Absorption heat pump unit, heat exchanger unit and heat supply system

An absorption heat pump and heat exchange unit technology, applied in the field of heat exchange, can solve the problems of limited heat in the condenser, increased resistance of the primary network, and increased volume of the unit, so as to improve the overall thermal perfection and reduce the primary return water The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

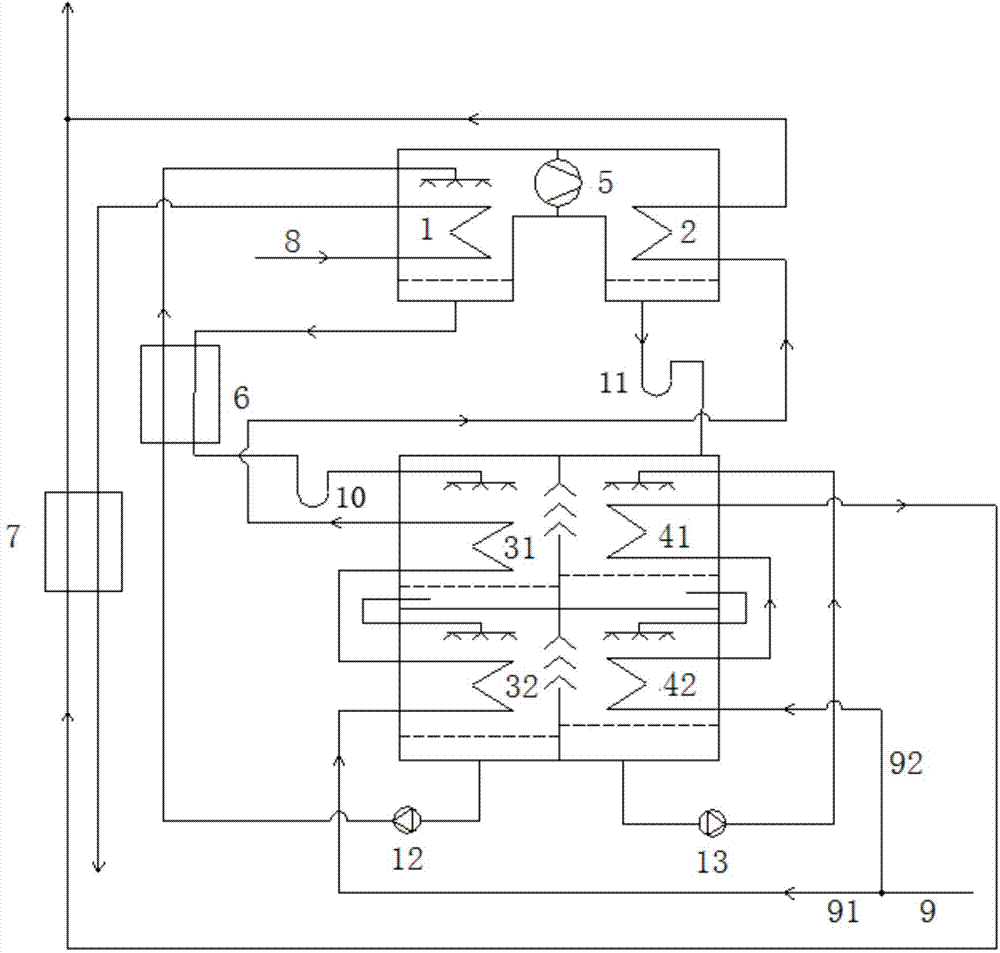

[0045] The first specific embodiment, a heat exchange unit with a water vapor compressor in the generation-condensation process:

