Integral type absorption type heat exchange machine unit

A heat exchange unit and absorption technology are applied in hot water supply equipment and heating fields to achieve the effect of reducing initial investment and power consumption of pump operation, reducing heating cost and improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

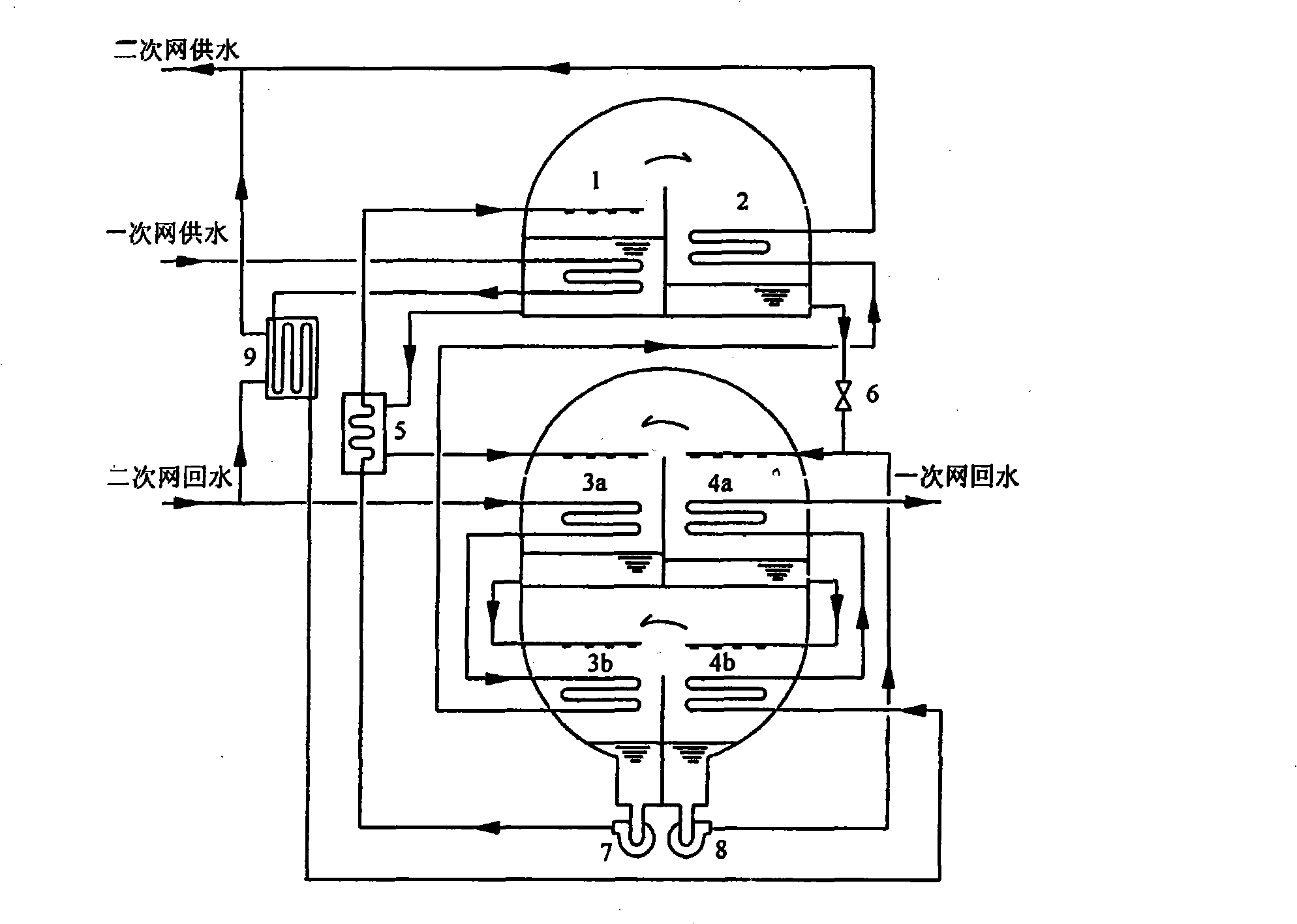

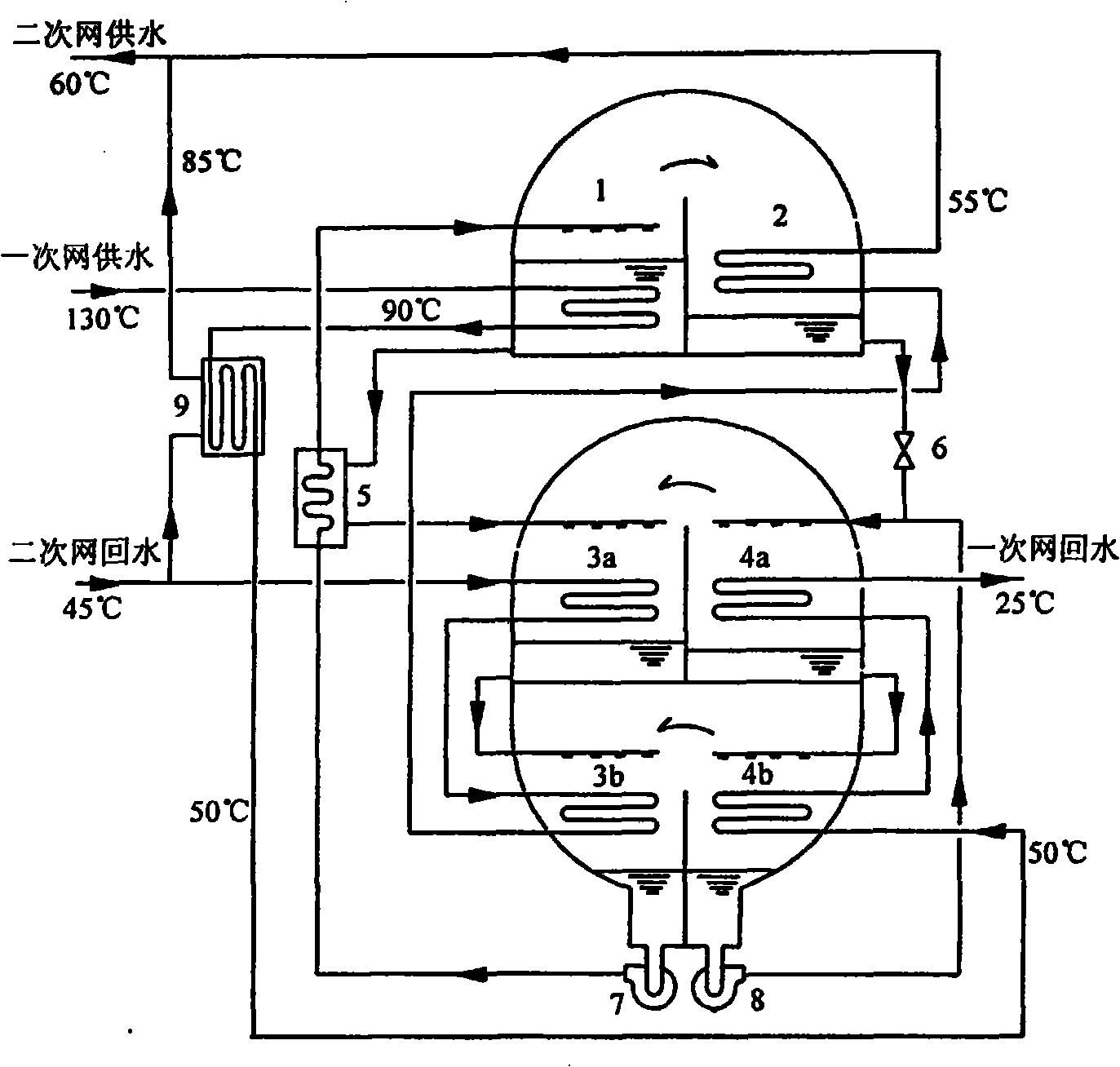

[0019] Such as image 3 As shown, the unit structure and figure 1 Same, lithium bromide dilute solution and the above-mentioned principle of refrigerant circulation process are the same. exist image 3 In the process, the primary grid water supply at 130°C first enters the generator 1 as a driving heat source, and exchanges heat with the dilute lithium bromide solution in countercurrent to make it evaporate and concentrate. After cooling down to 90°C, it flows out of the generator 1 and enters the water-water heat exchanger 9. The high temperature side is used as a heat source to heat the return water of the secondary network at 45°C, and after cooling down to 50°C, it flows out of the water-water heat exchanger 9, and then as a low heat source, it flows through the high-pressure evaporator 4b and the low-pressure evaporator 4a in sequence, releasing heat and cooling down to After 25°C, it will flow out of the unit as primary return water. The return water from the secondar...

