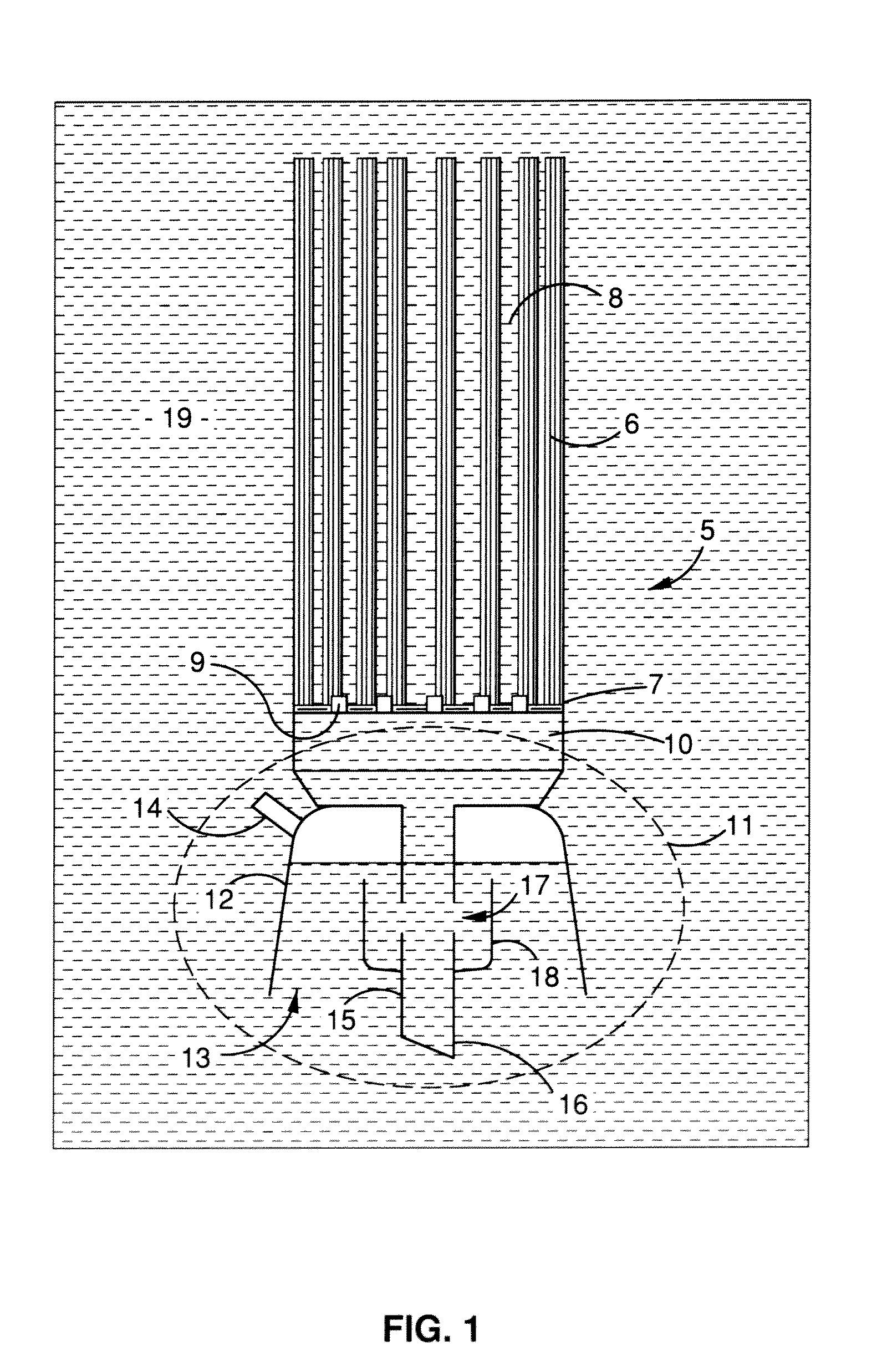

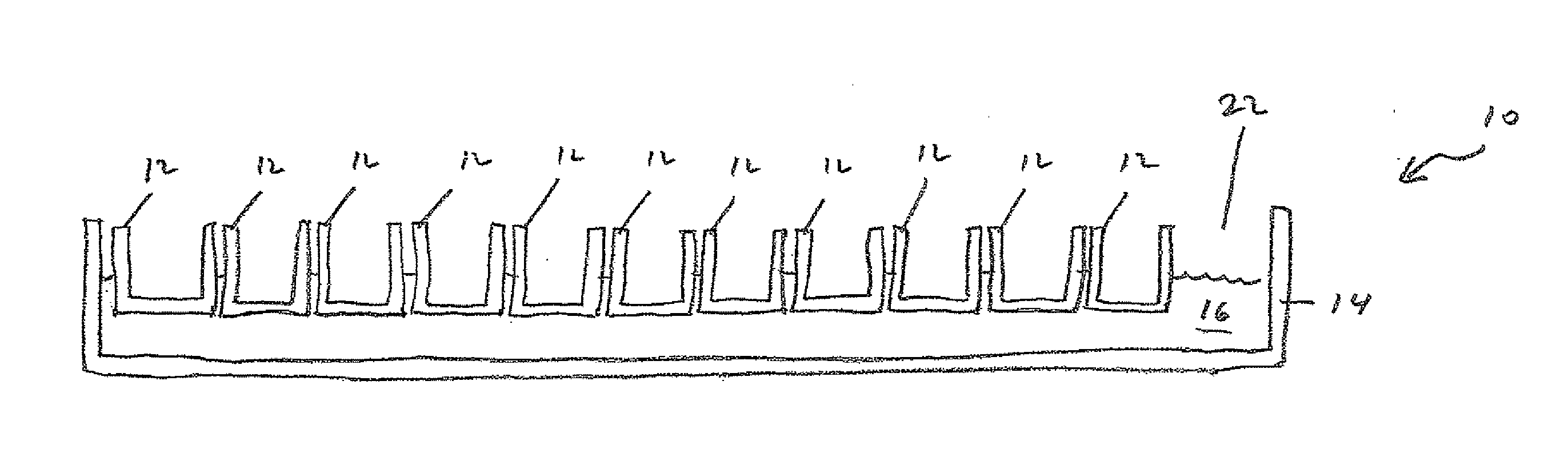

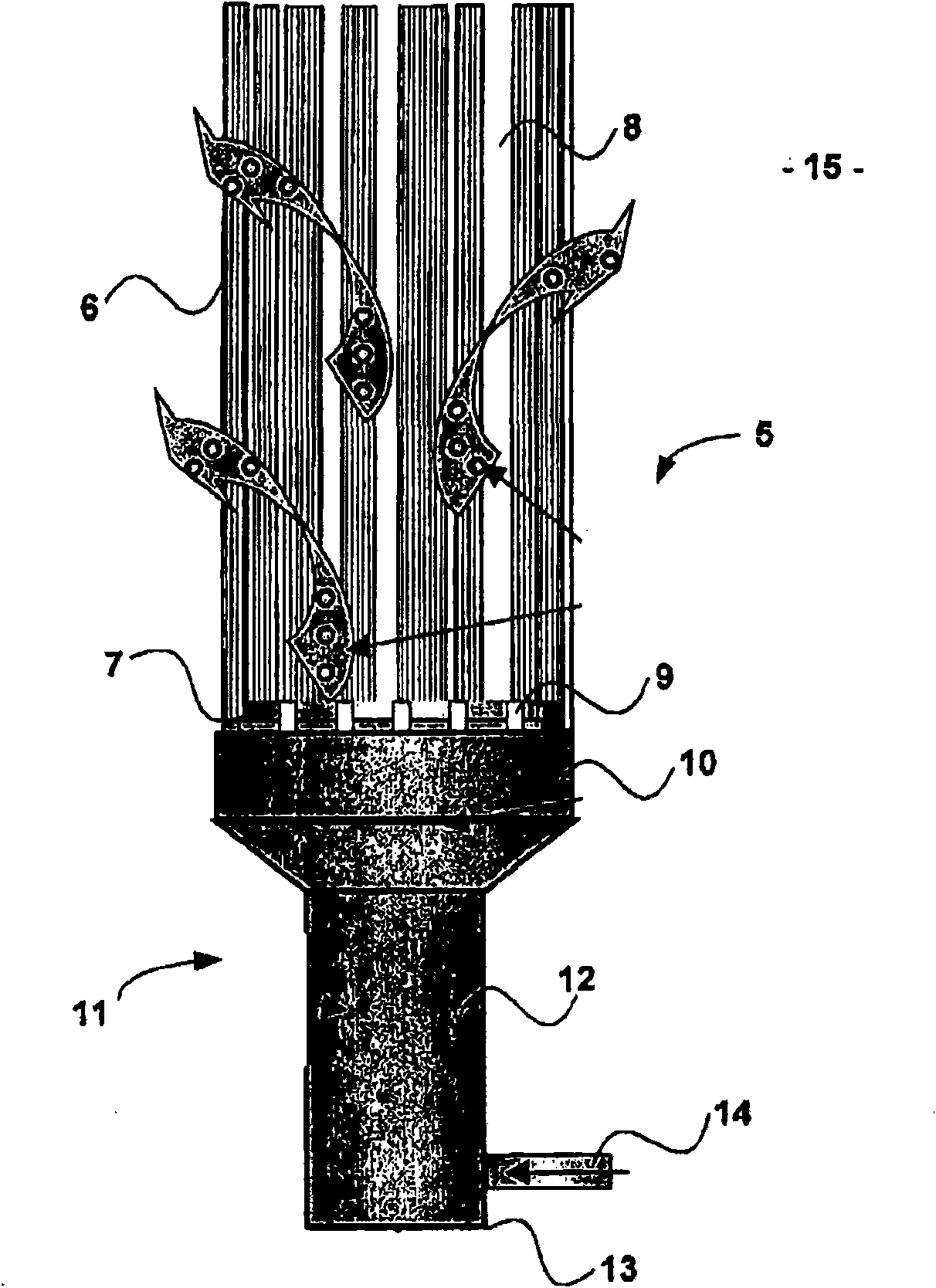

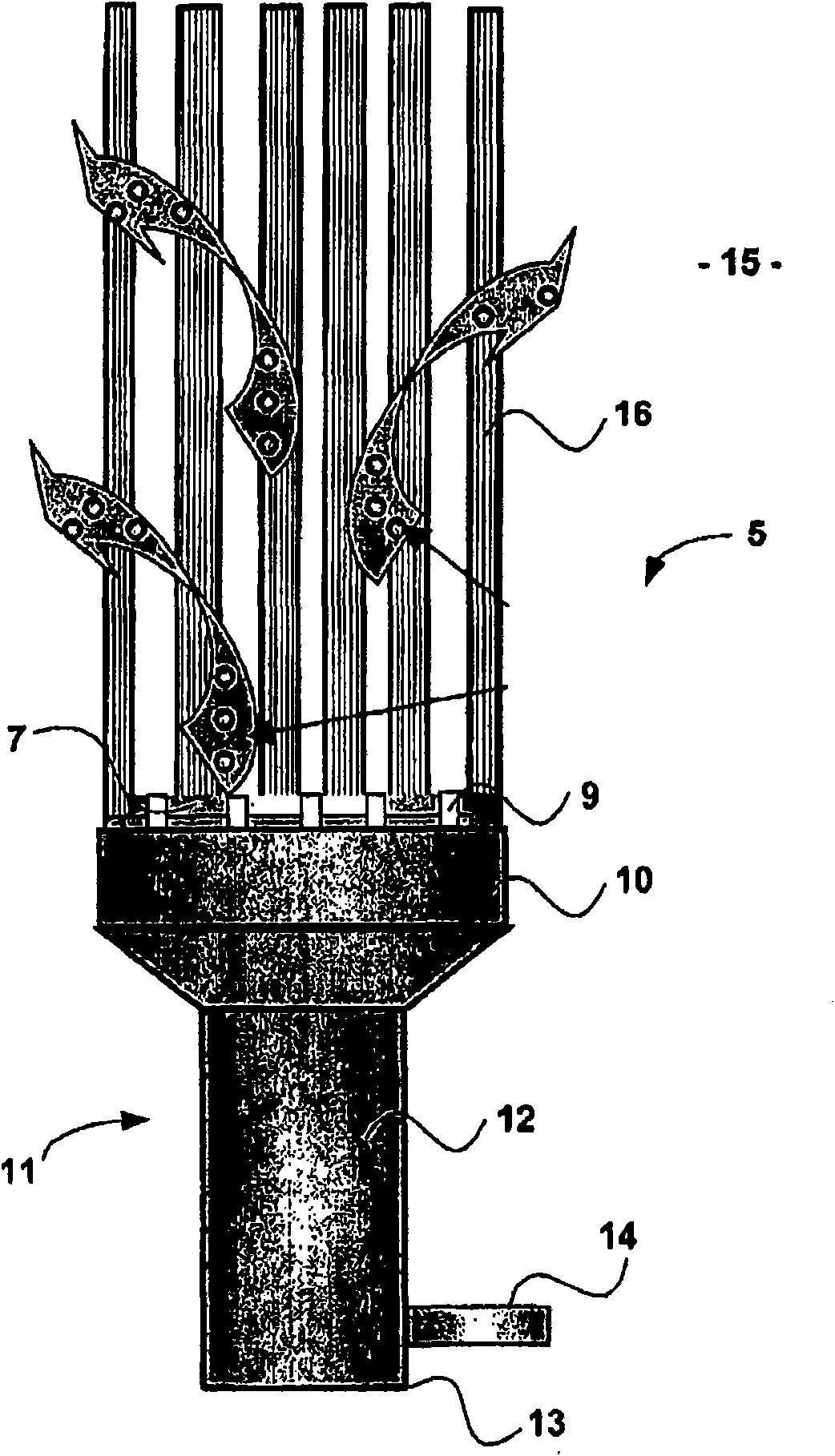

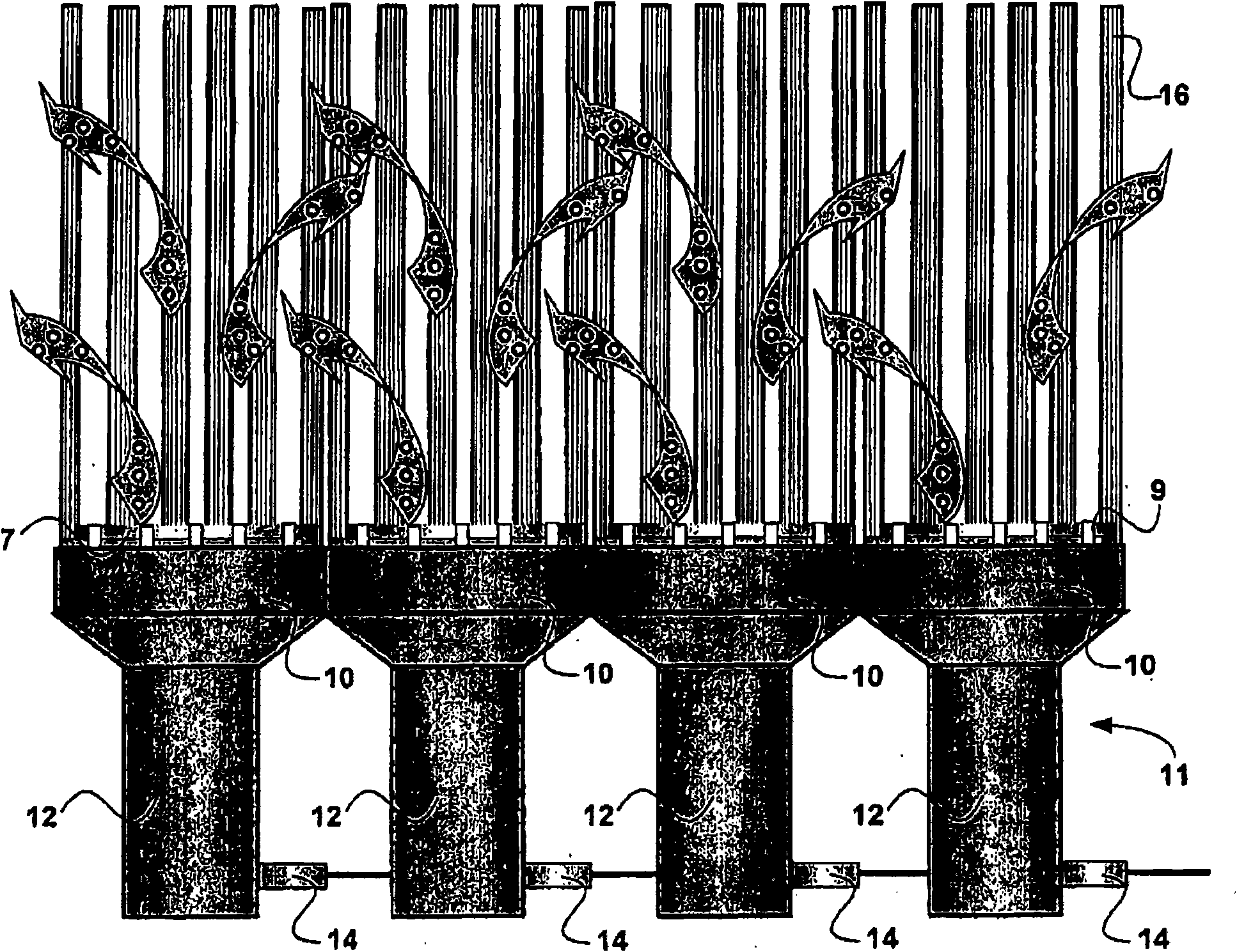

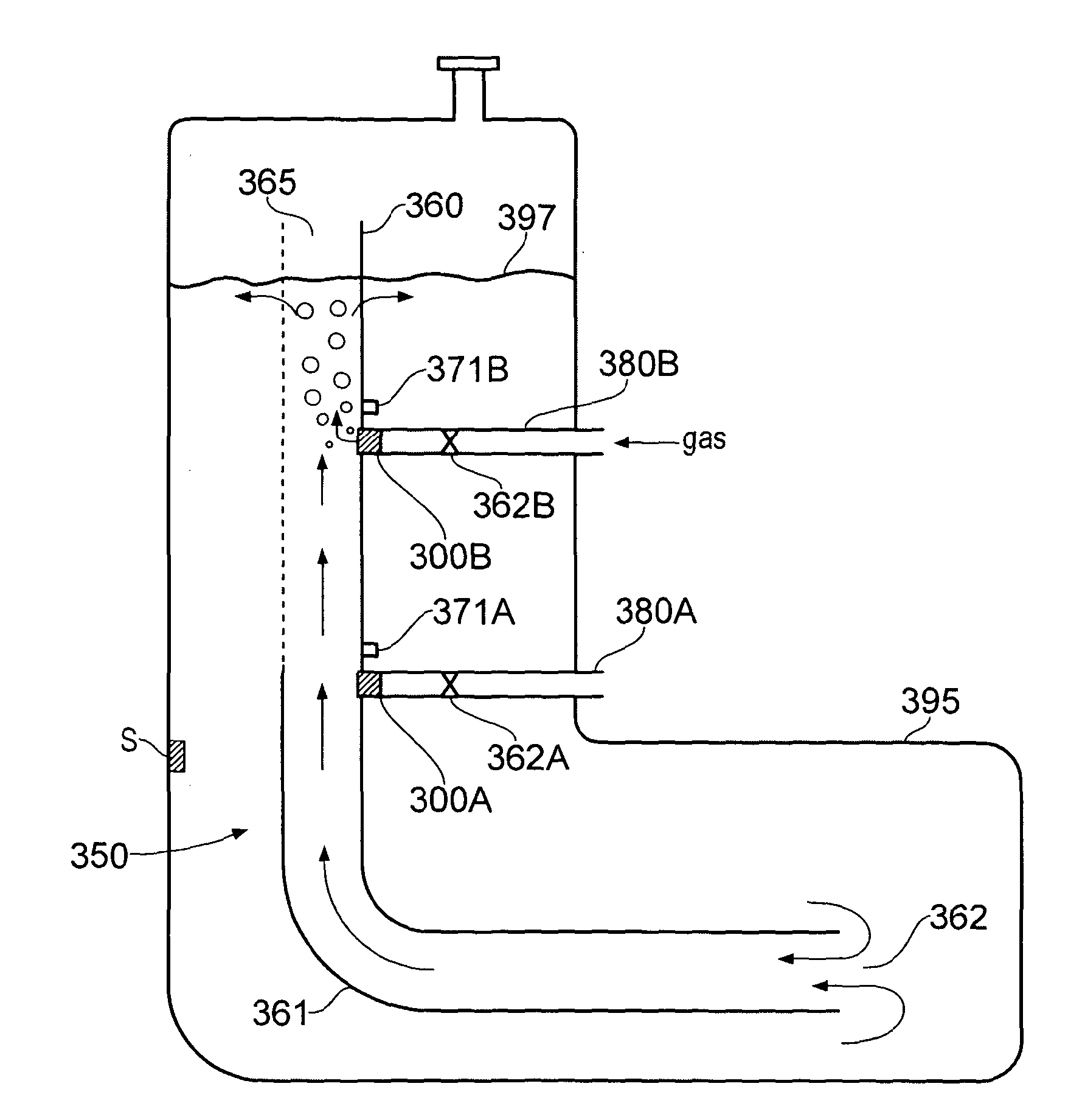

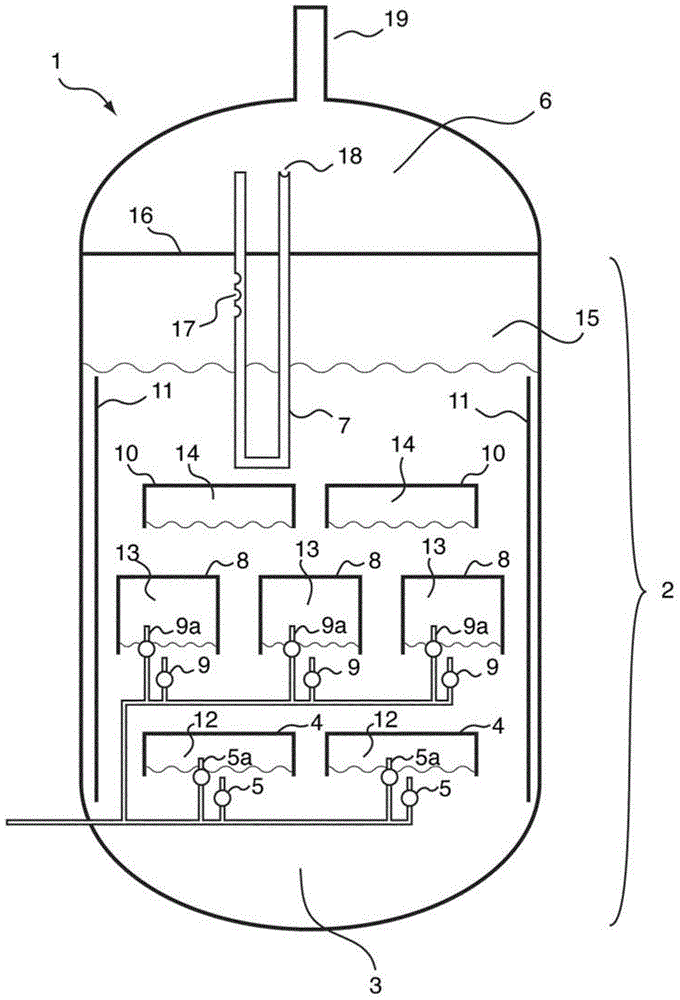

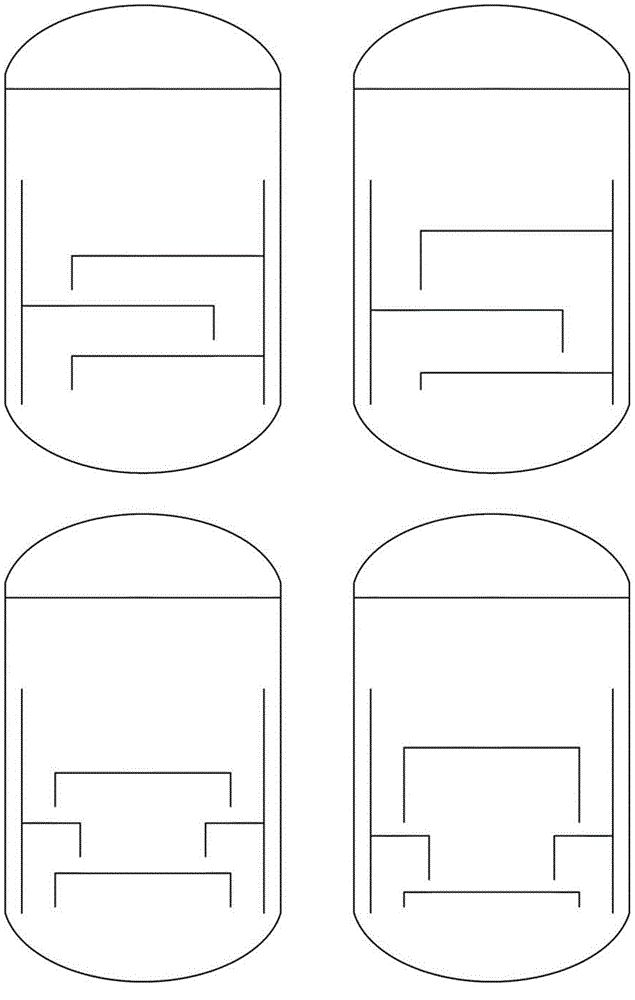

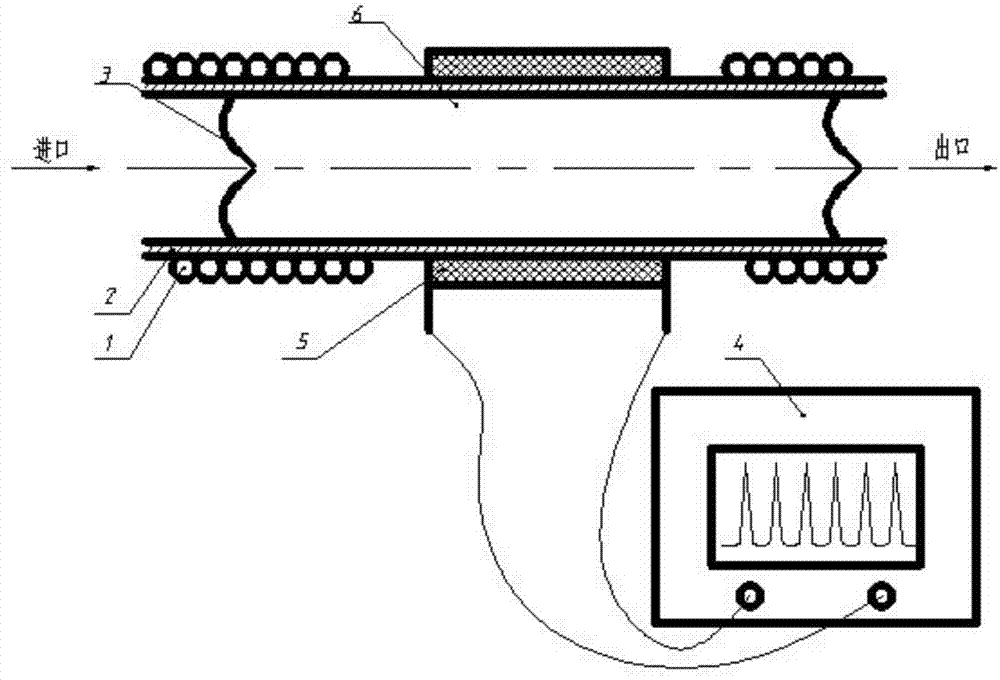

Membrane cleaning with pulsed airlift pump

ActiveUS8622222B2Easy to cleanReduces solid concentration polarisationUltrafiltrationTreatment involving filtrationLiquid mediumPorous membrane

A method of cleaning a membrane surface immersed in a liquid medium with a fluid flow, including the steps of providing a randomly generated intermittent or pulsed fluid flow along the membrane surface to dislodge fouling materials therefrom. A