Method and system thereof for synthesizing epoxy chloropropane by dichloropropanol

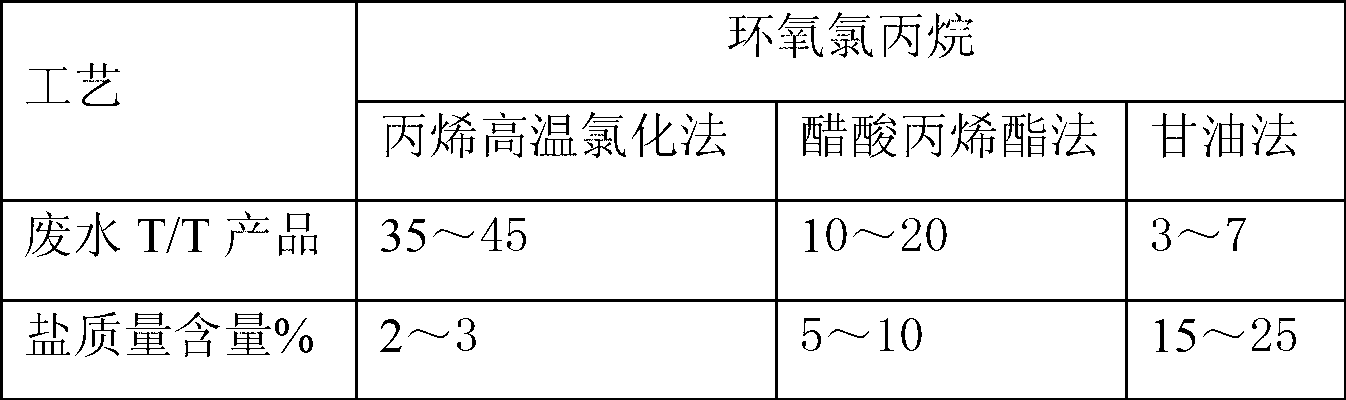

A technology of epichlorohydrin and dichloropropanol, which is applied in the direction of organic chemistry, can solve the problems of difficult saponification wastewater, slow material flow, regular parking and cleaning, etc., so as to avoid parking and cleaning operations, reduce the amount of saponification waste liquid, The effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

