Patching material for potholes of anti-icing road surface and preparation method of patching material

A repair material and anti-icing technology, which is applied in the field of material preparation and anti-icing pavement pothole repair materials, can solve problems such as shortage, impact on driving safety, and inability to store mixed materials for a long time, so as to achieve convenient and fast use and guarantee The effect of smooth road

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

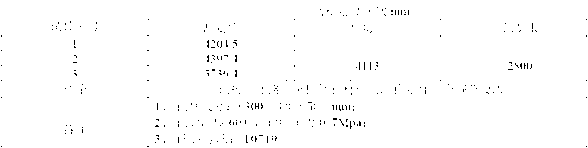

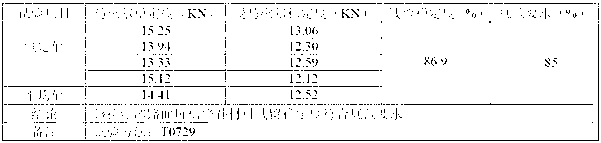

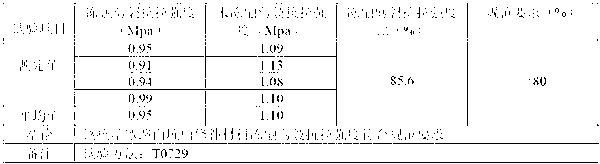

Embodiment 1

[0014] Example 1: An anti-icing pavement pothole repair material, which consists of: 89.5 parts of aggregate, 5 parts of cold-patched asphalt liquid, and 5.5 parts of anti-icing agent Verglimit-260; wherein the weight of cold-patched asphalt liquid consists of: 77 parts of asphalt, 20 parts of diesel oil, 3 parts of cold repair agent; the weight composition of the aggregate is: 14 parts of stone materials with a particle size of 9.5-16.5 mm, 21 parts of stone materials with a particle size of 6-9.5 mm, and stone materials with a particle size of 2.75-6 mm 25 parts, 38 parts of stone with particle size less than 2.75mm, and 2 parts of mineral powder.

[0015] The above-mentioned anti-icing pavement pothole repair material can be obtained by the following methods: 1) Stir the asphalt while heating, stop heating when the temperature of the asphalt reaches 165°C-175°C, add diesel oil and cold repair agent in turn and stir evenly to obtain cold Add asphalt liquid; 2) Mix cold asph...

Embodiment 2

[0016] Example 2: A kind of anti-icing pavement pothole repair material, its composition by weight: 89 parts of aggregate, 5.2 parts of cold-patched asphalt liquid, 5.8 parts of anti-icing agent Verglimit-260; wherein the weight of cold-patched asphalt liquid consists of: 78 parts of asphalt, 19.5 parts of diesel oil, 2.5 parts of cold repair agent; the weight composition of the aggregate is: 15 parts of stone materials with a particle size of 9.5-16.5 mm, 28 parts of stone materials with a particle size of 6-9.5 mm, and stone materials with a particle size of 2.75-6 mm 21 parts, 34 parts of stone with a particle size less than 2.75mm, and 2 parts of mineral powder.

[0017] The above-mentioned anti-icing pavement pothole repair material can be obtained by the following methods: 1) Stir the asphalt while heating, stop heating when the temperature of the asphalt reaches 165°C-175°C, add diesel oil and cold repair agent in turn and stir evenly to obtain cold Add asphalt liquid...

Embodiment 3

[0018] Example 3: An anti-icing pavement pothole repair material, which consists of: 88.5 parts of aggregate, 5.5 parts of cold patched asphalt liquid, 6 parts of anti-icing agent Verglimit-260; wherein the weight of cold patched asphalt liquid consists of: asphalt 80 parts, 17 parts of diesel oil, 2.5 parts of cold repair agent; the weight composition of the aggregate is: 16 parts of stone materials with a particle size of 9.5-16.5 mm, 27 parts of stone materials with a particle size of 6-9.5 mm, and 25 parts of stone materials with a particle size of 2.75-6 mm 30 parts, 30 parts of stone with particle size less than 2.75mm, 2 parts of mineral powder.

[0019] The above-mentioned anti-icing pavement pothole repair material can be obtained by the following methods: 1) Stir the asphalt while heating, stop heating when the temperature of the asphalt reaches 165°C-175°C, add diesel oil and cold repair agent in turn and stir evenly to obtain cold Add asphalt liquid; 2) Mix cold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com