Reinforced optical fiber composite high-temperature-resistant overhead insulating cable

An overhead insulated cable and optical fiber composite technology, which is applied in the direction of power cables, cables, circuits, etc., can solve the problem of high stability of communication functions and high current-carrying capacity of overhead insulated cables that do not meet the tensile strength, temperature rise and current-carrying capacity of overhead insulated cables. Satisfies the demand, but cannot meet the problems of safe operation of overhead insulated cables, etc., and achieves the effect of solving cable drooping, not easy to freeze, and small wind pressure load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with the best embodiment 。

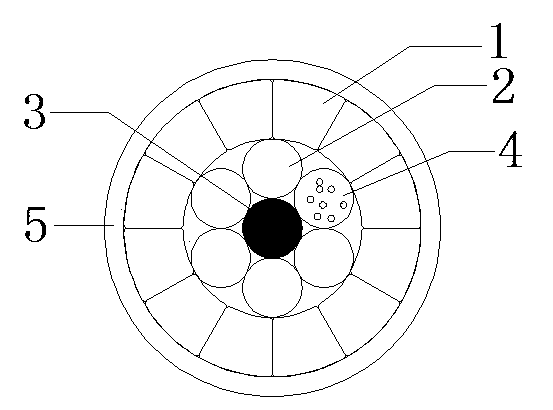

[0017] like figure 1 As shown, the present invention is a reinforced optical fiber composite high temperature resistant overhead insulated cable, comprising a carbon fiber composite reinforcing core 3, and the carbon fiber composite reinforcing core 3 is concentrically stranded with several round annealed aluminum conductors 2 and a stainless steel Sleeve optical unit 4; the circular annealed aluminum conductor 2 and the stainless steel sleeve optical unit 4 are provided with a number of circularly arranged special-shaped annealed aluminum monofilaments 1, and the outer portion of the annealed annealed aluminum monofilament 1 is provided with a high-temperature-resistant insulating layer 5. The high temperature resistant insulating layer 5 is made of silicon rubber or fluoroplastic. The special-shaped annealed aluminum conductor 1 is a fan-shaped primary aluminum conductor.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com