membrane module is also disclosed comprising a plurality of porous membranes (6) or a set of membrane modules (5) and a device (11) for providing a generally randomly generated, pulsed fluid flow such that, in use, said fluid flow moves past the surfaces of said membranes (6) to dislodge fouling materials therefrom.

Owner:EVOQUA WATER TECH LLC

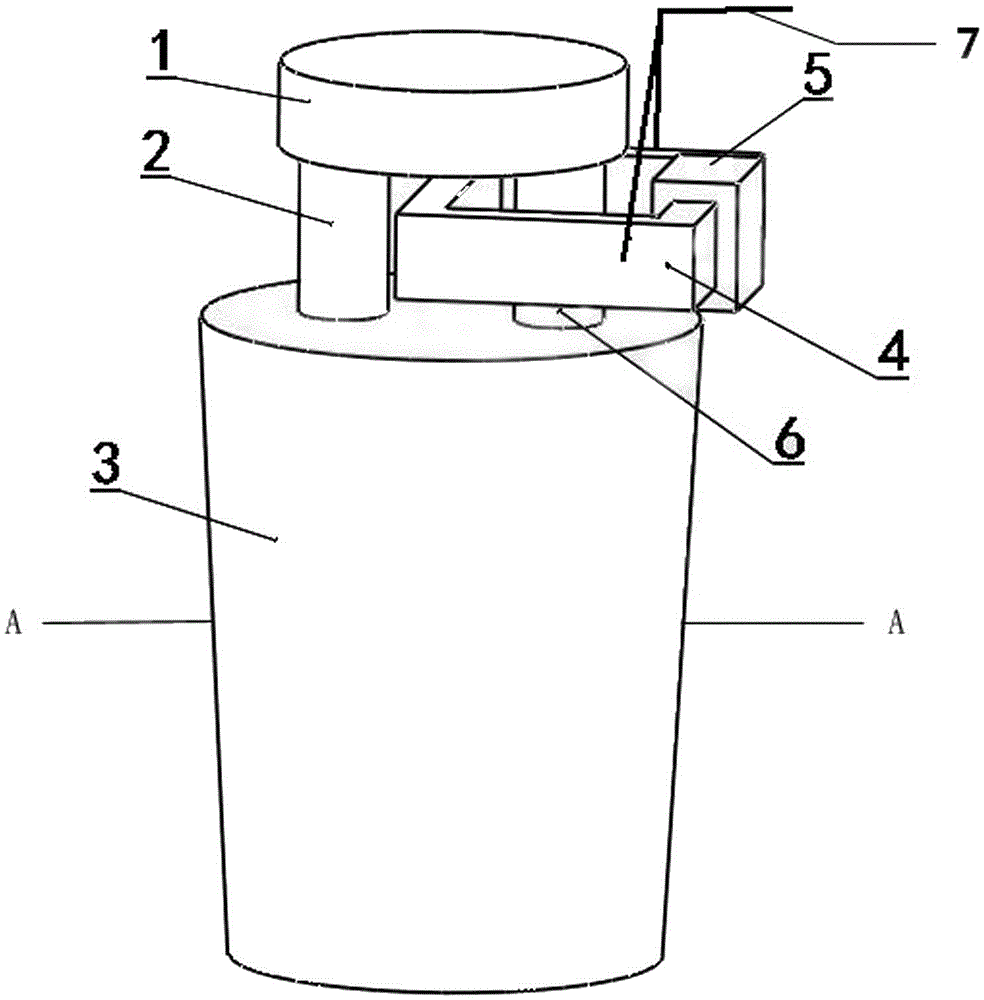

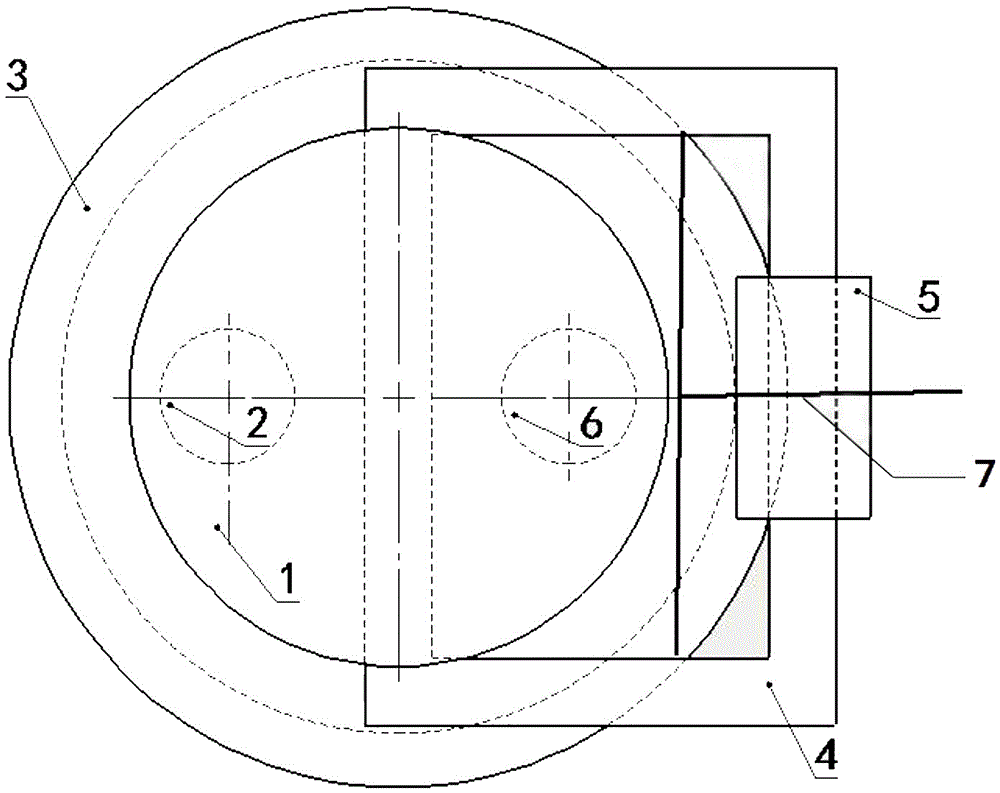

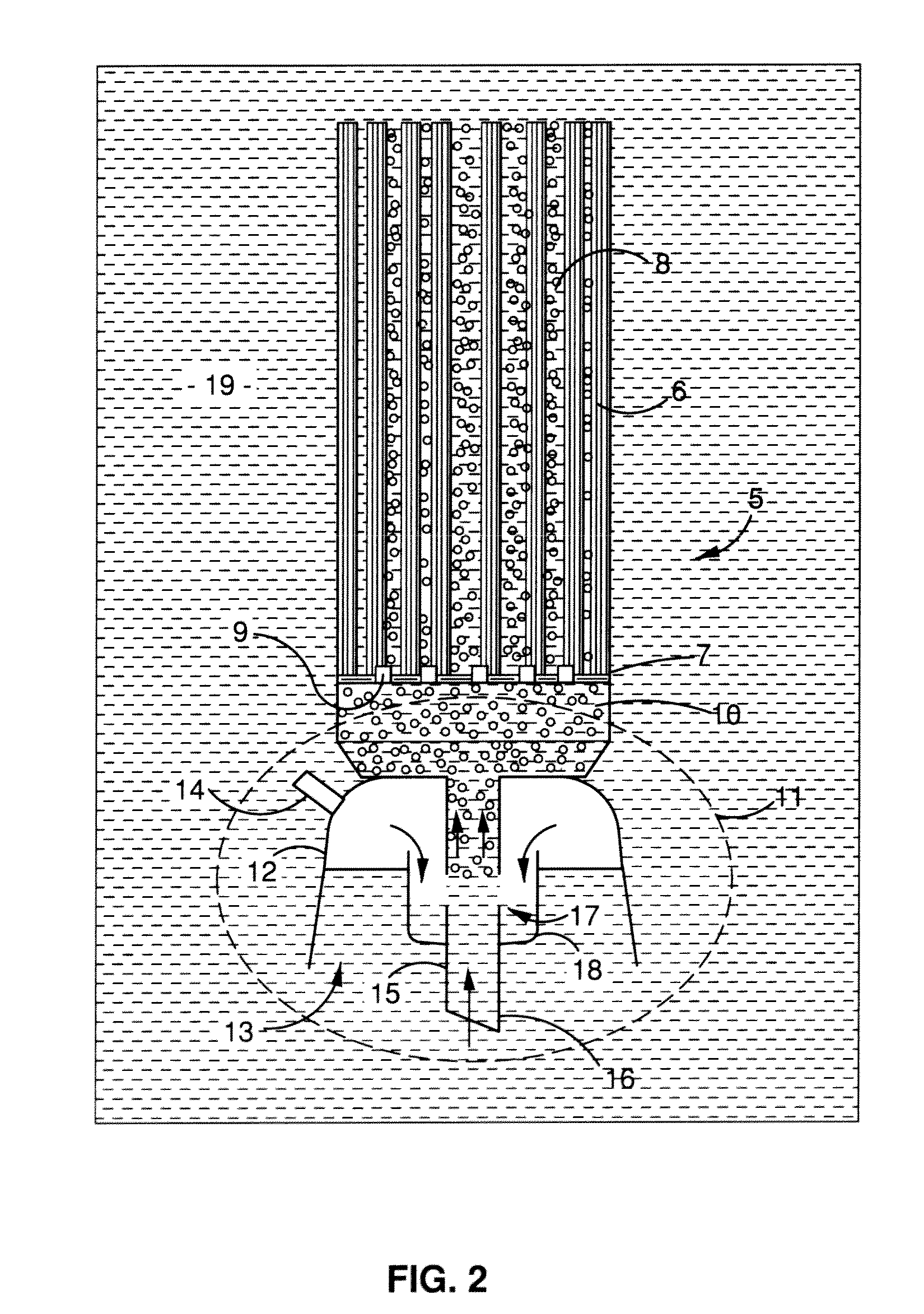

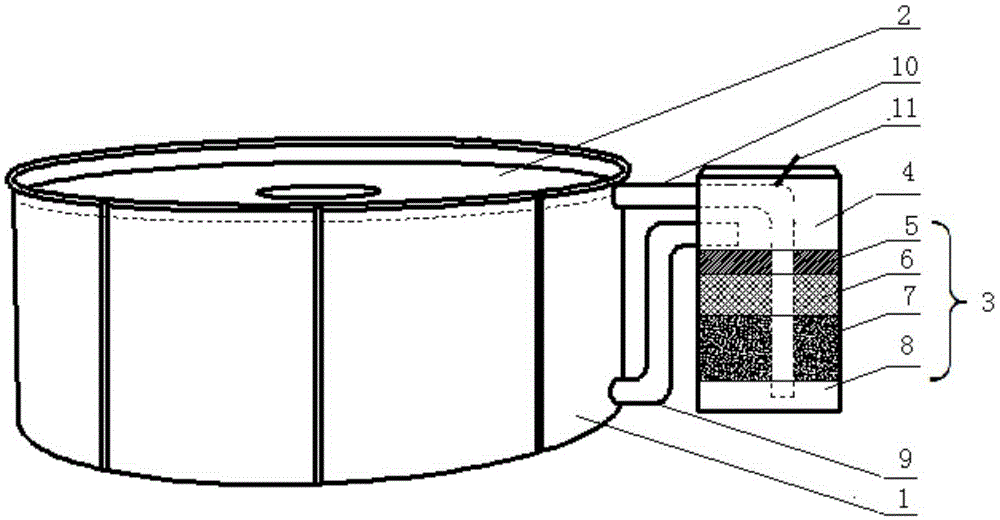

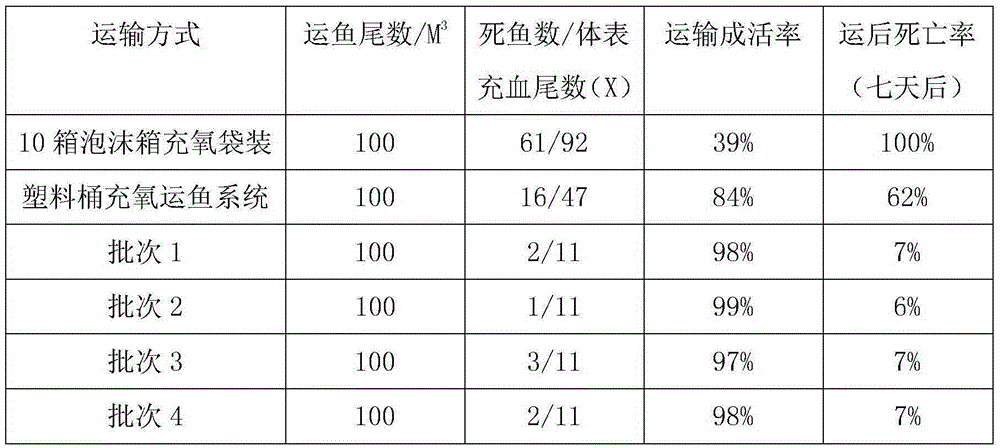

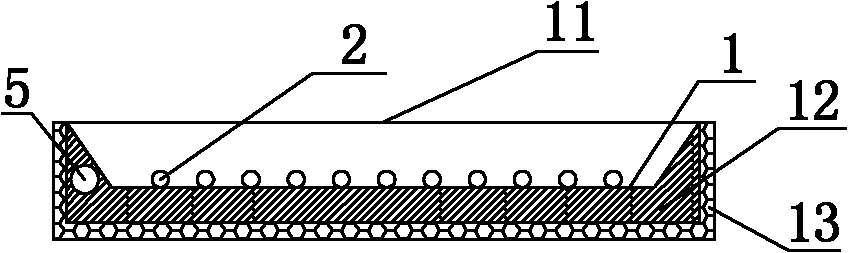

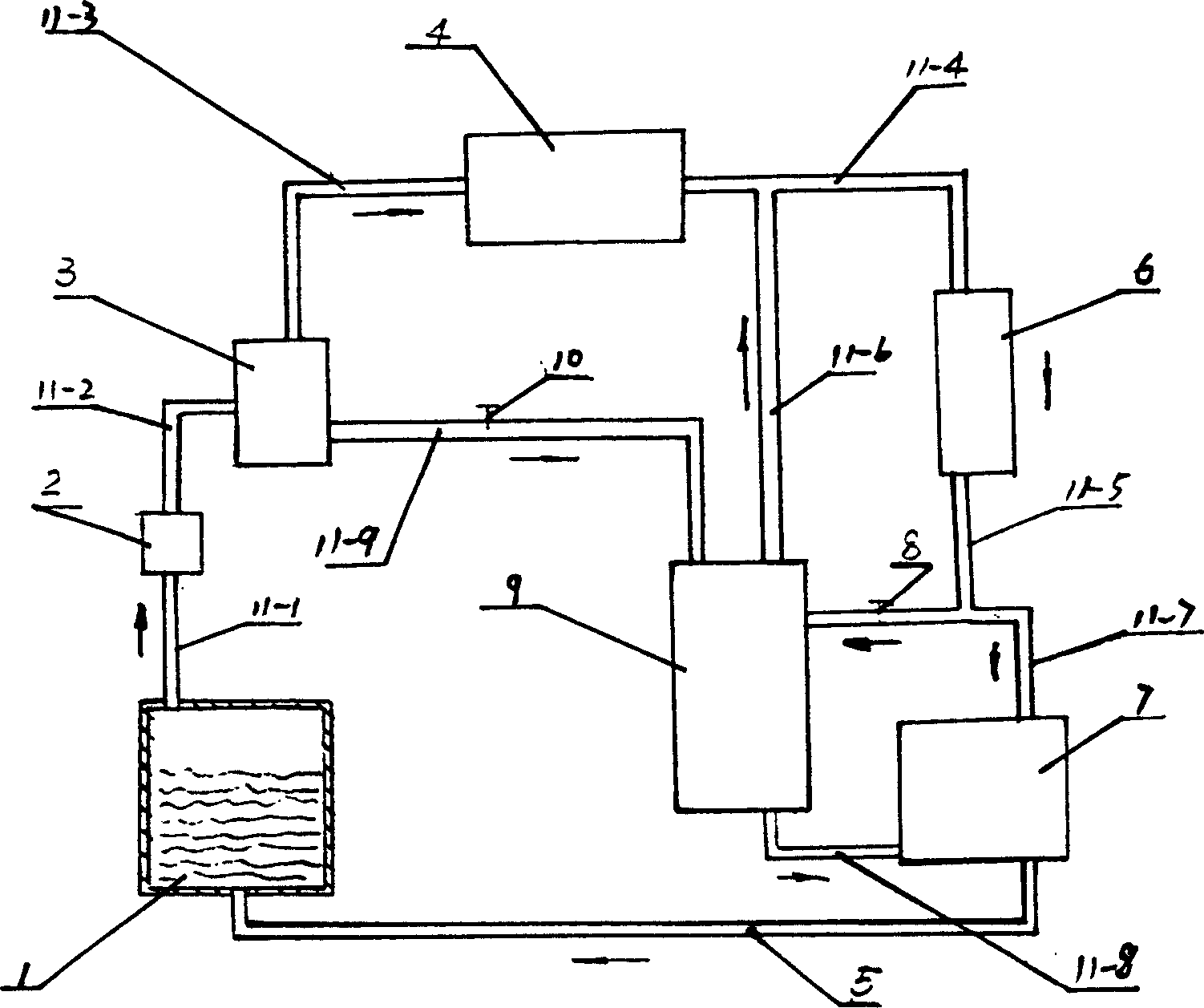

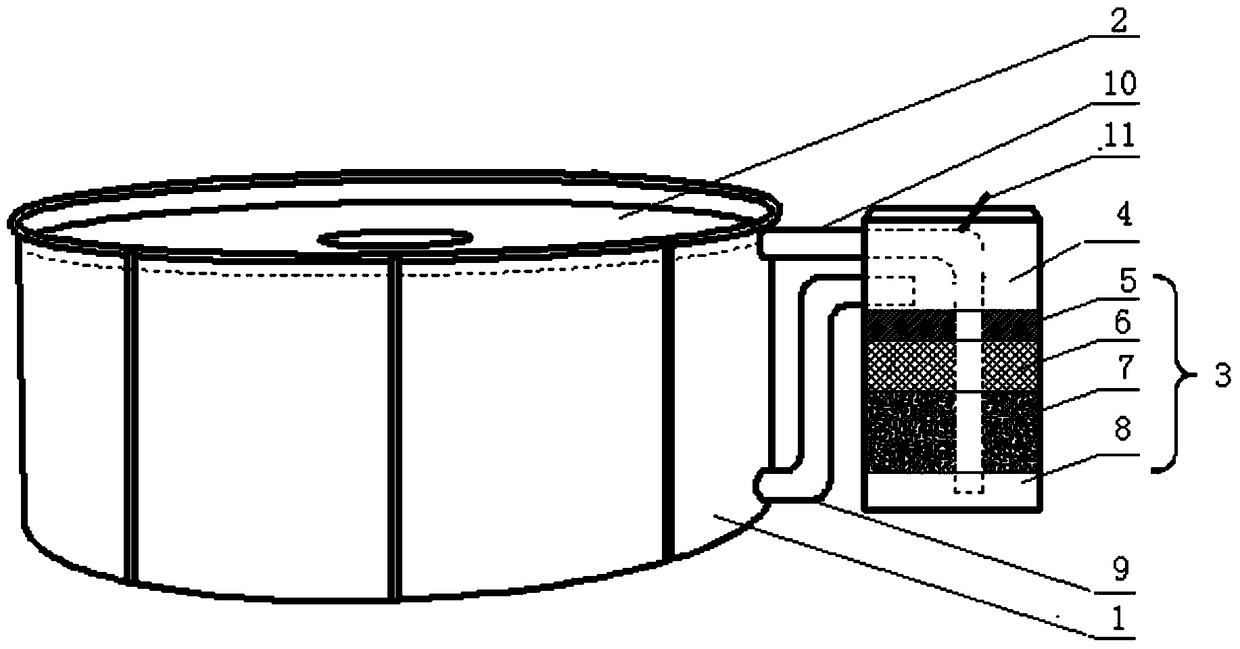

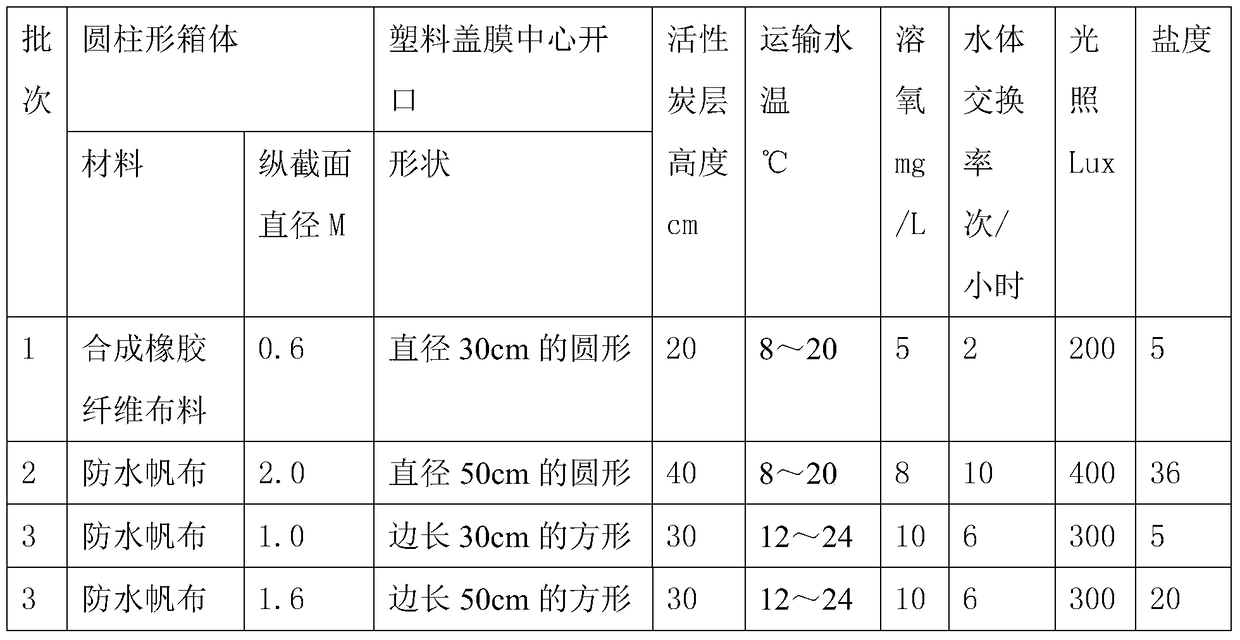

Equipment and method for improving live transportation survival rate of edgy fishes