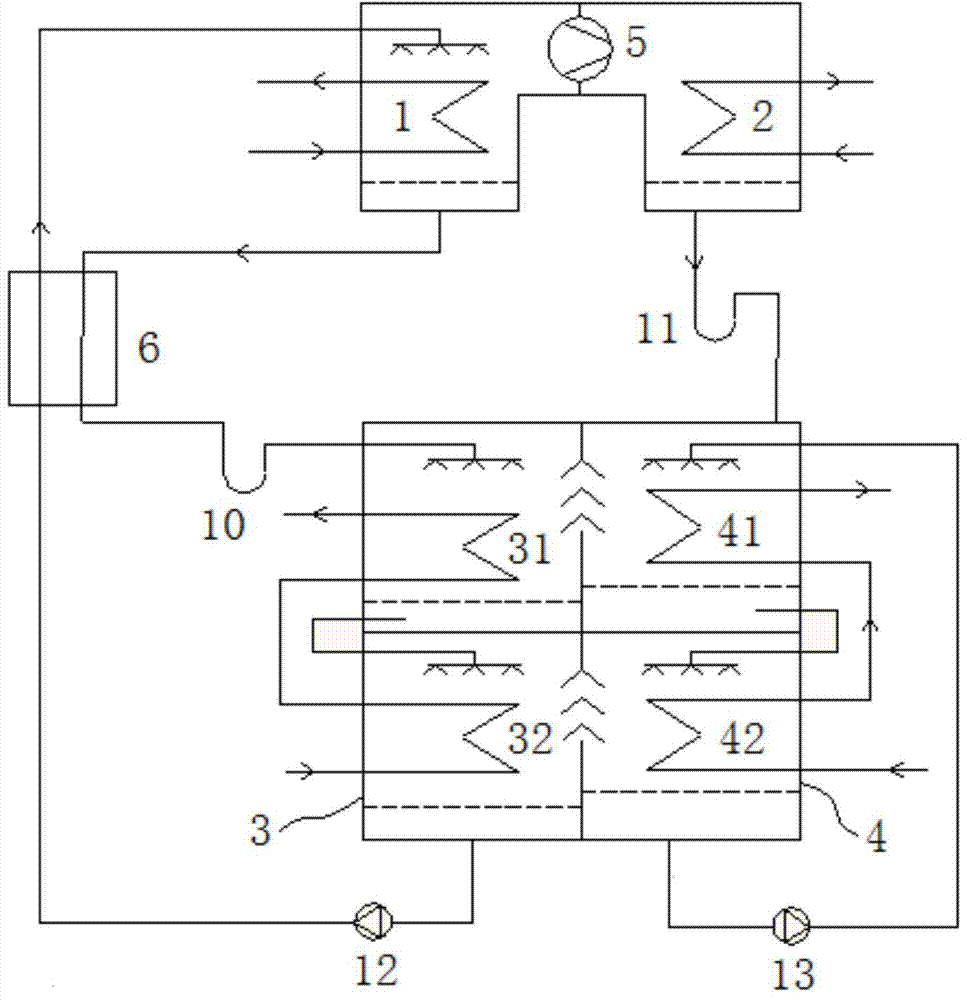

[0046] like figure 2 As shown, it includes generator 1, condenser 2, first absorber 31, second absorber 32, first evaporator 41, second evaporator 42, water vapor compressor 5, solution heat exchanger 6, water- Water heat exchanger 7, solution circulation pump 12, refrigerant water circulation pump 13, solution pressure isolation device 10, refrigerant water pressure isolation device 11, etc.

[0047] For the circulation of external water: the primary water in the primary water inlet pipeline 8 first enters the generator 1 to generate a solution; after flowing out from the generator 1, it enters the high temperature side of the water-water heat exchanger 7 to heat part of the secondary water; After flowing out from the water-water heat exchanger 7, it returns to the heat source as primary effluent. The secondary water inlet pipeline 9 is divided...

no. 2 Embodiment

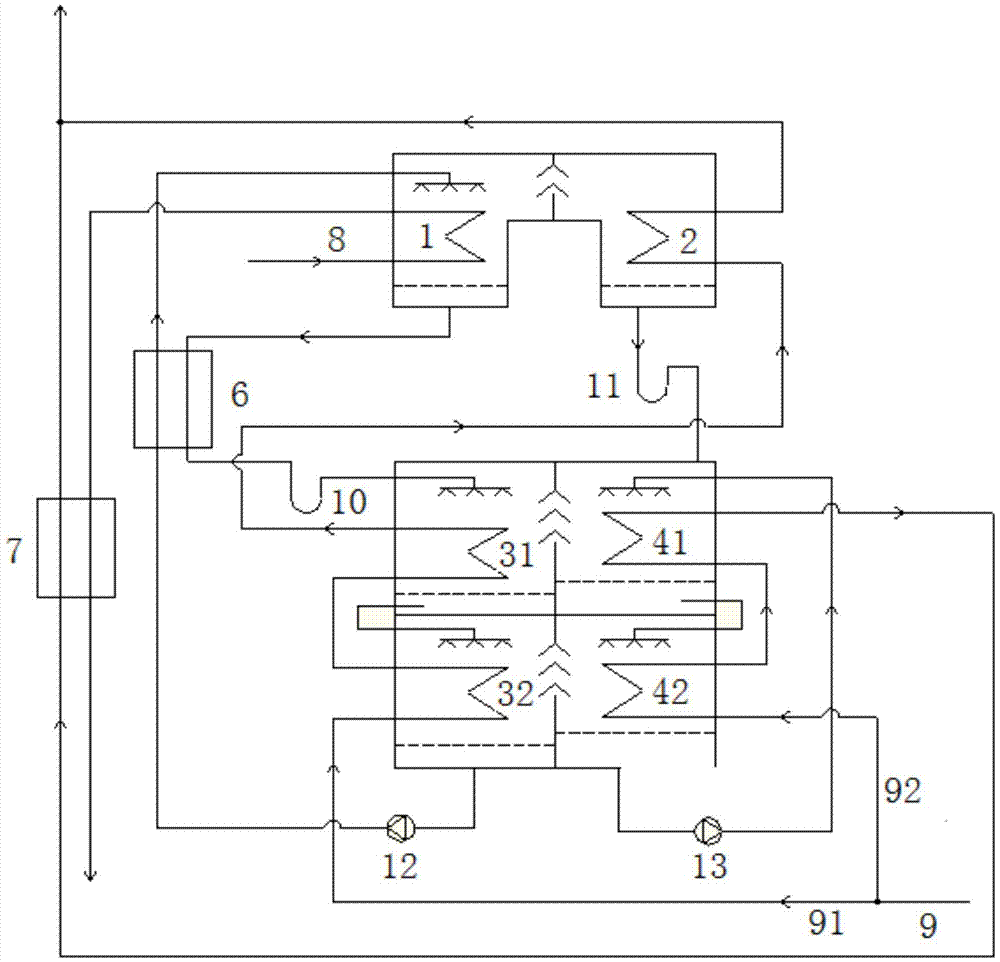

[0051] The second specific embodiment, the heat exchange unit of the anhydrous steam compressor in the generation-condensation process:

[0052] like image 3 As shown, it includes generator 1, condenser 2, first absorber 31, second absorber 32, first evaporator 41, second evaporator 42, solution heat exchanger 6, water-water heat exchanger 7, Solution circulation pump 12, refrigerant water circulation pump 13, solution pressure isolation device 10, refrigerant water pressure isolation device 11, etc.

[0053] For external water circulation: the primary water in the primary water inlet pipeline 8 first enters the generator 1 to generate a solution; after flowing out from the generator 1, it enters the high temperature side of the water-water heat exchanger 7 to heat part of the secondary water; - After the water heat exchanger 7 flows out, it returns to the heat source as the primary effluent; the secondary water inlet pipeline 9 is divided into two branches in parallel, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com