Solar flat plate collector capable of exchanging heat through micro-channel

A solar panel and micro-channel technology, which is applied in the field of solar energy utilization, can solve the problems of low heat exchange efficiency and heat collection temperature of the heat sink, large area of the heat sink, and difficulty in popularizing non-top buildings, and achieves a single flow direction. , Improve heat exchange efficiency and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

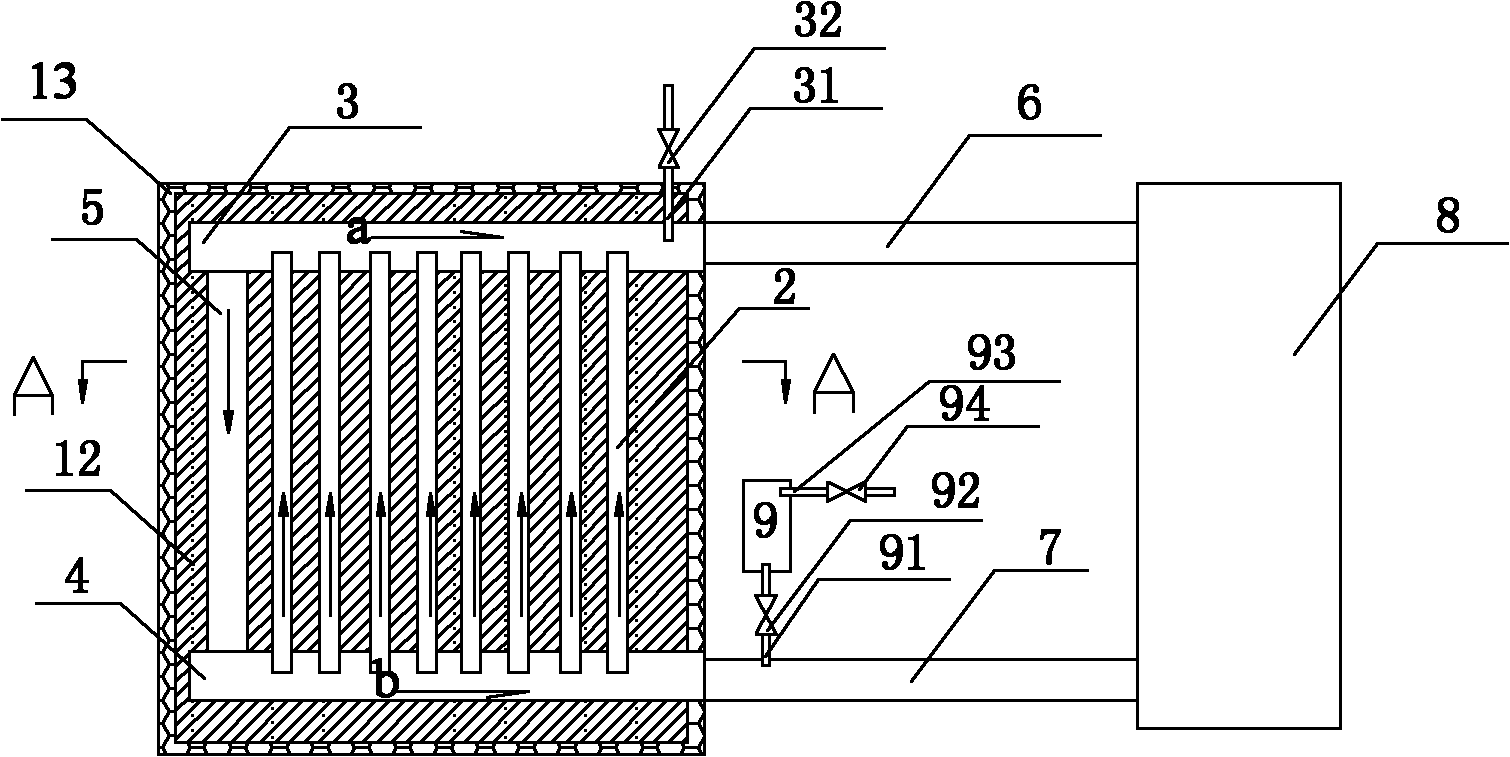

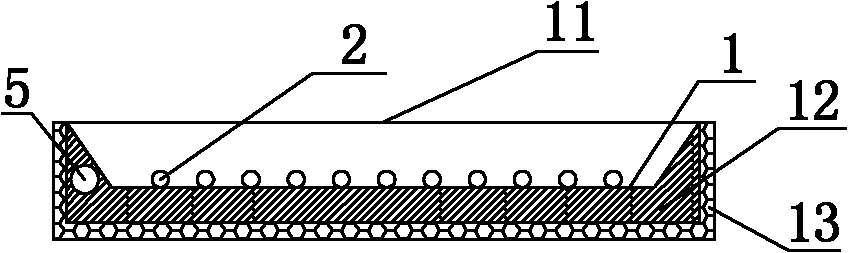

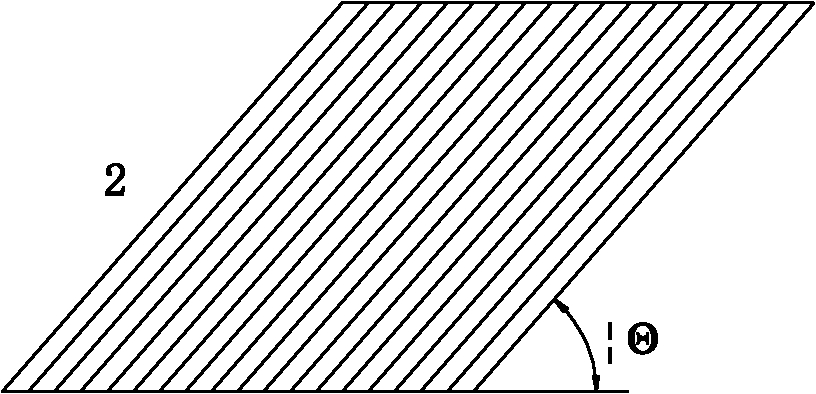

[0030] Such as figure 1 and 2As shown, a solar flat panel heat collector with micro-channel heat exchange consists of a transparent cover plate 11, a heat absorbing plate 1, a heat insulation layer 12, a frame 13, a gas collecting pipe 3, a liquid collecting pipe 4, a liquid return pipe 5 and several The micro-channel tube bundles 2 arranged in parallel and in parallel are composed of a gas collecting pipe 3, a liquid collecting pipe 4, a liquid return pipe 5 and several micro-channel tube bundles 2 arranged in parallel and in parallel with the external condensation section 8 to form a separate circulation pipe, and the gas collecting pipe 3 The height is higher than the height of the liquid collecting pipe 4, so that the liquid formed in the gas collecting pipe 3 flows back into the liquid collecting pipe 4 from the liquid return pipe 5.

[0031] In the above-mentioned separated circulation tube, the air outlet at the upper end of the micro channel tube bundle 2 is inserted ...

Embodiment 2

[0046] Such as Figure 4 Another kind of micro-channel heat-exchanging solar flat panel collector shown, its A-A sectional view is the same as figure 2 Consistent with that shown, the only difference from Embodiment 1 is that a liquid pump 10 is provided between the liquid connection pipe 7 and the condensation section 8, and the lower liquid outlet of the condensation section 8 is connected to the liquid through the second valve 102. The liquid inlet of the pump 10 is connected, and the liquid outlet of the liquid pump 10 is connected with the liquid inlet of the liquid connection pipe 7 through the first valve 101 . It is applicable that the liquid level in the condensation section 8 is always lower than the liquid level in the tiny channel tube bundle 2 . Its work flow is similar to embodiment 1, and difference is that the liquid level of condensing section 8 is lower than the liquid level in microchannel tube bundle 2, and there is reverse liquid level difference in cond...

Embodiment 3

[0048] The structure is similar to that in Example 1, except that the inclination angle of the micro-channel tube bundle 2 is adjusted to 90°, placed on a sunny outer wall, and the working fluid is driven by the bubble pump effect of the circulating working fluid in the micro-channel tube bundle 2 Flow to the cooling section 8. This flat plate collector is very suitable for non-top-level building users.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com