ActiveCN105393972AGuaranteed bearing capacityHigh hardnessPisciculture and aquariaWater storagePurification methods

The invention provides equipment for improving the live transportation survival rate of edgy fishes. The equipment comprises a tank (1), a plastic cover film (2) matched with the tank (1), and a water purifier (3). The water purifier (3) comprises a water distribution layer (4), an ice cube layer (5), a filter cotton layer (6), an active carbon layer (7), and a water storage layer (8), wherein the above layers are arranged from top to bottom. The lower part of the tank (1) is provided with a water inlet pipe (9) to be connected with the water distribution layer (4) via the water purifier. The upper part of the tank (1) is provided with a provided with a water outlet pipe (10) to be connected with the water storage layer (8) via the water purifier. The water outlet pipe (10) of the water purifier is provided with an airlift pump interface (11). According to the technical scheme of the invention, a water quality purification method for water in transportation facilities is provided for aquaculture practitioners during the transportation process based on the physiological characteristics of saury and shad. In this way, the collision injured risk of fishes when frightened is reduced, and the water quality of the transportation water is improved. Meanwhile, the metabolites of fishes are timely eliminated, so that the stress reactions of edgy fishes, such as saury and shad, are reduced. Moreover, the risk of mechanical traumas and the risk of physiological endogenous injuries during the transportation process are reduced. The live transportation survival rate of fishes is improved. Furthermore, the temporary-rearing or cultivation survival rate of fishes after the transportation process is improved.

Owner:SUZHOU FISHSEEDS BIOLOGICAL TECH CO LTD

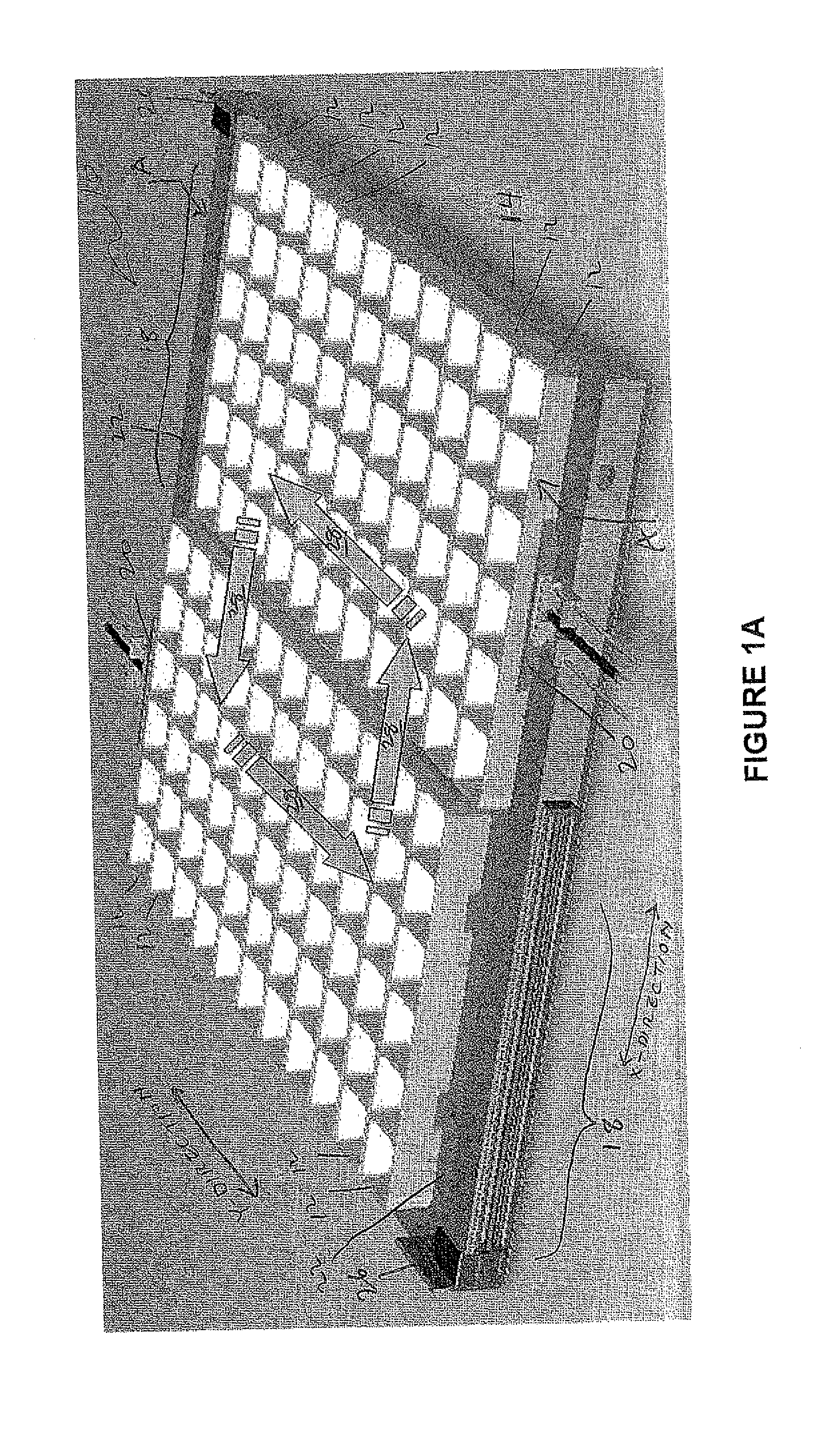

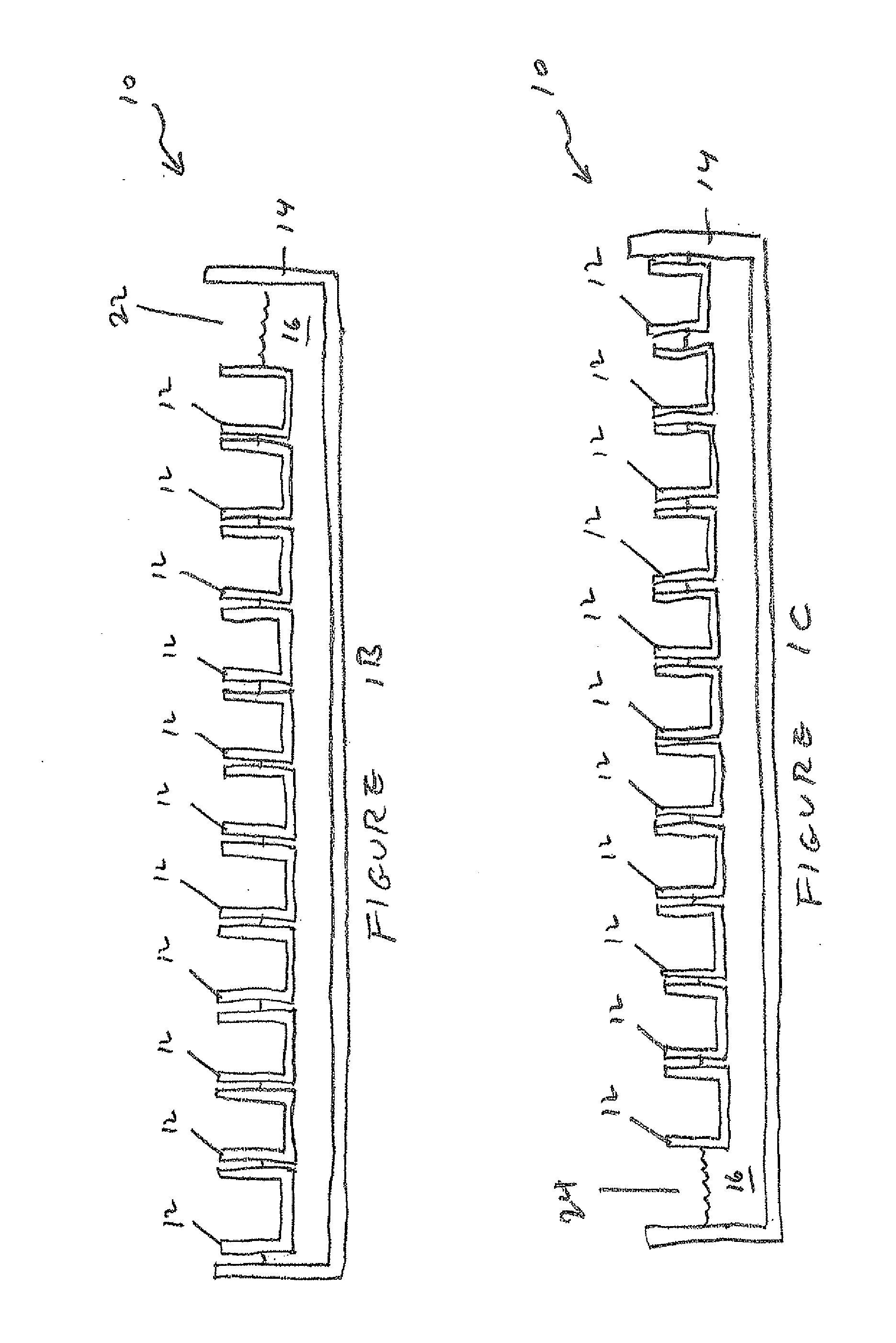

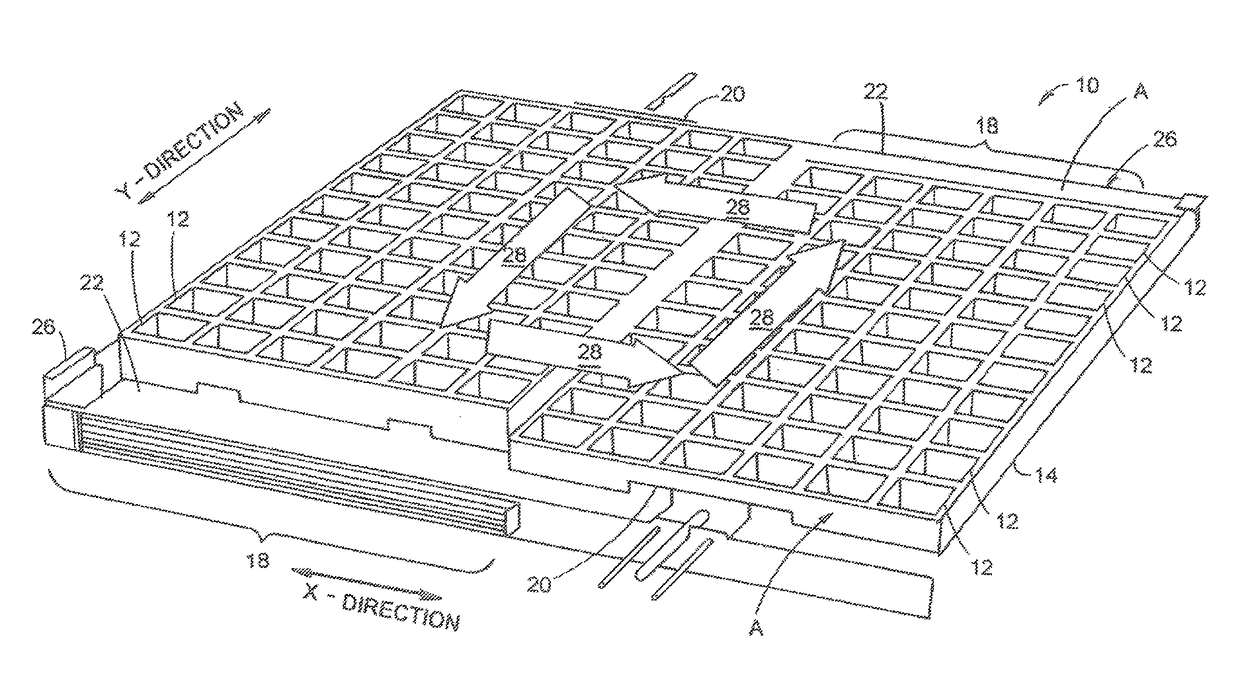

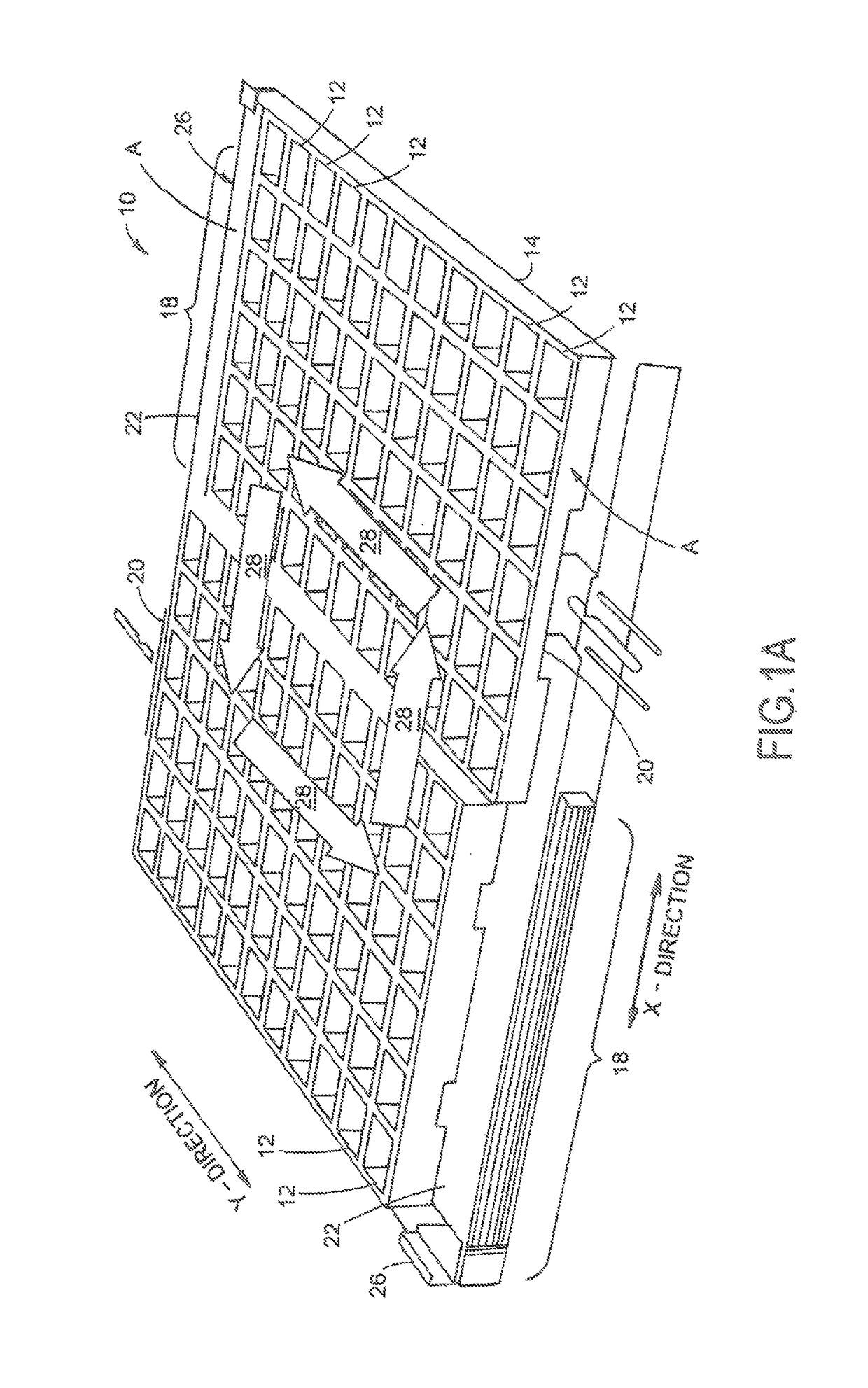

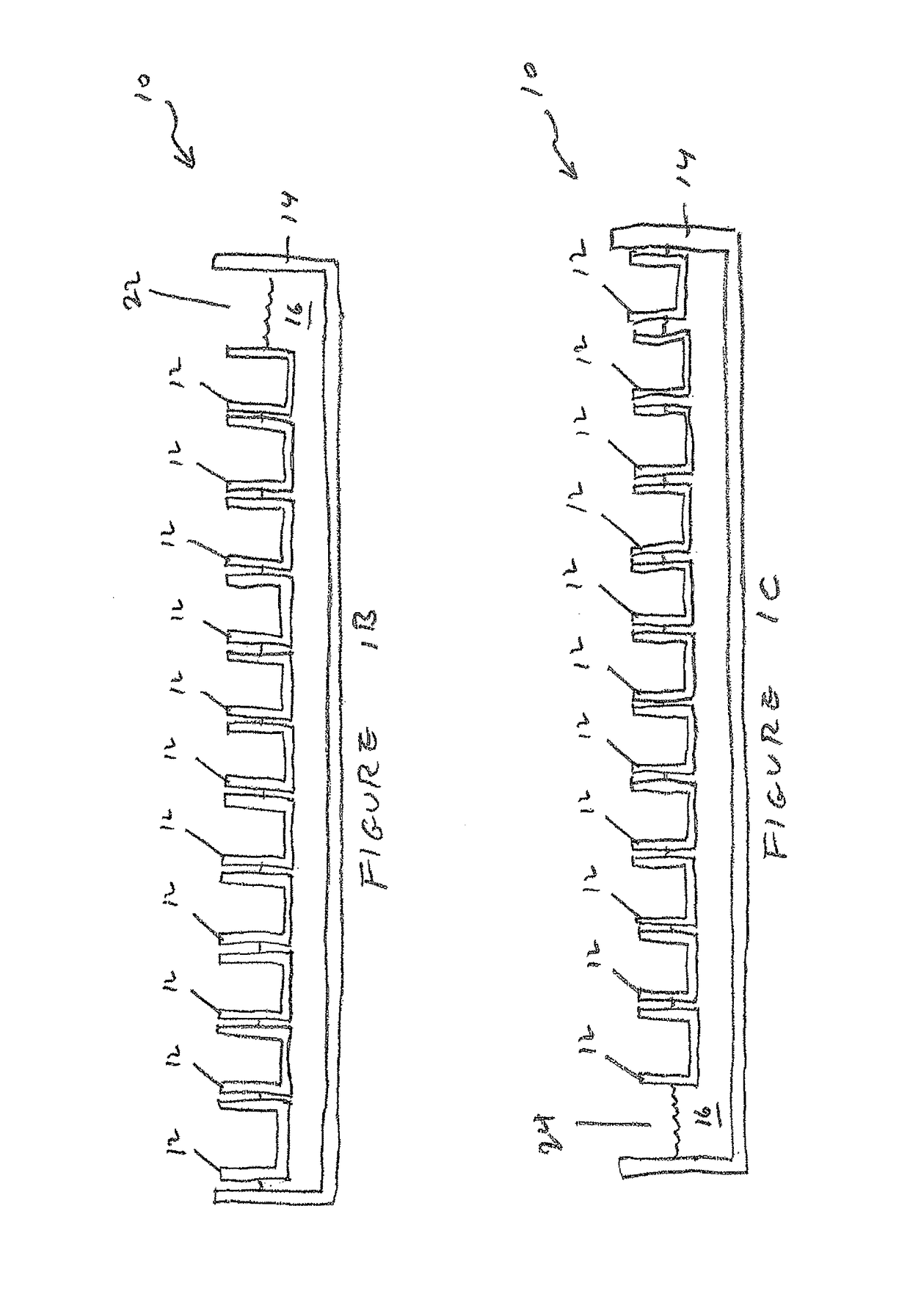

Automated hydroponic greenhouse factory

ActiveUS20150150202A1Reduce areaIncrease the areaFlower holdersPlant cultivationGreenhouseNutrient solution

Plants are grown in adjacent rows of trays that are rotated within a pool of a nutrient solution. The roots of the plants are at least partly immersed in the nutrient solution. Each row includes a gap wide enough to receive a single tray from an adjacent row. Using three rows, the plants are planted only in one of the rows, and later the rotation is used to space the planted trays one tray apart. Each tray is a parallelepipedal block with apertures for supporting respective plants. The long sides of the blocks have protrusions for preventing adhesion of the blocks. Airlift pumping circulates the nutrient solution past the roots and maintains at least 80% dissolved oxygen saturation in the nutrient solution. A screen of parallel inflatable tubes provides adjustable shade above the pool.

