Secondary heat exchange station heating system based on jet type heat pump for recovering primary grid backwater complementary energy

A technology of secondary heat exchange and heating system, applied in the energy field, can solve the problems of high cost, large number of overall systems, large floor space, etc., and achieve the effects of increasing heating capacity, reliability and safety, and improving heating capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

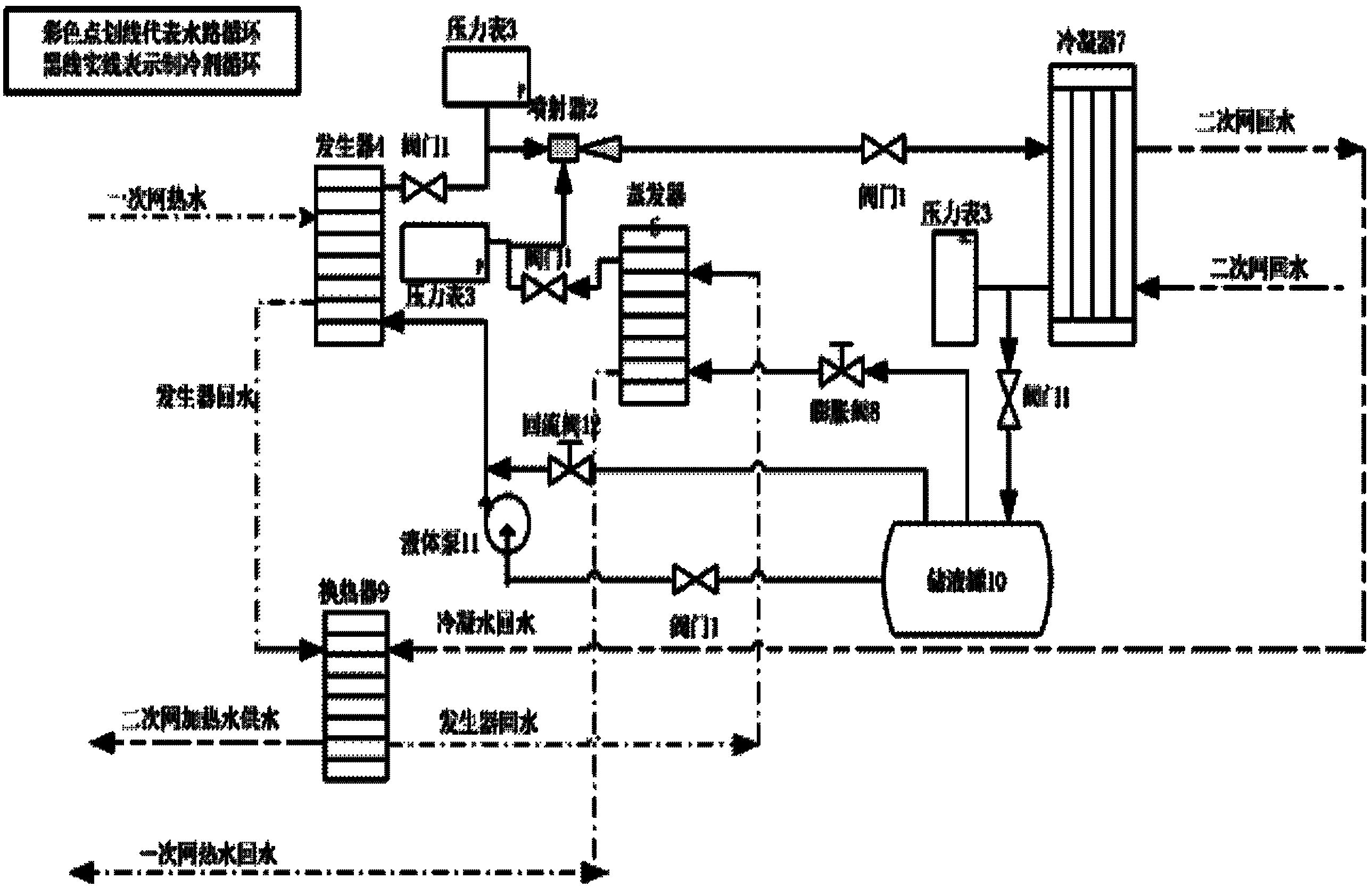

[0019] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0020] A heat exchanger 9 is added to the traditional jet heat pump system, and the specific implementation method can be divided into two parts: refrigerant circulation and water circuit circulation.

[0021] Refrigerant cycle mode: the working steam at the outlet of the generator 4 is connected to the working steam inlet port of the vapor-liquid ejector 2 . The outlet end of the condenser 7 is connected to the port A of the liquid storage tank 10 . The return valve 12 is connected to the port D of the liquid storage tank 10 . Port B and port C of the liquid storage tank 10 are connected to the expansion valve 8 and the liquid pump 11, respectively. The outlet of the evaporator 6 is connected with the injection port of the vapor-liquid injector 2 through a pipeline. The liquid pump 11 sends the fluid into the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com