Embodiment 2

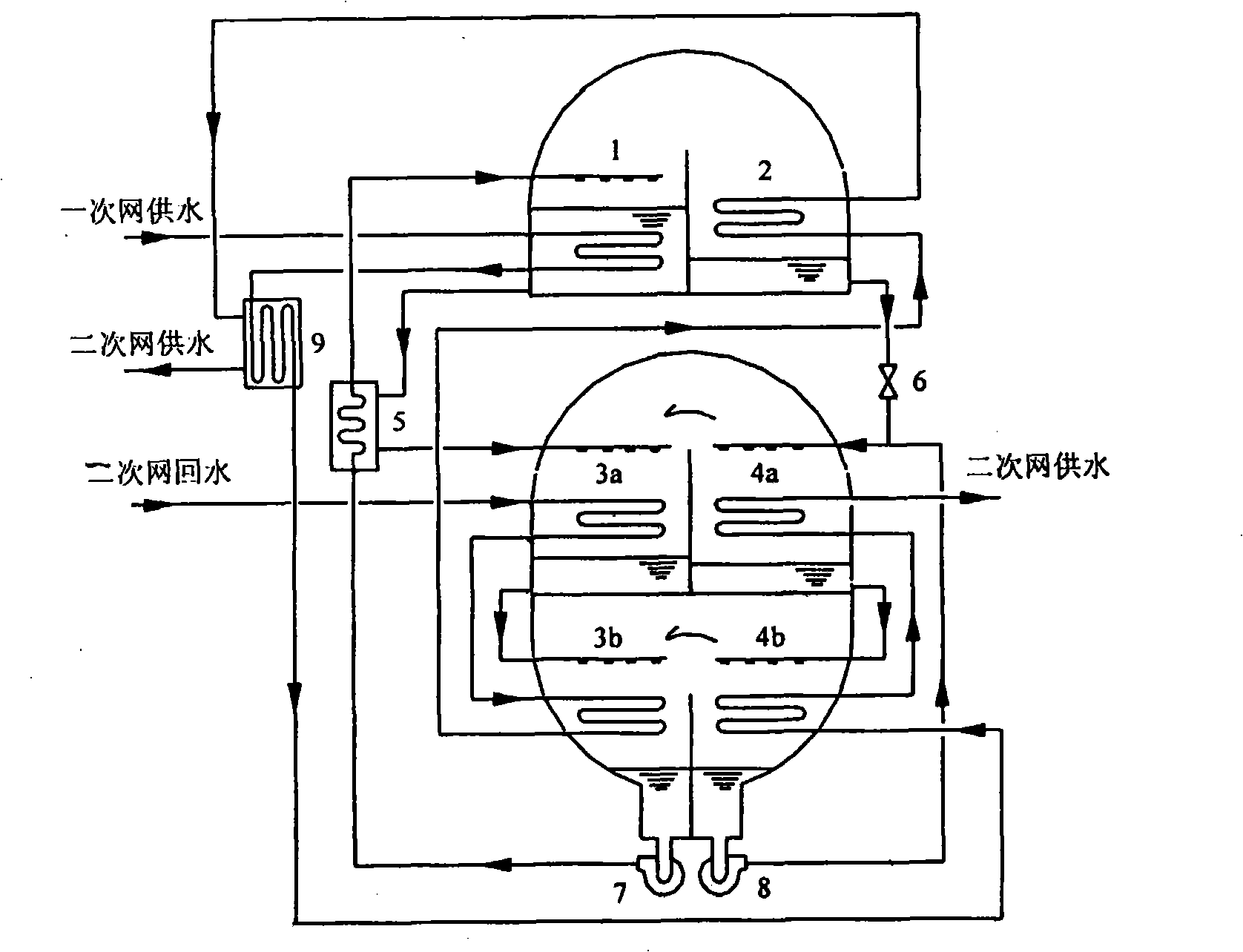

[0021] Such as Figure 4 As shown, the unit consists of generator 1, condenser 2, low-pressure absorber 3a, high-pressure absorber 3b, low-pressure evaporator 4a, high-pressure evaporator 4b, solution heat exchanger 5, throttling device 6, solution pump 7, refrigerant Pump 8, water-water heat exchanger 9, solution spray pump 10, mixer (or injector) 11 and various connecting pipelines and accessories. The dilute lithium bromide solution is heated to boiling by 130°C high-temperature hot water in the generator 1, and turns into a concentrated solution after generating steam. After cooling down through the solution heat exchanger 5, it is mixed with the dilute solution and enters the low-pressure absorber 3a, where it is absorbed by the low-pressure evaporator 4a. The refrigerant vapor generated in the cooling system emits heat of absorption, and the concentrated solution is diluted, and then mixed with the concentrated solution from the solution heat exchanger 5 through the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com