Owner:GROWPONICS GREENHOUSE TECH

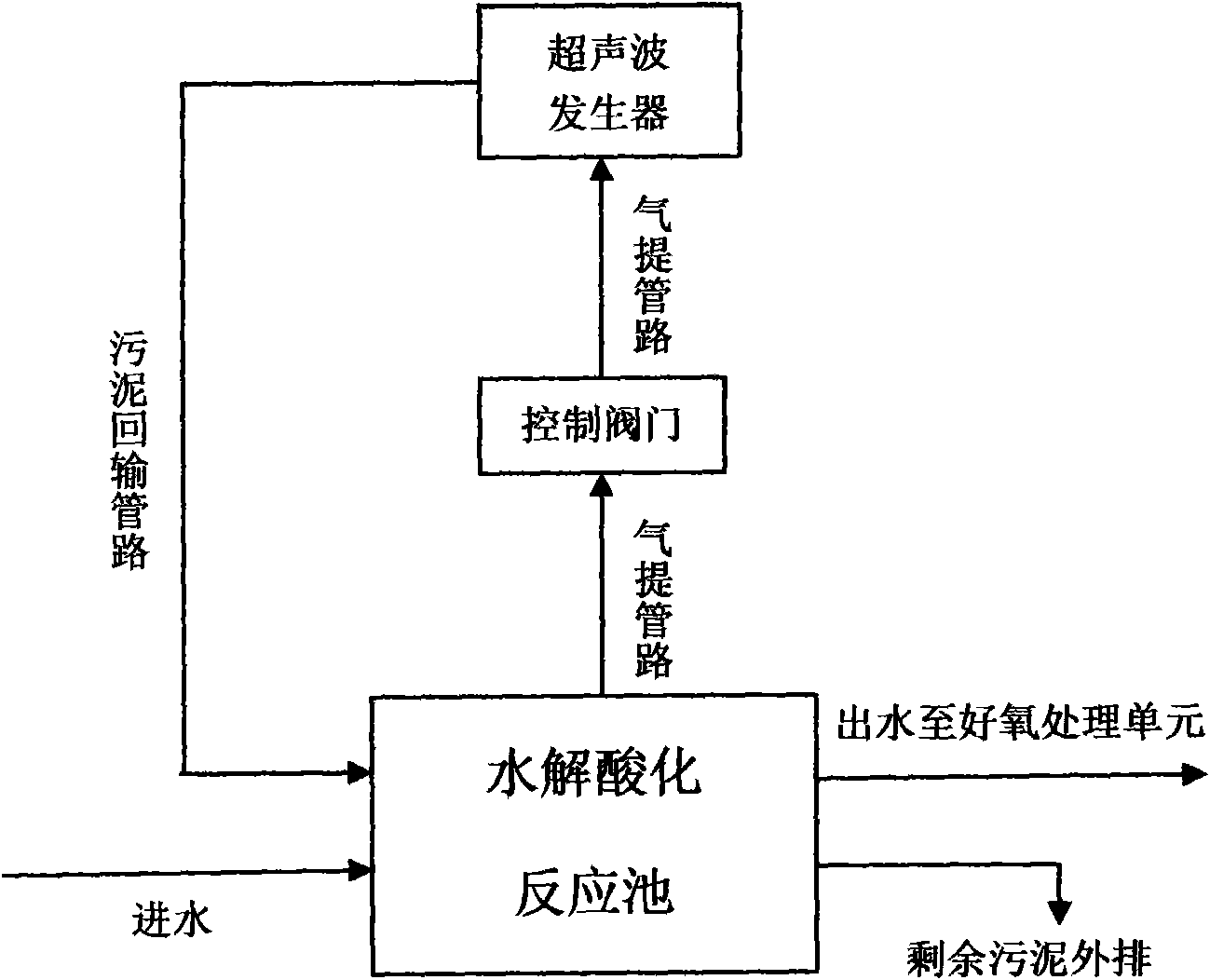

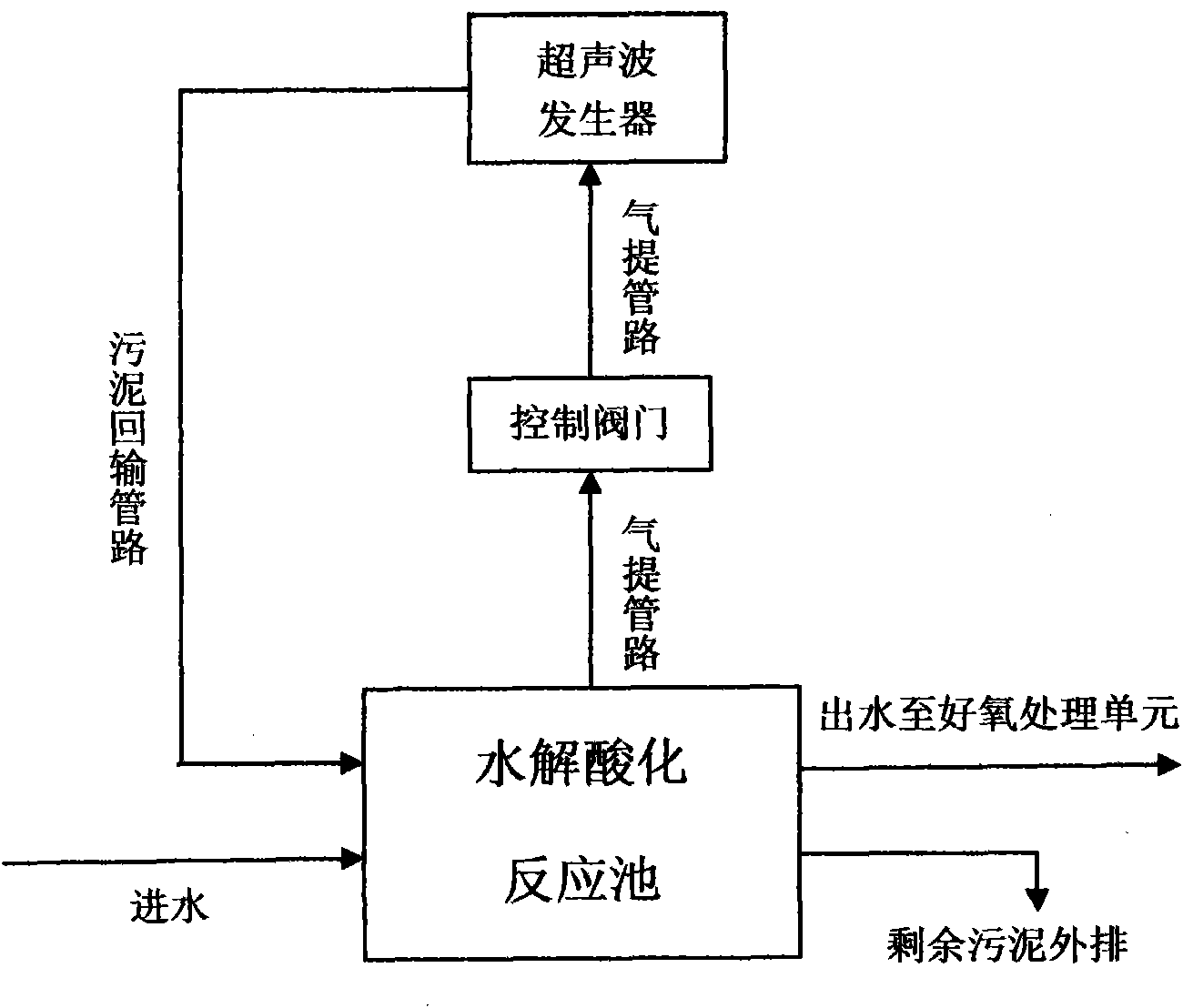

Pretreatment method of organic wastewater difficult to biochemically degrade

InactiveCN102050547AIncrease concentrationHigh activityWater/sewage treatment with mechanical oscillationsTreatment with anaerobic digestion processesActivated sludgeMicroorganism

The invention relates to a pretreatment method of organic wastewater difficult to biochemically degrade in the technical field of industrial wastewater treatment. The method comprises the following steps: organic wastewater passes through the suspended carrier which is arranged in a hydrolysis acidification reactor and activated sludge which sticks to the surface of the suspended carrier and then is discharged; the suspended carrier is transferred to an ultrasonic generator by an airlift pump, is irradiated and then flows back to the water inlet end of the hydrolysis acidification reactor; and the suspended carrier is mixed with the carrier in the hydrolysis acidification reactor to preferentially contact with the water inflow of the hydrolysis acidification reactor, and the activity of the microorganisms on the surface of the carrier is utilized to treat organic wastewater. By adopting the method, the treatment capability of the hydrolysis acidification technology can be increased, and the biodegradability of wastewater can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Automated hydroponic greenhouse factory

ActiveUS9848544B2Reduce areaIncrease the areaPlant cultivationCultivating equipmentsGreenhouseEngineering

Owner:GROWPONICS GREENHOUSE TECH

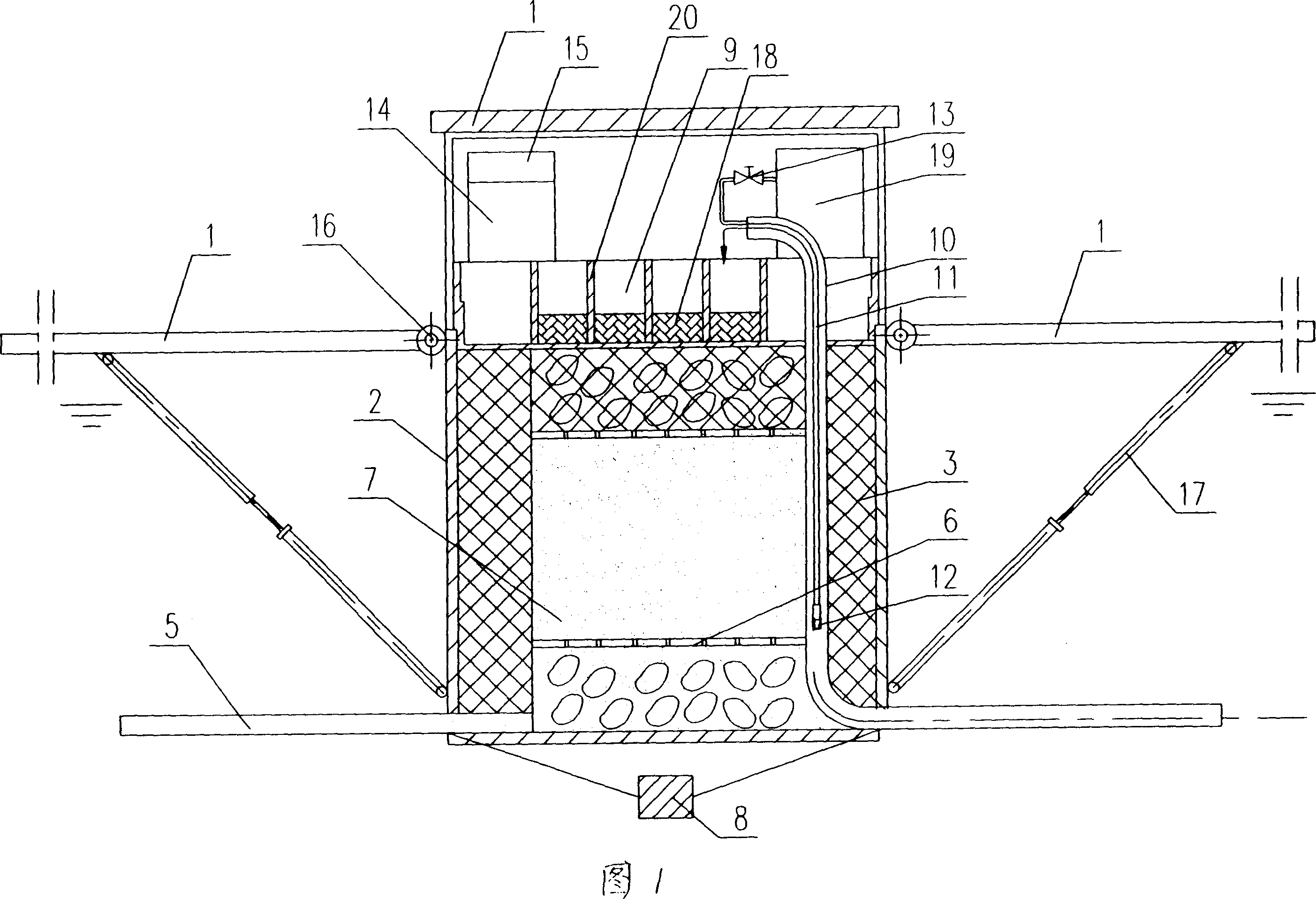

Solar energy light ¿C volt Nano water purification floating island

InactiveCN101050018AAvoid wastingSimple structureTreatment using aerobic processesPhotovoltaicsAir pumpWastewater

This invention discloses a solar photovoltaic nanoscale water purification island used in field waters. The island is composed of: a filler barrel, a water distribution disc, an airlift pump and a solar photovoltaic air pump. A hard pipe and a water outlet pipe are set at the bottom of the filler barrel. The filler barrel is surrounded by foam plastic floating bodies. At least two layers of mesh plates are set in the filler barrel, between which are filled with various nanoscale water purification biomaterials. A through hole is formed at the bottom of the water distribution disc. Through connected grooves are formed on the water distribution disc by trough plates. Filtering sponge is set in the grooves. The water distribution disc covers the filler barrel. An air transmission pipe is set in the hard pipe. One end of the air transmission pipe is connected with an aeration pump, while the other end is connected with an air exhaust stone. The water distribution disc extends from the upper end of the hard pipe. Two solar photovoltaic electric plates are connected with the filler barrel respectively. The output lines of the solar photovoltaic electric plates are connected with the storage battery and the aeration pump, respectively, via the control circuit of the charge / discharge controller. The island is suitable for field fishponds, wastewater treatment plants, pollution remediation waters and landscape green areas.