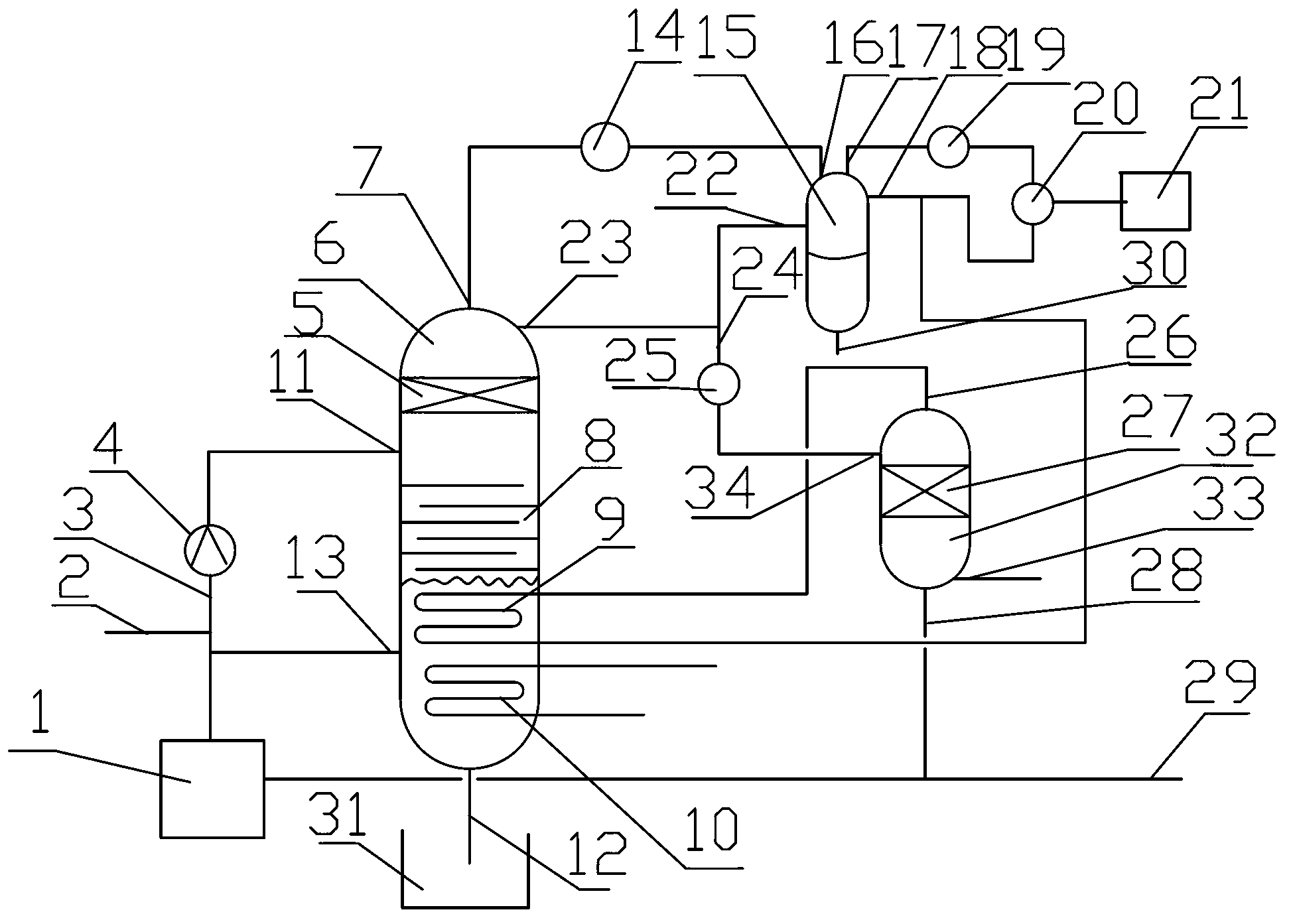

[0033] The external circulation pump 4 of the indirect heating circulation injection saponification reactor is a centrifugal pump. A section of structured packing is built in the upper part of the kettle body 6, and the number of theoretical plates is 8. Six sieve plates 8 are built in the middle part of the kettle body 6, and the heating medium in the saponified liquid heating tube 10 at the lower part of the kettle body 6 is water vapor. The temperature in the control kettle is 45°C, and the operating pressure is -95KPa (gauge pressure).

[0034] Add 395 kg / h of 98% dichlorohydrin produced by glycerin chlorination, 300 kg / h of 42% caustic soda, 59 kg / h of recycled water and circulating saponification solution into the feed port 3, and circulate through the external The pump 4 makes dichlorohydrin and lye mix and react quickly and sprays into the kettle body 6 of the circulating injection saponification reactor, and the epichlorohydrin and water generated are heated in the k...

Embodiment 2

[0040] The external circulation pump 4 of the indirect heating circulation injection saponification reactor is a screw pump. A section of structured packing is built in the upper part of the kettle body 6, and the number of theoretical plates is 4. Ten sieve plates 8 are built in the middle part of the kettle body 6, and the heating medium in the saponified liquid heating tube 10 in the lower part of the kettle body 6 is heat conduction oil. The temperature in the control kettle is 80°C, and the operating pressure is -15KPa (gauge pressure).

[0041] Lime slurry formed by mixing slaked lime (with a density of 2.5Kg / L before dissolution) at 180kg / h and recycled water at 360kg / h, and dichlorohydrin with a content of 20% produced by the propylene method at 1935kg / h, and recycling The saponification liquid is added to the feed port 3 together, and the dichlorohydrin and the lye are rapidly mixed and reacted through the external circulation pump 4 and sprayed into the kettle body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com