Plate heat exchanger state prediction method based on logarithmic temperature difference

A technology of plate heat exchanger and prediction method, applied in prediction, instrument, complex mathematical operation, etc., can solve problems such as hidden safety hazards and low measurement adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

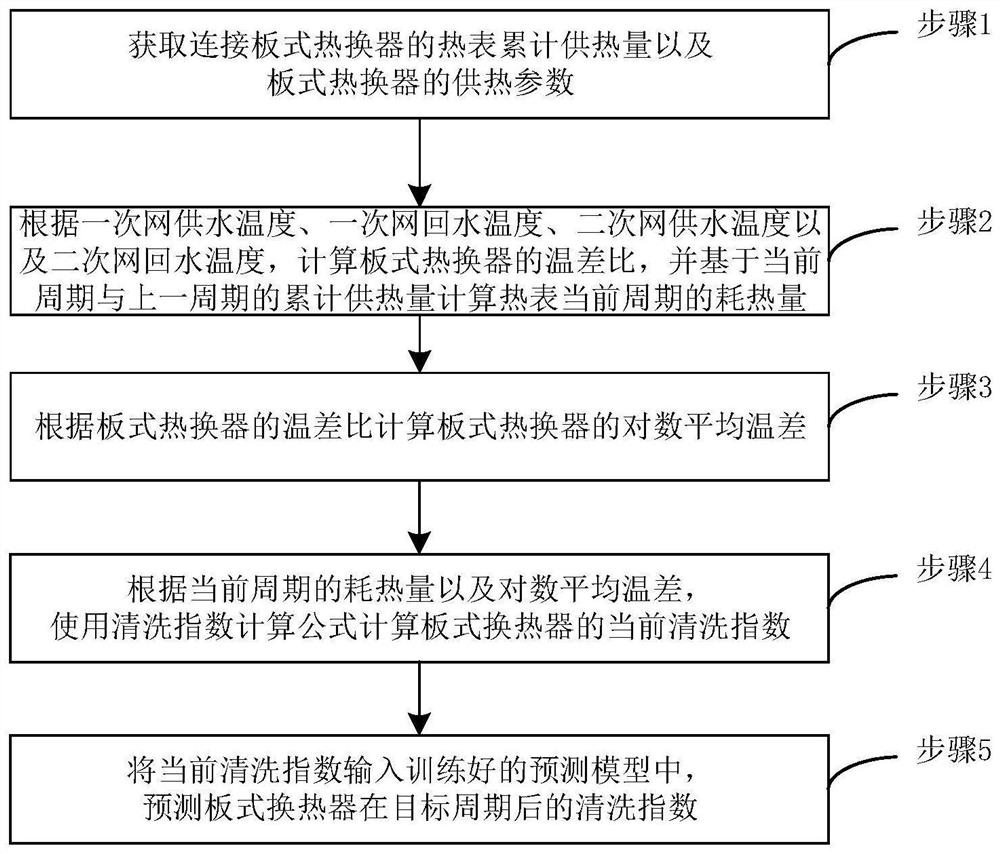

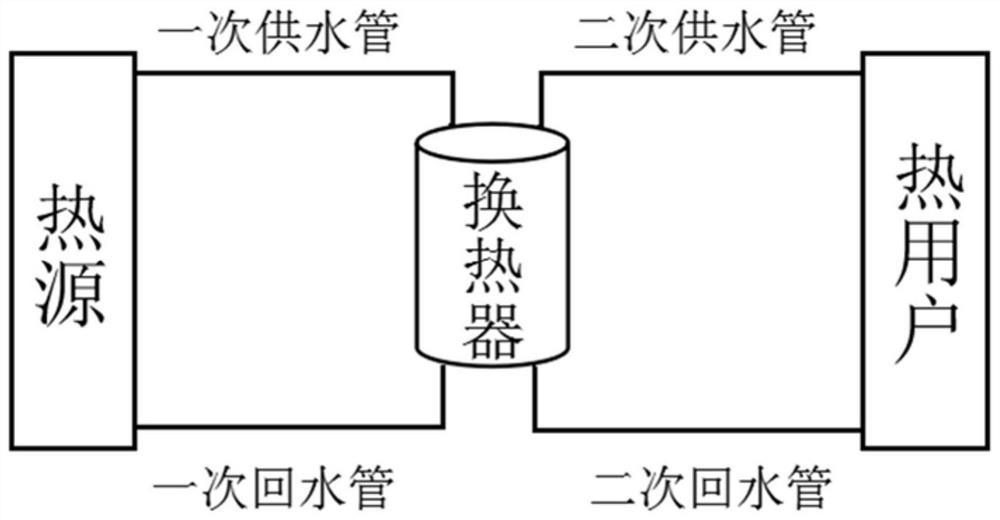

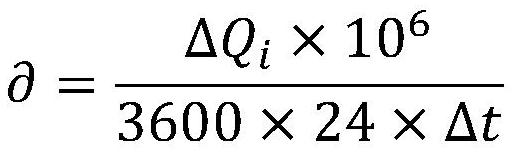

Method used

Image

Examples

Embodiment approach

[0062] As an optional implementation of the present invention, step 5 includes:

[0063] Step 51: Obtain historical blockage data of the plate heat exchanger;

[0064] Step 52: use the historical congestion data to train the preset Markov prediction model, set the historical congestion data to indicate the degree of congestion in different historical periods, so that the Markov prediction model can learn the features in the historical congestion data in a supervised learning manner, and Iteratively adjust the parameters in the Markov model until the output is consistent with the mark to obtain a trained Markov model;

[0065] Step 53: Input the cleaning index of the current cycle into the trained Markov model, and set the Markov output cycle to be consistent with the target cycle, and predict the cleaning index of the plate heat exchanger after the target cycle.

[0066] As an optional implementation of the present invention, after step 4, the cleaning index prediction method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com