Owner:上海金樱生态农业科技有限公司

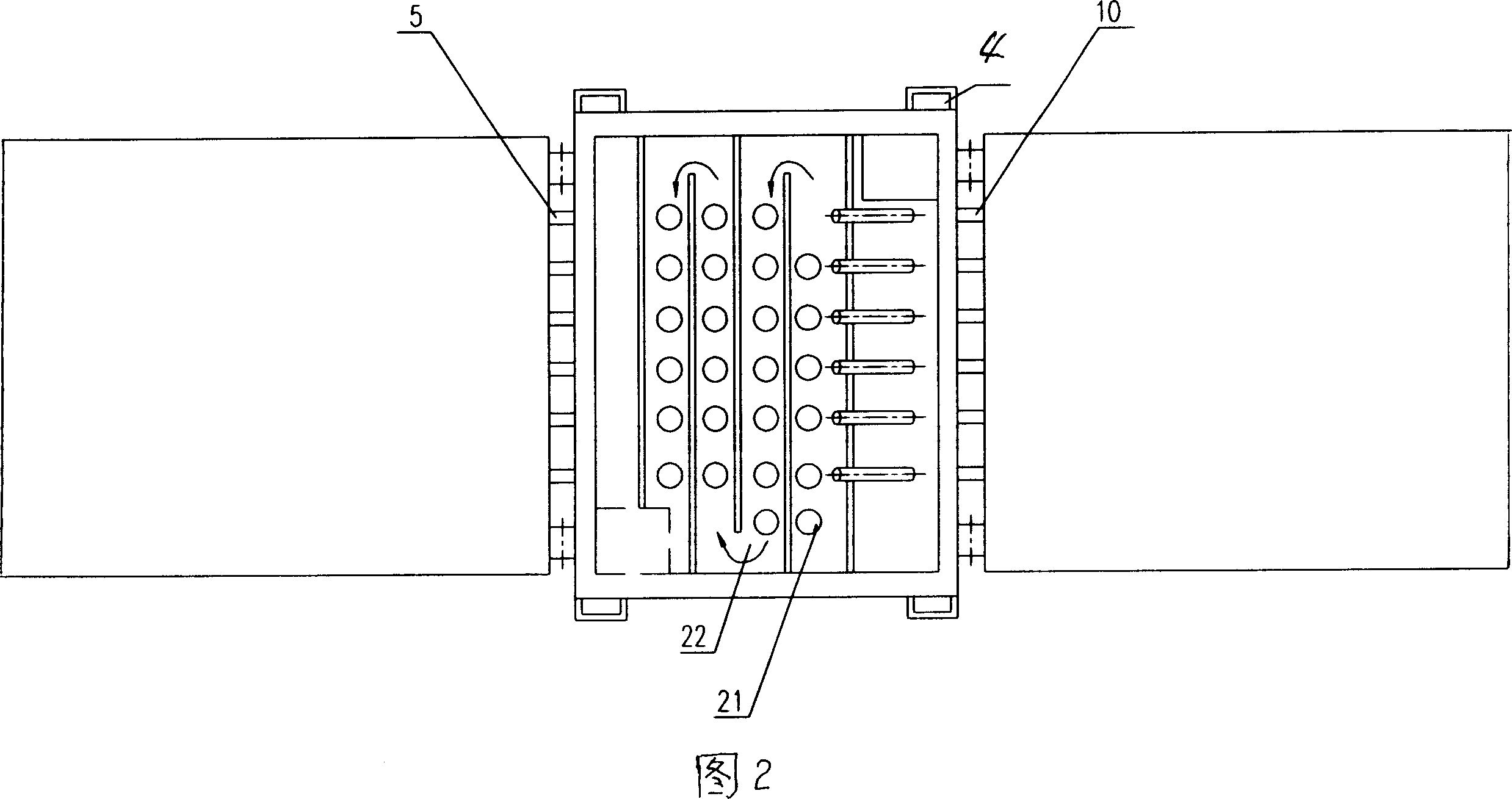

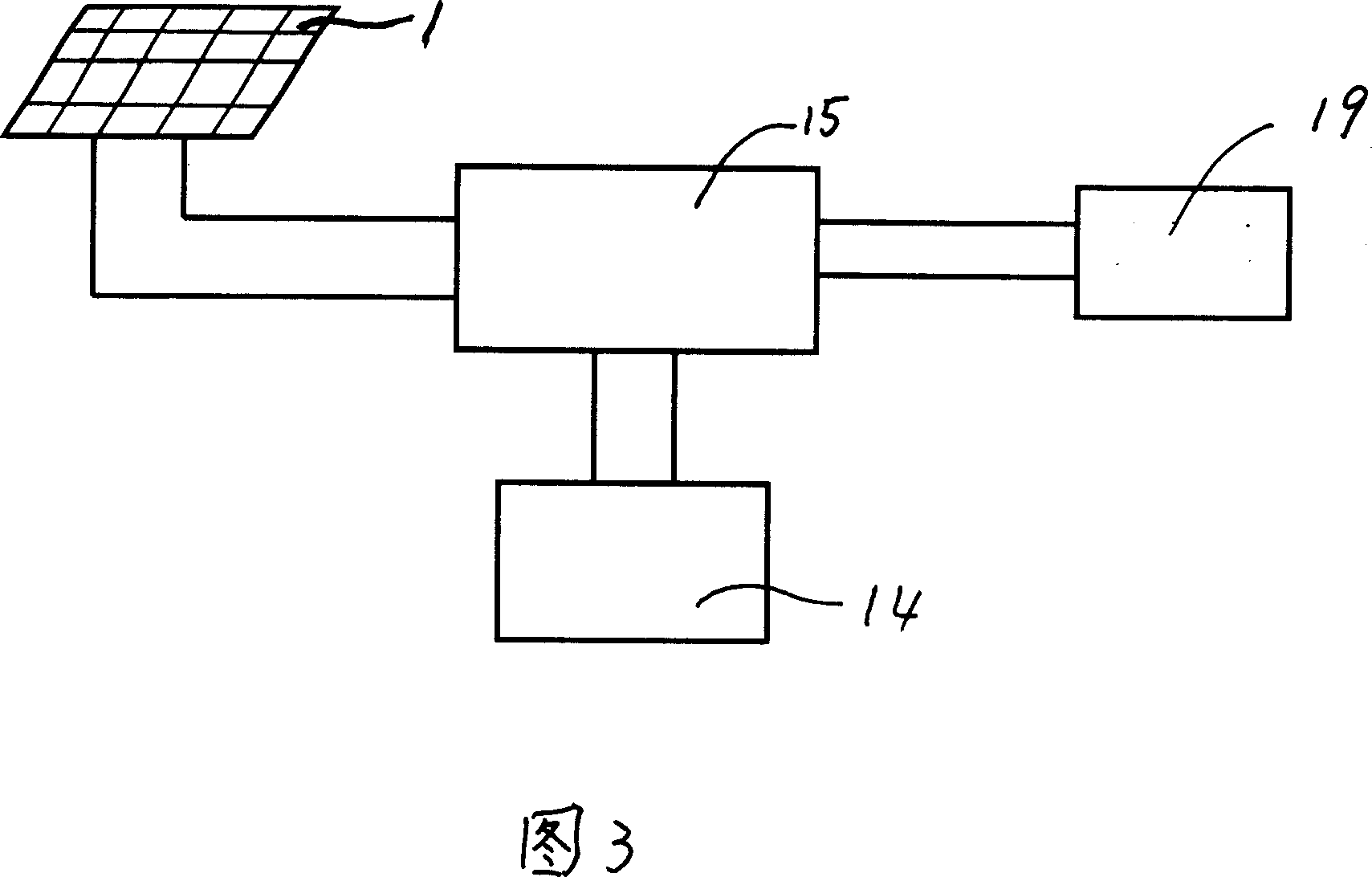

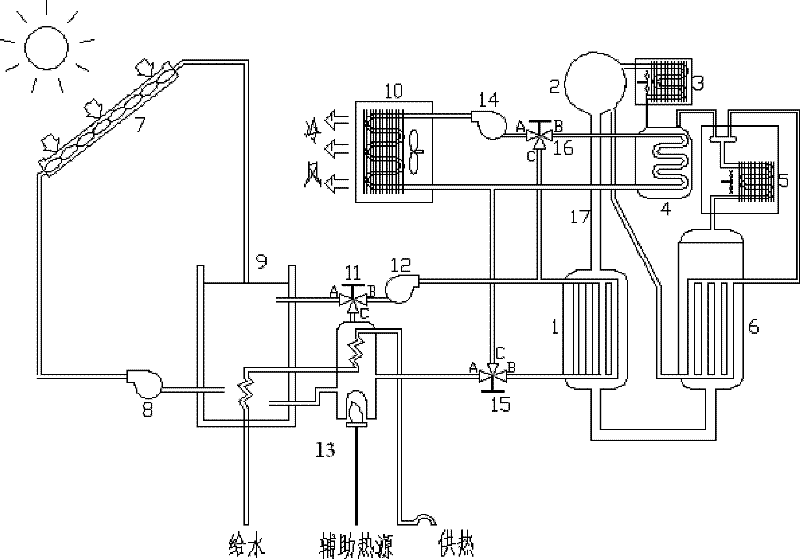

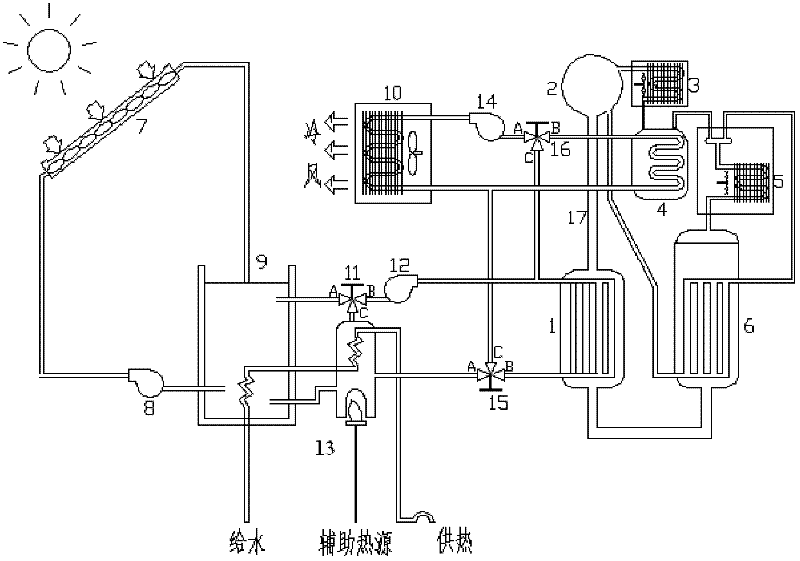

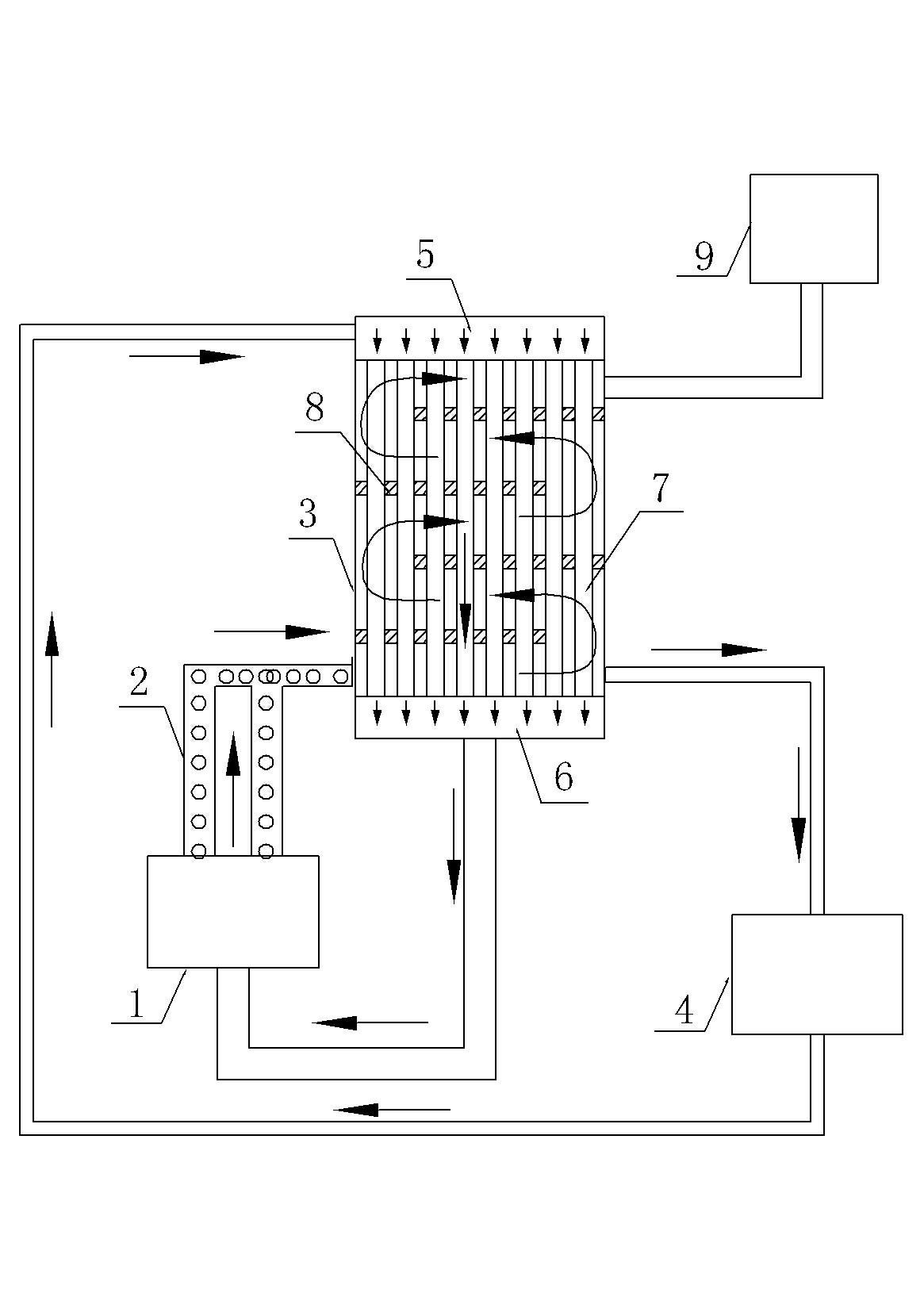

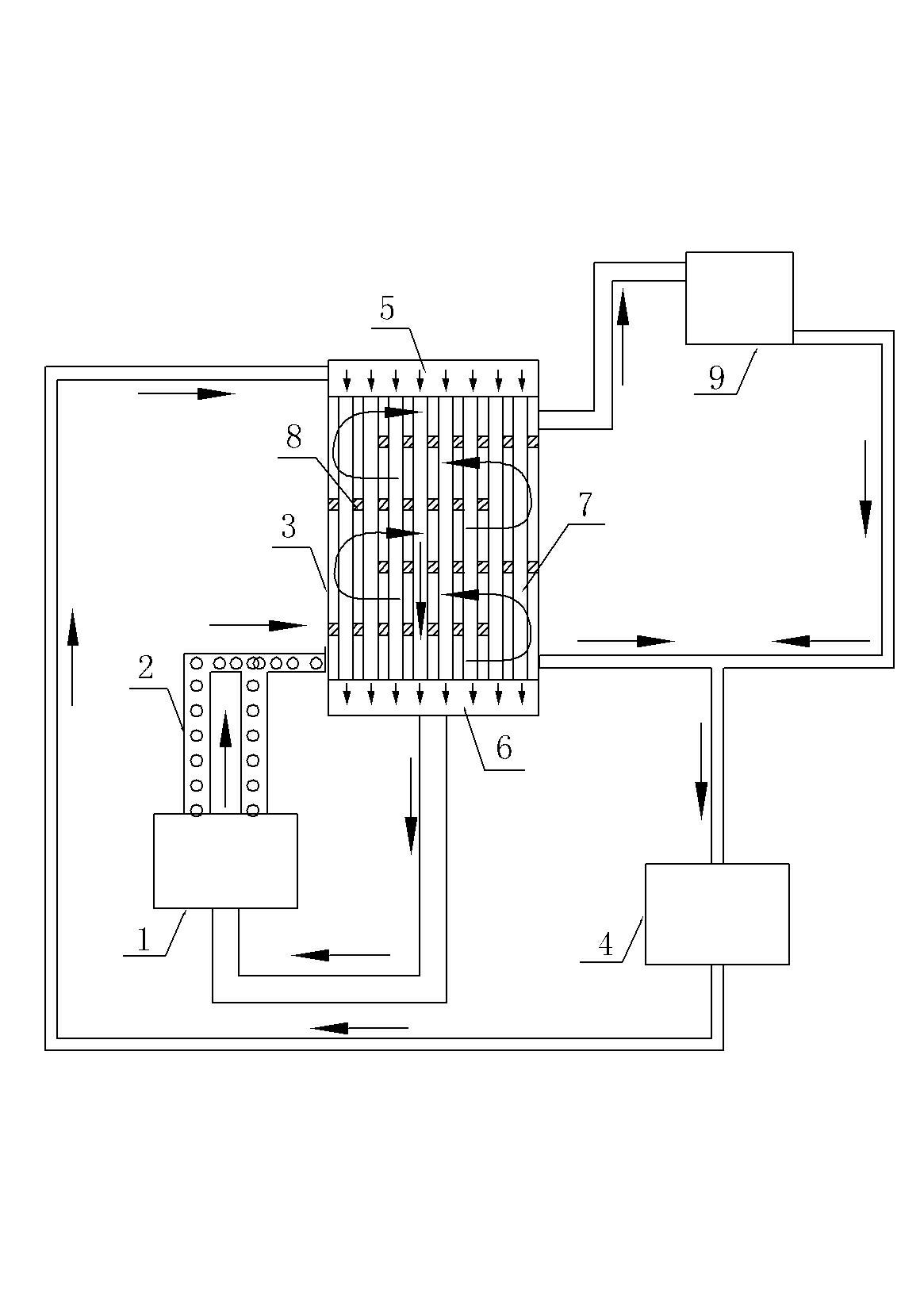

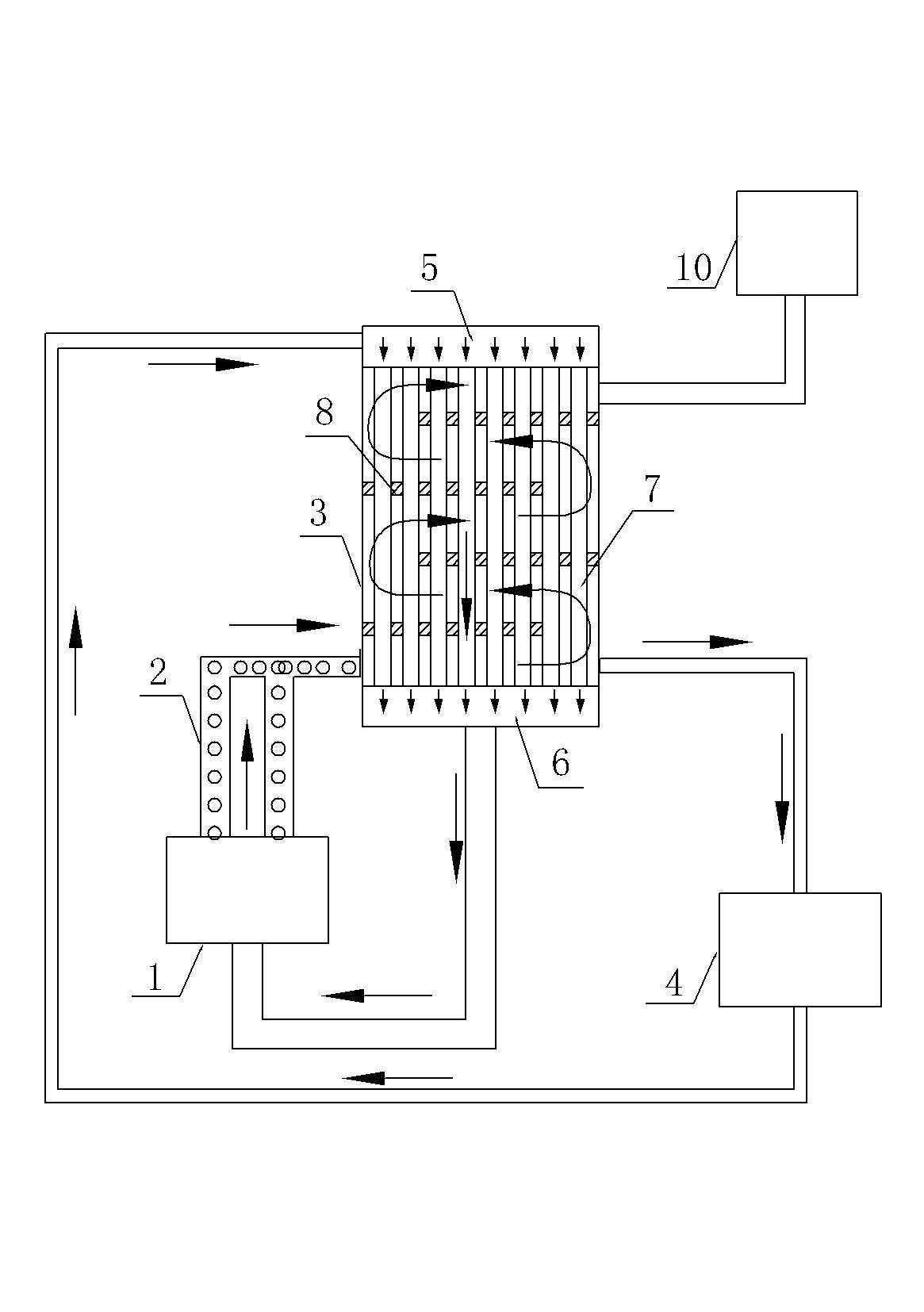

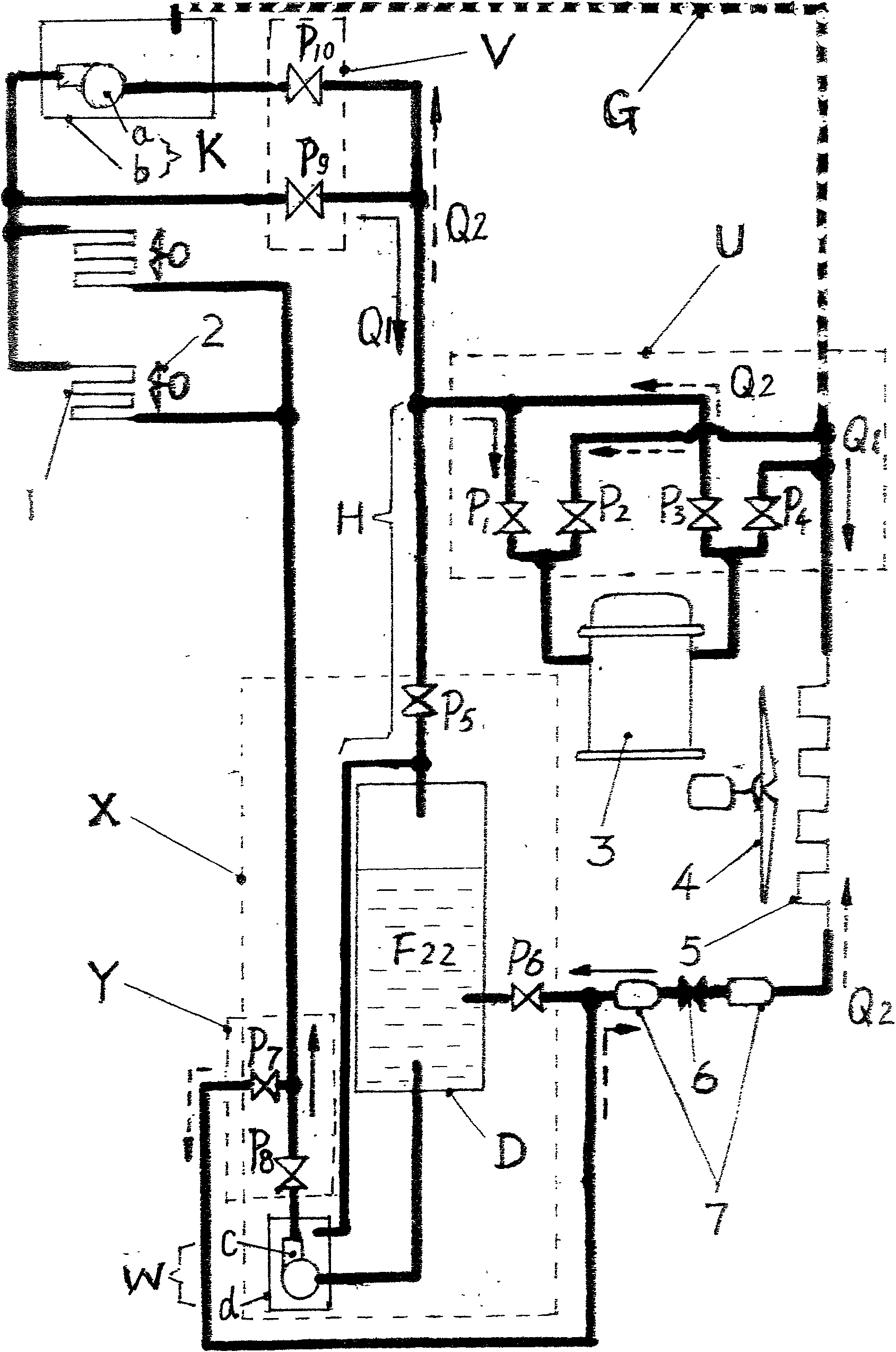

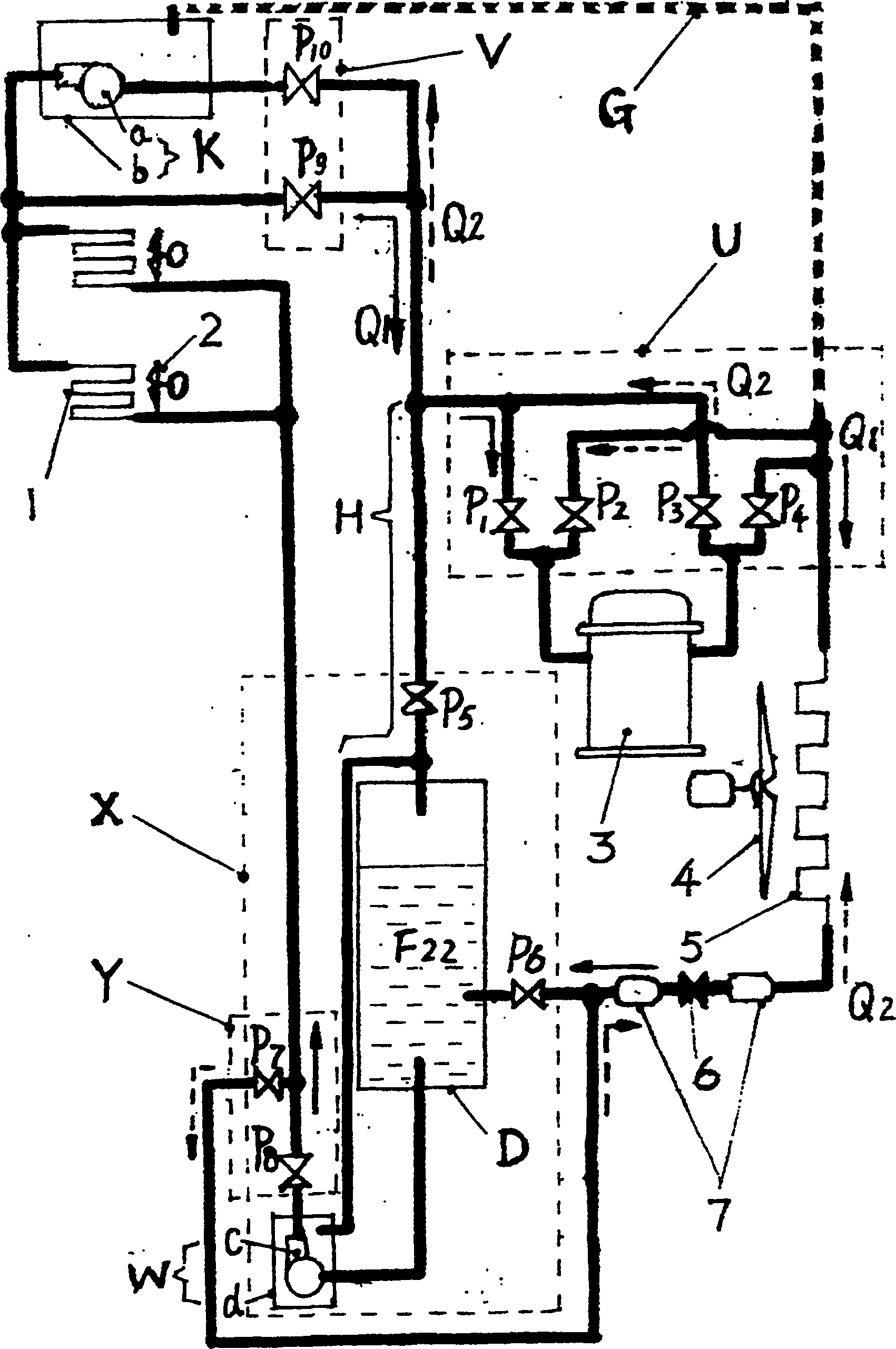

Domestic solar airlift pump absorption type air conditioning system

InactiveCN102538289AReduce noiseReduce power consumptionClimate change adaptationEnergy efficient heating/coolingEngineeringForced-air

The invention discloses a domestic solar airlift pump absorption type air conditioning system, which comprises a hot water system, an absorption type refrigerating unit, an air-conditioner indoor unit and a water and heat supply pipeline. The hot water system comprises a solar thermal collector and a first water pump, and the absorption type refrigerating unit comprises a generator, an airlift pump, a separator, a condenser, an evaporator and an absorber. The separator is highest in the absorption type refrigerating unit, the condenser, the evaporator, the absorber and the generator are sequentially lowered in position, the generator is connected with the separator via the airlift pump, and fluid in the parts is driven to flow by the aid of altitude difference and density difference. The absorption type refrigerating unit of the air conditioning system uses no mechanical pump, so that noise can be effectively reduced, power consumption is reduced, and cost is saved. Further, the condenser and the absorber both use a forced air cooling way instead of a cooling water system, application range can be widened, the system can be simplified, and miniaturization and domestication are facilitated.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

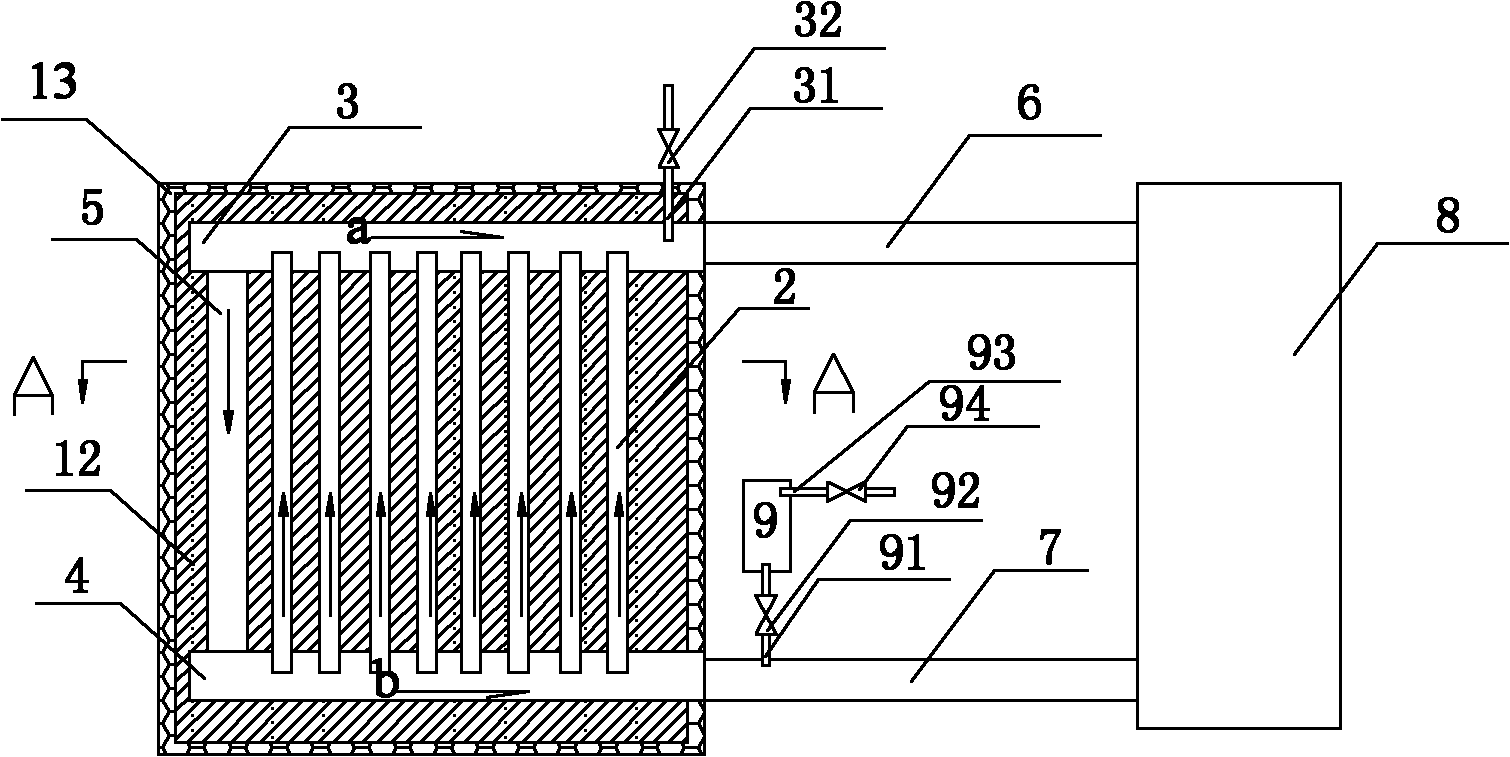

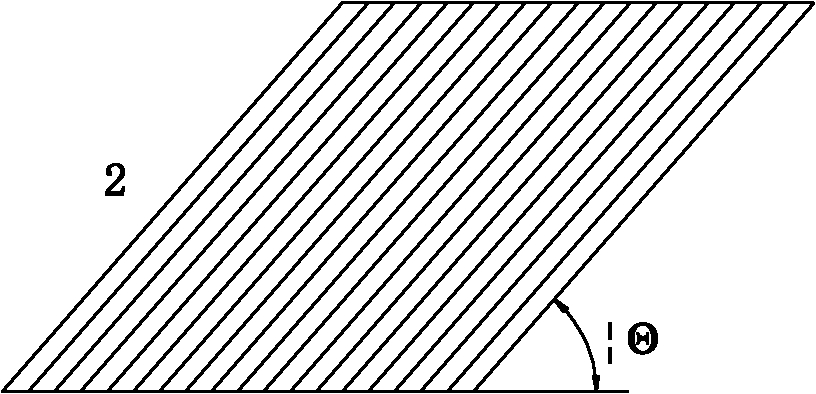

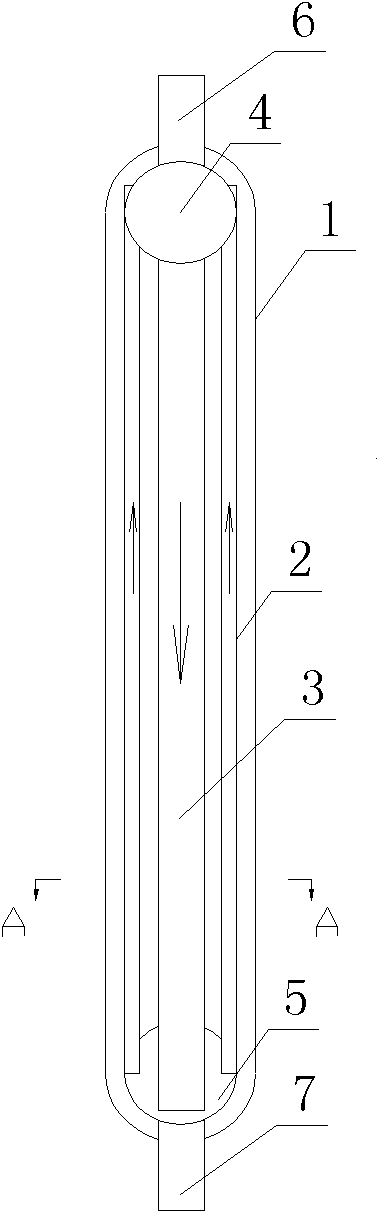

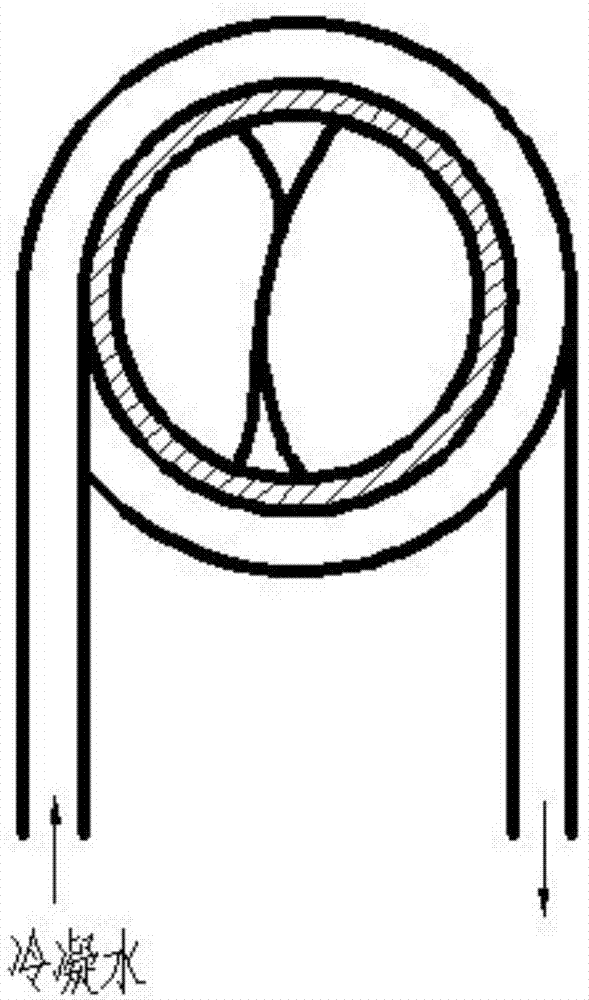

Solar flat plate collector capable of exchanging heat through micro-channel

InactiveCN102087053AReduce weightReduce areaSolar heating energySolar heat devicesHeat transfer efficiencyEngineering

