Sulfonate trimeric surfactant and preparation method thereof

A technology of surfactant and sulfonate type, which is applied in the field of sulfonate type trimerized surfactant for oil displacement and its preparation, can solve the problems of application requirements of complex formations, difficult to achieve by surfactants, etc. The method is simple, the operation is convenient, and the reaction conditions are mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

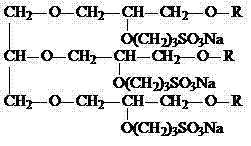

Image

Examples

Embodiment 1

[0018] (1) Preparation of Glycerol Triglycidyl Ether:

[0019] Dissolve 1 mol of glycerol in a mixed solution of 0.05 mol of tetrabutylammonium bisulfate and 6 mol of sodium hydroxide, and slowly drop the mixed solution into a reactor of 6 mol of epichlorohydrin under stirring, at room temperature After mixing evenly, heat up to 50°C, react for 5 hours, and after cooling, add 250ml of dichloromethane, filter, remove insoluble matter, and distill off the dichloromethane under reduced pressure to obtain a light yellow oily liquid glycerol triglycidyl ether ;

[0020] (2) Preparation of 1,2,3-tris(2-hydroxy-3-dodecyl ether-propanyl)glycerol ether:

[0021] Take 5 mol of dodecyl alcohol in a three-necked flask, slowly add 2 mol of metallic potassium at 60°C, and react until the potassium disappears, then add 1 mol of the glycerol triglycidyl ether prepared above, and react for 8 hours. After cooling, use dilute Hydrochloric acid solution to adjust the pH of the system to 7, then...

Embodiment 2

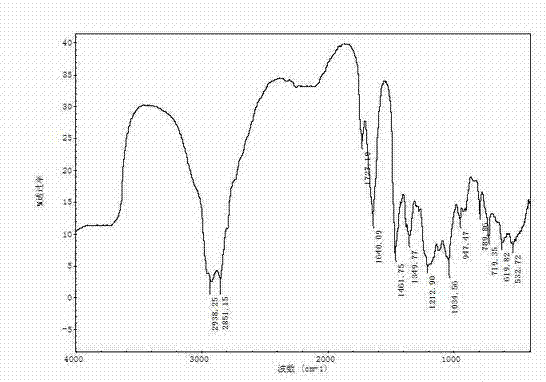

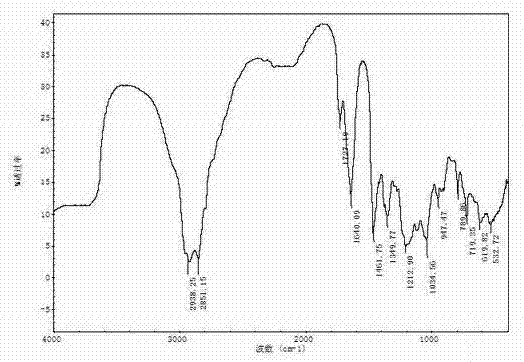

[0025] The structure of the final product TTSS-3-12 obtained in Example 1 was characterized by infrared spectroscopy, see the accompanying drawings for the spectrum, and the analysis of the spectrum is as follows: 2933.25 cm -1 for -CH 3 The asymmetric stretching vibration of , 2851.15 cm -1 for CH 2 Symmetric stretching vibration peak; 1461.75 cm -1 for -CH 2 - Deformation vibration, 1212.90 cm -1 , C-O stretching vibration, 1034.56 cm -1 It is the S=O symmetrical stretching vibration peak, 719.35 cm -1 for long chain-CH 2 - Swing vibration peaks.

Embodiment 3

[0027] The critical micelle concentration (cmc) and surface tension of surfactants are important parameters for evaluating surfactants. The present invention adopts full-range rotating drop meter / interfacial tensiometer TX-500C surface tensiometer to measure the performance of product, and experimental data is listed in table 1:

[0028] Table 1 Surface properties of different anionic surfactants (50°C)

[0029] Surfactant CMC / mmol.l -1 gamma cmc / mN.m -1 TTSS-3-10 0.080 26.8 TTSS-3-12 0.033 26.2 TTSS-3-14 0.0040 24.8 TTSS-3-16 0.0018 23.3 SDS 9.7 34.1

[0030] It can be seen from the above table that the cmc of TTSS-3-n series surfactants is 1-3 orders of magnitude lower than that of the same type of surfactants, such as sodium dodecylsulfonate (SDS), and the surface tension is also higher than that of SDS Smaller, with higher surface activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com