The invention discloses a solar flat plate collector capable of exchanging heat through a micro-channel, which comprises a transparent cover plate, a heat-absorbing plate, a thermal-protective coating, a frame, an air collecting pipe, a liquid collecting pipe, a liquid-return pipe, and a plurality of parallel micro-channel pipes forming a detachable type circulating pipe together with an external condensation section, wherein the air collecting pipe is higher than the liquid collecting pipe; a circulating fluid which has gas-liquid phase change within a heat-collecting temperature scope is filled in the detachable type circulating pipe; the volume of the filled circulating fluid is 10%-90% of the volume of the detachable type circulating pipe; and a stable airlift pump effect is formed in the micro-channel by the circulating fluid. By utilizing the high heat-transfer efficiency of micro-channel and the specific airlift pump effect, the heat-transfer efficiency of the solar flat plate collector is increased, the weight of a heat absorber in the traditional solar flat plate collector is reduced, and the range of application temperature and the scope of application occasion of the solar flat plate collector are widened.

Owner:ZHEJIANG UNIV

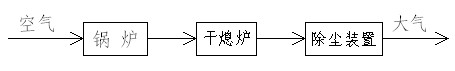

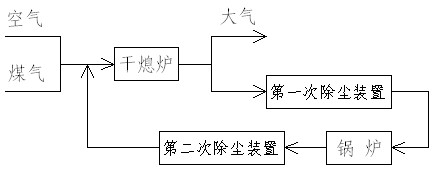

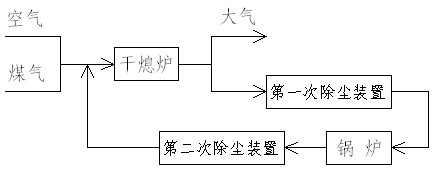

Oven-drying working process for coke dry quenching system

The invention discloses an oven-drying working process for a coke dry quenching system. The process comprises the following steps: step 1, drying a dry quenching oven with warm wind; step 2, drying the dry quenching oven with coal gas after the step 1 is finished; and step 3, after the step 2 is finished, putting red-hot coke in the dry quenching oven so that a refractory material is heated to 950-1050 DEG C at the speed of less than or equal to 30 DEG C / h, thereby completing the oven-drying operation. According to the oven-drying working process for the coke dry quenching system, in the warmwind drying process, the temperature of a boiler collecting box is in conformity with the temperature of a steam pocket, thus the gap generated due to the tremble of the boiler when an airlift pump works is avoided so that boiler steam can not be intermixed with dry air, thereby correctly and timely judging the drying condition of the dry quenching oven; and in the coal gas drying stage, the refractory material is heated according to a heating crystal form conversion curve through reasonably controlling the coal gas-air proportion and heating speed, thereby avoiding the conditions that mixed coal gas extinguishes, the refractory material is broken or damaged, and the like. Thus, by the process disclosed by the invention, the service life of the dry quenching oven refractory material can be prolonged, the safe work of a boiler system can be ensured and the service life of the boiler system is prolonged, and oven-drying working time can be shortened at the same time.

Owner:CHONGQING IRON & STEEL CO LTD

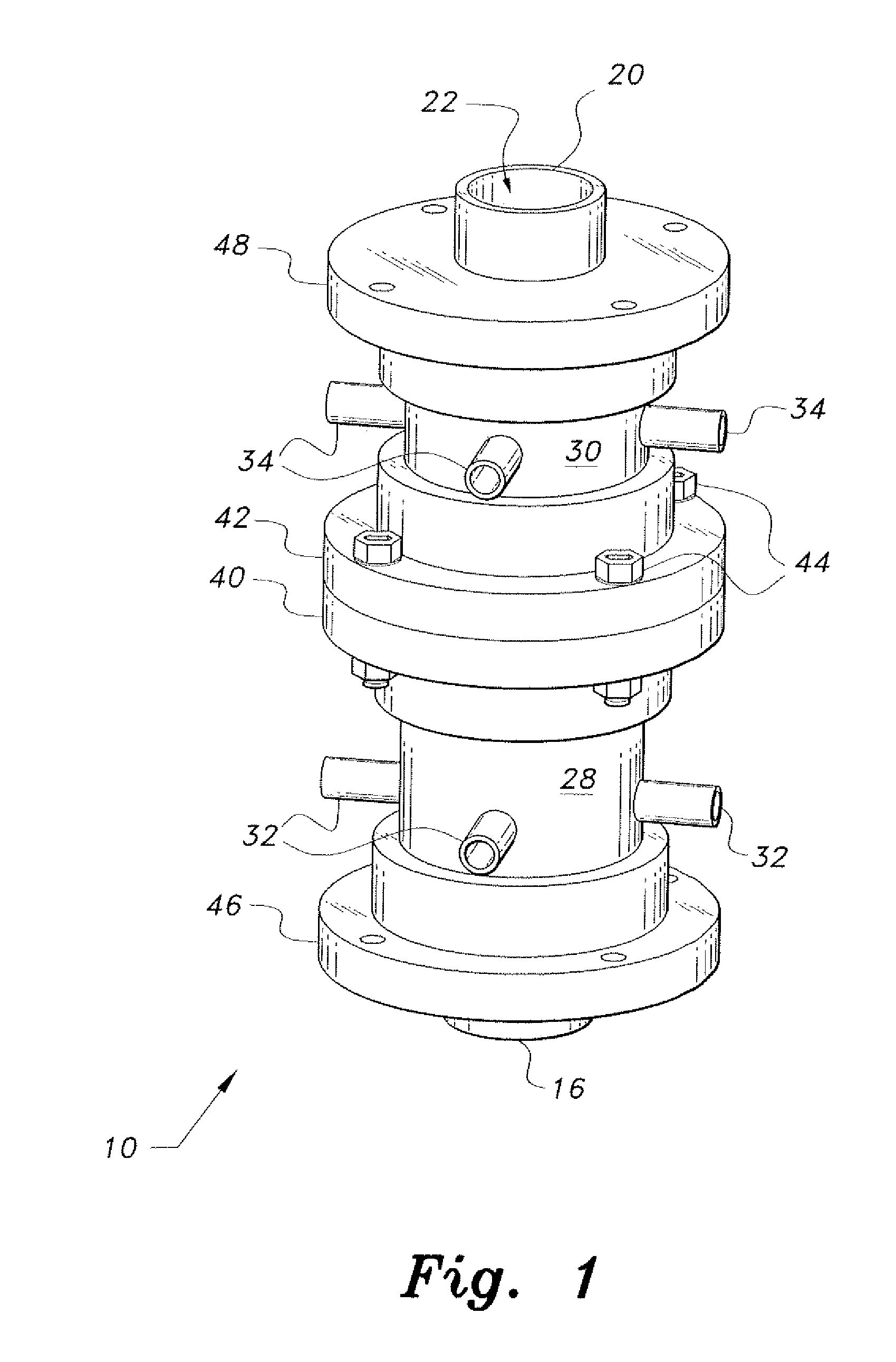

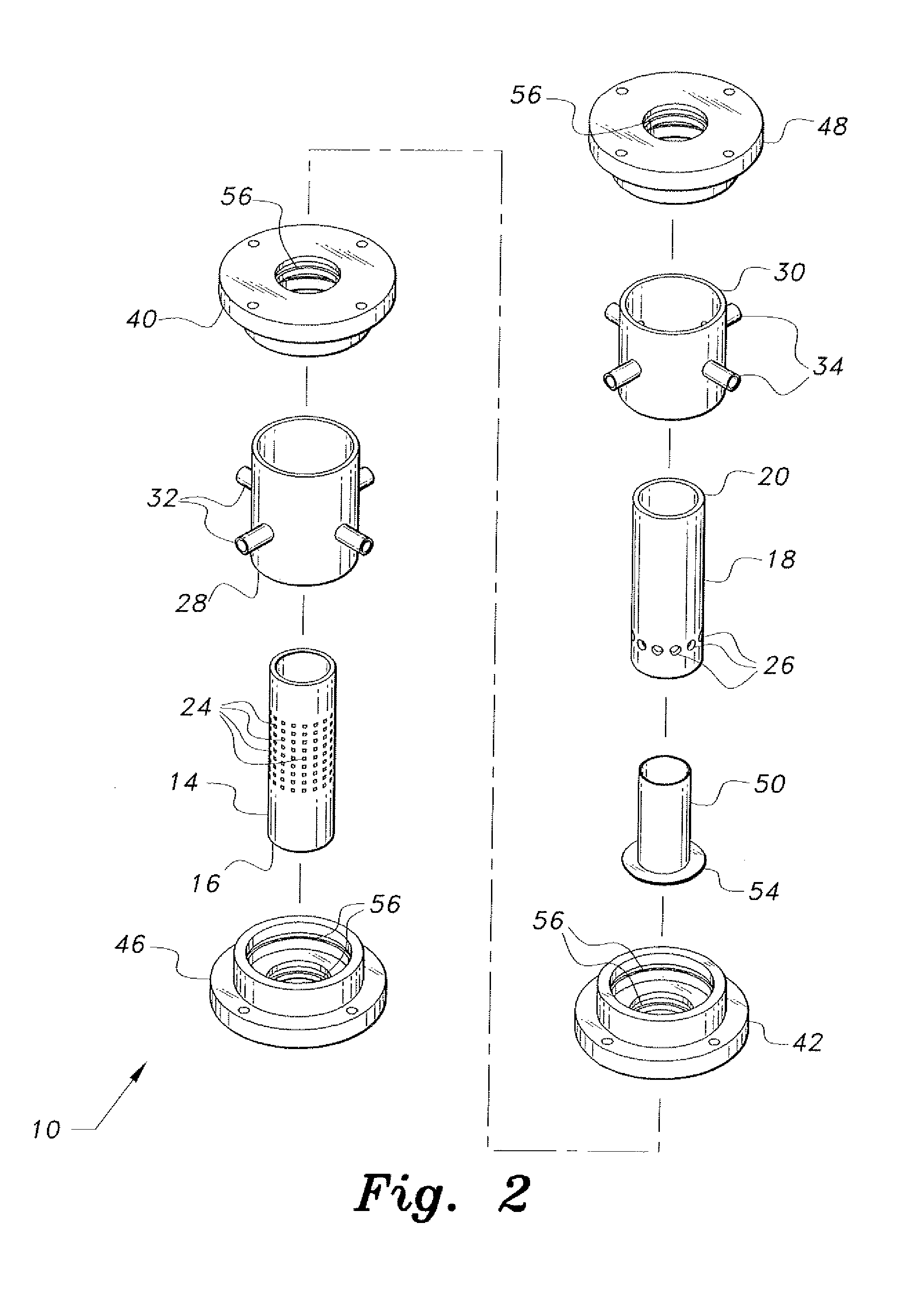

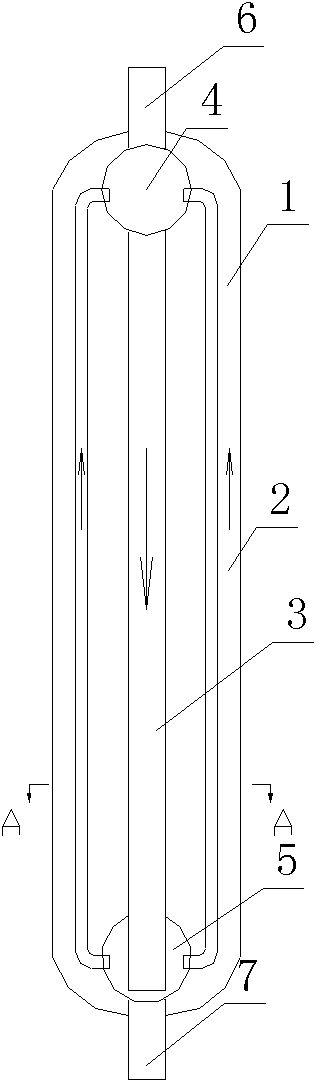

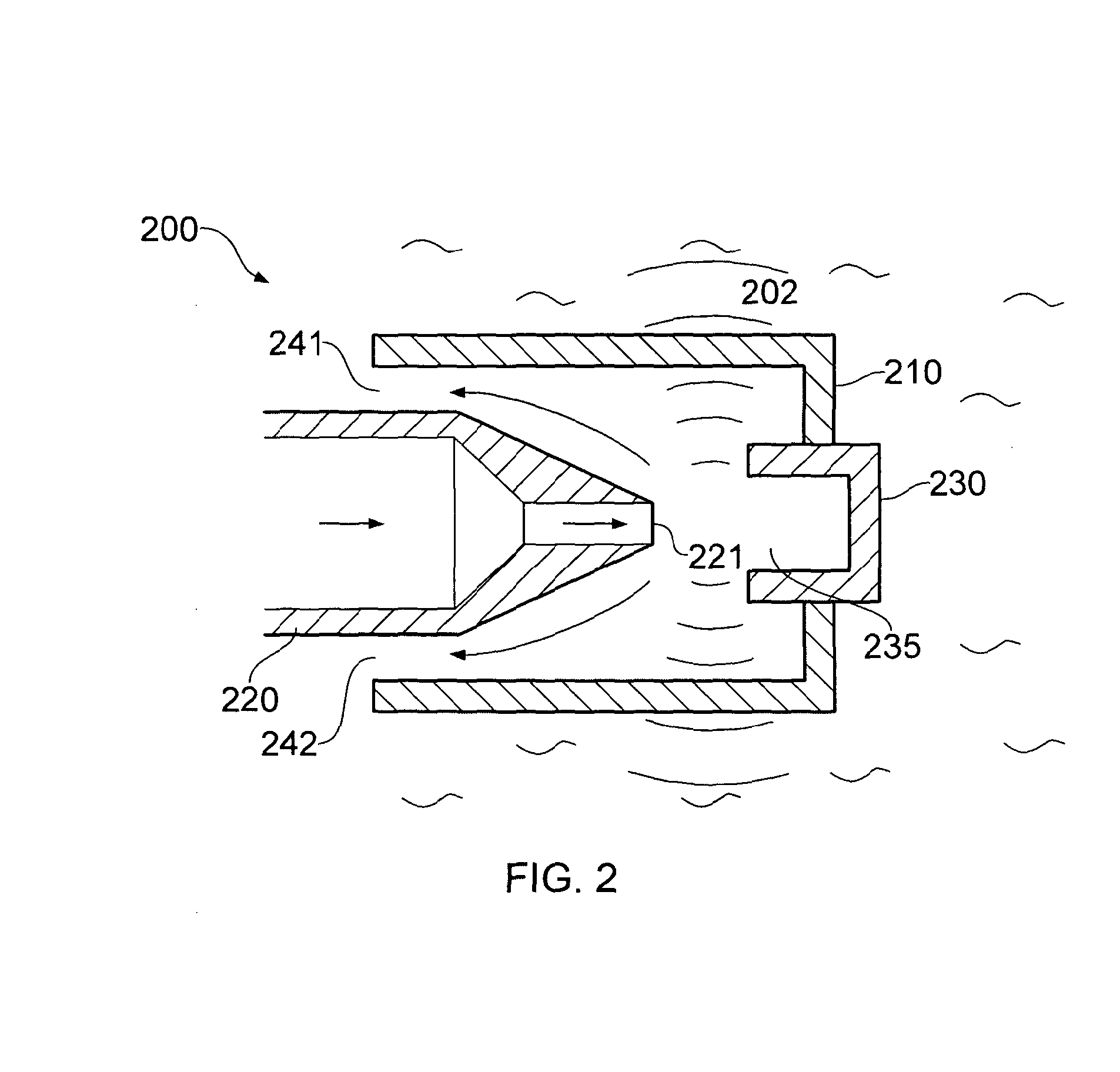

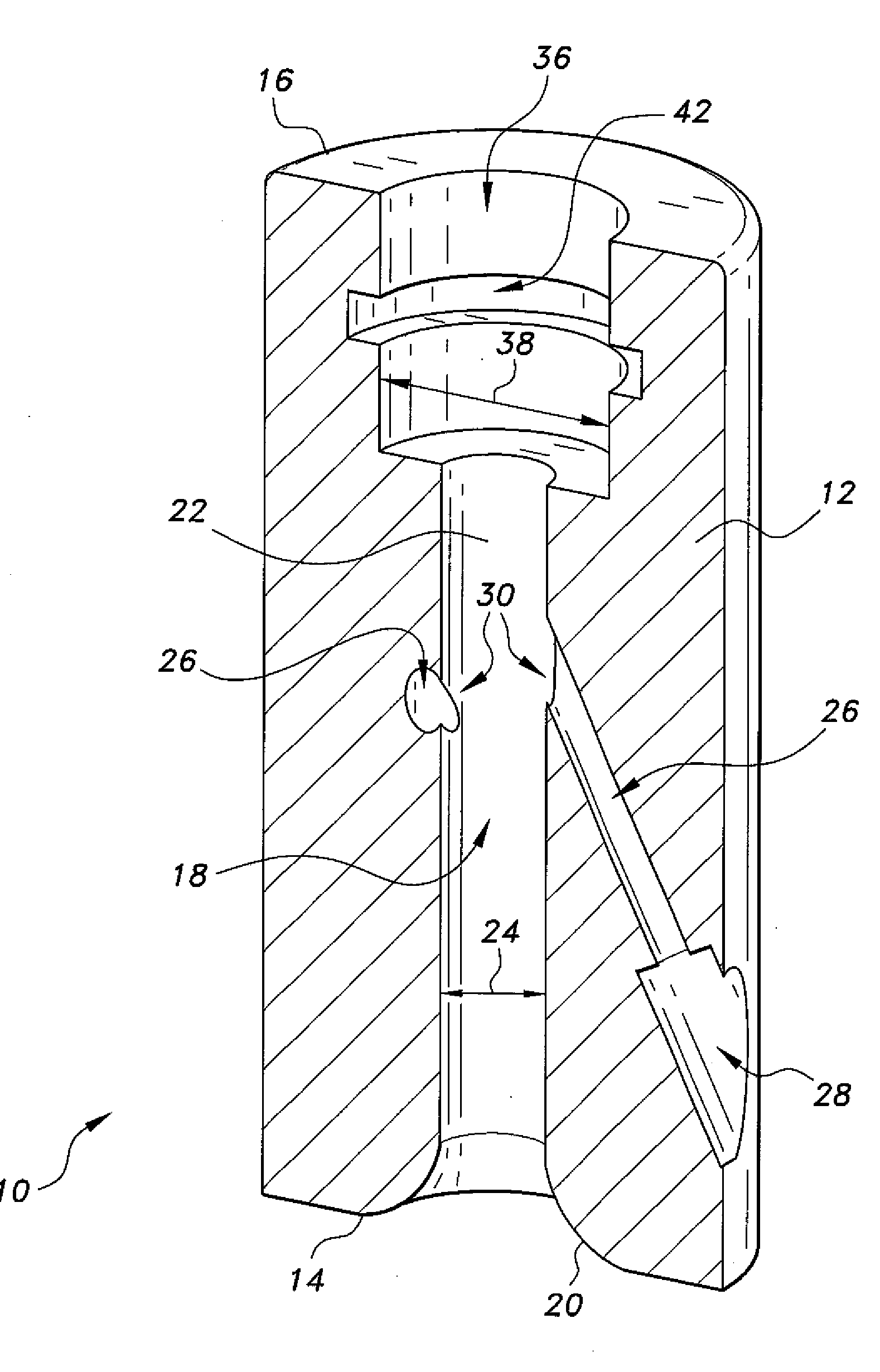

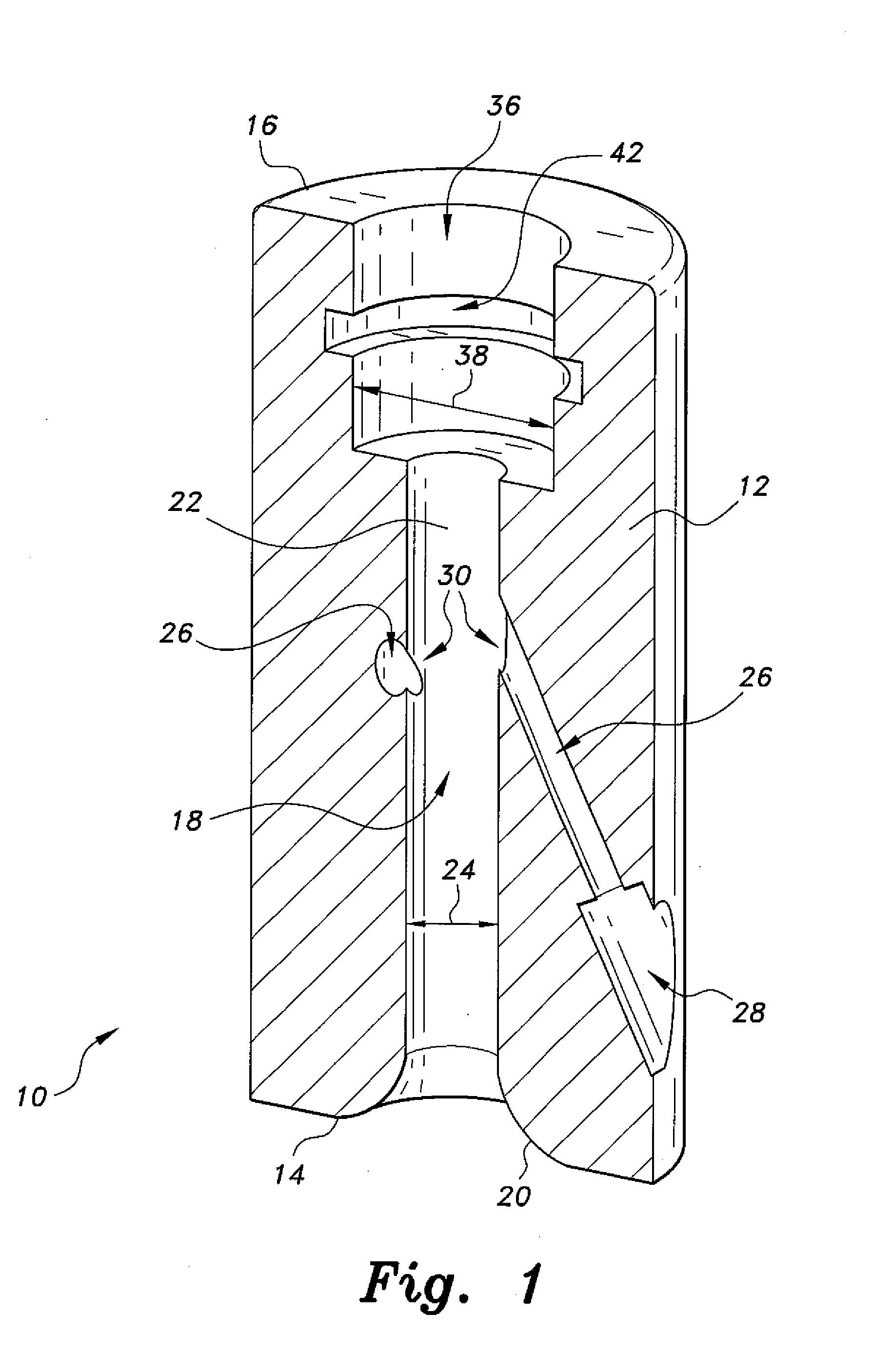

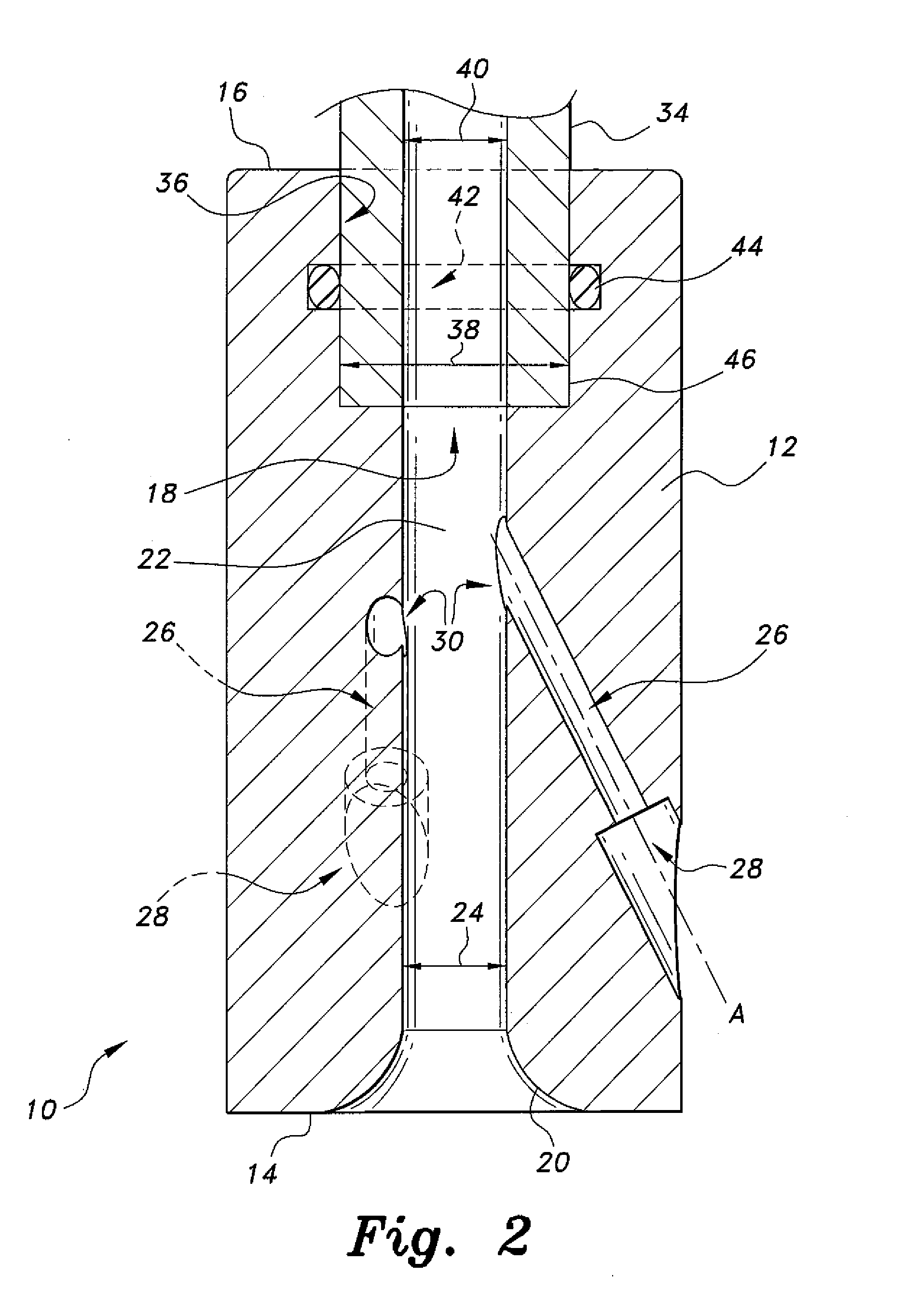

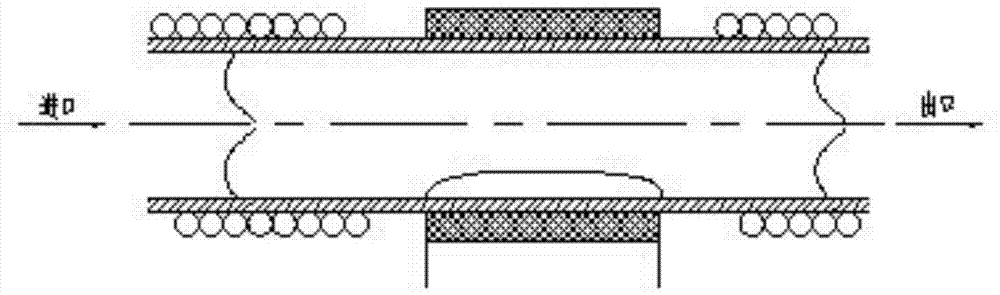

Dual injection airlift pump

InactiveUS20120308407A1Reducing hydrodynamic frictionImprove efficiencyPressure pumpsMachines/enginesDual injectionInjection air

The dual injection airlift pump has a hollow tubular body through which the liquid being pumped passes upward from the lower intake end to the upper outlet end. Air or other gas is injected into the liquid in the pump body, the less dense gas adding buoyancy to the liquid and entraining the liquid to rise toward the outlet end. The dual injection airlift pump includes two air injection stages, with the first or lower stage having a perforated interior sleeve allowing the gas to pass therethrough to be injected radially into the liquid. The second, upper stage has an impervious sleeve defining a gap between the sleeve and the interior surface of the pump wall, the lower end being sealed and the upper end open. Air is injected between the sleeve and pump wall, the air exiting at the upper or downstream end in an axially peripheral flow pattern.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Low-temperature hot-water warming system

ActiveCN102679441ASolve condensationSave electricityLighting and heating apparatusCentral heating systemEngineeringThermal water

The invention relates to a low-temperature hot-water warming system. Two heat exchange tube fixing plates are arranged in a cavity of a steam heat exchanger; the inner chamber of the cavity is divided into an upper chamber, a lower chamber and a middle chamber by the two heat exchange tube fixing plates; heat exchange tubes are arranged in the middle chamber of the cavity; two ends of each of the heat exchange tubes are respectively fixed on the two heat exchange tube fixing plates and are respectively communicated with the upper chamber and the lower chamber; a steam inlet communicated with the middle chamber is arranged on the cavity; a generator is communicated with the steam inlet through an airlift pump; a steam outlet communicated with the upper part of the middle chamber is arranged on the cavity; a storage with a steam chamber is communicated with the steam outlet; a lower edge of the steam chamber of the storage is higher than an upper edge of the upper chamber; a hot water outlet communicated with the middle chamber is arranged on the cavity; the hot water outlet is communicated with an inlet of a first heat exchanger; an outlet of the first heat exchanger is communicated with a water inlet which is communicated with the upper chamber on the cavity; a collected water outlet communicated with the lower chamber is arranged on the cavity; and the collected water outlet is connected with the inlet of the generator.

Owner:HEIMDALLR SHANGHAI ENERGY SAVING TECH

Solar evacuated tube collector for heat exchange in micro-channel

InactiveCN102102910ASpeed up heat transferNot easy to freezeSolar heating energySolar heat devicesHeat transfer efficiencyEngineering

The invention discloses a solar evacuated tube collector for heat exchange in a micro-channel. The micro-channel comprises a glass tube, a micro-channel tube bundle, a liquid return tube, a gas collecting cavity, a liquid collecting cavity, a gas guide tube and a liquid guide tube which form a separating type circulating tube together with an external condensation section, wherein a circulating working medium capable of generating gas-liquid phase change within the heat-collecting temperature area range is filled into the separating type circulating tube, and the filling amount of the circulating working medium is 10 to 90 percent of the inner volume of the separating type circulating tube, so that the circulating working medium has a stable airlift pump effect in the micro-channel. In the solar evacuated tube collector, by utilizing the high heat transfer efficiency and unique airlift pump effect of the micro-channel, the heat transfer efficiency of a solar collector is improved, the weight of a heat absorption body in the conventional evacuated tube solar collector is reduced, and the heat-collecting temperature is improved, so the expansion of the application temperature area range and the application occasion range of the evacuated tube solar collector is facilitated.

Owner:ZHEJIANG SCI-TECH UNIV

Super high-rise building air conditioner system for conveying energy by liquid pump or air pump instead of water pump

InactiveCN102654332ASolve the "powerless" problemFluid circulation arrangementAir conditioning systemsLiquid stateAir pump

The invention discloses a super high-rise building (such as tens of floors even hundreds of floors) air conditioner system for conveying energy by a liquid pump or an air pump instead of a water pump. A liquid refrigerant pressurized distribution device and a B-class gaseous refrigerant pressurized distribution device are added in the air conditioner system of a building; when a refrigeration air conditioner is required, the liquid refrigerant pressurized distribution device is started; when a heating air conditioner is required, the B-class gaseous refrigerant pressurized distribution device is started; the purpose of the super high-rise building air conditioner system is to perfect the CN100473913C patent technology which is favorable for saving energy and avoids the troubles that scales are likely to form and are difficult to remove; and finally, the purpose of 'conveying energy by a liquid pump or an air pump instead of a water pump' in the title is realized, i.e. air entering the room can be directly subjected to refrigeration or heating air conditioner by the liquid refrigerant or the gaseous refrigerant in the evaporator or the condenser in the air conditioner system. The implementation cost of the two refrigerant pressurized distribution devices is almost equivalent to the cost of omitted facilities related to the above water medium.

Owner:深圳市雅尔典科技有限公司

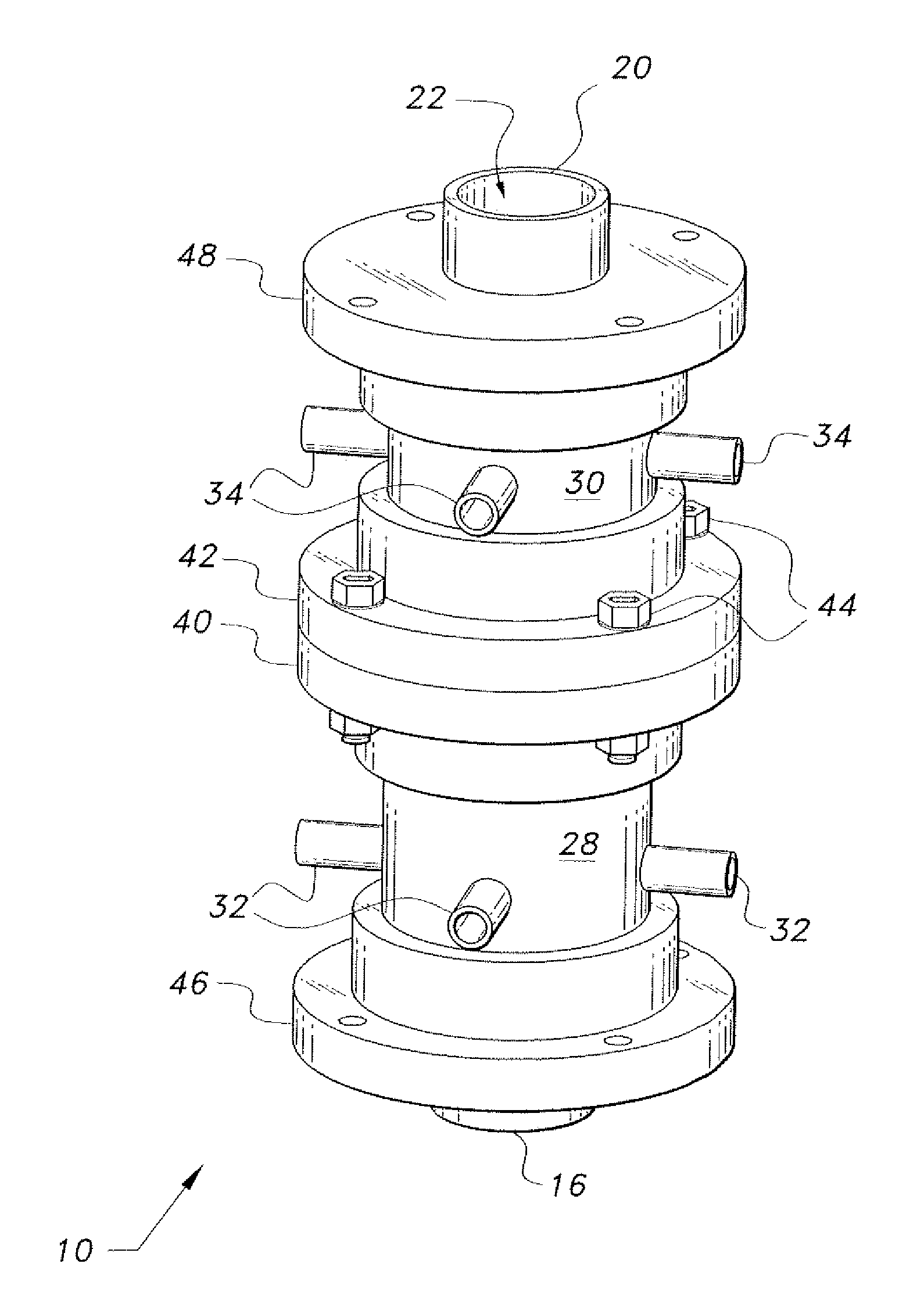

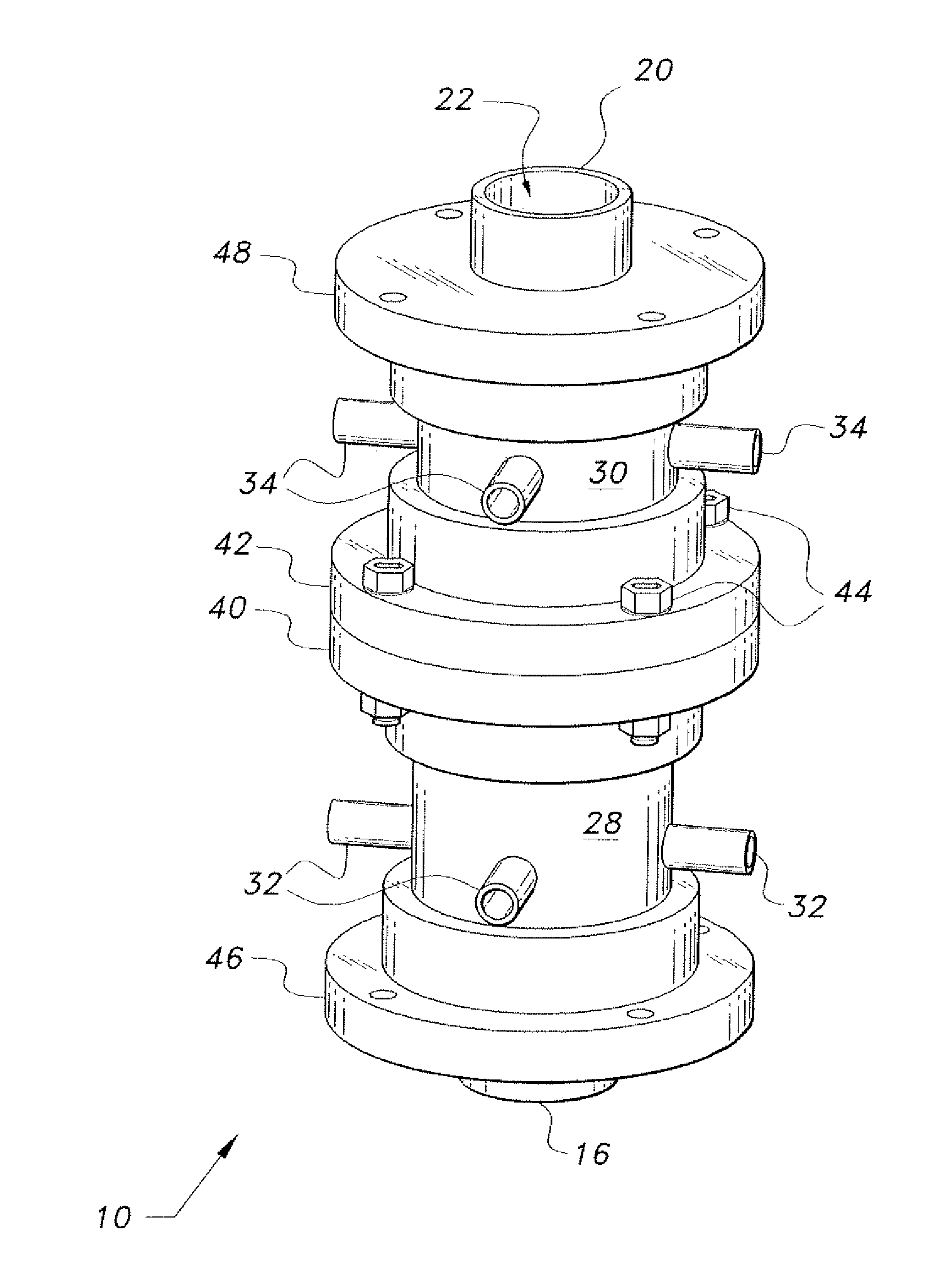

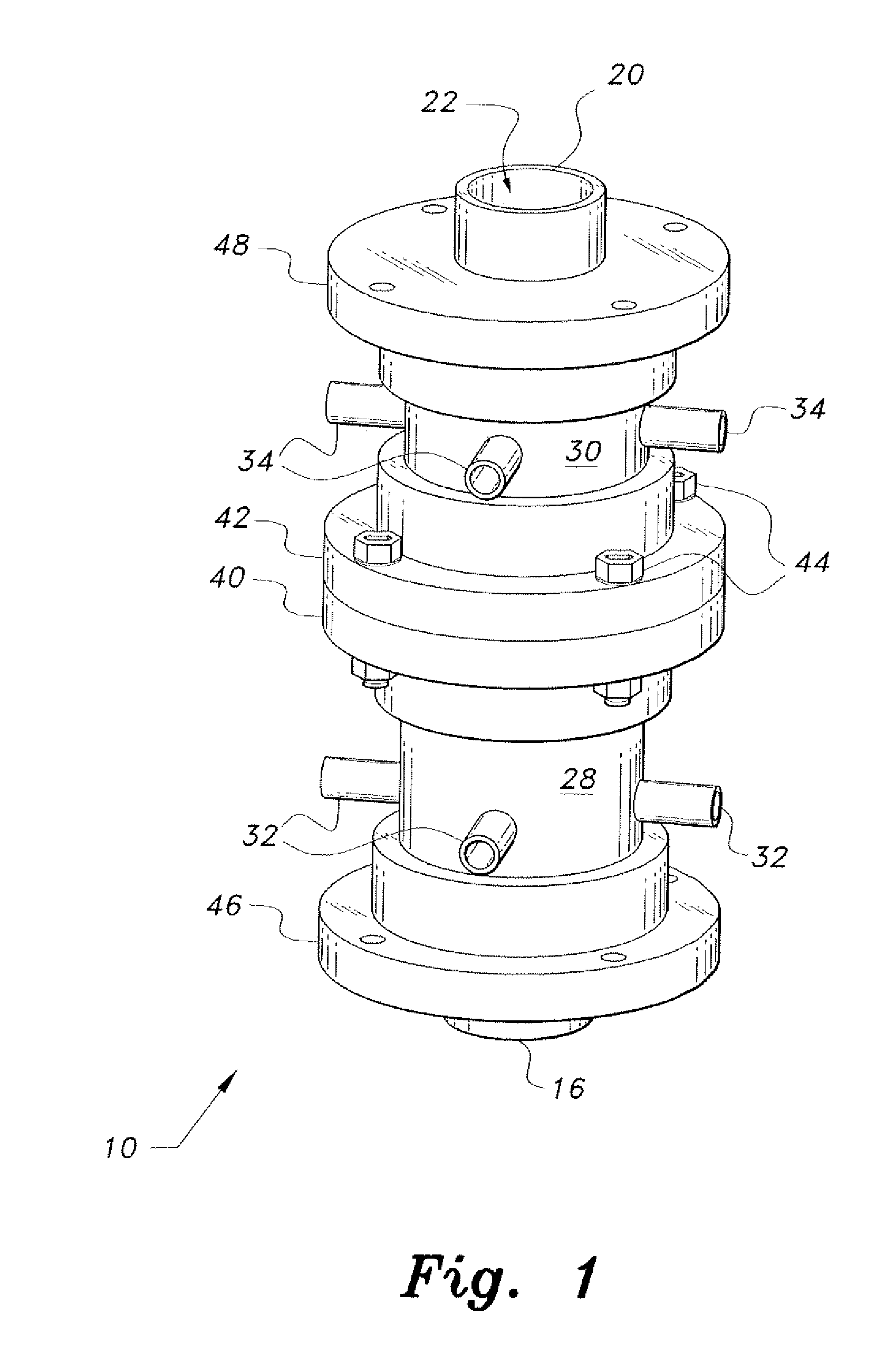

Membrane cleaning using an airlift pump

A membrane module (5) comprising a plurality of porous membranes (6), a gas-lift pump apparatus (11) in fluid communication with the module (5) for providing a two- phase gas / liquid flow such that, inuse, the two-phase gas / liquid flow moves past the surfaces of the membranes (6) to dislodge fouling materials therefrom. The gas-lift pump device (11) includes: a vertically disposed chamber (12) ofpredetermined dimensions submersed to a predetermined depth in a liquid medium (15), wherein the chamber (12) has an upper portion (10) in fluid communication with the membrane module (5) and a lowerportion (13) in fluid communication with the liquid medium (15); a source of gas (14) in fluid communication with the chamber (12) at a predetermined location therein for flowing gas at a predetermined rate into the chamber (12) to produce the two-phase gas / liquid mixture and to produce a flow of the mixture into the membrane module (5). The dimensions of the chamber (12), the submersion depth ofthe chamber (12), the rate of flow of gas and the location of gas flow into the chamber (12) are selected to optimize a flow rate of the two phase gas / liquid mixture into the module (5).

Owner:EVOQUA WATER TECH LLC

Solar refrigeration machine

InactiveCN1737453ATo achieve the purpose of refrigerationNo noiseClimate change adaptationEnergy efficient heating/coolingEngineeringRefrigerated temperature

This invention discloses a solar refrigerator, characterized in that it uses the coolant such as silver chloride as the actuating medium of the absorption refrigerator. The refrigerator comprises generator, airlift pump, gas and liquor separator, chiller, evaporator, absorber, liquid tank, one-way valve and pipe; when evaporating, the silver chloride is stable, so it can not bleed air and cause corrosion; besides, when alkaline is in the gas pressure, it can evaporate in the temperature of minus 33 Deg.c, so it can refrigerate in proper or little pressure ratio.

Owner:韩鸿兴

Gas lift pump apparatus with ultrasonic energy generator and method

ActiveUS20130160688A1Adverse effectImprove concentrationAnimal huntingAuxillariesLiquid mediumEngineering

Gas lift pump apparatus comprising a column through which a liquid medium may be pumped by gas lift, the apparatus comprising a delivery device for delivering a flow of a gaseous fluid into the liquid medium, the device comprising means for generating ultrasonic energy therein by the flow of gaseous fluid therethrough, the device being operable to launch the ultrasonic energy into the liquid medium in the column.

Owner:COLDHARBOR MARINE

Reactor and process for preparing hydrogen sulphide

InactiveCN104603048AHigh purityImprove hydrogen conversionHydrogen sulfidesHigh temperature liquid-gas reactionRefluxProduct gas

The reactor comprises: a lower reactor region (2) for accommodating a sulfur melt (3); non-pressure-bearing first caverns (4) for temporary accommodation of a product gas mixture that is formed by exothermic reaction and comprises hydrogen sulfide, sulfur and hydrogen; non-pressure bearing second caverns (8) arranged above the first caverns and for temporary accommodation of the product gas mixture formed in the first caverns and for formation of further hydrogen sulfide by exothermic reaction of sulfur and hydrogen to form a product gas mixture; and a gas collecting region (6). The reactor comprises: a lower reactor region (2) for accommodating a sulfur melt (3); non-pressure-bearing first caverns (4) for temporary accommodation of a product gas mixture that is formed by exothermic reaction and comprises hydrogen sulfide, sulfur and hydrogen, and a supply device for controlled supply of pressurized gaseous hydrogen per first cavern; non-pressure bearing second caverns (8) arranged above the first caverns and suitable for temporary accommodation of the product gas mixture formed in the first caverns and for formation of further hydrogen sulfide by exothermic reaction of sulfur and hydrogen to form a product gas mixture; and a gas collecting region (6) for accommodating the product gas mixture at elevated temperature and elevated pressure relative to standard conditions. One of the second caverns comprises a supply device suitable for controlled supply of pressurized gaseous hydrogen. The reactor further comprises: non-pressure-bearing third caverns arranged above the second caverns; non-pressure-bearing installed devices suitable for continuous transfer of a total amount of product gas mixture formed in the lower reactor region to the gas collecting region, where a catalyst is present in the installed devices suitable for reacting sulfur and hydrogen still present in the product gas mixture to form hydrogen sulfide; an inner wall that allows continuous circulation of the sulfur melt according to an airlift pump principle in the course of operation of the reactor with involvement of a space between an outer reactor wall and the inner wall; a reflux condenser suitable for condensation of the sulfur present in the product gas mixture; and an input line suitable for transport of the product gas mixture from the gas collecting region to the reflux condenser and a return line suitable for return of the condensed sulfur to the reactor. One of the second or third caverns has a greater volume than each of the first caverns, and / or one of the second or third caverns has lower heat removal for construction reasons than each of the first caverns. The installed devices are arranged such that, the installed devices are present in thermal contact with the sulfur melt after sufficient filling of the lower reactor region with the sulfur melt. The catalyst is cooled by transfer of heat to the sulfur melt if the installed devices contain the catalyst. An independent claim is included for a process for preparing hydrogen sulfide by exothermic reaction of sulfur with hydrogen at elevated temperature and elevated pressure relative to standard conditions to form a product gas mixture comprising hydrogen sulfide and sulfur.

Owner:EVONIK OPERATIONS GMBH

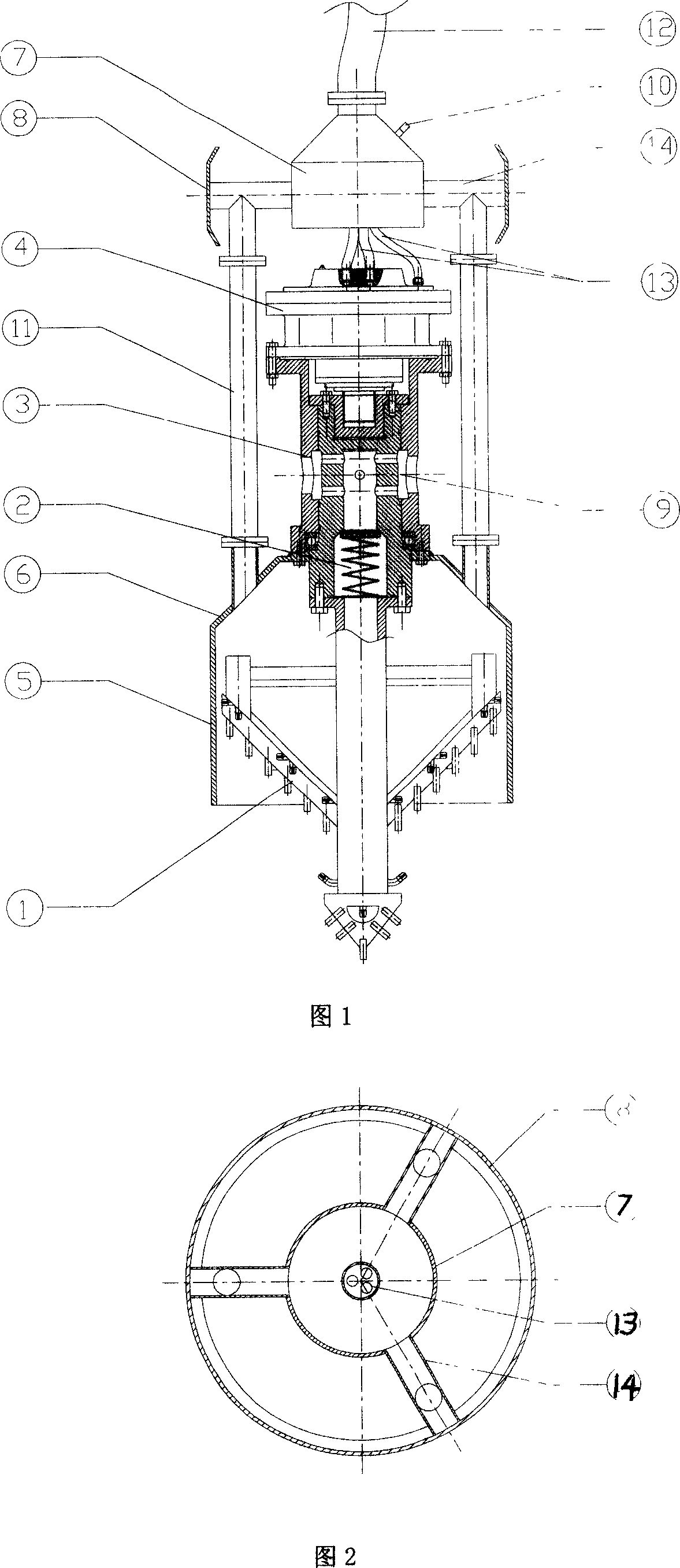

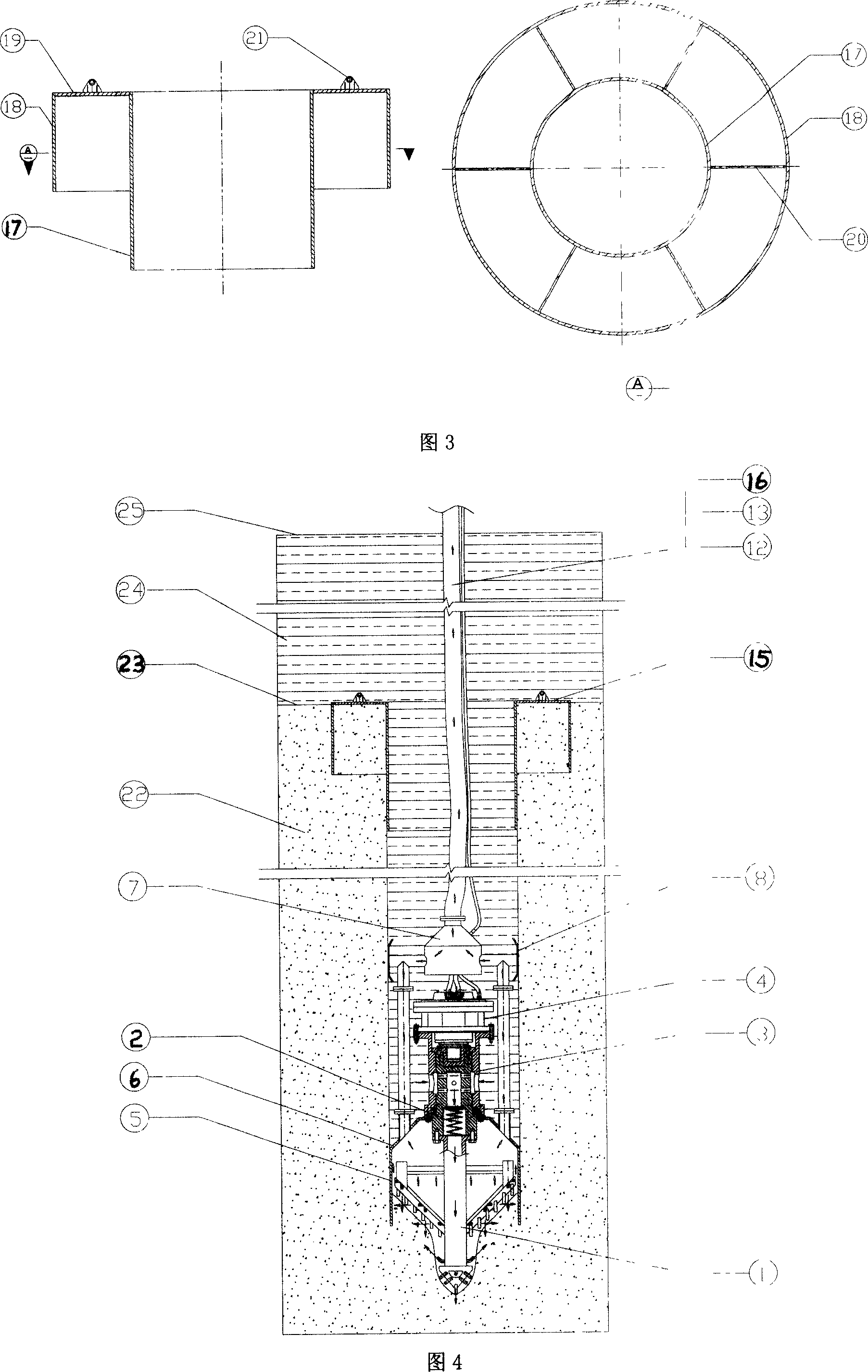

Self-injection underwater perforating twist-sucking drilling machine

InactiveCN1963139AReduce usageLow construction costDrill bitsLiquid/gas jet drillingLow voltageSelf penetration

A self penetrating underwater drilling and sucking machine comprises a jet bit (1), a low voltage cut-off valve (2), a overflowing swivel head (3), a hydraulic motor (4), a suction hood(5) (6), a pneumatic lift pump (7), a sliding sleigh (8), a slurry output hose (12), a hydraulic pipe (13) and a high pressure air pipe (16). The overflowing rotating head (3) that is short and consistent in length will be replaced by the traditional drill rod string that extends when it drills deeper and deeper. Self-penetration of the drill can be realized relying on the pressure gap inside and outside caused in the slurry releasing process by the sucking hood conical surface. A slurry releasing hose (12) connected to the pneumatic lifting pump on the driller, leads to the operating boat on the water. The waterborne operating boat controls the driller through a hydraulic pipe (13) and a high pressure air pipe. The perpendicularity of the drilling hole and stability of the aperture are ensured of with the sliding sleigh (8) and the protective wall structure (15) respectively. The inventions excels itself with its small size and light weight of the driller, feasibility of operating on the sea, effective in cost reduction and it successfully avoids the traditional driller's dependency on some big scale drilling ship.

Owner:NEPTUNE OFFSHORE ENG DEV

Dual injection airlift pump

InactiveUS8596989B2Reduce frictionAdding further buoyancyPressure pumpsMachines/enginesDual injectionEngineering

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

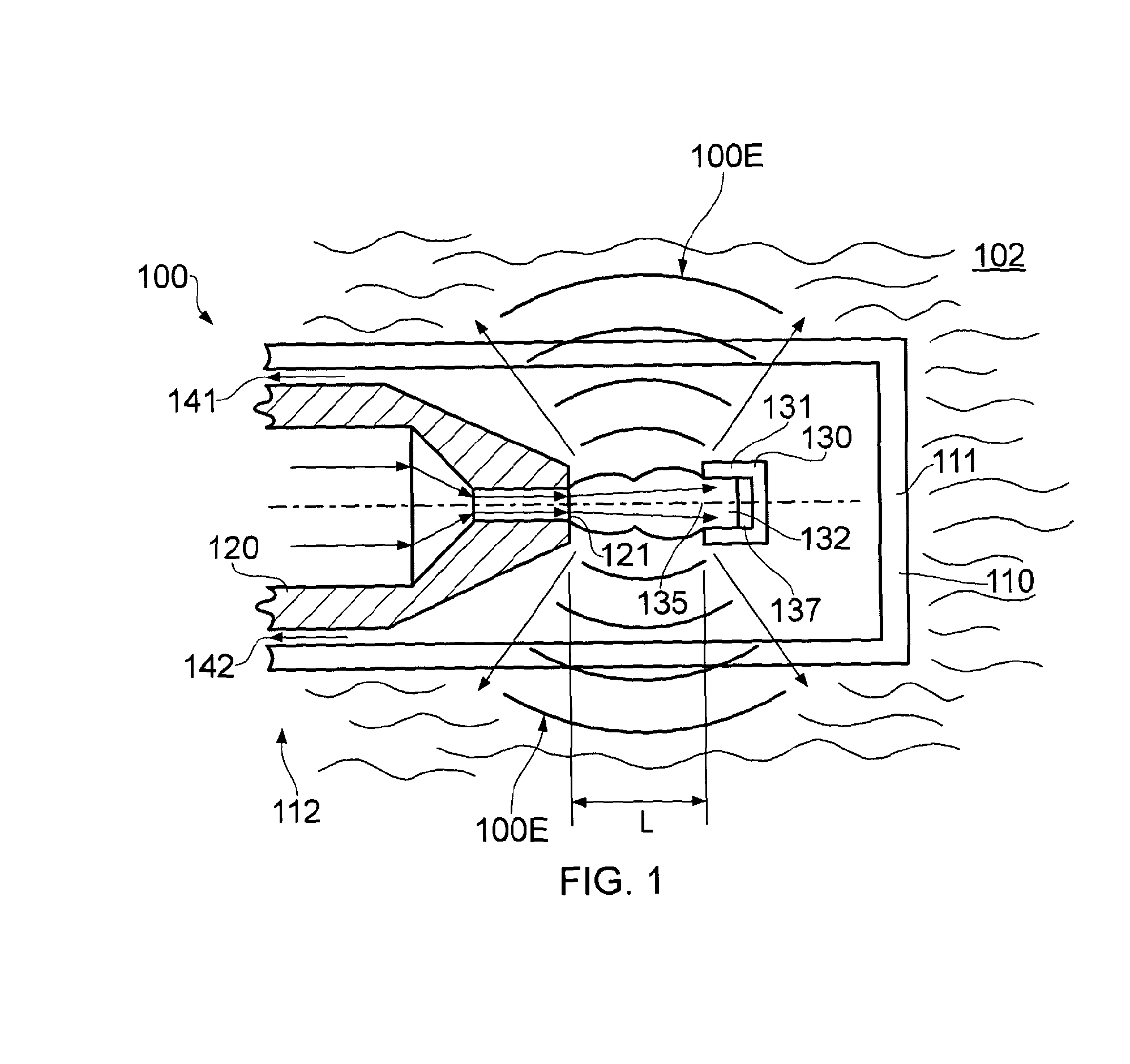

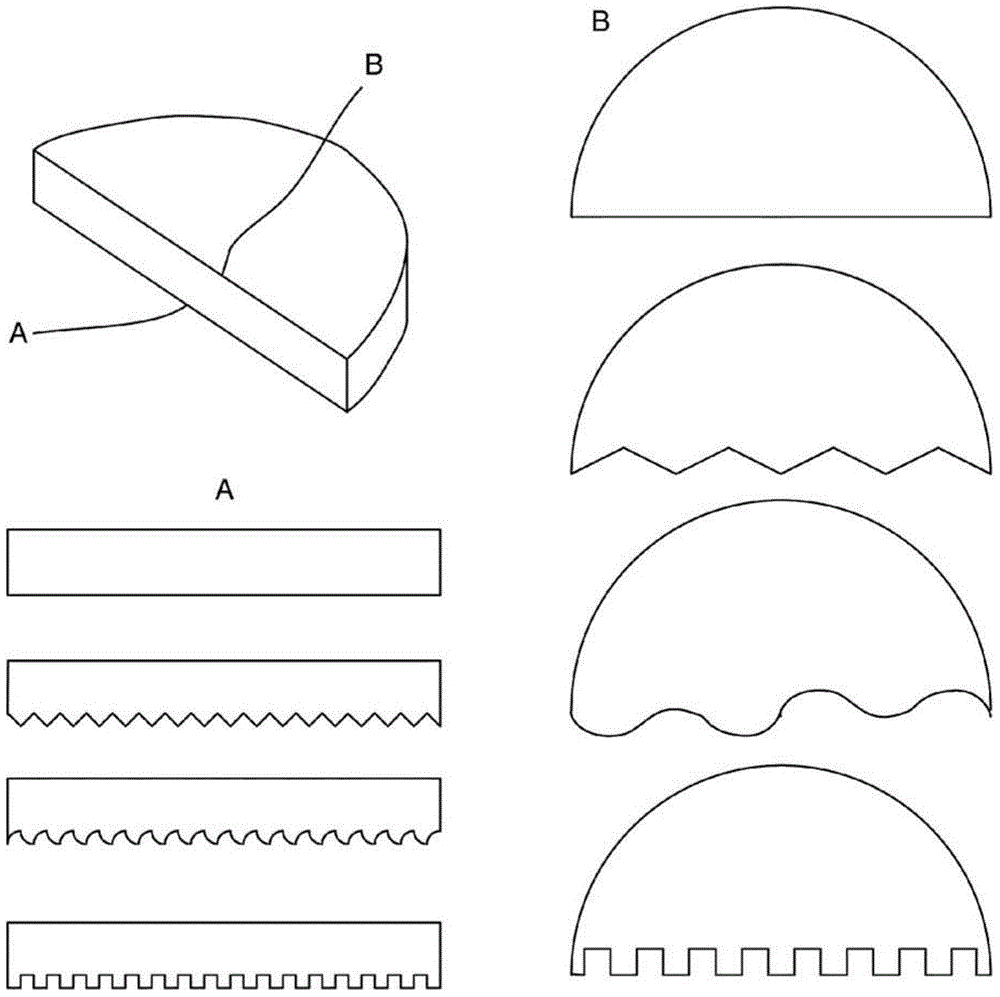

Airlift pump with helical flow pattern

InactiveUS20140356194A1Enhanced entrainmentReduce pressurePressure pumpsJet pumpsPressure decreaseCentrifugal force

The airlift pump with helical flow pattern includes a nozzle body having a fluid passage therethrough. A plurality of air or gas injector nozzles surrounds the central passage. The outward side of each nozzle is tangent to the fluid passage wall through the body to produce circumferential flow in the fluid passage. Each of the air injector nozzles is also inclined in the direction of flow through the body, the tangential inclination resulting in a helical flow pattern through the body. The centrifugal force generated by the circumferential and helical flow through the body results in a pressure decrease through the core of the fluid passage, thereby enhancing entrainment of fluid into the device to increase its efficiency. The fluid passage through the nozzle body is devoid of any structure, and the inlet end of the passage is smoothly radiused to further increase the efficiency of the device.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

A kind of equipment and method for improving the survival rate of live body transportation of irritable fish

ActiveCN105393972BImprove survival rateImprove transportation survival ratePisciculture and aquariaPurification methodsMetabolite

The invention provides equipment for improving the live transportation survival rate of edgy fishes. The equipment comprises a tank (1), a plastic cover film (2) matched with the tank (1), and a water purifier (3). The water purifier (3) comprises a water distribution layer (4), an ice cube layer (5), a filter cotton layer (6), an active carbon layer (7), and a water storage layer (8), wherein the above layers are arranged from top to bottom. The lower part of the tank (1) is provided with a water inlet pipe (9) to be connected with the water distribution layer (4) via the water purifier. The upper part of the tank (1) is provided with a provided with a water outlet pipe (10) to be connected with the water storage layer (8) via the water purifier. The water outlet pipe (10) of the water purifier is provided with an airlift pump interface (11). According to the technical scheme of the invention, a water quality purification method for water in transportation facilities is provided for aquaculture practitioners during the transportation process based on the physiological characteristics of saury and shad. In this way, the collision injured risk of fishes when frightened is reduced, and the water quality of the transportation water is improved. Meanwhile, the metabolites of fishes are timely eliminated, so that the stress reactions of edgy fishes, such as saury and shad, are reduced. Moreover, the risk of mechanical traumas and the risk of physiological endogenous injuries during the transportation process are reduced. The live transportation survival rate of fishes is improved. Furthermore, the temporary-rearing or cultivation survival rate of fishes after the transportation process is improved.

Owner:SUZHOU FISHSEEDS BIOLOGICAL TECH CO LTD

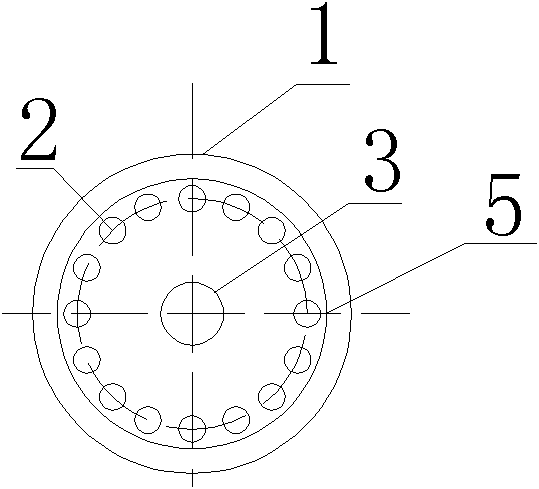

Novel airlift pump structure

ActiveCN104265610AEffective generationPlay the role of transportationFlexible member pumpsPositive-displacement liquid enginesFilm resistanceCapillary Tubing

The invention discloses a novel airlift pump structure which can be used in a millimeter-size hydraulic system for providing power. The volume is periodically increased and decreased through expansion and contraction of hot bubbles, so that the liquid suction and drainage functions are achieved. A pump mainly comprises condensation hoses, a capillary tube, artificial valves, a pulse signal generator, thin-film resistor heaters and liquid. The condensation hoses filled with condensate water are wound around the tube walls, adjacent to an inlet and an outlet, of the capillary tube, the liquid flows in the capillary tube, the thin-film resistor heaters are attached to the outer wall of the capillary tube, the pulse signal generator is connected with the thin-film resistor heaters, the artificial valves are installed in an inlet pipe and an outlet pipe of the pump, and therefore one-way flow is achieved. The novel airlift pump structure is designed emphatically and the work principle of the structure is explained in detail. The liquid flows in the designated direction through the pump when pulse signals are received and the pump is suitable for occasions without the continuous flow supply requirement.

Owner:江阴智产汇知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com